Indeed, the efficiency of a traditional fireplace is quite low. Today it is being replaced by an improved air heating system with a fireplace, which allows not only to quickly heat the fireplace room, but also the entire two-story cottage.

Mistakes when choosing an air-heated fireplace

The generally accepted scheme for selecting heating equipment is unacceptable in this case.

Most believe that the power of the firebox is adjusted to the area of the room at the rate of 1 kW per 10 m2. Time has shown that choosing a firebox for fireplaces for a country house with air heating requires an integrated approach. Gas stoves that are too powerful lead to overheating of the apartment. Residents have to open windows or reduce the amount of heating fuel they use. Frequent temperature fluctuations provoke colds and other unpleasant symptoms - weakness, dizziness and insomnia.

Fireplace area calculation table

How to calculate the required firebox power for an air-heated fireplace? Experts advise contacting sales consultants with this question. It is necessary to contact a specialist correctly, that is, by providing information on the area of the room, type of ventilation and number of rooms. Only in this case will the seller select the required power of the equipment.

Heating with a fireplace: principle of operation, positive qualities and disadvantages

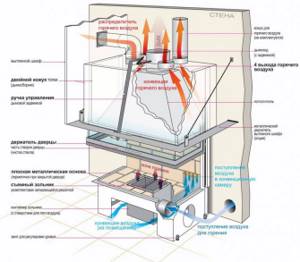

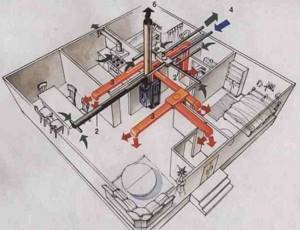

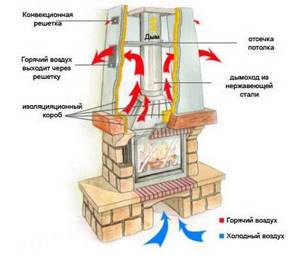

An air-heated fireplace is an entire heating complex; its main parts are a casing and an air duct system running throughout the entire area of the room. The casing accumulates warm air and distributes it in the desired direction. The heating method is based on a simple law of physics. Warm air from the lower pipes rises to the top and heats the entire required area. The larger the room that needs to be heated with one fireplace, the more complex the duct design.

The main advantage of the convection type of heat exchange over a standard fireplace design is its efficiency. The downside is that it is necessary to design the entire system in advance, at the stage of building a house. This takes into account the area of the heated room, the thickness of the walls and the features of the construction of a residential building. In addition, it is necessary to correctly position the air ducts, taking into account the basic principles of cold air supply.

The casing plays a major role. Heating a house occurs in several ways: radiation, convection or heat exchange.

Fireplace with air heating - a whole heating complex

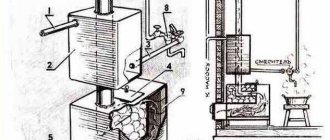

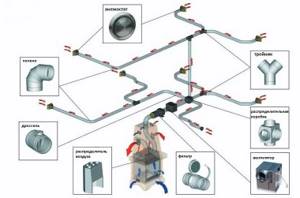

The design of the fireplace with a convection system consists of 9 parts:

- Fireboxes;

- Portal;

- casing;

- Fan;

- Filter;

- Ventilation grilles;

- Firebox stands;

- distributor;

- Air tees.

Those who decide to install an air-heated fireplace in their dacha with their own hands will be slightly disappointed - the installation process is not for beginners in construction. The best solution in this case is to order a diagram of the location of fans and pipes from specialists.

Some features of self-designing a fireplace

The house design must necessarily include sections devoted to the construction of the fireplace and its individual elements.

Each fireplace has its own chimney above the firebox, the cross-sectional area of the chimney channel should be 1/10 of the firebox area. The distance from the junction of the chimney with the combustion duct must be at least 5 meters.

The chimney duct should be equipped with a special damper, which will separate the firebox from the chimney, and a hole designed to remove soot that accumulates during operation. The design of the gate valve can be retractable or fastening (using piano hinges).

Average fireplaces can weigh about 500 kilograms or more. Therefore, it is necessary to provide a sufficiently strong and reliable foundation under the fireplace.

If you are installing a fireplace in an already built house, you may need to carry out additional work to strengthen the load-bearing structures.

Air-heated fireplaces

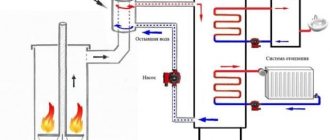

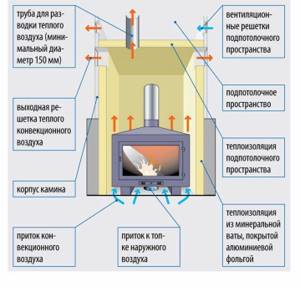

Air heating of rooms and premises with a fireplace involves heating the air passing between the body of the firebox and its outer surface.

Diagram of a fireplace with air heating. Click to enlarge.

Heated air is distributed throughout the rooms of the house using pipeline channels installed in the walls or ceilings.

Aluminum or steel pipes are ideal for installing air channels.

In simpler schemes, a gravitational method is used to supply air, based on different densities of cold and warm air.

Fireplace air heating of this type does not depend on electrical energy, but it can be used to heat just a few rooms.

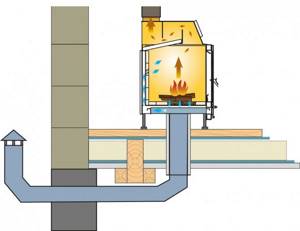

Fireplace air heating of a house with a large number of rooms and a pipeline length of more than 3 meters should be carried out according to a forced circulation scheme.

Such a scheme should include a pump that supplies air under the firebox body or above itself.

Forced air circulation can provide high-quality heating for a fairly large country house.

When choosing and installing such a circuit, you should remember that air exchange occurs in a closed cycle.

It is more rational to build a fireplace with air heating during the construction of the house, since otherwise you will be faced with tedious and very costly work - punching holes intended for laying air ducts.

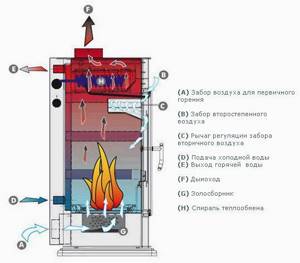

Fireplaces with water mantle

The firebox of fireplaces with a water mantle has one significant structural difference - the body of the firebox consists of two layers, between which heated water circulates.

The fireplace in your room is not only an element of the interior, but also a source of heat.

