Home » Construction

Author Reading time: 11 min. Published 12/12/2019

Any sealing of polyurethane foam will take a little time and effort, but working with it is easy and simple.

Polyurethane foam is a polyurethane sealant, which is produced in special cylinders with a volume of 500 and 750 ml. It is very easy to use and does not require additional equipment (except, of course, for professional types). Thanks to its basic properties, polyurethane foam fills any space, seals cracks, fills voids, and connects various materials. This product can reach any hard-to-reach places due to its ability to expand, increasing in volume.

Polyurethane foam can be used for:

- connections;

- sealing;

- sound insulation;

- thermal insulation.

This product is widely used in construction and industry.

Sealing occurs by filling various cracks in cold rooms, in roofing materials, sealing voids when installing doors and windows.

Very often we are faced with the problem of unpleasant noises associated with the operation of air conditioners, pipes, and hoods. The main reason for this is the appearance of cracks, which in turn cause rattling and various sounds that get on our nerves. An excellent way to eliminate this problem is sound insulation with polyurethane foam.

. Thanks to its properties, this product does not allow unnecessary sounds to pass through, and by sealing the cracks, you will get rid of drafts and rattling. In addition, polyurethane foam is a good option for soundproofing an entire house or a separate room. This way you can not only insulate your room, but also get rid of extraneous sounds from the street and neighbors.

Now it is very difficult to find good polyurethane foam on the market that would meet all the parameters. Sometimes manufacturers use low-quality material to reduce the cost of their products, and consumers suffer from this first of all.

The Belinka company always monitors production and is responsible for each product.

For example, BELINKA BELPUR PU FOAM GUN polyurethane foam has all the necessary properties. A high degree of adhesion allows it to be used with all materials; it quickly sticks to the surface, does not crumble when hardened, and can withstand the chemical effects of weak acids and alkalis. It is necessary to work with such mounting foam using a special mounting gun.

But this does not mean that you will have difficulties completing the task; on the contrary, working with such material is easy and simple. Remember that you need to take care of such a gun, wipe it with a special solution after each use, then it will serve you for many years. The hardening time depends on the level of temperature and humidity, so for a better effect you can moisten the surface to be treated with water. Complete hardening will occur in approximately 5-12 hours. Thanks to new technologies, manufacturers have achieved a longer shelf life; now polyurethane foam can be stored for just over a year, which cannot be said about other one-component polyurethane foams. This product is ideal for sealing and sound insulation. I can't help but be pleased with the price offered by Belinka.

It should be remembered that polyurethane foam hardens very quickly, “tightly”, it is quite difficult to remove it, so be sure to wear clothes and special gloves for protection.

Any polyurethane foam does not tolerate ultraviolet rays well, so when finished it should be treated with paint, sealant, or plaster, then it will last much longer.

Polyurethane foam is known to have excellent soundproofing properties. It is especially in demand if it is necessary to soundproof a balcony, loggia or window opening. In this section, noise insulation and sound insulation with foam, we will tell you what role the use of foam plays in the process of creating acoustic comfort.

Reasons for noise entering the home

Very often, ordinary window openings cause unwanted noise to penetrate into the room. The thing is that certain voids are formed between the window profiles and the walls. Sound, with its consistent movement, certainly tends to occupy them. To keep unwanted sounds out, many acousticians often use construction foam in their work. Even when replacing conventional double-glazed windows, you could probably observe a situation where employees of any company use polyurethane foam after replacing double-glazed windows. And this is a completely justified choice in favor of quality material.

Process and processing features

To apply liquid sound insulation indoors, you need special technical equipment.

Under pressure, the chemical composition is applied to the surface, forming a polyurethane layer. Such insulation will protect the house from noise, cold penetration and various pests. The work process is simple. If working with other materials requires certain preparation, then in the case of polyurethane foam, all this is not needed. If there are large peeling elements on the surface of the wall, then they can be dismantled, but otherwise nothing is needed.

Application technology

The technological process of applying sound insulation has some similarities with painting. Liquid noise insulation must be applied evenly, like regular paint in several layers. Do not hold the sprayer at one point for a long time to prevent large foam formation. The thickness of the layer should be three centimeters, this is enough for the material to provide the necessary level of protection.

