K-Flex thermal insulation is an innovative breakthrough in the production of thermal insulation materials from the Italian brand of the same name. Heat and sound insulation materials are produced mainly for pipes in the form of sheets and sleeves of different diameters with a self-adhesive coating.

The insulation is made using a completely new technology from synthetic foam rubber with a closed-cell structure. We will talk further about the characteristics, features, advantages and disadvantages of this material.

Features of the K-flex material

The basis for creating thermal and sound insulation is foamed rubber - a unique material in many respects. But it is interesting not in itself, but in the finished products. The company lists several types of products:

- Industrial thermal insulation.

- Universal thermal insulation type ST.

- High temperature thermal insulation SOLAR ST.

- Ecological insulation Eco.

- Thermal insulation of ventilation systems.

- Acoustic materials.

All types of technical characteristics of K-FLEX differ depending on the purpose; we will briefly consider them separately.

Types of insulation

Industrial thermal insulation K-FLEX is used in refrigeration equipment, air conditioning and ventilation systems, and energy. K-FLEX ENERGO and K-FLEX ENERGO PLUS materials have been developed that operate in environments with a wide range of aggressiveness and can withstand temperatures from -200 to +180 0C. A distinctive feature of the materials is ease of installation.

Specially designed fastening systems make it possible to insulate not only pipelines, but also tanks, hydraulic accumulators, and thermal junctions. Preparation for the heating season and replacement of insulation is carried out as soon as possible.

Universal thermal insulation is designed to protect industrial pipelines, heating systems, petrochemical facilities, and refrigeration units from heat losses. It is used practically without restrictions at all facilities, except those where special requirements for toxicity during combustion are put forward.

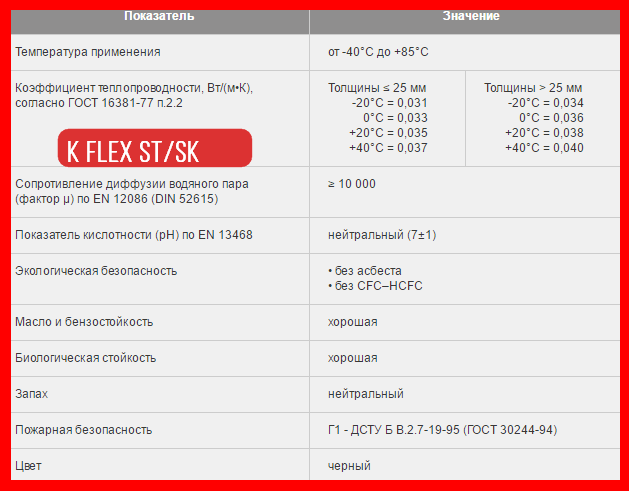

Operates in a very wide temperature range - from -40 to +85 0C. It has a low thermal conductivity coefficient in the range of 0.032 – 0.040 W/(m•°C), practically does not absorb water vapor and is well resistant to oils and petroleum products, and is not susceptible to rot and mold.

ST insulation is easy to install. In addition to covers for pipes, the kit includes: corners, tees, hangers, tapes and other auxiliary materials. Available both without insulation and covered with aluminum foil.

K-FLEX materials, in addition to their high quality, are attractive because you can find a solution to any problem related to thermal insulation using only the company’s product catalog. For example, industrial thermal insulation

Application area

Thermal insulation material K-FLEX is one of the most suitable materials for performing insulation work on various technological and engineering communications for civil and industrial purposes.

