How many bricks do you need for a stove - how to calculate correctly

One of the most ancient options for heating a home is a brick stove. Despite their more than solid lifespan, many owners of private houses are still interested in such stoves. This is not surprising - brick stoves do not depend on electricity, gas and regular complex maintenance. In addition, the stove can be used as an additional heat source.

The arrangement of the furnace has a number of nuances - despite all the structural simplicity, the furnace still needs to be designed, selected high-quality materials and carried out efficiently at each stage of the work. One of the design stages is calculating the amount of brick needed for the job. How many bricks are needed for a stove will be discussed in this article.

Preparing for the installation of the furnace

Before installing the stove, you need to carry out a number of preparatory work:

- If a gas main is connected to the house, then the location of the stove must be coordinated with the gas and fire service so that the structure can be used absolutely legally. In addition to the location, you also need to pay attention to the features of the stove - for example, it can be built into a wall or located in close proximity to flammable materials.

- For the stove it is necessary to calculate and make a separate foundation. The perimeter of the foundation should protrude beyond the contours of the stove by at least 5 cm on each side. To fill the foundation, you can use either reinforced concrete or ordinary sand-lime brick. In the latter case, the foundation rows must be reinforced with mesh so that the structures do not deform. The soil under the foundation must be compacted well, and a sand cushion at least 5 cm thick must be placed on it.

- The room must have high-quality ventilation. Even if gas is not supplied to the house, ventilation is still needed - thanks to it, the stove will have good draft. The lack of high-quality ventilation causes a vacuum to appear in the room, due to which the stove “pops” noticeably during operation.

- If a gas main is connected to the house, then the location of the stove must be coordinated with the gas and fire service so that the structure can be used absolutely legally. In addition to the location, you also need to pay attention to the features of the stove - for example, it can be built into a wall or located in close proximity to flammable materials.

- For the stove it is necessary to calculate and make a separate foundation. The perimeter of the foundation should protrude beyond the contours of the stove by at least 5 cm on each side. To fill the foundation, you can use either reinforced concrete or ordinary sand-lime brick. In the latter case, the foundation rows must be reinforced with mesh so that the structures do not deform. The soil under the foundation must be compacted well, and a sand cushion at least 5 cm thick must be placed on it.

- The room must have high-quality ventilation. Even if gas is not supplied to the house, ventilation is still needed - thanks to it, the stove will have good draft. The lack of high-quality ventilation causes a vacuum to appear in the room, due to which the stove “pops” noticeably during operation.

Calculation of brick volume

Let's consider one of the simple and popular calculation methods that allows you to quickly find out how much brick is needed to build a Dutch oven.

Formula

This formula uses the following parameters:

- B – planned furnace height;

- P – height of one row;

- O – the number of bricks in the first row.

Let's say it is planned to build a Dutch house 2.4 m high, at the base of which there are 24 bricks. The height of one row is 7 cm (the thickness of one brick).

- Subtract 0.3 m from the planned oven height for cutting. Thus, after subtraction, 2.1 m remains.

- The resulting number should be divided by the height of one row, resulting in 30 rows.

- We multiply the resulting value by 2/3, that is, we subtract 10 rows.

- 20 rows remain.

- We multiply the resulting number of rows by the number of bricks in the base (24 pieces).

- We get 480 bricks.

- Let's add 50 bricks for cutting.

The result is 530 bricks - the required number to build a thirty-row Dutch oven.

The following parameters are used:

- Chd – number of rows in the chimney;

- N – the number of bricks in one row of the chimney.

These simple calculations will allow you to determine how many bricks will be needed to build a Dutch oven.

In terms of laying a stove, they usually indicate the required number of bricks, and many professional stove makers know this. But there are options in which you can easily calculate how much material is needed for any stove, for example, a Swedish brick stove, for any home.

The calculation sequence will be as follows: multiply the amount of brick laid out completely in the first row by the height (number of rows), and then subtract 1/3 from the result obtained. This way you can make an accurate calculation of the amount of material for the project.

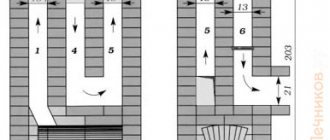

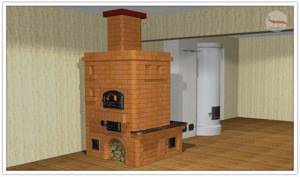

Brick oven diagram.

To make a more accurate calculation, you can use numerical data. Here's an example:

- The base is 3x4 bricks, which means the continuous row will be 24.