Heated water is supplied to the radiators of the heating system using special pipelines.

The installation of a special heat exchanger (coil) in the upper part of the fireplace will provide the opportunity not only to heat the premises, but also to heat water for domestic purposes, the circulation of which will be carried out through special pumps.

Fireplace structure with water mantle. Click to enlarge.

Manual regulation of the operation of fireplaces is possible by increasing or decreasing the flow of air into the fireplace firebox. Automatic regulation is carried out through the operation of thermostats with which the pumps are equipped.

7196f3e665317c6c8bc3485445b7def9.jpe ad128a56e9475981dd8e2bebc4210d60.jpe

Thermostats ensure automatic activation of the pumps after heating the water to the required temperature.

Making a fireplace with your own hands

Installing a heating fireplace unit is simple. The main thing is to strictly follow the recommendations of specialists. Comply with building codes and fire safety regulations. Use high quality building material.

Step 1. Preparation

Consumables are purchased in advance from a hardware store:

- Red brick;

- fireclay brick for firebox;

- cement, sand for mortar;

- roofing felt;

- facing tiles;

- cast iron wood burning chamber with glass door;

- metal corners;

- sandwich pipes for the chimney;

- thermal insulation material with foil base;

- reinforcing mesh;

- boards for formwork.

Tools:

- building level, plumb line, protractor to control the laying of bricks;

- marker, tape measure - for marking;

- Bulgarian;

- drill;

- hammer;

- chisel.

We determine the location for the structure. We make a preliminary drawing.

Device installation methods:

- Wall-mounted. The unit leans against the wall surface. The chimney line is masked under the wall. The chimney becomes part of it. Fire safety requirements are taken into account. The wall surface in contact with the device is insulated with basalt fiber.

Wall fireplace

- Built-in. Suitable for small rooms. Installed in a niche. Takes up little usable space. Provided at the time of construction of the building.

Built-in

- Standing separately. Looks luxurious. Takes up a lot of space. Installed in the center of the room. The chimney circuit for removing combustion products is routed through the roof. Set up when designing a private house.

Standing separately

Step 2. Foundation

The durability, safety of the structure, and the efficiency of the air heating system depend on the base.

Step by step guide:

- The foundation is marked on the floor 15-20 cm larger than the stove.

- A pit is dug 0.7 m deep.

- Wooden formwork is installed around the perimeter of the marking.

- The formwork is waterproofed to protect against high humidity. High density polyethylene film is used.

Foundation

- Sand mixed with gravel, 0.15-0.2 m high, is poured into the bottom of the pit.

- The foundation is poured with cement mortar up to the height of the formwork, 0.15 m short of reaching the finished floor.

- To increase the rigidity of the base, a reinforcing mesh is provided. The cement mortar is well leveled. The evenness of the resulting foundation is checked.

The technological break is about 1 month. The foundation must dry.

Step 3. Arrangement of the fireplace. Wall insulation

Let's start laying the base of the brick structure:

- Floor tiles are laid 0.15-0.2 m beyond the perimeter of the fireplace structure. For good adhesion, primer is used for laying ceramic tiles. It takes a day to dry.

- Laying starts from the corner. The width of the seam joints is 2-3 mm. For beginners, it is better to purchase construction crosses.

- Upon completion of the work, wipe off the grout with a damp cloth. It's difficult to do once it dries.

- Layouts are laid around the perimeter.

Wood layouts

Step 4. Wall cladding with thermal insulation

Fire safety must be observed. Especially for buildings with wooden walls. Thermal insulation material - basalt fiber, superisol boards. The cladding is done with tiles. A heat-resistant compound is used for gluing individual units.

Step 5. Pedestal, combustion chamber

The pedestal is constructed from aerated concrete blocks and bricks. Aerated concrete building material is highly durable. The blocks are placed on construction glue. Metal corners increase the reliability of the structure.

The firebox is installed in grooves. They are made with a jigsaw. Each subsequent layer of the stove is checked with a building level for evenness.

Installation of the combustion chamber is carried out in two persons. The weight of the models is 40-50 kg. One person cannot install the structure smoothly.

It is recommended to properly organize the space under the firebox. Part of the thermal energy will escape through the bottom. It is not worth placing an air heating unit on blocks.

There is a brick apron on both sides of the chamber. Masonry and cladding are done using the dressing method.

Step 6. Installation of the chimney circuit

Constantly check the evenness of the chimney portal. Avoid branches. They negatively affect cravings.

When venting the chimney through the roof or wall, use a pass-through metal pipe. Additionally, provide mineral insulation.

The outer part of the chimney line is fixed with clamps. The top is covered with a cap and grille that prevents debris and precipitation from entering the system.

Step 7. Arrangement of the air casing

Installing a plasterboard casing:

- A metal frame is installed around the fireplace. The sheets are screwed with a drill;

- Foil “fireworks” will help protect the structure from fire;

- the place for the ventilation holes is marked on the drywall;

- thermal insulation of the casing cavity is performed with mineral wool;

- convection pipes are connected to a metal pipeline with good flexibility. Passes warm air masses through the system;

- If necessary, fans are installed to create forced draft.

Cladding will give the device a beautiful appearance. Laconically fits into the interior of the house. Protects the unit from destruction and cracking. Decorative stone, red brick, facing plaster, and tiles are used.

Reliable fastening of the decorative layer is carried out with adhesive mixtures that retain their properties at high temperatures.

Laying starts from any corner. The gap between individual units is taken into account. There is space left for the baseboard.

Each element is tapped with a rubber mallet. The evenness of the masonry is checked.

Step 9. Kindling, checking draft

The first kindling is carried out a few days after completion of construction. Glue mixtures need to dry well.

Objects and things that could ignite are removed from the fireplace. The firebox door closes tightly. Warming up is done gradually. The draft in each room is checked.

If the work on installing the fireplace was carried out in accordance with building codes, labor protection requirements, and fire safety, the heating system will effectively heat the entire house. No additional heat sources are required. Air heating will be sufficient.

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...

Heating scheme

Heating of the house can be carried out using units of different categories. Intermittent burning fireplaces provide heat to the room for up to a quarter of a day with a single load of firewood.

Long-term burning devices with an equal amount of fuel increase this period to 8 hours. Even at minimum power, the volume of heat generated will vary from 3 to 6 kW. High heating levels are achieved with the air supply wide open. In this case, depending on the design, from 2 to 4 kilograms of firewood will burn per hour.