Stage 1. Preparatory

There is no preparatory stage as such when treating with liquid sound insulation, but you can clean the wall surface from peeling elements. It also doesn’t hurt to cover the floor with plastic film or paper. Foam that gets on the floor will dry out and be difficult to clean.

If there are wires and sockets on the wall, then they should be covered first so that in the end you do not have to completely change the wiring. A special corrugated casing should be used for cables. Upon completion of the preparatory work, equipment is brought in and application can begin.

Stage 2. Primer

The surface of the wall should be treated with a primer. As with any finish, the primer provides maximum adhesion to the coating. You can apply the primer either with a hand tool: a roller or brush, but also with a spray gun. Liquid impregnation of walls is a prerequisite when working with surfaces.

@zhidkaya_shumoizolyatsia

Thanks to the primer, fungi or mold do not form on the surface of the wall under the sound insulation. The primer must be applied evenly over the entire surface. It is better to start applying from the top of the room, this way you will not get smudges.

Stage 3. Applying sound insulation

Polyurethane foam must be applied in two stages. The first layer is thin for the binder, and the second is denser. It is during the application of the second layer that a reliable soundproofing coating is formed. The polymer expands, and the resulting bubbles will be an excellent insulating layer. When working with polymer, a special pressure-operated tool is used. When the insulation layer has reached three centimeters over the entire surface, you can finish processing and put away the equipment.

Stage 4. Drying

After completing the application of the polymer material, it must be allowed to dry. Depending on the manufacturer and composition of the foam, drying time may vary. When sound insulation hardens, it forms a dense porous structure. The outer surface of the coating is uneven, so to bring the wall to perfection it is necessary to use facing slabs or panels. As an option, you can use decorative panels, which, despite their small thickness, also have a certain level of sound insulation. When all finishing and installation work is completed, the object can be handed over to the owner.

Today, the variety of soundproofing materials is so great that you can choose according to your requirements and wishes. When it comes to a large apartment, using frame sound insulation in it will be beneficial for you, since its cost is cheaper than using liquid sound insulation. Liquid sound insulation of the floor in the apartment, as well as the walls and ceiling will make the room comfortable and convenient. The optimal treatment option is considered to be a small living space. Thanks to the insignificant thickness of the soundproofing layer, those important centimeters will be preserved in the apartment.

As stated earlier, only an integrated approach to sound insulation guarantees effective and reliable protection from various noises and sounds. By installing external and internal sound insulation in your apartment, you don’t have to worry about your sleep and peace of mind.

Advantages of construction foam

Polyurethane foam has a number of significant advantages. This explains its frequent use today. In particular, construction foam is sold in a liquid state; after use, it increases significantly in volume. Another very important and trustworthy property is its ability to harden quickly. It only takes a few minutes for the foam to harden. This is a building material that is universal in its effects; it has excellent contact with wood, concrete and numerous other surfaces.

For an individual selection of sound insulation solutions, we ask you to call our specialist.

Spending time in your own home, you want to take a break from everyday worries and be extremely comfortable. But sometimes extraneous noise prevents this from happening. It turns out that sound insulation is one of the main conditions for a comfortable stay. In this case, soundproofing foam, that is, liquid sound insulation or other types, will help.

Extra expenses

Polyurethane foam is often used to save money.

Indeed, a foam container is cheaper than complex sound insulation. But this saving is questionable: given the low strength of this material, you may encounter corrosion and serious damage to the body. As a result, you will have to spend money on repairs and new sound insulation. Standardplast specialists recommend refusing to use polyurethane foam and other materials not intended for use in a car, for your own safety and benefit. Professional sound insulation is the best solution that guarantees both your comfort and the safety of the car.

Types of noise

There are many different noises, here are some of them:

- Airborne noise. This noise is particularly annoying and creates an uncomfortable feeling. Airborne noise is produced when vehicles drive and due to the operation of equipment outside the window. Loud neighbors or passers-by, sounds made by animals (dogs, cats and others) - all this includes airborne noise.

- Impact noise. This type of noise appears due to some kind of knocking. The annoying sound of the percussion variety produces disturbances in the air, and the knocking can be heard over long distances.

- Structure noise. Occurs in ventilation ducts due to improper operation of the water supply. Unpleasant sounds of a structural type can be heard through various devices in the room. These are various heating, plumbing and ventilation communications.

