In what cases is a balcony or loggia insulated from the outside of the house?

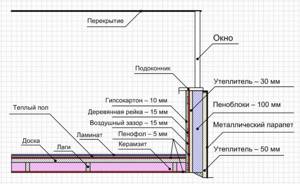

A reasonable owner will not make major repairs to the same property twice. If you already take on the task of remodeling the balcony, then change it completely and radically - insulate it on the outside and finish it on the inside. An example of such a change option is the installation of a French balcony with an integrated thermal insulation layer and ready-made finishing of all surfaces.

However, when it comes to loggias and balconies with an integrated concrete slab, there can be no talk of any ready-made metal-plastic option. The maximum that can be done from plastic in this case is to install window frames around the perimeter. In addition, a radical replacement costs a lot of money, and finishing and insulation using the existing frame can save more than a third of this amount.

If we approach the issue of insulation from a technical point of view, then, clearly, it should only be carried out outside the balcony box. Several factors speak in favor of this:

- External insulation of a facade is a more effective measure than internal insulation, since the cold is contained from the outside in relation to all materials and surfaces, including load-bearing ones. A concrete slab, protected from the street, cools the interior space of the loggia to a much lesser extent;

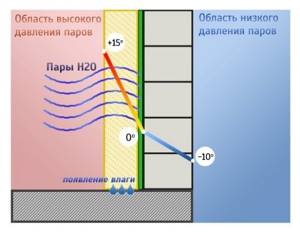

- With internal insulation, water condensation at the border of the temperature change enters the living area (internal walls “sweat”), it is better to shift this undesirable phenomenon outside the loggia;

- Also, the advantages of external insulation include the fact that thermal insulation, even the most modern, is quite massive, extensive and can take up useful space from a small balcony. This phenomenon is not desirable for most apartment owners. This issue should be approached with maximum rationality;

- It is also important that external insulation helps to significantly improve the overall design of the balcony.

The practical side of the issue suggests that performing work outside is associated with some disadvantages:

- If we are not talking about the first two floors, then this work is difficult to do with your own hands due to the danger of falling from a height. You will need specialized climbing equipment and an experienced craftsman who is used to performing such types of work;

- The facades of some houses are valuable architectural monuments and any actions to transform them will be suppressed by the city authorities. If the reconstruction cannot be carried out in a common architectural style with the house, then such work is prohibited and will be immediately suspended by the architectural department;

- With a small budget, resorting to the help of specialists is problematic, as is erecting new parapets, strengthening the foundation slab, etc.

In these three cases, the best option is to create internal thermal insulation. You can find out more about this in a separate article: how to insulate a balcony or loggia from the inside.

Finishing the insulating surface

Any waterproof sheet materials (corrugated sheets, siding, PVC panels, etc.) are suitable for exterior finishing. They are secured using anchors, the length of which is not greater than the total thickness of the insulation and parapet fencing.

Another option for exterior finishing is plaster. First, coat the insulation sheets with a primer. Then secure the fiberglass mesh on top (between two layers of glue), and reinforcing corners in the corners. You can start plastering. To learn how to sheathe a balcony with corrugated sheets, watch this video:

Finishing when deciding whether to insulate a balcony from the outside allows you to hide all the defects that appeared during the work. To achieve the best effect, after you have insulated the balcony from the outside, take care of the heating system. Don't forget about electrical wiring, sockets and lighting systems.

Choice of insulation.

Despite the large initial costs of selecting and purchasing building materials for insulation, they are returned many times over in the form of savings on heating, costs for long breaks in ongoing repairs, and most importantly, comfortable living conditions will be provided. Therefore, it is worth choosing high-quality and effective heat insulators.

Putting a barrier in the way of the cold should only be made of insulating materials. Reflective thermal insulation in this case will be redundant and useless. The most popular materials from the suitable category are:

- Fiber insulation (cotton wool);

- Synthetic boards (foam plastic, polystyrene foam);

- Foams (foamed polyethylene, foamed polyurethane, penofol).

All these types of materials have their own disadvantages and advantages, which are taken into account when choosing them. The decisive factors in this case will be: thermal conductivity, thickness of the insulating layer, installation method and financial costs.

Fiber insulators

This category includes all types of insulating wool: basalt, stone, glass wool. It’s worth saying right away that glass wool, stone wool and slag wool are cheaper, but their use on the balcony is not advisable for a number of reasons: toxicity, a prerequisite for the development of allergies, acidity (an aggressive environment for metal) - only basalt wool is an acceptable material for apartment conditions .