The power with which heating fireplaces will operate can be calculated based on the size of the heated room. In a room with a ceiling height of 2.8 meters, 1 kW of heat is enough to heat 10 m2 of area. Accordingly, with a power of 10 kW, such a furnace can serve 100 m2 of area.

Air

When energy moves from one medium to another, the amount of heat transferred is significantly reduced. A properly designed air-fired fireplace can solve this problem by reducing the number of thermal transitions. Its design involves burning fuel in a separate chamber, heating the metal part of the firebox and the air inside the room. Energy transfer is carried out using flexible thermally insulated channels connected to other parts of the residential building.

Air flows can move naturally or be adjusted in the desired direction by a forced injection system. With a vertical orientation, normal air flow is enough for high-quality heating. If the location of air-heated fireplaces is far from the rooms to which heat needs to be delivered, it is recommended to install special fans.

Vodyanoye

If the house has a conventional wood-burning unit, you can connect a heating system to it and achieve good results in terms of thermal efficiency. A water circuit is installed inside a fireplace of this design, connected to the general heating communications of the home. The combustion of wood in its firebox increases the temperature of the coolant in the pipes and due to this provides high-quality heating of the entire building. The two main connection schemes imply the operation of open and closed systems, respectively.

To install a fireplace in a house and connect open heating to it, you will need to hang an expansion tank above it, which works on the principle of communicating vessels. With a closed method of connecting the furnace, a common tank is used in the design, rather than a separate expansion tank being built in.

Types of fireplaces for home heating

First of all, fireplaces are distinguished by the type of combustion chamber device:

- Open fireplace. This is a decorative option for a heating structure - a fireplace without walls looks beautiful, but its efficiency is low, it only heats the room in which it is located, and only partially if the room area is large.

- Semi-open fireplace. It is attached to the wall or recessed into it; one of the walls is missing, which allows you to observe the combustion process. The heat transfer potential of this design is already higher; it can be used as a full-fledged additional source of heating for the house.

- Closed fireplace. In the vast majority of cases, this is a fireplace built into the wall, separated from the room by a metal damper or heat-resistant glass. This is the safest fireplace option in terms of fire hazard and the most efficient fireplace option in terms of thermal potential. Such a fireplace stove is quite suitable for heating a house even as the main source.

In order to use a fireplace as a source of heating for a home, it will need a distribution system that will distribute the heat throughout all the rooms. On this basis, fireplaces are divided into two groups: with water heating and with air heating.

Fireplace with air heating

These are closed type fireplaces in which there is no direct contact with the room air. The fireplace design includes air ducts that distribute heated air throughout the house. Both natural and forced distribution of hot air throughout rooms can be used to increase efficiency. Such fireplaces come in both floor-standing and built-in types.

Natural convection circulation of flows is effective for heating only one room. To heat several rooms, forced injection of hot air is necessary. This is done using built-in fans powered by electricity. Air ducts lead to each room, which is supposed to be heated using a fireplace.

Fireplace with water heating

Fireplace heating of a private house can be organized using a fireplace with a water circuit.

This fireplace is connected to the radiator water heating system of the house. As an additional functionality, it has a hob. There are such varieties as fireplace stoves with a water circuit made of cast iron and other metals.

A fireplace with a heat exchanger can be used as a spare, backup method of heating a country house, for example, when using a gas boiler as the main source. Such a fireplace can be used without heating water for heating, which can be important in the summer.

Chimney installation

After the “body” of the fireplace is ready, you can begin creating the chimney. Its passage must correspond to the calculated value. The top of the chimney should be reliably protected from precipitation. For these purposes, you should use a wide smoke hood made of galvanized sheet metal.

There is no better material for a chimney than red ceramic brick. Here's what one of our forum participants thinks about it.

The advantages of a brick chimney are considerable. It is much more difficult to achieve the formation of condensation in a brick pipe than in a sandwich - you have to try. The combustion of soot is not dangerous; the heating of the outer surface of the pipe in the attic is minimal or even completely unnoticeable. The durability of a properly laid brick pipe is many decades.

As a chimney, you can use a galvanized pipe made of heat-resistant steel. Such a chimney is made multi-layered (the result is a kind of “sandwich”), and it is covered with plasterboard on three sides.

During periods when the fireplace is inactive, any chimney becomes the cause of drafts. In order to avoid such a harmful phenomenon, special valves (gates) are installed in the chimney shaft. They open only when the firebox “comes to life”, filling the room with pleasant warmth.

The cross-sectional area of the cylindrical chimney with the area of the fuel portal should have a ratio of 1:10.

Particular attention should be paid to the height of the outer part of the chimney:

- if the distance from the ridge to the chimney is less than 1.5 m, then the chimney must be at least half a meter higher than the ridge;

- if the distance from the chimney to the ridge is more than 1.5 m, then the upper cut of the chimney should not be lower than the level of the ridge.

Advantages, disadvantages

The positive qualities of the units include:

- operating principle of a simple fireplace model: the release of thermal energy from the stove occurs during the process of fuel combustion;

- chimney ducts are designed to remove carbon monoxide. If you additionally provide channels through which air will move by convection, the temperature levels will become higher;

- there is no localization of heating zones near the fireplace;

- simplicity, lightness of the air circulation system of the coolant;

- high level of security. Compared to a water circuit, even the slightest hole in the pipeline can cause a break. Hot water can cause burns and severe harm to a person;

- lack of coolant;

- lightness, simplicity of turning on and off the heating;

- in comparison with a water circuit, significantly cheaper;

- no temperature differences across localization zones.

Negative sides:

- cost of organizing the system. Constant fuel supply;

- fuel cost.

Is it effective to use fireplaces in the home?

Any fireplace is, first of all, a decorative element of the interior, which, thanks to modern developments, can effectively participate in heating rooms. Thus, heating a house with a fireplace with an air duct has a simple structure and an equally simple operating principle, and therefore is inexpensive. However, the low efficiency of the circuit sometimes calls into question the entire feasibility of erecting such a structure.

The operating principle of a fireplace with a water circuit, as well as the structure of the heating element itself, is more complex than the previous version, which explains the high cost of both equipment and installation work. However, the efficiency of 70% of fireplaces with a water circuit makes this equipment an excellent alternative source of heat in the house when the main heating element (boiler) is turned off. This video will help you figure out how to properly install a fireplace with a water circuit:

PS And remember, just by changing your consumption, we are changing the world together! © econet

Advantages

Let's look at the main advantages of fireplaces with convection heating, and then move on to the device. Heating systems with air circulation have a whole list of advantages over a classic fireplace; we will highlight only the most significant of them.