- The height is taken as the distance from the floor to the ceiling. This can be 2 m 40 cm. But approximately 30 cm should be subtracted from this height, taking into account the cutting height. In this case, 2 m 10 cm will remain.

- Knowing that the height of one row is 7 cm, you need to use the following formula: divide 210 by 7. We get 30 rows.

- Now 1/3 is subtracted from this number. As a result, 20 rows will remain.

- This number of rows is then multiplied by the base of 24 pieces, resulting in a total of 480 pieces. But you also need to remember about cutting, for which you will need 50 pieces. Total - 530 pieces.

Any stove has a pipe. If in the project it is brick, then it also needs to be calculated. In 1 m of pipe there are normally 14 rows, and in 1 row - 6 pieces. This means that you need to multiply 6 by 14. The result is 84. Now this value should be multiplied by the height of the pipe in meters, and we will get the required volume of the required building material. For example, we multiply 4 m of pipe by 84. The result is 336 bricks; for the construction of a Dutch oven, the calculation will be different.

The obtained values are, of course, conditional. There will still be an error, but these numbers will give you an idea of the total number of bricks and allow you to plan future costs. When the volume of material has been calculated, you need to select its type.

Stocking up on materials

If you have chosen the type of stove (“mini” or “maxi”), a firm decision has been made to build a Dutch oven - it’s time to stock up on materials and select tools.

The following materials are required

- standard size refractory kiln bricks;

- clay;

- crushed stone;

- sand;

- water;

- roofing felt;

- thin steel wire.

In addition, you should take care of the facing materials. The furnace heats up to a very high temperature; accordingly, a number of requirements are imposed on the facing materials:

- high strength and heat resistance

- resistance to mechanical stress

- low porosity structure

- thickness from 6 mm.

Several modern and traditional types of building ceramics meet these requirements: majolica, terracotta, tiles, clinker tiles and porcelain stoneware - which differ in the installation method and design.

The volume of materials used in construction is taken structurally. In this case, it is necessary to calculate how many bricks are needed to build a Dutch oven.

During construction you will need the following tools:

- level;

- Master OK;

- roulette;

- container for building materials;

- shovel.

In addition, you will need stove dampers that regulate the draft and burning rate of fuel, and a combustion door.

Let's move on to calculating the number of bricks required to build a Dutch oven.

Determining the quality and calculating the quantity of bricks

When purchasing material, you need to carefully check its quality. The most important thing is integrity and strength. A good block can withstand a strong hammer blow while producing a ringing, high-pitched sound. One of the fragments should be split - inside it should be a uniform color and the chip should be even. Grooves and irregularities on the surface are a consequence of the technological process and are not considered defective.

Blocks are counted in order. There is simply no other way to obtain an accurate result. The stove is a hollow structure, the need is calculated in pieces, which are then converted into cubic meters. It is in such units that products are released and shipped.

Since different types of stones will be used in construction, their quantity should be calculated in the following areas:

- base;

- walls;

- facing layer;

- channels;

- chimney;

- fireboxes;

- decorative elements.

Types of kiln bricks

Kiln bricks can be divided into three types:

- Quartz contains a small sand content.

- Fireclay is made from fireproof clay.

- The main one contains a lot of limestone-magnesia mass.

Refractory brick can withstand high temperatures for a long time. It has high strength, which makes it difficult to machine. Fireclay clay is used in its production. Available in different forms, it does not have cavities or voids inside. A distinctive feature is a metallic ringing sound when you tap on it. When broken, it splits into large pieces without forming crumbs. Its resistance to high temperatures and chemicals makes it an ideal candidate for firebox lining.

The outer layer of the stove can be made of ceramic bricks. It is not so resistant to high temperatures, but it also has some advantages: it is easy to process. It can be given any shape using a pickaxe. When choosing such a brick, you should carefully study its appearance: there should be no cracks, and the geometry should exactly repeat the standard. The shade of the product should not differ across the entire surface.

When you purchase ceramic bricks, look at its name. The old nomenclature called it “grade 1 red.” Modern technologies make it possible to give the product yellow and white shades.

Recommendations for choosing bricks

In order to purchase high-quality material that will not let you down even after several years of use, you should carefully approach the selection procedure. Simple tips will help you do this:

- The counterfeit contains foreign inclusions, such as individual pebbles or pieces of limestone.

- It is advisable to buy the entire amount of material at once from one manufacturer and one batch.

- Brick that was not fired has a pale appearance and deviations from standard dimensions.