Mineral wool (basalt, stone).

Glass wool.

Slag-like.

Advantages of stone (and basalt) wool:

- high thermal insulation properties;

- good sound insulation;

- moderate convective properties;

- the ability to maintain its structure for decades;

- inertness to fire;

- environmental friendliness.

Flaws:

- the need to waterproof the insulation, create sheathing and use materials for its cladding, which complicates the technology and leads to additional financial costs;

- if the insulation is laid in one layer, then there is a risk of cold bridges appearing between the wool blocks and the sheathing;

- hydrophobia – large volumetric shrinkage of this material when wet.

When choosing between mineral wool (basalt or stone) and glass wool, it is worth considering that mineral wool is easier to work with, shrinks less after installation, and is more environmentally friendly. It has better heat and sound insulation properties. Glass wool, in turn, is cheaper and less attractive to rodents.

Slag is produced from blast furnace waste. It absorbs more moisture and contains an increased amount of chemicals, including acids, which can be released upon contact with water, leading to corrosion of metals nearby. The advantage of silk wool is its relatively low price.

Synthetic boards

In one general group are foamed synthetic substances, which are produced in the form of slabs that vary in thickness. Comparing them with each other, we can identify the undoubted leader within this group. It is extruded polystyrene foam (penoplex). It is not as brittle as polystyrene foam, and its insulating properties are higher and its price category is close to its younger brother.

Styrofoam.

Expanded polystyrene (aka penoplex).

The advantages of penoplex stem from the disadvantages of fibrous materials:

- he is not afraid of moisture;

- can be used without additional sheathing, just protection from ultraviolet radiation is sufficient;

- due to its strength, it can form planes for future finishing;

- very low thermal conductivity, allows you to buy the material cheaper by choosing the thinnest sheets (20 mm);

- lightness is an additional plus that affects the weight load that falls on the balcony slab.

There are no ideal materials, so some disadvantages are revealed:

- its surface and structure form an insurmountable barrier to water vapor, which manifests itself in the moistening of the layers under the polystyrene foam boards;

- it is destroyed under the sun's rays, if not for this drawback, then no finishing coating would be required at all;

- expanded polystyrene easily ignites and is difficult to extinguish, which often leads to fires from smoking on loggias, and toxicity during combustion aggravates this disadvantage.

Foams (foam roll insulation)

All materials of this type have a relatively low price due to the application format (rolls) and the use of cheap raw materials. Foamed polyethylene and penofol are closely related types of roll insulation. The difference is that penofol has a layer of foil that reflects infrared radiation. This type of thermal insulation is rather auxiliary. It is more often used for insulation from the inside of a room, as a reflector of radiant and convective heat. Outside, it is used on the upper floors as an insulating layer under siding, corrugated sheets, and PVC boards.

Foamed polyethylene.

Foamed penofol.

Polyurethane foam

Polyurethane foam occupies a special niche among construction foams. It has a unique method of application to surfaces, which is unique to it - spraying in liquid form.

Pros of polyurethane foam:

- due to the characteristic application feature, it allows you to quickly complete dangerous work at height;

- no thorough surface preparation is required before use;

- moisture resistant;

- very light weight;

- quick fixation.

There were some drawbacks:

- requires the participation of third-party specialists with their own equipment in the process;

- ignites easily, releasing carbon monoxide;

- afraid of ultraviolet rays;

- forms a vapor-proof surface that spoils the microclimate of the apartment.

Summarizing all of the above, we can safely conclude that the choice of insulation depends on the type of parapet available, the finishing coating, the height of the location, and plans for using the internal space:

- On old balconies with a metal parapet, if it is the first or second floor, they try to use mineral wool. In combination with a non-flammable facing coating (aluminum siding, corrugated sheeting), this option allows you to create relatively safe and environmentally friendly insulation;

- As the number of floors increases, it becomes more and more difficult to complete the sheathing, and the basalt cotton wool layer is replaced with a penofol pad in combination with penoplex, which is hidden under the sheathing;

- For insulation of loggias and balconies with brickwork, the use of sheathing and sheathing is rare. The classic option, which is used in such conditions, is plastering with penoplex followed by painting.

- When concrete slabs have an uneven, damaged surface that needs to be preserved from further destruction, it is necessary to use polyurethane foam. It’s good if a whole garland of balconies or loggias is processed in this way, then the cost of the work will be less and will be divided among several customers.