Heat distribution diagram throughout the house

- Heat transfer by radiation stops completely when the fireplace is stopped. When a fireplace with a convection heating principle goes out, the air continues to circulate for some time, heating all the rooms. This fact contributes to fuel economy and increased efficiency.

- Due to the fact that air is used to heat the house, it is possible to increase the efficiency of the fireplace due to additional heat exchange not only in the firebox area, but also in the chimney.

- Air circulation implies the arrival of new portions from the outside. This provides additional ventilation in the room.

- Compared to water heating, where energy is transferred in two stages, an air heating circuit directly transports the coolant, which will fill the room.

- The presence of fans that participate in the circulation of the coolant increases the length of the channels with air ducts to 10 meters.

You need to think about the possibility of installing a fireplace when building walls. Firstly, it is easier to build a foundation for a fireplace when there is no floor covering yet, and secondly, the installation of air ducts requires partial destruction of the walls. During their construction, you can immediately equip the rooms with channels.

How does it work

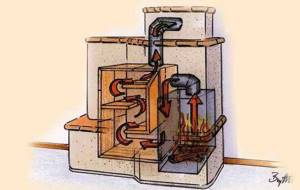

To fully appreciate the effectiveness of a fireplace with an air circuit, you will have to consider the principle of heat transfer in a classic fireplace. As you know, there are three ways to transfer thermal energy. The thermal conductivity of air is quite low, so this method has never been considered as the dominant one.

The advantages of convection had not previously been objectively assessed, so the key bet was placed on radiation. A classic fireplace with an open firebox did not even heat the air in the room, but the surrounding objects, and they, in turn, transferred heat to the air and the room warmed up. However, it was impossible to even dream of transferring heat to other rooms.

Over time, the transfer of matter, as a method of transporting energy, became more and more of interest to furnace masters. Modern air heating from a fireplace is based on the fact that heated air is distributed throughout the rooms. The design of such a fireplace accomplishes two main tasks:

- efficient heating of air masses;

- their transmission over a distance.

Scheme of operation of the air heating system

The first task is helped by hollow channels that are installed in the fireplace body between the firebox and the outer wall. They can be made in the form of a labyrinth in order to increase the area of contact of air with the heated walls of the firebox.

Good to know: Outdoor fireplace with barbecue, how to build such a complex with your own hands

The Russian stove in the chimney area is constructed in a similar way. Only tap heat transfer occurs from hot air to the walls. The air from below enters the channels through special holes and heats up. Convection currents move upward and as they move, the air temperature rises even more. Natural convection alone is not enough to move air through winding channels. It is necessary to use fans that pump in new portions of air and displace the heated masses that provide heating to the room.

The second task is achieved by distributing the air duct throughout the rooms. Warm air flows through the ducts into neighboring rooms. If the length of the air duct does not exceed 3 meters, then natural convection is used for transportation. Otherwise, forced circulation is ensured.

Construction of a classic brick fireplace

Strictly speaking, open hearths are not suitable for heating private cottages due to the low efficiency of burning wood, the efficiency is only 20-30%. While the fire is burning in the firebox, heat spreads throughout the room through infrared radiation. After attenuation, the heating intensity decreases and stops after 2-3 hours, when the brickwork has cooled.

Despite their low heat transfer rates, fireplaces remain attractive to homeowners because they create a unique homely atmosphere. The structure of a classic English hearth is shown in the diagram and includes the following elements:

- underground part - foundation;

- base of 2-3 rows of bricks;

- bottom part with a protruding pre-furnace platform;

- portal - brick frame of an open firebox;

- smoke collector - an umbrella-shaped channel tapering upward above the combustion chamber;

- the fireplace tooth at the beginning of the smoke collector serves for better heat extraction from hot gases;

- chimney pipe leading to the roof;

- the traction force is regulated by a valve.

Diagram of a classic open hearth

If the construction budget allows, then the outside walls are tiled, as was done above in the photo. It is not necessary to decorate the walls of the structure - the correct brickwork looks quite neat.

a7ab4a51a9a07018fb67959eed591a6c.jpe

This is interesting: Marble portals for fireplaces - we understand from all sides

Fireplace as a heating device

So, having chosen a fireplace, it was necessary to find out whether it would be suitable as a solution to the task at hand. Fireplace as a heating device? Why not.

Although recently, a fireplace has gone from being a completely utilitarian heating device, which it traditionally was, for example, in England and European countries (Russians preferred stoves), to becoming, rather, a design “thing” in the interior, plus a demonstration of the owner’s wealth. Most often, a fireplace is an expensive pleasure, and in some cases it can become a true luxury item, the cost of which is quite comparable to the price of an entire dacha in a prestigious area.

Fireplace as a luxury item

A modern fireplace can easily perform different functions: be only an excellent interior decoration (for example, bio-fireplaces) or, in addition to its decorative role, also serve as a source of heat. The main thing is to choose the right model and perform installation taking into account your needs.

Types of fireplaces

Since this article is about the fireplace as a heating device, we will not waste time considering purely interior options and decorative methods for decorating the exterior

Let's turn our attention to the combustion part

traditional english fireplace

An English fireplace is a fireplace with an open rectangular firebox. The Rumford fireplace is an improved variation of the classic English fireplace; it has a trapezoidal firebox. From a heating point of view, this is the least efficient device. Its efficiency is usually very low: from 5 to 20%. An open firebox does not allow you to regulate the combustion intensity; the hearth burns a lot of fuel, producing intense heat during operation, and quickly cools down when active combustion stops.

Classic open fireplace of the English type with a rectangular firebox

modern indoor fireplace

Today, consumers more often choose closed-type fireplaces - those with a tightly closing door with fire-resistant glass. The door allows you to use fuel more economically. In addition, “advanced” models have built-in valves that regulate the combustion intensity. Manufacturers of some fireboxes claim that the efficiency of their products reaches 85%.

Of course, they are lying: the efficiency for devices running on such unstable fuel as firewood is a very subjective concept. The efficiency of a fireplace or stove depends not only on the design of the firebox itself, but also on the type of firewood (hot birch, oak or larch, or so-so firewood - alder or poplar), on its humidity and other things.

Closed fireplaces: many different ones, but are they all good?

In its modern design, the fireplace is a metal box - a fireplace insert or a factory-made fireplace cassette with a thick door equipped with glass and adjustment knobs (various valves, vents, dampers). There is also a pipe for connection to the chimney. The combustion chamber can be cast iron or steel, lined with fireclay plates.