- The listed recommendations will help you correctly select and calculate the material for laying the stove. The process itself will require not only high-quality materials, but also solid experience.

Now you know how many bricks are needed for the stove. It is not difficult to calculate the amount of stone needed to build a stove on your own. Errors can only occur in numbers that need to be double-checked several times. Construction work on the construction of a furnace requires not so much an exact amount of material as its good quality. There are a large number of seemingly similar materials on sale, but they all have different quality.

The described calculation methods are used only in cases where the work is planned to be carried out independently. Hired workers will perform all calculations using their own methods. Don’t be afraid to pick up a calculator and then go to the store and purchase the necessary materials in the required volume.

Types of mortar when laying a furnace

Ordinary cement mortar is not suitable for installing a stove or chimney, since it cannot withstand high temperatures; it is used only when constructing the foundation of a stove. For laying a firebox or ash pit, where the solution is in direct contact with the fire, a clay composition is used, since the clay only becomes stronger when fired by fire. Lime mortar is used to lay out the chimney and chimney.

Calculation of the amount of required materials

The easiest way to calculate materials is to hire specialists who will select and provide you with a choice of a suitable stove design, in which all costs are calculated, down to the last brick. A project suitable specifically for your home, with an individual arrangement of walls and roof. If you decide to build a stove yourself, you will encounter a lot of problems in calculations, the correct location of the stove, compliance with fire safety, the appropriate choice of chimney, calculation of the depth and design of the foundation, and if you have never laid brick, you will not be able to lay out the stove beautifully , with straight seams, uniform stitching. If you are confident in your abilities and construction skills, you will be able to build your own stove, having previously studied a lot of important information on the technology of stove laying and fire-prevention cutting.

Preliminary work

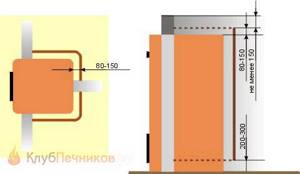

- If your home has natural gas, you will need to coordinate the location of the furnace with the gas and fire departments and obtain all the necessary documents and seals. Since the stove can be built into a wall or adjacent to it, it is located in a fire hazardous proximity to wooden walls and wooden roofing elements.

- Depending on the mass of the furnace, calculate the size and load-bearing capacity of the foundation. The foundation is the basis of absolutely any oven. It should be emphasized that the perimeter of the foundation must exceed the perimeter of the stove itself by at least 5 cm on each side. The foundation can either be poured with concrete mortar, with mandatory reinforcement, or laid out from ordinary sand-lime brick. The foundation rows are reinforced with masonry mesh to avoid deformation. A sand cushion, at least 5 cm thick, is installed under the base. The soil under the cushion is carefully compacted.

- Ventilation in the room is also a requirement of the fire department if you have natural gas. In addition, ventilation contributes to good draft in the oven, without “reverse pops”. Since the lack of air flow creates a vacuum in the room during operation.

Next, you will need to calculate the amount of materials. The most numerous of them is brick. Moreover, when constructing a stone oven, different types of bricks are used. To lay out the firebox or furnace, that is, in places of the highest heating, refractory clay brick (fireclay) is used, note that it has a rather high price, which is why it is used only in those places where it is necessary. For laying a chimney, the use of fireclay bricks is not advisable; it is more appropriate to use fireproof bricks; they do not have direct contact with fire, but can withstand temperatures of up to 1000 degrees. To install the outer part of the pipe, which is exposed to climatic aggression, frost-resistant brick is used; it is less susceptible to deformation from temperature changes, for example, sand-lime brick, which can crack under such conditions. Ceramic bricks, which have a beautiful appearance, are used for lining the stove.

The best oven

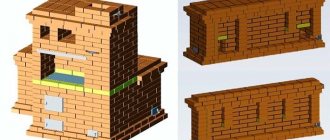

The Dutch oven is characterized by ease of operation, simple design and high productivity.

The compact Dutch woman can be used in a country house or in the country. It heats up quickly and cools down slowly when the damper is closed.

The classic version of the stove is rectangular in shape, with extended chimney channels above the firebox - intended only for heating.

However, over time, various shapes arose: triangular, round, trapezoidal. Various options for using Dutch ovens have also appeared: in addition to heating ones, there are heating and cooking stoves that are combined with a stove, there are combinations with a fireplace, with a stove bench, and with a container for heating water.

A Dutch oven can become the basis for a heating system based on the circulation of heated water in pipes.

