Date of publication: May 14, 2018

“The fireplace is the heart of any home”: a familiar phrase? Of course, it’s familiar, and also, to put it mildly, very often used. No one argues that the hearth is the heart of the house; this fact has long been undisputed, since it is a reliable constant. But what’s surprising is that the heart of any home, the hearth, also has its own heart! It is a firebox, or, in alternative names, a combustion chamber, cassette, insert. It is in this place that all processes of heat generation take place, which is so important and pleasant for all of us, people.

Prerequisites for creating a closed, cassette-type fireplace

But it was not always so. Many centuries ago, a fireplace was a complete product and was not divided into such concepts as “firebox” and “lining”. It was laid out from stones, bricks or other available non-combustible materials, a channel was made for the smoke to escape, and a fire was lit right in the middle of these stones. Thus, we can say with confidence that any hearth of those times was of exclusively open design. That is, with a poorly made chimney, in those days there was a high probability of smoke entering the room. At the same time, the open format of the hearth always implies its lower thermal efficiency, since thermal energy is wasted aimlessly in all directions, not always having time to reach the power that will provide real heat for the house.

Types of cassettes

Choosing a fireplace with a cassette as a heating option is necessary taking into account its power and the area of the room. Information can be obtained from the instructions or from a consultant. The firebox of this unit can be of two types:

- The open version heats up quickly and is easy to use. The main disadvantage is the low heat transfer after switching off.

- The closed type eliminates this drawback. Such models are made of steel or cast iron using refractory ceramics, which provides them with a relatively high level of efficiency.

In the elite design of the cassette, fireclay lining is used, which enhances the strength and reliability of the fireplace. By the way, the cassettes are interchangeable - you can always purchase a more necessary option.

This is what a cassette insert looks like

The closed fireplace is a 20th century invention from Sweden that revolutionized the world of the heating industry.

A cassette-type fireplace is an invention of the 20th century. On the world market, the first creators of a closed fireplace were the Swedes, namely the developers of the now famous Keddy factory. It was they who came up with the cassette - firebox: a full-fledged combustion chamber, closed on three or two sides and on top with thick non-combustible materials, and on one or two sides having a door, which, in turn, also closes. With this invention, they revolutionized the global fireplace industry, creating a fundamentally new type of hearth and heating level.

Having thus opened a new page in the history of the heating industry, the Swedes, these inhabitants of the harsh northern lands, laid the foundation for a fundamentally new approach to their work for absolutely all manufacturers of fireplace products. Closed fireboxes have spread throughout the world at record speed. However, the Swedes did not oppose this and were only happy. Today, every manufacturer of heating products has fireplace cassettes in its product range.

Where does the construction of a cassette fireplace begin?

If the house already has a major chimney, there is no doubt about where to place the fireplace. At the chimney, all surfaces to which the fireplace will be adjacent are prepared.

Even a cassette fireplace requires a project. It is best to plan the location of the heat source at the stage of building a house

And if construction is taking place in a finished space, you need to pay attention to the safety of the structure by drawing up a general diagram for installing the fireplace. After determining the installation location, you need to make a base for the fireplace. To do this, lay a layer of insulation (or thermal insulation) directly on the floor.