Depending on the model, the firebox can be equipped with a smoke collector of different designs, a second afterburning chamber, a thermal casing, convection channels, a circuit for installing a water heating system and other necessary and useful devices that increase the efficiency of the device and the comfort of its use.

Fireplace Invicta Gaya Ardoise. Photo from invicta.su

In addition to fireplace inserts and fireplace cassettes, there are also fireplace stoves, caminetti (self-sufficient fireplace inserts that do not require additional decorative framing), just stoves and just fireplaces. That is, in addition to the traditional stove product, built from bricks by a master stove-maker directly on site, good ready-made options are offered for sale, made in production conditions, using modern engineering solutions.

More details about the design of fireplace inserts and the agony of choosing the best firebox, fireplace or stove should be written separately. Here I want to talk about the option that was chosen for this particular project.

Principle of operation

Factory models of heating boilers for such fireplaces have a heat exchanger around the body in the form of a spiral or a radiator made of thin pipes through which water or air circulates. When heated, they flow through heating pipes to radiators in other rooms.

A fireplace with a water circuit using wood fuel has a low efficiency, not exceeding 60%. In addition, simple models require constant supply of firewood to effectively supply the house with heat. Pellet fireplaces are free from these problems. They use pellets as fuel, which have a higher specific heat of combustion than wood. The pellets are automatically loaded from the back of the firebox. You can regulate the flow rate and, therefore, the power of the fireplace using the electric control panel.

Fireplaces with ductwork can have an efficiency of up to 80%. Complex models can be designed with heating functions in the firebox and wall. This ensures maximum heating of the circulating air. Unlike water circuits, air systems require fans, which requires additional wiring and more power consumption. But the pipes for them are less demanding in terms of strength; most often they are made of thin and cheap aluminum.

For safety, most air and water fireplaces are equipped with a safety glass door. Heat penetrates into the room through this glass due to infrared radiation. This eliminates the possibility of sparks entering the room, and the owners can enjoy the view of a bright flame. To keep the glass shutter clean, it is protected from soot.

What power electric fireplace to choose

Almost all the power of an electric fireplace is spent on the operation of the heating element - the heating element; other functions that create the illusion of a burning flame consume a small part of the energy in the total volume and these indicators can be neglected when calculating the heated area.

Therefore, most often, when choosing the power of an electric fireplace, you can be guided by the following rule - in order to heat 1 sq.m. rooms with standard ceilings of 2.5-2.6 m require 100 W of electric fireplace heating element power.

Thus, a 2 kW (2000 W) electric fireplace is designed for installation in a room of about 16 - 20 square meters, a 1 kW - 8 - 10 square meters, etc. It is this rule that should be taken as a starting point when choosing it.

If heating is only an additional, not the most important function of an electric fireplace, and you install it only for beauty, you can take any one you like in the store, the main thing is to make sure that the cross-section of the power cable will be sufficient for the fireplace to operate.

In an ordinary apartment, house or cottage, when the length of the supply line is not too high, up to 50 m, electric fireplaces with a power of up to 3.5 kW can be connected using a standard three-core cable VVGng-LS with a cross-section of 2.5 mm.sq.

Air channels - device features

As with laying the firebox, brick or metal are used when installing the channels of the air supply system. You can also use special flexible pipes, which can be bought here, but they are recommended only for short sections, as they interfere with air movement. Failure to comply with this condition will require the installation of more powerful fans, which will increase the cost of your fireplace.

Don't forget about the thermal insulation of the channels. This will not only reduce heat loss, but also increase the safety of the entire structure. For high-quality air movement (minimizing air resistance):

- ensures the most even surface of the inner part of the channels;

- the number of bends in the system is reduced;

- straight channels of large diameter are laid;

- the fireplace and the air duct are connected by separate channels.

Thus, a fireplace with combined heating allows you to quickly heat the rooms of the house, has a simple design, is safe and has a low price. However, you will have to work a little in the field of cleaning the chimney and firebox, and take care of arranging the storage area for firewood.

Features of an autonomous fireplace

In terms of its functions, this device combines the qualities of a hearth, a classic stove and a modern heater.

- What it has in common with the first is the presence of an observation window, although covered with a protective screen, which allows one to receive aesthetic pleasure from the sight of the flame. There is also a drawback inherent in these structures: air for combustion is taken from the room, however, in this case - in the minimum required volume.

- The device combines with the second heating method – convection. The flame heats the body of the device and the latter radiates heat into the room. Just like a traditional stove, if there are no special additional devices, it can heat 2, maximum 3 adjacent rooms and only with the doors open, of course.

- A common property with a modern heater - an electric hearth, for example, is precisely calculated power, which allows you to select the optimal result. The second similarity to the electric analogue is that the device can be installed in the house at any time if there is a chimney. The construction of a foundation or reinforcement of the foundation is not necessary here.

Features of the stove device

Fire brick dimensions

It has been proven above that air circulation is much more efficient than traditional fireplace heating. High efficiency indicators are maintained due to the special design of the stove. It is worth noting that gas fireplaces are not much different in the design of stoves.

A cassette fireplace is the most demanding design for the correct arrangement of the stove. To equip it, builders use only refractory bricks or metal structures made of cast iron.

Cast iron stoves are considered the most heat-intensive and efficient heating devices.

Fans are located above the stove. Practice has shown that heating a house with a fireplace depends on their reliability. Therefore, experts recommend choosing only fire-resistant fans if you plan to install them yourself.

As for decorative elements, their presence is optional for a private home. However, summer residents are actively buying fireboxes with decorative elements with glass doors, modern opening mechanisms, etc.

When choosing a stove for a fireplace in a country house, special attention should be paid to the power of the device, which can be determined in the technical data sheet. The power of the stove increases with its size

Experts have come to the conclusion that it is better to buy stoves 10-15% more powerful than the equipment requires.

Diagram of air heating in the fireplace

Separately, it is necessary to note the closed stove. The lockable design further increases the power of the entire structure due to the smoldering provided by the closed door. As a result, not only the power of the equipment increases, but also the savings in fuel consumption increases due to a decrease in air supply. Thus, a closed firebox is an effective and economical equipment for heating a room.

Floor and recessed installation

Devices with a closed firebox are available in two types of installation - they are placed on the floor and built-in. Both types differ in design features and some installation nuances.