An electric pump will ensure stable movement of water in the pipes. Such a heating system will increase the heating of the room, save fuel and is a good solution for a large house, say, on two floors.

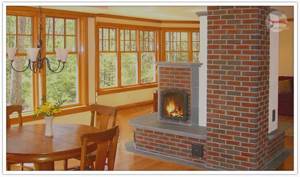

Skillful design will allow you to make such a stove part of the decor, effectively integrating it into the interior of the room.

Life time

The service life of a Dutch oven is about 25 years if it is used correctly.

Note that the Dutch engine is designed for heavy fuel of good quality. It should be heated with coal or wood; garbage, wood chips, sawdust and other waste fuel will not work . This is due to the fact that the stove operates optimally in the smoldering mode, which is provided by wood and coal.

Using wet fuel will cause the chimney to become clogged with soot.

Anyone, with basic bricklaying and installation skills, can make such a stove with their own hands.

Place

The location of the Dutch oven, its size and the length of the chimney should be chosen taking into account the size and features of the house. Most often, the stove is located near one of the main walls of the house , not far from the entrance to the room.

It is important to create a thermal curtain from the cold penetrating from the front door and evenly warm the room. In addition, to monitor the serviceability of the Dutch oven, clean it and clean it, access to all its walls should be provided.

Calculating the amount of bricks for the stove

- Furnace sections Foundation

- Firebox

- Chimney and pipe

Since ancient times, open fire has been one of man's best friends. It provided warmth, food, and drove away dangerous predatory animals. That is why to this day we feel calm and tranquility when watching the play of flames.

However, the oven gives us more than just visual effects. Despite the development of modern technologies, it still helps to heat the home and cook food just as before. Moreover, many believe that food made in this way is many times tastier than that prepared on a regular stove. All in all, a stove is a welcome part of almost any home. Therefore, you need to approach its construction very thoughtfully. An important step is choosing the material and calculating how many bricks are needed for the stove.

As a rule, some parts of it are built from rather expensive brick blocks, so purchasing an excessively large quantity will hit the budget hard. Let's figure out exactly what bricks we need and how many of them we need.

Furnace departments

Any stove, be it Russian, Dutch, Swedish or a sauna structure, consists of several main sections. For each of them, the material should be selected separately, since certain characteristics required specifically for a specific part of the hearth are important.

Foundation

The first step is to build the foundation. Since the structure is usually located on the ground floor, the proximity of the ground must be taken into account. Therefore, a concrete slab is usually laid as the first layer, below the floor level, and a layer of waterproofing is applied to it.

Thus, we get a layer that will withstand the mass of our future structure, and also will not allow moisture and cold that come from the soil to affect it. Solid brick rows are usually laid on top of the waterproofing layer; there can be from two to four.

This is the second part of our foundation. As a rule, clinker material is used for it. This is due to the fact that it has very high strength, it is not afraid of loads, so such a base will easily support the weight of the entire stove.

Brickwork calculator - how many blocks do you need to build? + video

One of the first questions asked by a person who plans to make a stove in his home is how many bricks are needed for this purpose? The problem is even more pressing if the brick is expensive. These kinds of questions, as a rule, make sense if a person knows what kind of stove he wants, the rest is just talking shop.

If the stove is made according to some project, then the number of bricks must be indicated. As a rule, stove makers also have several ready-made solutions in stock, where the consumption of bricks is also taken into account.

But are there any universal ways to find out how many bricks are needed for any stove? I addressed this question to professional stove maker Leonid Shadrin.

Having listed everything that has already been written above, Leonid proposed a simple formula for counting bricks, but with the amendment that it is also quite conventional.

Its essence is as follows:

- take the number of bricks needed for the first row of the furnace, laid out completely

- multiplied by the number of rows in height (the height of one row is 7 cm)

- a third is subtracted from the result obtained

For example, the base of a stove measures 3 by 4 bricks. This means there are 24 bricks in the first continuous row. Now you need to know the height of the stove. Let’s say the height from floor to ceiling is 2 m 40 cm.

From this size we subtract 30 cm (cutting height), we get 2 m 10 cm. The height of one row is 7 cm. Thus we get 30. From this number we subtract a third of it (30: 3), that is, 10.

We got 20 rows, multiply by 24, and in the end we have 480 bricks. Let's add 50 for cutting, for a total of 530 bricks.