Insulation with polyurethane foam

Not long ago, spray-on soundproofing was not available to the average homeowner. Its price was much higher than other methods. The cost of consumables and related products was high, and the procedure itself was almost inaccessible. Recently, the development of the production of raw materials for the production of polyurethane foam has made it possible for anyone who wants to equip their home with such insulation.

Thanks to sprayed sound protection, you can isolate yourself from various types of noise at a cost comparable to other types of sound insulation.

Peculiarities

Soundproofing a room with polyurethane foam is done by jet spraying a composition of certain reagents, namely:

- polyester in interaction with polyisocyanate, forming foam with a high expansion rate;

- fire retardants that prevent smoldering and the formation of corrosive smoke in the event of a fire.

After combining the components in the sprayer and applying them to the plane of the walls or other surface, instant polymerization and hardening of the polyurethane foam occurs.

Excellent sound insulation is formed, and all thanks to the fact that 90% of the formation are fine air bubbles.

Residents who simply need soundproofing of their living space can resort to the help of companies offering a full range of services. Many of them have materials that meet safety standards, the latest technology and reasonable prices.

Advantages of the method

When performing soundproofing of residential walls with polyurethane foam by spraying the composition onto the base, an additional number of problems are simultaneously solved:

- Producing thermal insulation of a room without seams with a service life of up to thirty years.

- Waterproofing walls in rooms with high humidity, for example, in the bathroom or kitchen.

- Soundproofing the floor covering, in addition to damping out extraneous noise, creates a layer on top of the screed that absorbs moisture in an amount of two percent. Whereas polystyrene foam absorbs up to ten percent of moisture.

- Rooms with a corner location in a panel building will have thermal insulation and protection from fungi and mold, due to the reduction in vapor permeability of the walls on the street side.

- Noise insulation of the ceiling surface in the room will not require auxiliary hanging devices and difficult repair work; it is perfectly hidden under suspended ceilings.

- Polyurethane foam interacts well with any surface, which makes it possible to spray on top of any base, including surfaces made of concrete, wood and gypsum fiber. At the same time, it fills all the seams and flaws in the evenness of the plane.

- The use of polyurethane foam in a wooden house makes it possible to eliminate the installation of layers in the ventilation system and waterproofing, making it possible to spray it from the inside onto the plane of the roofing material.

Features of fine sound insulation

Membranes are convenient because they take up little space, but at the same time isolate sounds very effectively.

Recently, thin sound-proofing materials have become quite common, which provide protection without loss of living space.

They are called soundproofing membranes. Their installation can be done not only on walls, but also on the ceiling, partitions or floor.

Thin wall sound insulation has a number of significant advantages:

- The thickness of the product is only 3.7 mm. The material is able to provide maximum sound insulation with minimal loss of space.

- There are practically no other protection options with the same effectiveness.

- The product is made from environmentally friendly components. The composition does not contain bitumen and rubber. The material itself is quite durable and has an increased service life. It is these characteristics that have ensured such popularity of membranes.

- Installation of the products is quite simple, even a person who does not have construction skills can handle it. A structure is created whose thickness does not exceed 5 cm. In this case, the noise level will be reduced by approximately 70%.

Installation of the membrane begins with the installation of the frame.

To install the membranes, you will need to build a metal frame, its fastening will be carried out using direct suspension.

This is what will save most of the space. The procedure for this is as follows:

- the frame is being built;

- slabs based on mineral wool are laid in it;

- the membrane is stretched;

- the structure is covered with a sheet of plasterboard. For more information about modern soundproofing materials, watch this video:

The length of 1 roll of membrane is 5 m and the width is 1.25 m. The weight of 1 m² of material is approximately 8 kg.

Application area

The materials used for the manufacture of polymer foam have a large expansion ratio, the volume of the composition expands up to twenty times, which justifies the limitations in use:

- the temperature of the sprayed surface should not exceed 100 degrees;

- do not expose to direct sunlight or other ultraviolet exposure.

This can happen when:

- insulation of external parts of a building or structural parts devoid of finishing material;

- thermal insulation of pipes designed to pass high-temperature liquids.