Floor-standing fireplaces for heating several rooms are fairly simple devices that in appearance resemble classic fireplace stoves with a standard operating principle. They are also placed near the wall, which provides great operational advantages and high heating efficiency through air distribution. The fireboxes of such devices differ in the number of glasses and options for viewing the fire. If the firebox is equipped with straight and two side windows, then the fire will be visible from three points in space at once. The fireplace is installed taking into account the classic recommendations for installing wall-mounted devices - on a small fireproof pedestal or platform, the body itself is attached to the wall and floor for stability. Once the installation work has been completed, you can begin to operate the device. Everything is simple and fast (if you have installation skills).

The second type of installation is built-in fireplaces. The peculiarity is that such devices do not take up free space in the house; they are installed even where there is a shortage of living space. The design is a rectangular firebox with a mount for embedding; communication wiring for air distribution is also carried out in the walls. Before installation, it is necessary to prepare a niche for a fireplace of a certain size. The result is a modern fireplace, the firebox of which has a wide view of the flame. The difficulty lies in installing communication channels inside the walls - a professional can handle this kind of work.

A fireplace heating project is always developed in advance.

Even those fireplaces that have a closed firebox are not capable of becoming effective sources of heat. In order for such a fireplace to fully heat the house, it is necessary to make modifications to the device.

Which is better: a fireplace with a water circuit or with air ducts?

This question cannot be answered unequivocally. The advantages and disadvantages of both systems are based on the characteristics of the heated room and the desired temperature conditions in the rooms.

Heating fireplaces with a water circuit have the following advantages:

- efficiency;

- low cost;

- the fireplace circuit is easily integrated into the existing heating system of the house;

- possibility of preparing hot water;

- low cost of equipment;

- low energy price.

A heating fireplace with a water circuit has disadvantages:

- low efficiency;

- the need for constant energy loading;

- manual mechanism for adjusting the intensity of work.

If we compare fireplaces with open and closed combustion chambers, the efficiency of the first is 20%, and the second is 70%.

An air-heated fireplace is the easiest to make with your own hands, because the equipment is not complicated. The layout of the air channels itself is also easy to organize. The room reaches the desired temperature within a few minutes.

Disadvantages of a fireplace heating system with air ducts:

- constant circulation of dust in the house due to the operation of fans (in the case of forced air circulation);

- increased noise level due to air movement through air ducts;

- the temperature in the room drops just as quickly as it rose after the fireplace went out;

- low efficiency;

- the need for manual control of the combustion reaction;

- the need for constant loading of energy into the firebox.

Heating a house with a fireplace with a water circuit and air ducts can be an excellent alternative source of heat, but not the main one. Such heating elements operate on inexpensive energy. But fireplaces can be afforded by those people who are not too lazy to constantly throw firewood into the firebox, control the intensity of their combustion and periodically clean the chimneys.

What is a fireplace?

A fireplace is a type of stove that generates heat by burning solid fuel. The classic option is firewood, just like a regular wood-burning boiler, but you can heat the fireplace with coal, and special briquettes or pellets. Fuel burns due to air draft created by the design of the fireplace. The blower channel ensures the flow of cold air into the main chamber where combustion occurs. The smoke goes into the smoke collector and is then discharged through the chimney, providing sufficient draft for the active combustion process of wood. The resulting heat is distributed throughout the house depending on the design of the fireplace.

The fireplace consists of four main parts:

- Portal. This is the external, frontal part of the fireplace, which has both a structural and decorative function. It can be made of brick, natural stone, marble, artificial stone. The portal is decorated with various decors; it can be made in any style that suits the interior of the house. The upper part is used as a mantelpiece.

- Firebox. This is the central part of the fireplace, the chamber in which fuel is burned and heat is produced for heating. To make the firebox, fire-resistant metal or heat-resistant brick is used. It may be open or have a door.

- Hailo (smoke collector). Only needed for fireplaces with an open firebox. It is a special chamber where smoke is collected before entering the chimney.

- Chimney. A vertical pipe for removing smoke outside the house, providing draft for active combustion of fuel in the main chamber of the fireplace.

The fireplace has several varieties, each of which has its own design features, and therefore fireplaces are classified according to several criteria.

With combined heating

They talk about combined heating when the fireplace gives off heat not only by radiation from the flame, but also by heating the air inside it. If everything is clear with the heat from the flame, then what is meant by heating the air in the fireplace?

In this case, the air temperature increases in special channels located between the firebox cavity and the lining material of its walls. Warm air enters the room through ducts in the walls or ceiling. To avoid its mixing with combustion products, the latter are discharged through the chimney.

Heated air can enter the air ducts in the walls:

- By natural convection. It is achieved due to the difference in the density of cold air and warm air.

- Forced convection. In this case, air is forced into the channels using fans.

With the help of control systems, you can control the power of these fans and, as a result, the distribution of heat in the house.

The design of air ducts must be carried out while working on a house project. In this case, you can provide for a lot of nuances in the operation of the future fireplace, including the type of fuel used.

The efficiency of the air duct system is based on certain basics that are known only to specialists, and it is recommended that you contact them. Thus, the greatest efficiency from a fireplace can be achieved by installing a simple system of channels, its centralization.

Those who are concerned about the cleanliness of the air in their home should know that it is best to use supply air to operate the fireplace. Otherwise, the following unpleasant situation will arise: polluted air from the fireplace room will enter the heating system, and under the influence of high temperatures it will return back in an even worse condition.

Diagram of operation of a fireplace with air heating

Horizontal duct for fireplace

The air channel can be brought outside through the underground, while the passage through the ceiling must be insulated. Visualization: Vladimir Grigoriev/Burda Media

It makes sense to provide a horizontal channel when designing a building. The air duct is laid along the shortest path to the outer wall in the thickness of the first floor ceiling or in the underground space and is brought out through the base. The channel is best made from a thin-walled stainless steel pipe or aluminum corrugated hose with a diameter of 100 mm. When laying a subfloor inside a structure (in a screed, between beams or joists), the pipe must be insulated with basalt wool and enclosed in a steel or aluminum casing. This will avoid the formation of condensation on its outer surfaces, dampening and cooling the floor. To make the intensity of the incoming flow less dependent on the direction and strength of the wind, it is necessary to provide a vertical section on the street with a height of about 0.5–1 m. In addition, the pipe should be equipped with a head with an umbrella and a metal mesh to prevent rodents.

The air duct is connected to the pipe located on the bottom of the firebox. Photo: EdilKamin

Experts do not recommend supplying air from the underground, because there is always a risk of the draft overturning, in which sparks will fall on the subfloor boards and flammable insulating materials. In addition, unpleasant odors from the underground may enter the house.