Finishing the facade of a balcony or loggia insulated from the street

The surface of a loggia or balcony, covered with thermal insulators, must not only be insulated, but also have a good aesthetic appearance. In addition, the insulation itself requires reliable protection from moisture and ultraviolet radiation, and some topcoats may have heat-saving characteristics.

The choice of finishing option depends on the type of insulation used, the preferences of the apartment residents, their financial capabilities, as well as on the overall composition - the balcony should fit well into the picture of the house as a whole.

In addition, you should consider how the finished area will be used. Will it be a full-fledged part of the apartment (an additional room) or will its role be a utility room?

There are several ways to apply finishing, but they are divided into two groups: dry cladding and wet plastering. Decorative boards or sheets made of various materials are used for cladding. All types of moisture-resistant plasters are suitable for plastering, which can be left as is or painted.

Sheathing with corrugated sheets

This option is the least energy-saving, since it is performed using metal coated with a layer of zinc and polymer paint. It is better to use a wooden or welded frame made of profiled pipe for fastening corrugated sheets, and non-flammable basalt wool as insulation. On the upper floors, it is more convenient to replace heat insulators with rolled materials - penofol or polyethylene foam.

Profiled sheeting.

If you use thin corrugated roofing sheeting and put old plywood or used OSB underneath it, then you can achieve significant savings. In this case, any available insulation is placed under the OSB.

Balcony covered with corrugated board.

The large area of one steel sheet allows you to cover the entire balcony in several steps, significantly simplifying installation. The color solutions that become available with the use of this material are more diverse and simplify the selection of a composition that will fit into the surrounding landscape.

Siding

This profile cladding material is made of vinyl or aluminum. Thanks to its strength, high chemical resistance and insensitivity to moisture, this solution used for cladding a balcony or loggia is the most durable. The material is not susceptible to corrosion and deformation, like corrugated sheeting, there is no delamination and light aging, like PVC, it is reliable during installation and operation - all only the most positive characteristics.

Siding.

It is worth adding to this that it does not burn at all, or burns, but weakly. Any type of insulation can be used under it, but it is advisable to combine aluminum strips with mineral wool. It must be borne in mind that the price solution of this method is the most expensive, but despite this, the largest percentage of balconies are sheathed with siding.

Finishing the balcony with siding.

Plastic lining

A board made of PVC is a heat insulator and can even be used with penofol, which will significantly save money. In addition, the polymer panel itself is cheaper than siding. Its installation is quite simple; even a non-professional can handle it. The most difficult operation is securing the starting bottom strip at the base of the loggia.

Plastic lining of various colors.

A variety of color options, absolute immunity to moisture and the price factor could make this finishing option the most optimal, but there are negative nuances:

- plastic burns;

- it slowly deteriorates from exposure to the sun and weather conditions;

- requires great care during installation and operation.

Balcony finished with plastic siding.

Decorative plaster

This type of finishing work is used more often on loggias and balconies with a brick parapet. The scope of work is related to the insulation of a concrete slab or masonry and subsequent final decoration. The main disadvantage of this solution is that it is convenient to carry out plastering work only while outside, and this is already dangerous and will require hiring industrial climbers.

You can use both penoplex and mineral wool under the plaster, but still, working with the first option of insulation is easier and more reliable.

The facade is covered with decorative plaster.

Strengthening the parapet structure

The balcony parapet can be:

- Metal - from corrugated sheets, rods, metal strips, pipes - in old houses.

- From reinforced concrete slabs of “light” concrete - in panel houses starting from series 121.

- Made of brick - in most modern brick or monolithic-frame residential buildings.

The material from which the parapet is made plays a significant role in the choice of not only the insulation material, but also its thickness and installation methods.

If the balcony parapet is made of corrugated sheeting or metal welded structures, preliminary cladding of this metal structure from the side of the balcony (loggia) will be required - otherwise the metal “ribs” of the corrugated board will spoil the entire appearance of the insulated balcony and will serve as “bridges” of cold that will negate all your efforts.

In addition to installing an internal screen that will hide the metal structures (made of chipboard, plasterboard, PVC siding, plywood), it will be necessary to create a layer of insulation that would completely hide the elements of the metal structures, otherwise in winter they will freeze and the cost of heating the balcony ( loggias) will be excessive.