The method of applying polyurethane foam by spraying is used in the following areas:

- soundproofing of floors in housing and walls in houses built of panels, wood or brick;

- thermal insulation of not very heated pipelines laid above the ground or buried at a shallow depth from ground level;

- thermal insulation of refrigeration chambers, refrigerators of various modifications and purposes.

Areas of application

Insulating materials can be used to protect buildings of various types - not only residential, but also for technical purposes. Insulation can protect the room from excessive humidity, electric current and noise exposure.

Moisture protection

The issue of waterproofing is one of those problems that can be solved with the help of paint and varnish material. It should be noted that most paints, one way or another, have waterproofing properties. However, if you need truly serious protection, you cannot do without a special coating. After coating with this composition, the surface will withstand even direct exposure to water for a long time.

Waterproofing coatings must have certain qualities:

- The paint should be intended for both interior work and facade finishing, since double-sided painting provides more reliable protection.

- It is desirable that, in addition to moisture resistance, the paintwork material is resistant to ultraviolet rays and temperature changes.

- The composition should include anti-salt additives and antifungal drugs. Antiseptic qualities are very important for good waterproofing, because moistened material is an ideal place for the development of mold and mildew.

Note! The quality of the paint and varnish material is influenced not only by its shelf life, but also by storage conditions. The paint should not be in too cold rooms (at sub-zero temperatures) or too hot

Information on storage times and conditions can be found on the product packaging.

Noise insulation

An increased level of sound insulation can be achieved by painting the surface with special paint. Soundproofing coatings have a number of characteristic features:

The basis of this type of paint is bitumen or an acrylic composite element. Both substances have a number of features: acrylic is better suited for interior work, since it is practically odorless (water-based), and bitumen is much more effective outdoors, but is not suitable for indoors, as it smells unpleasant

At the same time, bitumen coatings are much cheaper than acrylic ones, which is important when painting large areas. The maximum level of sound insulation can be obtained if the composition is applied in a thick layer. It is recommended to use a brush or roller as a working tool

The paint dissolves in a synthetic composition. For insulating moving elements (for example, machine or car parts), bitumen-based paints and varnishes are best suited. This group of paints is capable of absorbing not only sounds, but also vibrations.

Polyurethane foam spraying method

Ceiling sound insulation in multi-storey buildings is applied by continuous spraying of a composition of interacting reagents onto the surface of the base using several approaches, the number of which is determined by the thickness of the ceiling from the top floor and depending on the financial capacity for installation work. If suspended ceilings made of plasterboard are provided, then before you start spraying the insulation, you need to install the ceiling frame structure, and when equipping the ceiling with tension material, there is no need for these actions, since the main parts are mounted on the walls.

Noise insulation on the floor is carried out using two methods:

- between the logs on which the floorboard is laid;

- on the floor from the lower floor, which forces polyurethane foam to be filled with concrete mortar fifty millimeters thick.

Before applying polyurethane foam to the partitions between rooms and external walls, you need to install the sheathing using wooden bars or metal profiles, which make it possible to attach a mesh for plaster or cladding with sheet building materials.

Stages of soundproofing a steel bathtub with polyurethane foam

Before you start work, don’t be lazy, make your life as easy as possible.

- Cover the floor of the room in which the work will take place with film or old newspapers.

- Turn the bathtub over and place it in the center of the room so that you can easily reach anywhere in the bathtub.

- Cover all pipe connections and the overflow hole with adhesive tape.

- Check the readiness of the foam can; if possible, adjust the thickness of the jet within twenty to thirty millimeters - experience shows that such a layer of foam is most optimal.

- Be sure to treat the outer surface of the bowl (hereinafter we will only talk about the outside of the bathtub!) to remove dirt and dust, and then run a solvent over it to remove grease.

- After the solvent has dried, generously apply a mesh of silicone sealant or liquid nails to the walls of the bathtub (this will ensure better adhesion of the foam solution to the smooth surface of the tank) and only then begin the process of applying the foam itself.

- Do this in a circle, as if wrapping a bathtub with large foam threads, being sure to connect the already applied layer with the next one; start from the bottom, from the sides, and gradually work your way up to the bottom of the bath - naturally, without foaming the drain holes. Do not rush under any circumstances, do not leave any gaps between the “threads”, do everything smoothly and carefully.