Project No. 1 – compact mini-fireplace

This hearth is suitable for heating a room of 16-20 m² in a country house or a small country house. Another option for using the structure is as an outdoor barbecue built in a garden gazebo. A special feature of the fireplace is the side convection channels that heat the air in the room. The size of the building is 102 x 51 cm.

To lay out a mini-fireplace, you will need the following materials:

- solid ceramic brick – 240 pcs. (chimney pipe is not taken into account);

- inspection door 24 x 14 cm – 1 pc.;

- cast iron grates 18 x 14 cm;

- valve 25 x 14 cm;

- stainless steel sheet 1 mm thick, size 500 x 1000 mm;

- sheet of black or galvanized metal, laid in front of the firebox, dimensions - 70 x 50 cm.

Sectional drawing of a mini-fireplace. Convection channel outlets are provided on the side walls

The mini-fireplace shown in the drawing is laid out in the following order:

- The first tier is solid. On the second, 3 air channels are laid - 2 side and one in the middle, located under the grate.

- On the third row, the bottom part and the grate nest are formed (made 5 mm wider than the product). Then the grill itself is installed.

- From the 4th to the 10th tiers a fireplace insert is built. On row V, 2 metal rods Ø5 mm are laid for mounting a stainless steel sheet.

- In the 10th row, the rear brick protrudes a quarter into the firebox, the side stones move outward by 40 mm. The width of the firebox in this place is 49 cm.

- The ends of the side stones of the 11th tier are filed at an angle of 28° to the vertical line. You will get the supporting platforms of the arched vault. 2 stones in the depths of the firebox are placed on edge.

- The vault is built from 9 stones, cut in the form of a trapezoid with base sizes of 65 and 52 mm, as indicated in the order. The circle radius is 51 cm.

- On the 12th tier, the formation of the vault is completed, the upper steel rods are installed and a stainless screen is installed.

- Tier 13-14 forms the outlet openings of the convection channels. An inspection door is installed here.

- 15th row - the ceiling is being built, 16-18 - the beginning of the chimney.

The master will tell you in detail the algorithm for laying a mini-fireplace in his video:

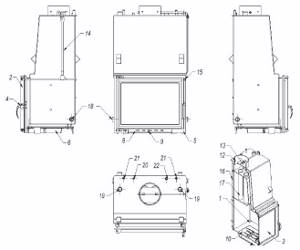

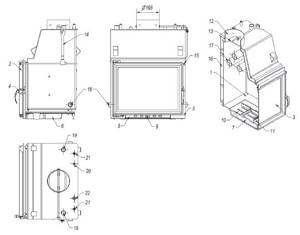

Equipment design

The basis of the fireplace is a steel casing (16). The combustion chamber (1) is mounted in it. The cast iron door (2) prevents heat from escaping from the combustion chamber. For this purpose, it is equipped with tempered glass (3) and a deadbolt (4). The combustion chamber casing (5) is connected to the frame using cast iron axles. The bottom of the firebox is made of thick cast iron (6). Grate bars (10) are laid on top of it.

Fireplace set.

Today, a fireplace heating element can be purchased on the market for similar equipment. However, some people want to make a water heating fireplace with their own hands. To do this, you need to familiarize yourself with its device in more detail.

They also have an impressive thickness, since a direct oxidation reaction of the energy carrier occurs here. Gas fireplaces for heating do not have a grate, since ash is not formed here, which should accumulate in the ash pan. The combustion chamber has a cast iron fence (11). It also performs a decorative function and acts as additional protection against loss of burning fuel. The ash pan (7) at the bottom of the device is necessary to collect solid combustion products. It must be retractable.

Fireplace components with water heating circuit.

The combustion intensity of the energy carrier is adjusted through the supply of primary air. The regulating function is performed by a window (8) in the ash pan and a manually controlled throttle (9). Secondary air, necessary for afterburning of gaseous combustion products of wood and solid particles that rise along with gas flows, enters through a hole in the tempered glass of the door.

A do-it-yourself fireplace with a water heating circuit is equipped with smoke pipes through which the smoke passes into the chimney (12). A mandatory attribute of the chimney is a regulating damper (13). The angle of its inclination is determined by a special mechanism (14). The supply of cold coolant from the heating circuit occurs through the lower pipes (18). The heated coolant leaves the fireplace through the upper pipes (19). Pipes 20-22 are intended for installation of a coil and a thermostat.

Project No. 2 - simple heating fireplace

The dimensions of this structure are 112 x 65 cm, height – 2021 mm. The internal size of the portal is 52 x 49 cm. Accelerated heating of the room is provided due to the convective air channel. The set of building materials looks like this:

- clay solid brick – 345 pcs.;

- the valve used in the chimney is 250 x 130 mm;

- 2 steel equal angle corners 45 mm wide and 70 cm long;

- metal sheet 500 x 700 mm.

The peculiarity of the masonry of the fireplace shown in the diagram is the placement of a large number of bricks at the base on an edge. Above, a narrow long channel is arranged where the heated air of the room moves. Let's move on to the construction algorithm:

- The first tier is solid, consisting of bricks placed “on the butt”. On the second tier, a heating channel with a cross-section of 65 mm is formed, on the third, the base of the firebox is laid.

- From the 4th to the 9th rows the portal walls are erected. The duct moves inside the back wall of the fireplace. On the 9th tier, corners are placed - floor supports.

- Tier No. 10 – firebox overlap. On the 11th row, the front stones extend 130 mm, the 12th tier is a fireplace mantel. The convective channel is divided into 2 narrow shafts.

- Rows 13-25 make up the smoke box. The heating channel ends at the 14th tier.

- Row No. 26 covers the flue, which narrows to the chimney. The valve is installed on the 27th tier.

- The remaining rows 28-31 form the beginning of the chimney.

The test fireplace lighting technique is demonstrated in the latest video:

Masonry

Scheme for laying rows for a corner fireplaceOrdering an English fireplace

Cover the dried foundation with a double layer of roofing material. This will provide the necessary protection for the base.

Prepare mortar for brickwork. Traditionally, fireplaces are laid using a solution based on pre-soaked clay.

Laying the first row is best done using mortar with a small addition of cement (approximately 10-20% of the total mass of the mixture).

Calibrate the bricks in advance, selecting the most suitable sized products for laying each row.

Before starting laying, immerse the bricks in water for a while. This will allow the products to become saturated with moisture. Otherwise, the bricks will take water from the clay mortar, which will lead to a significant deterioration in the quality of the masonry.

Lay out the first row of bricks edgewise. Check that the row is laid out correctly with a square and level. Make sure the opposite sides and diagonals of the base are the same length.