The pipe is calculated separately. In one linear meter of tube, 14 rows of bricks are taken as the norm. For example, if there are 6 bricks in one row of a pipe, then there are 6 x 14 = 84 bricks per meter. Let’s say the pipe is 4 meters long, then 84 x 4 = 336 bricks are needed per pipe.

Here is such a simple formula. Of course, the figures obtained are somewhat arbitrary, but they allow us to estimate how much brick is needed for the stove and plan future financial expenses.

___________________________________________________

If you have to choose which ceiling to make, you don’t need to think long, just follow the link, choose and rejoice! Stretch ceilings here https://www.potolok.name/, wide range, quality of materials and service!

pechky.ru

Methods for calculating the amount of bricks for a kiln

Calculations are not the most difficult thing, but they require attentiveness, intelligence, accuracy and accuracy. Professionals often use a tape measure, plumb lines, levels, and certain rules to determine the amount of building stone, mortar and financial costs, but there are simple schemes for beginners. It's enough just to be friends with a calculator.

Method one

This method is based on a conditional formula: count the amount of material in the 1st continuous row, multiply by the number of rows in height (one row is approximately equal to 7 cm), subtract a third from the result. Let's assume that the base of the oven is 3x4.

Then the first row will take 24 bricks. A building 2.4 meters high with a cut of 30 cm will have 20 rows: (240-30)/7 = 30-1/3 = 20. Multiplying by 24 bricks of the first row, we get the number 480. At least 50 will be needed for cutting.

As a result, we have 530 pieces.

The basis for the calculation is to take the amount of material in the first continuous row.

It should be taken into account that a separate calculation is carried out for the pipe. If they usually take four linear meters, each with 14 rows, then in total such a structure requires 336 bricks (6 pieces per row). Summing up the results, we get 866 units of building material for a small stove. Based on this calculation, you can already plan a purchase of at least 5,000 rubles.

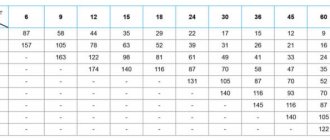

Method two

The formula is a little similar to the previous one, only at the last stage we do not subtract one third, but multiply the result by the filling factor (for heating stoves - 0.8, for a stove with a heating panel - 0.65).

In a building measuring 90x90 cm, for the first row you will need 24.5 bricks, for 30 rows, multiplied by a stable indicator of 0.65, - 477.75 pieces. Round up to 480. On average, a four-sided chimney 4 m high takes 224 bricks (56 pcs./m). Plus 56 for cutting.

The overall result is 760. You will have to spend a little more than 4,500 rubles on this stove.

Both methods of calculation are conditional. For a Russian stove, a “Dutch stove” (three-turn construction) and a stove with a stove, the calculation is carried out separately for each component.

Now regarding the calculation of the number of bricks when laying a heater

It all depends on the amount of building stone. For every 100 bricks you will need at least 30 kg of clay and 70 kg of sand, plus 10-20 kg of cement for the pipe.

That is, for the furnace option from Method 1 you will need 260 kilograms of the first component and 607 kilograms of the second. For a 4-meter pipe it is better to take the maximum amount of cement.

Also, to increase the strength of the solution, it is recommended to add 150 g of salt for every 10 kg of clay. Only 390 grams.

Which brick is suitable

Choosing the right brick is very important when creating a stove. It must be of high quality in order for the stove to be economical, heat up quickly and retain heat for a long time. The quality of bricks can only be determined by personal inspection.

Fireclay contains 70% fireclay clay. Its main qualities are refractoriness and fire resistance. It is from this material that a brick oven will be of high quality. It heats up quickly, but it takes a long time to release heat. Brickwork is also made from solid ceramic bricks. It is created artificially and when fired it becomes durable, moisture-resistant and heat-resistant.

It is advisable to choose a brick that is whole, without cracks, of the correct shape, and of a standard size. How much will be needed for the future stove depends on this size and the quantity in the tray. Usually there are 250 pieces in a pallet, but sometimes there are other quantities depending on the manufacturer. Ceramic bricks must have smooth edges in order for a product made from it to look aesthetically pleasing.

Foundation? Foundation!

A Dutch oven, despite its light weight, needs a foundation. You can equip the foundation in two ways - from cement mortar or from bricks. Both options have their own characteristics.

We invite you to read why fire comes from a chimney

In turn, a Dutch brick foundation will be noticeably more expensive, but at the same time it is much easier to make.

Let's consider a method for forming a cement foundation for a Dutch oven.

You need to do the following:

- Prepare a pit, the depth of which is at least 50 cm. The area of the formed base must be larger than the size of the planned furnace.