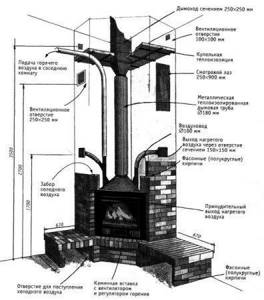

A reinforced concrete screed is placed on it under the fireplace pedestal. Screed thickness up to 15 mm. The light weight of the future structure allows you not to break the finished floor in order to strengthen the base of the fireplace. It is convenient to use aerated concrete blocks to build a pedestal. Give them the shape and required dimensional parameters with a rasp or hacksaw. Subsequently, this durable material can be plastered or faced. To lay aerated concrete blocks you will need a solution or glue. Laying is done in the usual way. But you need to take into account that the portal threshold will need to be issued immediately. Let's say, natural stone. The stone plinth is glued to the pedestal using heat-resistant glue or fixing the material with dowels and screws. When creating the base for the “filling” of the fireplace, we must not forget about the technical holes for subsequent maintenance of the fireplace. The ventilation and inspection openings of the fireplace are covered with decorative grilles after finishing work is completed. After completing the masonry, you need to level the upper wall of the pedestal. To do this, it is plastered with cement mortar, a 10-15 mm layer. A layer of asbestos cardboard and iron is required for thermal insulation. It is placed under the cassette space. Accurately calculate the installation location of the fireplace cassette in the finished pedestal: it is necessary to plan a sufficient amount of space for the heating system, calculate it so that the metal hose-chimney can be conveniently connected to part of this system in the cassette. If the cassette firebox is mounted in an existing fireplace, the main thing is to tightly connect it to the chimney. The mobile fireplace cassette is installed on a ready-made pedestal. It is better to first place it on the bars and then remove them one by one, making sure that the cassette fits securely and clearly into the prepared niche.

Frame and cladding of cassette fireplace

We proceed to lining the base and shelf of the hearth. When using aerated concrete blocks, steel corners are needed along the perimeter of the structure, which will serve as the frame of the structure. They are welded at the outer corner.

- To decorate the mantelpiece, you can use marble, which is laid with heat-resistant glue. You need to let the glue dry thoroughly. To prevent the slabs from moving during drying, they are tightened to the fireplace base with clamps.

- A duralumin or profile frame will easily hold plasterboard sheathing, which is secured with metal screws (19-25 mm).

- In addition to the casing, you will need to attach protective glass for the cassette to the frame.

- After the glass, heat-insulating mats are also attached to the frame, one side of which must be foil-coated.

- If you want to arrange a place for storing firewood, you need to attach brackets to the frame on which a shelf for storing fuel will be installed. It is also finished with heat-insulating mats.

- The frame is covered with any decorative material: tiles, tiles, natural or artificial stone. Be sure to use hot melt adhesive so that the fireplace serves you for many years.

Features of cassettes for fireplaces: is cladding always necessary?

But what are the features of such products? How do they differ from the traditional hearths of our distant ancestors? The fact is that cassette fireplaces for a country house, cottage, city apartment or commercial space are almost always a set of “firebox + cladding + chimney”. In rare cases, the “cladding” item may be excluded - for example, when the cassette is simply sewn into the wall, implementing the so-called built-in fireplace project.

A decorative frame can serve as a cladding in such solutions. Or it may not protrude - it depends on the artistic preferences of the user, since the cladding almost never affects the heating characteristics of the hearth. With the exception of those projects in which the cladding is made of natural stone soapstone, which is endowed with the ability to super effectively accumulate heat from fire in its structure and then release thermal energy into the surrounding space for a record long time.

Installation features

Compared to the brick type, the cassette type is lighter and does not require additional reinforcement. It can even be mounted on the ceiling of a high-rise building. If there are doubts about the strength of the house, you need to pay attention to the weight of the fireplace indicated in the documentation.

Chimney

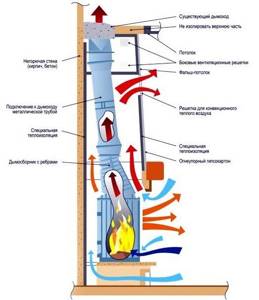

A fireplace with a cassette has its own installation subtleties, which also need to be taken into account when choosing a device. The chimneys of such devices are always under constant control. Extreme temperatures with the threat of overheating are the main reason for close attention.

During installation, it is necessary to create a gap between the structure and the casing that is wider than for a regular traditional fireplace. Then an insulating layer is laid, separating the pipe from the outer box. The material you can use is a double layer of mineral or basalt wool.

When operating a cassette fireplace, you can use a pipe with a smaller cross-section than usual. It is also allowed to use more bends when installing the chimney, since soot does not settle in a cassette fireplace even with prolonged and intense burning.

Fireplace installation and operation diagram

Installation rules:

- A cassette fireplace is safer than a traditional one, but only if all the rules for its installation are followed.

- The plane for fixing must be absolutely flat. For wooden floors, the layer of wood must be removed and a concrete base installed, raising it to the level of the floor.