The recommended thickness of seams is up to 0.5 cm.

The masonry is carried out in accordance with the order. The following will be a procedure that is relevant for most existing types of fireplaces. For the rest, rely on the drawings you have.

Laying a fireplace, step-by-step instructions

Lay out three continuous rows of the base.

Laying a fireplace, step-by-step instructions

Second step

Lay out 4-5 rows with an ash pan.

Fireplace laying, step-by-step instructionsFireplace laying, step-by-step instructions

Third step

Lay out 6-7 rows with the arrangement of the bottom and frame of the brick fireplace.

Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Circle and formwork for laying an arch subfloor Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions

Fifth step

Lay out rows 14-19 with a smoke collector.

Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions

Sixth step

Lay out 20-25 rows of the fireplace with a chimney arrangement.

Arrange the base and continuous rows of masonry using a trowel or trowel. The chimney and fuel chamber are laid out manually, because

at these stages it is very important to control the quality of the solution used

Apply fireplace mortar to the middle of the bricks. The edges of the elements must remain free.

When laying out each row, adhere to the chosen order. For greater convenience, you can number the products.

Pay special attention to the quality of the masonry of the fuel compartment and smoke exhaust ducts - these elements must be laid out as evenly as possible and as airtight as possible. Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions

Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions Laying a fireplace, step-by-step instructions

To form a beautiful curved fireplace vault, apply a gradual overlap of masonry elements

It is important that the overlap size does not exceed 50-60 mm in each row

The construction of curved lintels is carried out using temporary formwork - circles. To fix such formwork, use supports under the fireplace vault being installed.

Start laying from the brick installed in the center, and then carry out symmetrical laying in both directions.

Periodically check the verticality of the smoke exhaust pipe. Even the slightest deviations from the vertical can lead to smoke in the room.

Laying a fireplace, step-by-step instructions

To lay the chimney, use a mortar with added cement, similar to the mixture used when laying out the fireplace base.

The smoke exhaust pipe must be covered with a layer of fire-resistant insulation to increase fire safety. Insulation is installed where pipes pass through the structure of the house (floors, roofing, etc.). The most commonly used insulation materials are asbestos based.

Fireplace chimney

System design and placement

It is best to entrust the design of your heating system to professionals. Their job is to calculate the power of the equipment and plan its installation taking into account all the parameters of the room.

The quality of system operation is affected by:

- how well the doorways and walls are protected - the amount of heat loss depends on this;

- volume of heated premises, their location;

- air speed - are fans needed and what power?

- furnace power - the device must heat the incoming air quickly enough, taking into account heat losses;

- The diameter of the air ducts is how much air and how quickly should pass through them.

After making basic calculations, determine the installation location of the furnace.

The air duct system in most cases is assembled from steel pipes using special elements, including:

- transfer case,

- tee,

- adjustable knee, etc.

Pipes are soundproofed to minimize noise from air flow.

The fan is installed in the system next to the heat source. Mechanical and carbon antibacterial filters are installed at the air duct outlets to protect against dust and odor, respectively. The openings are covered with grilles.

Built-in automation and remote thermostats make it easy to set the necessary settings to maintain a comfortable temperature.

Errors in calculations can lead to overheating of the furnace during operation of the system; in addition, during operation, the latter may vibrate and make noise.

Fireplace insert

Traditionally, the fireplace itself is not much different from its simpler counterparts. Their operating principle is the same - to ensure high-quality combustion of fuel and therefore it consists of:

- Fireboxes.

- Firebox stands.

- Smoke exhaust.

- Casing.

But then the improvements begin, for which the following details are needed:

- A fan or even several.

- Pipes that increase thermal efficiency.

- Distributor and air tees.

- Filter.

- Ventilation grilles located both in the casing and in the rooms.

Designing and installing an air-heated fireplace yourself is not an easy task. This needs to be done during the design of the house itself, which means it is better to entrust this issue to specialists who can correctly calculate not only the location of the air ducts, but also the dimensions of the fireplace itself.

Types of fireplaces by material of manufacture

To construct aqua fireplaces, brick, natural stone, ceramics, cast iron, steel sheet, basalt fiber insulation, and heat-resistant glass are used.

Brick

The fireplace stove can be custom-designed to almost any configuration. Finishing with tiles will emphasize the individuality of the interior. As a rule, high-quality working bricks (refractory) are used in such fireplaces.

Requires careful adherence to technology and high-quality installation. Installed on a separate foundation. The high starting cost is justified by the increased comfort.

Metal

The most profitable due to the optimal price/quality ratio. Light weight, affordable price, simple installation, and varied designs contribute to their widespread distribution.

Combined

They combine the comfort of infrared fireplace heating, the heat capacity of a massive stove, and the functionality of a water heating system. They have the highest possible efficiency. They release accumulated heat for a long time after the fire goes out.

A combustion chamber with a heat exchanger is built in during the construction of a brick or stone fireplace facade. Since access for repairs will be difficult later, the cast iron option is optimal. A separate foundation is required, so it is recommended to use a durable ceramic chimney.

Safety precautions when using fireplaces

To avoid injury, burns and fires, when using fireplace heaters you should adhere to the following rules:

- You cannot cook food directly in the firebox or use it in any other way for other than its intended purpose;

- Do not pour water on burning fuel, as this can lead to cracks in the combustion chamber;

- Do not place foreign objects on the surfaces of the fireplace, especially those that can ignite under the influence of high temperature;

- the combustion chamber and ash pan must not be cleaned of any remaining unburned fuel until the unit has completely cooled down;

- Do not operate the fireplace if any faults are detected in the combustion chamber;

- Young children should not be left near a working or hot fireplace without adult supervision.

Do not leave children unattended near the fireplace

Fireplaces are one of the oldest ways to heat a home. However, using additional equipment built into them, you can provide comfort and warmth throughout the entire house.

Determination of basic dimensions

The ratio of the size of the fireplace and the room

Perform the necessary preliminary calculations. Determine the volume of the room allocated for the construction of the fireplace. The firebox opening should be 1/50 of the room volume you calculated.

The height of the portal should be 2 times the depth of the firebox.

The dimensions and ratios given are very important. If the depth of the firebox is greater than the permissible value, the fireplace will significantly lose heat output. With a smaller firebox size, smoke will occur.

Select the dimensions of the smoke openings taking into account the dimensions of the combustion area. The cross-sectional area of the chimney should be 10-15 times smaller than the area of the firebox.

The optimal diameter of round chimneys is 100-150 mm. The length of the smoke exhaust pipe can reach 500 cm or more.