K-Flex insulation is used for the installation of thermal insulation at housing and communal services, industrial facilities, during the construction of heating, sewerage systems, water supply pipelines, air conditioning and ventilation systems, including for thermal insulation:

- process pipelines and tanks with negative and positive temperatures,

- pipelines of heating networks with underground and above-ground methods of laying them

- pipelines of heating systems, cold or hot water supply,

- equipment for refrigeration units and low-temperature pipelines,

- air ducts and air conditioning and ventilation systems,

- oil pipelines, gas pipelines, pipelines with petroleum products,

- flange connections of pipelines, coupling and flange fittings,

- technological devices and pipelines of industries with high requirements for air quality and purity,

- technological devices at enterprises of the oil refining, chemical, gas, food industries,

- water tanks in water supply and fire extinguishing systems,

- tanks for storing petroleum products, chemicals, petroleum products.

K-Flex catalog

Thermal insulation materials K-FLEX for industrial use are based on foam rubber. During the production process, various mineral and polymer substances are added to the composition, which make it possible to obtain completely different materials. Thermal insulation K-FLEX catalog, which can be seen on the company’s website, is intended primarily for industrial use. Scope of application:

- Thermal power engineering.

- Oil and gas industry.

- Utility services.

- Food industry and trade (cryogenic plants).

- Ventilation and air conditioning.

- Acoustic design of premises.

K-FLEX products are created in such a way as to maximally cover the need for high-quality, durable and inexpensive thermal insulation in a wide variety of industries.

Installation of K Flex insulation

*

Insulation of pipes with this material is carried out taking into account clear requirements:

- Work should be carried out at an ambient temperature of at least +5°C

- apply insulation adhesive to a degreased surface;

- clean the insulated communications from dirt, dust and rust.

Surface cleaning should be carried out with materials intended for this purpose. If you use some improvised means, the insulation may not stick to the entire required surface.

Direct installation of insulation is carried out in the following sequence:

- A thin layer of glue is applied to the cleaned, pre-degreased dry surface of the pipe and to the insulation itself. Adhesive consumption – 0.15 liters per 1 sq. m area;

- when the glue hardens during work, it is diluted with a special k-flex cleaner;

- if you choose insulation with a self-adhesive surface, the above steps can be omitted;

- the glue should dry for 3-5 minutes, after which the insulation is directly installed on the surface of the pipe;

- if the product is in the form of a sheet, the installation is carried out in such a way that its middle falls on the top of the pipe;

- the insulation, in the form of a tube, is carefully cut lengthwise and installed on the pipe.

Installation of K-Flex materials is quite simple, and even a beginner in thermal insulation work can install it themselves. At the same time, it provides reliable protection against exposure to cold air. The insulation has sufficient flexibility, which allows it to insulate pipelines of any configuration.

Main types of K-FLEX products

Thermal insulation materials made of foam rubber can, with a certain degree of convention, be divided into several main groups. The convention is that the scopes of application often overlap, and sometimes it is impossible to draw a significant and clear boundary.

For example, industrial thermal insulation K-FLEX ENERGO can be used in the same place as universal ST. But there are also highly specialized types of insulating materials that cannot be replaced - their parameters are quite specific and focused on use in specific conditions.

Thermal insulation groups

- Industrial.

- Environmentally friendly.

- Universal.

- Heat resistant (high temperature).

- Ventilation.

In addition, special materials are produced to improve room acoustics.

What is K Flex?

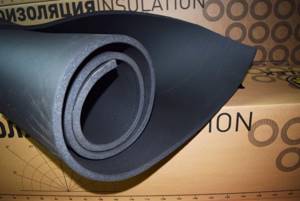

K-Flex is a high-tech insulation for working with pipelines. It is foamed rubber. This is a synthetic material, the closed pores of which lead to good moisture resistance of the material.

The rubber itself is produced in the form of tubes or sheets of various shapes and diameters. It has a variety of protective or self-adhesive coatings that increase its performance. Rubber is an elastic material, which allows it to be used for the production of insulation used in industry and construction work.

The product is available in the form of sheets or tubes

*

Thermal insulation material has good moisture resistance, low thermal conductivity and vapor permeability. All this is thanks to the special cellular structure of foam rubber. The technical characteristics of K Flex insulation make it possible to use it for insulating heating mains in the basements of multi-storey buildings without additional waterproofing.