- The area around the fireplace must also be laid with heat-resistant tiles. It is better to free the walls located next to the heating device from finishing and treat them with protective materials.

- When choosing a place for the stove in the house, you should protect it from contact with electrical wiring.

- If the house has an existing chimney of a suitable cross-section, it should be cleaned and used to install pipes into a finished channel, saving on costs.

- Cuffs and couplings will fix the pipes rigidly and firmly.

- The new chimney must have an exit to the street, fixed from the outside.

- For proper installation, you need to make gaps between the firebox, floor and walls. You can check the distances in the technical data sheet of the device.

- The hood is covered with stone, brick, and plasterboard. From the inside, reflective thermal insulation is attached to the walls and finishing material.

- To reflect heat and protect equipment from overheating, use basalt or aluminum foil. To cut plaster of suitable size, use a regular hacksaw. Plasterboard structures are fixed with heat-resistant glue. For fastening elements of the box for mounting exhaust grilles, holes are made in the drywall.

Before lighting the fireplace for the first time, the structure must be allowed to dry completely. This usually takes up to two weeks.

The use of fireboxes in design: innumerable possibilities for creating interior solutions

The beauty and convenience of insert cassettes lies in the ability to cover them with any facing materials, or ready-made facings made of marble, brick, soapstone, ceramics, tiles, and so on and so forth. For any type of firebox, there is a ready-made lining that will match the dimensions and proportions of the firebox, while demonstrating excellent design and artistic performance.

The ability to create unique fireplace solutions using the “firebox + lining” set is also expanded by the fact that the variety of firebox shapes allows you to design fireplaces of the most varied configurations, location methods, and dimensions.

Modern equipment of cassettes and fireboxes for efficient heating: basic systems and devices

Of course, the most important parameter of such products, be it a traditional wall-mounted, corner cassette fireplace or simply built into the wall, is the type of materials from which they are made, as well as the equipment with modern options and systems that guarantee a high level of heating. The entire operation of the fireplace and the level of quality and comfort of the heating system depend on these systems. It is the firebox, and not any other components of the hearth, that are responsible for the heating characteristics of its operation.

Modern cassettes are always equipped with a number or a whole range of special devices, for example, such as:

- combustion air supply system

- sophisticated air flow distribution system in the combustion chamber

- multi-level combustion of flue gases

- system for the beneficial use of flue gas energy to increase heat output

- warm air accumulation and distribution system

- hot air distribution system to adjacent rooms

- "clean glass" system

- system for regulating combustion and setting the desired temperature conditions

Advantages and disadvantages

Any fireplace model exhibits its advantages and disadvantages in different conditions.

An undoubted advantage will be the versatility of the design, which perfectly complements any interior. A wide range of models allows you to decorate the interior in your favorite style - from classic to baroque.

The downside is the possibility of the furnace releasing heat only in operating condition. Many owners of such fireplaces install a device in the form of a brick shield that retains heat. This option can be used for any cassettes.

Another option is to use the cassette as a boiler. A tank must be connected to it, playing the role of a heat accumulator for the batteries. This system is only applicable to certain types of cassettes. An alternative option is air distribution to rooms, however, in this case the cassette must be heated after 5 hours.

If desired, the cassette can be lined with any materials ─ from wood to artificial stone. According to SNIP standards, a cassette fireplace can be installed even by residents of apartments on the top floors of high-rise buildings.

Another advantage of the design is a special heat-resistant glass damper that blocks the escape of heat through the chimney. This feature distinguishes a fireplace with a cassette from other types.

A short chimney can be considered an advantage, since combustion products are not released as intensely. The chimney must be installed in any case, in accordance with safety standards.

Materials for the production of fireboxes and features of cassette doors

When it comes to materials, cassettes are made from either thick cast iron, durable boiler steel, or a combination of cast iron and steel. The interior of the combustion chamber is always lined with refractory materials that increase the heat efficiency of the entire device: fireclay, brick, refractory ceramics or special composite materials. The cassette also always has a door or several doors (depending on the configuration), which, in turn, are equipped with reliable locking mechanisms to eliminate the possibility of smoke entering the room or unauthorized attempts by children to open the fireplace. Many models of fireboxes have an “open door + slide damper” combination - this is when, when adding firewood, the slide damper automatically opens and all the smoke is effectively “sucked” into the chimney.