It is best to use summer polyurethane foam for this, which gives a thicker layer, sets faster with the metal and hardens faster.

If you need protection from noise...

A modern soundproofing or sound-absorbing mixture has mostly only positive reviews. All homeowners intrigued by the properties of the polyurethane foam spraying technique can contact trading companies, whose professional employees can help make the home insulated from extraneous noise in houses built from any building material. Calculation of the final cost of the work will be made based on the results of measurements, calculation of the total treatment area and the required thickness of polyurethane foam spraying, which depends on the thickness of the ceiling between floors or pouring concrete mortar and walls between apartments in the building.

Liquid sound insulation

Liquid polyurethane foam fills all the smallest cavities well.

Liquid sound insulation of walls is carried out by spraying polyurethane foam. This material has good sound insulation properties. The liquid mixture for walls fills almost any hole, while creating a layer of monolith that prevents the penetration of unnecessary sounds. After hardening, the foam does not have much weight, so there will be no unnecessary load on the coating.

Liquid sound insulation of the walls in the apartment will also protect against rodents and many insects. The polymer can be applied without preliminary preparation; the construction of a frame is also not required. During operation, a minimal amount of contamination is generated. The service life of the foam is extremely high; the coating can last up to 50 years. For more information about finishing walls with polyurethane foam, watch this video:

The only disadvantage of this method is the need to use a professional tool. There is no particular point in purchasing it; the best option is to call a specialist. The cost of such treatment is approximately 1500-2000 rubles for 1 m².

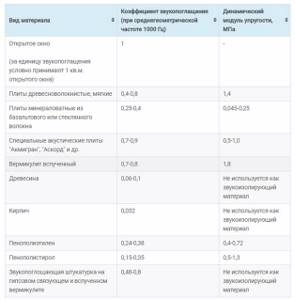

In the following table you can see the sound absorption rates of various materials.

Advantages of liquid sound insulation

Foam has high adhesion to all types of surfaces.

Liquid sound insulation solution has the following advantages:

- After treatment, the wall acquires excellent heat and sound insulation properties. This will not only get rid of extraneous noise, but also save on heating.

- The polymer is able to penetrate into the smallest cracks, which will allow you to process openings in doors and windows. This procedure, in addition to soundproofing, will help you forget about drafts.

- High adhesion to surface. There is no need to install the lathing; the polymer can also be applied to the ceiling without prior preparation. After work, a minimal amount of contamination is formed.

- Possibility of complete sealing of the room. After processing, a monolithic layer is created that will fill all the holes between the structures.

- Lightness of the material. The hardened foam has minimal weight, so there will be no load on the load-bearing elements of the home.

- Thanks to its structure consisting of small cells, sound insulation allows you to suppress sound waves over a wide range.

Types of polyurethane foam for liquid sound insulation

The Russian-Chinese material has quite affordable prices.

There are quite a large number of varieties of polyurethane foam.

This material is manufactured in different countries, the types differ in their effectiveness and, of course, cost.

The most common options are the following:

- Synthesia polyurethane foam. Produced in Spain. The main advantages include reasonable cost, environmental friendliness and the ability to use at any time of the year at any temperature.

- Ecotermix. Manufactured by China together with Russia. The material has a high level of fire resistance and is able to provide protection against the formation of mold, mildew and other bacteria. The cost of such products compares favorably with its main competitors.

- Demilec polyurethane foam. Manufactured in the USA and belongs to premium soundproofing materials. It is the highest quality and most reliable solution for protection against extraneous noise. The only drawback is the high cost, but you have to pay extra for quality.

- Bayer polyurethane foam. It is a reliable solution from a German brand. The product quality is at an acceptable level; spraying is carried out using a special device. For more information about the components for the production of polyurethane foam, watch this video:

As can be seen from the article, liquid sound insulation is the optimal solution for protection against extraneous noise. This processing option allows for maximum protection efficiency, while the service life of the product is at an extremely high level.

The most obvious purpose of paint or plaster when applied to the walls of a house is to give the surface a more attractive, updated look. However, this is not the only task of the finishing material.

It is equally important to protect the base material and residents from adverse environmental influences. For example, you can protect yourself from noise using soundproofing paint and plaster.

Other types of insulating materials protect against moisture and electrical current. This article will discuss the types and features of the use of insulating materials.