Main characteristics of the material:

- density - 65 - 80 kgf/m3

- thermal conductivity coefficient - 0.032 at -20°C and 0.036 at +20°C

- temperature range -70°С – +110°С

- toxicity - does not contain freons, asbestos and chlorine-containing substances;

- vapor permeability - less than or equal to 0.09 mg/m

- fire safety class - G1

- the number of closed cells in the structure is more than 90%

The material contains fire retardants, which prevents spontaneous combustion and the spread of fire. The toxicity of the insulation is quite low, which makes its use safe. The synthetic rubber that the insulation is made of has a long service life. The warranty on the material is 20 years or more, which is confirmed by tests.

Characteristics of the main thermal insulation groups

The group of industrial thermal insulation has the widest range of material properties. Here are ready-made products for protection against heat loss and external influences:

- pipelines;

- refrigeration units;

- hydraulic accumulators;

- heat generators;

- machines and mechanisms.

The main material is K-FLEX ENERGO. On its basis, a number of tubular, film and sheet insulation materials have been created. Almost every item in the K-FLEX catalog is related to this material in one way or another.

It is created on the basis of butadiene-nitrile acrylic rubber and is a closed-cell foamed elastomer. It is the closed pores that determine one of the aspects of the versatility of a heat insulator - it does not absorb water, is not afraid of high humidity, given its porous structure, and has significant resistance to the diffusion of water vapor.

Fire retardants in the form of heterogeneous molecules, other polymers and minerals are introduced into the composition of rubber. They determine the physical and chemical properties of the finished insulation and a large number of varieties. The rubber in the K-Flex material can be considered chemically inert - it is resistant to petroleum products, alkalis, acids and most technical liquids. The application temperature of the material is within -200….+105 0С.

In addition to K-FLEX rubber materials, the catalog includes insulation made from mineral and glass wool. A prominent representative is K-SHIELD STANDART. This is a fiberglass material with precisely dosed additives of calcium, silicon, magnesium oxides and some other substances. The result is a group of non-flammable, environmentally friendly thermal insulation materials. K-SHIELD is distinguished by high moisture resistance and anti-corrosion protection of insulated materials.

Benefits of foam rubber insulation

Technical thermal insulation K-FLEX, made on the basis of foam rubber, has excellent operational and thermophysical properties. It contains not only rubber, but also other elements that are added by extrusion followed by foaming and vulcanization.

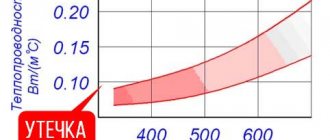

Low thermal conductivity of materials

Insulation products have such features as small cell size, porosity, and optimal volumetric weight. These characteristics of K-FLEX materials made it possible to reduce the main components of thermal conductivity (convective, conductive).

Low vapor permeability

A special feature of the K-FLEX product structure is that it has closed cells. This made it resistant to the diffusion of droplets of moisture and vaporization. High humidity can lead to the destruction of thermal insulation materials and an increase in thermal conductivity. But K-FLEX products do not have this drawback. Since it has a high resistance to diffusion, during operation it does not accumulate water or become moistened. This ensures that the thermal insulation characteristics of the materials remain unchanged.

Easy to install insulation

Traditionally, a thermal insulation system consists of several parts. It consists of two layers - thermal insulation, cover and fastening elements. It can be supplemented with two more layers - protective and vapor barrier. They are necessary when installing a thermal insulation system during its subsequent operation at low temperatures.

K-FLEX products have a very low level of vapor permeability. This allows you to avoid laying a vapor barrier layer when installing the system. By eliminating the need to install an additional layer, the design of the heat protection system is significantly simplified. This leads to a reduction in the number of installation operations, a reduction in the time required to carry out the necessary work, and a reduction in the cost of laying insulation.