If the parapet is made of reinforced concrete slabs or bricks, everything is much simpler - no additional work will be required to change the design of the parapet.

Insulating a balcony/loggia from the outside with mineral wool - step-by-step instructions

Basalt wool is used to insulate hollow siding sandwiches on old-type balconies (with a metal parapet). The implementation of this option should be discussed in more detail:

The use of fibrous heat insulators requires the creation of sheathing and sealed layers of vapor barrier, and these structures cannot be made correctly if, at the same time, you are inside the balcony. Therefore, such a solution is available to residents of the first and second floors, when it is realistic to reach the place of work from the ground or stairs;

- First of all, you should assess the condition of the fences and the edge of the foundation slab (or base slab). If required, you need to remove the old metal parapet and build a new one, welded from a 30x40 mm profile pipe, and the edge of the concrete base of the balcony can be reinforced with a 63 mm corner.

If necessary, replace the parapet.

2. The metal fence is covered with a layer of protective alkyd enamel, and the wooden beams are treated with an antiseptic;

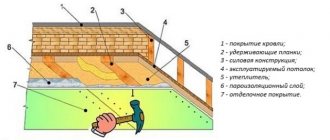

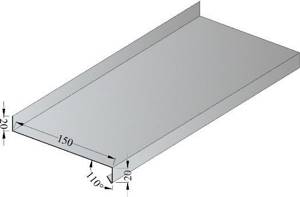

3. A lower ebb is installed along the perimeter of the slab;

The ebb tide ensures the drainage of rainwater.

4. A wooden sheathing made of dry treated beams, measuring 50x50, is fixed to the parapet. The construction of this frame is a very important step, since it will bear the weight of the cladding, insulation and window frame. Therefore, the tree should be attached to metal screws, screwing them into a profile pipe, and the vertical and horizontal guides must be set exactly according to the level and tension of the thread;

Installation of sheathing.

Only dry wood should be used - wet wood can change its geometry and spoil or damage the cladding.

5. At the top, a tie beam is fixed on which the window will subsequently be installed;

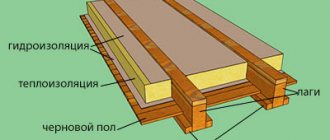

6. Vertical bars are located at a distance of 450 mm from each other. Mineral wool easily changes its shape and compresses, so it is important to create cells from wooden lathing into which 500 mm cotton wool blocks will fit tightly with slight compression;

7. The first inner layer of a vapor barrier membrane (for example, isospan) is hemmed to the wooden sheathing. In this case, it is necessary to orient the isospan roll horizontally - then the moisture-repellent coating will be obtained without joints. The rough side of the film should be turned inward and fixed with a construction stapler to each side surface of the vertical beams, so as to create pockets for laying insulation;

Vapor barrier membrane.

8. Mineral wool is placed in the prepared niches and covered with another layer of isospan on top, this time the rough side is turned outward and secured with a stapler;

Laying insulation.

9. Additional elements are installed on the trim beams (top, bottom and corner) and the siding process begins;

The process of covering a balcony with siding and insulation is similar.

10. The top element of the siding will be cut to the level of the ebb, which will be placed under the window frame, therefore, it is installed with a margin for trimming;

11. The inside of the parapet is also sheathed with any pre-selected finishing material (OSB board, PVC lining, etc.);

12. The remaining gaps near the walls and foundation are closed with polyurethane foam.

Mineral wool insulation can be replaced with penoplex, then all work can be done without risk - while being inside the balcony. First, the outer lining is made, then polystyrene foam is inserted and fixed, and finally, the inner lining is installed. This procedure is available to residents of the upper floors.

What to do with condensate?

Now let's return to the problem of condensation, which in turn leads to the appearance of mold and mildew. If you decide to insulate the walls of your balcony with materials that do not withstand moisture well, you will need to make a water barrier. This is a design that prevents moisture from accumulating on the outer fence. First you need to install insulation boards, and then install a vapor barrier, and all seams will need to be sealed with construction tape in order to ensure the highest quality thermal insulation. But the price for this will be that the walls of the balcony will not breathe.

If the option proposed above does not suit you for some reason, then you should use materials that have low vapor permeability, such as polystyrene foam, extruded polystyrene foam or penoplex. First, the insulation is glued to the walls using a special construction adhesive, after which a fiberglass mesh is mounted on it. By the way, if you decide to use polystyrene foam, then you need to use not glue, but a special sprayer, which then foams and dries.