Types of cassette models

The cassette for the fireplace can have a certain variety. The choice of a suitable model is made based on such parameters as power, size and heating footage:

- Cassettes for fireplace stoves can be installed in an open hearth. Such models are characterized by low efficiency and are designed for heating rooms with a small area;

- Heat cassettes for fireplaces are often installed in a closed combustion chamber. Such stoves are more efficient, and the cassettes themselves have higher power and are intended for heating houses with a fairly large footage.

The most expensive are multifunctional models...

Classic fireplace set…

Corner cassette fireplaces take up little space...

Closed fireplace: optimal level of safety and heating efficiency

At the end of our populist review, I would like to note that buying a cassette fireplace for a country house is always not only an effective, but also a safe solution. Closed fireboxes provide additional safety in the operation of the fireplace, since the closed door does not allow sparks, cinders and coals to fly in all directions. At the same time, it is in the closed space of the combustion chamber that all combustion processes, the generation of thermal energy of the required level, and the afterburning of harmful substances occur clearly and correctly. An open-type firebox (and there are undoubtedly such types) cannot provide such a high level of all heating processes.

We make a decision

Before you make your choice and decide in favor of such fireplaces, you will need to study not only the structure of the cassette fireplace, but also its distinctive features, which include not only advantages, but also disadvantages:

- Manufacturers offer ready-made lines, the models presented in which differ not only in their size and placement method, but also in style (from baroque to minimalism);

- Such stoves cool down quickly enough and are not able to continue heating when not in use. In order for the heat to be retained for as long as possible after the end of the fire, it is recommended to make the portal from a material such as brick;

- Some types of cassettes can be connected to special pumps and tanks that provide heating of water and its distribution throughout the general heating system of the house. Such fireplaces are also classified as having a water circuit;

- Also, the adjustable mechanism can be not only water, but also air. In this case, heating of the structure must be done after a short period of time, for example every 4-6 hours;

- Due to the need for a chimney, such heating units can be placed exclusively in private houses or on the top floors of multi-apartment high-rise buildings;

- The smoke exhaust duct in such models is always equipped with a glass damper. Due to this, the efficiency and speed of heating of such methods increases significantly.

For finishing frames you can use

A closed combustion chamber has a higher heat capacity...

Model equipped with support legs without portal

Built-in cassette hearth

The video in this article will help you learn in more detail about the advantages and disadvantages of such combustion chambers.

Domotekhnika is the first company to bring a closed firebox to Russia in the 90s of the 20th century

In Russia, the first popularizer of cassette fireplaces and closed fireboxes is. More than 20 years ago, we were the first in the domestic market to bring a Swedish closed-type firebox from the Keddy factory to Russia. Today, any store of our company in all regions of Russia has in its assortment cassettes and inserts from both the Swedish inventors of such products - the Keddy company, and many other European manufacturers. It is important to note that one of the first fireplace inserts we brought, Keddy, still works perfectly and heats the company’s salon at 10 Uralskaya Street in St. Petersburg.

In our company you can either buy a fireplace or order a full range of accompanying services: ordering, delivery, installation, commissioning, service.

Description of the device

The cassette fireplace occupies a special niche in the range of home fireplaces. It has a fundamentally different structure, distinguishing it from similar structures. Before moving on to the description, we note that, due to its uniqueness, it can be installed not only in a private house, but also in an apartment, even on the top floor.

The main element of the fireplace is the firebox, made in the form of a cassette. Although this cassette is not yet ready for use, it is a stand-alone device that combines all the necessary functions for full operation. The cassette can be inserted into any prepared niche and, in case of malfunction, can be quickly replaced with a new one.

Manufacturers offer a huge number of different options to choose from, which differ in power, size, appearance, and functions. Before choosing a cassette model, you should familiarize yourself with the operating principle of such a device. Decide which type of fuel is suitable in specific conditions and choose a location for installation based on rationality and technical capabilities.