Operating temperature range

Protective materials of this brand have a wide range of operating temperatures - from –190 to +150 °C. This insulation characteristic of K-FLEX has been confirmed by tests. The maximum operating temperature is confirmed by certification tests, the minimum - by experiments that were carried out at the Russian enterprise JSC CryogenMash and in the French laboratory LNE.

Long service life

An important parameter for the durability of a material is the duration of its service life, during which the heat flow is no higher than the value established for it by the standard. The Mosstroy Research Institute conducted a study, the result of which showed that the service life of products made on the basis of foam rubber is 25 years. The study was carried out according to the methodology of the All-Russian Scientific Research Institute "Stroypolymer".

High fire safety

K-FLEX insulation products contain additives that significantly increase the fireproof properties of materials. This made them resistant to combustion; fire affecting the insulation does not spread over its surface. In addition, K-FLEX products are low toxic. When exposed to high temperatures, it does not emit combustion products and does not generate smoke. These characteristics allow the use of insulation on objects that must meet high fire safety requirements.

Sanitary safety

Insulating materials are environmentally friendly. They do not emit hazardous substances, fibers, or dust. They do not have an unpleasant odor. These characteristics of K-FLEX products allow it to be used in premises that require strict sanitary and hygienic requirements. Insulation can be installed in schools, kindergartens, medical institutions, and food production plants.

Excellent corrosion resistance

Corrosion occurs in situations where the site allows water or vapor to penetrate the insulating material. The aggressive substances they contain have a negative effect on the metal, destroying it. K-FLEX materials are not subject to moisture during operation and have high diffusion resistance. This made them reliable protection for metal surfaces from corrosion.

Environmental Safety

K-FLEX products are environmentally friendly. The manufacturer does not use fluorinated and halogenated hydrocarbons for its production. The result is that there is no negative impact of insulating materials on the planet’s ozone layer. The advantages of K-FLEX products include the fact that they are resistant to moisture.

This prevents the formation of bacteria, mold, and fungi on them. The material does not emit volatile organic compounds. The environmental safety of products is confirmed by certificates. The presence of official confirmation of the safety of K-FLEX materials makes it possible to use them in public places and industrial premises where electronic products are produced.

Technical characteristics of K-Flex

| Characteristic | Brand K-FLEX | |||

| ST | SOLAR HT | ECO | AIR | |

| Density, kg/m3 | 40±15 | 70±25 | 70±25 | 40±15 |

| Thermal conductivity, W/(m-K) at the average temperature of the heat-insulating layer, °C | ||||

| -100 | 0,023 | — | — | — |

| -50 | 0,028 | — | — | — |

| -40 | 0,032 | 0,034 | 0,034 | 0,032 |

| -20 | 0,034 | 0,036 | 0,036 | 0,034 |

| 0 | 0,036 | 0,038 | 0,038 | 0,036 |

| 20 | 0,038 | 0,040 | 0,040 | 0,038 |

| 40 | 0,040 | 0,042 | 0,042 | 0,040 |

| 60 | — | 0,045 | 0,045 | — |

In the K-FLEX catalog you can find materials for any application that requires technologically advanced, inexpensive and most effective thermal protection.

Full station wagon

Thermal insulation k flex st/SK is rightly classified as a universal insulation product. It has excellent characteristics and is recommended for pipelines with temperatures from -200 to + 105 ° C. The specific thermal conductivity coefficient is extremely low, especially when maintaining negative temperatures, and is only 0.024 units. Therefore, experts strongly recommend it for use in the construction of cryogenic equipment and pipelines.

K flex st/SK tubes are 2 m long, with an internal diameter from 6 to 170 mm. Thermal insulation layer - 6-50 mm. The k flex st product line has tubes that are not cut lengthwise.

Rolls and plates of k flex are 1 m wide. Roll insulation has a minimum thickness of 3, plates - 6 mm. 1m2 sheets of k flex are packaged in bales 30 cm high.