- Make a cushion of gravel 10-1 cm thick and carefully compact it.

- Install the formwork and place a reinforcing frame made of metal rods, the thickness of which is 1 cm.

- Prepare the cement mixture and gradually pour the reinforcing structure.

- Cover the foundation with cement powder.

And now the solution.

High-quality masonry of a Dutch oven with a stove requires the preparation of a clay mortar. The strength and heat resistance of the Dutch oven and its tightness during operation depend on the quality of the solution.

The ratio of binding elements in the clay mortar depends on its purpose:

- for masonry work or

- for finishing a stove with a stove.

The frozen mixture must have a high level of rigidity. Masonry mortar of the correct consistency will be plastic and viscous, it will not crumble and will not be liquid.

I'll answer the second part of the question first.

Indeed, many people ask a similar question when installing a stove in a bathhouse themselves. If you decide to build a sauna stove out of brick, then you cannot do without creating a solid foundation.

From the point of view of construction safety, it is necessary to remember one formula (most stove makers use it): for one ton of stove mass, a casting of 10 cm of reinforced concrete base is required. Calculating the total weight of the structure is quite simple: we multiply the number of bricks by 8 kg (the weight of one brick is M - 150 or M - 200) and add 15% to this figure (this is the weight of the mortar and additional stove devices - heaters, fittings, etc.) . Be sure to calculate the weight of the chimney, pipe and crown, which will also create additional load on the foundation.

Another additional factor that should be taken into account when casting a foundation for a brick kiln is the type of soil on which you will lay it. The fact is that if your sauna is used only periodically, the soil underneath will freeze, and, as a result, the foundation of the stove will experience seasonal soil fluctuations.

If the bathhouse is located on heavy clay soils (builders call such soils heaving), then ground vibrations will be significant. An incorrectly cast foundation may not compensate for soil movements and, as a result, the furnace may crack or completely collapse.

On such soil, a columnar foundation can be considered ideal. It is done this way:

- The area of the furnace base is measured and 10% is added to each edge of the foundation length.

- A fertile layer is selected to a total depth of 30-50 cm (a rare sauna stove will be more than five tons).

- At the corners of the pit and in the center of the site, with a drill hole with a diameter of 12-15 cm, holes are made to the depth of soil freezing in your area (even if you divert wastewater into a sewer, the groundwater, having nourished the soil layers, will cause the soil to swell in winter).

- The pits are vertically reinforced (possibly three rods, maybe four). The diameter of the reinforcement is at least 8 mm (fiberglass reinforcement can be up to 6 mm) and filled with concrete (standard concrete, grade M-400. If you do it yourself, use the formula: 1:3:1 - one part cement - three parts sand - one part gravel).

- After the concrete “sets” (48 hours after casting), we make a sand cushion at the bottom of the pit, the thickness of the cushion for casting is at least 5-7 cm. We carefully compact the cushion (many craftsmen use the “spilling” method instead of tamping - they pour water on the sand cushion and the sand itself is compacted to maximum shrinkage density).

- The walls of the pit are waterproofed with roofing felt or other material.

- Formwork with a height of at least 10 cm is placed above the ground.

- After this, the foundation is reinforced. You can use reinforcing bar, laying it at intervals of 10 cm (bar diameter is at least 6 mm), the second layer is perpendicular to the first, the screed is made by twisting wire or plastic clamps. Many stove makers use masonry mesh to reinforce the foundation (the mesh should be no more than 10 cm). Both the reinforcing bar and the masonry mesh are laid at a distance of 5 cm from the sand pad, as well as in layers every 10 cm of pouring the concrete pad.

- Concrete must be poured in one go (one work shift), this will avoid concrete delamination (it happens that in hot weather the layers set unevenly and as a result the concrete does not have the required strength).

- The total setting time of a concrete pad depends on its thickness. As a rule, laying the furnace base begins two weeks after casting the foundation, but first they make an iron corner trim along the upper edge of the concrete pad

If you intend to pour the foundation for a brick stove in a bathhouse, which will be built on light soils (sandy loam, sandy, etc.), then seasonal fluctuations in the soil are not so pronounced here, so the depth of casting the foundation is not tied to the depth of soil freezing. You just need to remove the fertile layer and make a depression in the soil equal to the thickness of your foundation, based on the total mass of the entire structure, and then use the algorithm of actions outlined above.

These, in principle, simple steps will allow you to be sure that the stove you installed in the bathhouse will last for a long time.