More recently, a thermal insulation material called isolon appeared on the construction market and quickly gained popularity due to its excellent technical characteristics and low price. Any other material is inferior to isolon in at least one parameter and has no advantages over it (except for price, if the material is very cheap). There are many types of isolon, but there is also a leader among them in all respects - foil isolon.

Foil-coated isolon has the properties and characteristics of a regular one, but also has a number of individual advantages that have virtually no effect on its price. These advantages are achieved thanks to a simple addition - a reflective coating applied to the isolon layer.

Isolon - what is it?

This material is an elastic polyethylene foam with a closed-cell structure. In addition to the fact that isolon is hygienically and environmentally safe, it has an extensive range of insulating characteristics. Thanks to its cellular structure, foamed polyethylene practically does not absorb liquid and moisture, and also has a high level of heat and sound insulation.

For your information. Most often, foil-coated isolon is used for the home, which has a thin metallized coating on one or both sides. The use of foil significantly increases thermal insulation, which is due to the reflective properties of the material.

Foil polyethylene foam

Depending on the production technology, folgoizol is available in two types:

- cross-linked polyethylene foam (PPE);

- non-crosslinked polyethylene foam (NPE).

In the first option, polyethylene molecules are cross-linked together, thereby increasing the thermal insulation properties and achieving a longer service life. This process can be carried out both chemically and physically, each of which allows one to obtain the required parameters.

Non-crosslinked isolon has fewer chemical bonds, and therefore is inferior in characteristics to PPE. However, given the relatively simple production, its price is more attractive to the consumer.

Roll of foil insulation

Properties and technical specifications

The unique technical characteristics of folgoizolon set it apart from other building materials intended for insulation and sound insulation of various structures. Below are the main properties of isolon.

- High level of thermal insulation. The thermal conductivity coefficient of foil insulation is 0.031 W/mK, which is an excellent indicator when compared with other insulation materials. For example, the use of 10 mm thick isolon allows you to replace:

- 12 mm polystyrene foam;

- 45 mm wood or mineral wool;

- 150 mm bricks.

- Effective hydro-, steam- and sound insulation. The closed cell structure provides maximum resistance to the absorption of moisture and water vapor, and also prevents the penetration of sound waves. This characteristic is applicable even for a very thin layer.

- Elasticity and light weight. For construction purposes, foil isolon is produced in the form of sheets or rolls with a material density of 19-38 kg/m³. It is quite light and pleasant to the touch, and most importantly, it does not require the use of special tools for mechanical processing.

- Resistance to chemical products. An important characteristic of isolon is its resistance to oil, oil and gasoline. In addition, it is compatible with almost any building material: concrete, gypsum, lime, wood, etc.

- Long service life. Since this material is made on the basis of polymer raw materials, it is not susceptible to biological influence and, accordingly, to the process of decay. The service life without degradation is more than 80 years.

- Safety. In the production process of folgoizol, no toxic or harmful substances are used. It is odorless and can come into contact with human skin without any health consequences.

Advantages

The material in question, as a rule, is a layer of foamed polyethylene, covered on one side with aluminum foil:

Two layers of foil insulation: foil and polyethylene foam

As a result, we can talk about the following number of undeniable advantages inherent in this insulation:

- Excellent thermal insulation qualities . They are due to the low thermal conductivity of foamed polyethylene, which is 0.031 W/(m×K). So, if the thickness of foil insulation is 1 cm, then it insulates no worse than:

- 1.2 cm polystyrene foam;

- 4.5 cm wood;

- 15 cm brick;

- Cellular structure . How is it useful? The fact that it prevents steam, sound and moisture from penetrating through the material. That is, walls, floors or ceilings covered with the material in question will be protected from negative manifestations of dampness, and residents from the penetration of extraneous noise;

Due to its cellular structure, foil-coated isolon is also used as a waterproofing material

- Low weight . It is easy to install and transport with your own hands without the use of special equipment. In addition, it does not exert any pressure on the base;

Foil insulation does not require a serious fastening system when insulating the ceiling, since it weighs very little

- Chemical inertness . Resistant to gasoline, oil and oil. Compatible with any building materials: brick, wood, concrete, plaster, lime and so on;

Balcony insulation with foil insulation can be done directly onto the brick

- Durability . All components of the insulation under consideration are made from polymers. Consequently, they are not subject to decay processes and can last at least eighty years;

- Thermal reflective properties . In addition to the fact that foil-coated isolon does not allow heat to pass through, it also reflects thermal radiation due to the presence of a foil layer;

When installing foil insulation sheets, be sure to lay them with the foil surface inside the room. Otherwise, it will not reflect thermal radiation from heating sources.

Laying foil insulation must be done with the foil inside so that it can reflect thermal radiation back into the room

- Simple instructions for use . This thermal insulation material is sold in the form of mats or rolls, which can be easily unrolled and attached to any surface;

When installing foil insulation, do not forget to seal its joints with foil insulating tape to prevent thermal leaks.

Foil mounting tape is used to insulate the seams between foil-coated isolon sheets

- Versatility . It is used both for internal finishing works and for external ones. The self-adhesive version of the material in question is especially suitable for outdoor work; it does not require the use of additional adhesives during installation;

The photo clearly shows that foil-clad isolon can be used for thermal insulation of the roof from the outside

- Acceptable price.

Flaw

The most significant drawback worthy of mention is the soft structure of foil insulation, which makes it inconvenient to lay under the screed.

Life time

Since foil insulation appeared relatively recently, it is not yet possible to determine the exact expiration date. However, after conducting experiments, we can say that the material does not lose its properties for 200 years.

The service life of the installed insulation depends on the adhesive used. If the adhesive composition has passed its expiration date, then you can re-install it with the same heat insulator.

There are a lot of insulation materials on the construction market. The choice is so wide that the question arises, which is better. To answer, you need to compare the characteristics of the thermal insulation material and the scope of application - street, living room, garage or agricultural building.

Disadvantages and application features

The list of disadvantages of foil isolon is much shorter than the list of advantages. Main disadvantages:

- relatively high price;

- the need for careful transportation and careful installation (it is important not to damage the aluminum layer);

- Isolon can only be painted or covered with a protective film; you cannot paste wallpaper or apply plaster - any finishing materials “load” the insulation with their weight, increasing the risk of its breakage.

When using isolon, it is very important to follow certain rules so that the material does not lose its characteristics:

- insulation sheets should be laid end-to-end, using aluminum tape to seal the seams;

- When insulating surfaces, it is necessary to leave ventilation gaps between the isolon and other elements, otherwise condensation will form and the materials will begin to deteriorate;

- foil-coated isolon cannot be laid near electrical wiring, as aluminum conducts current.

Foil-coated isolon is an innovative material used for noise, heat and moisture insulation in everyday life and industry. It perfectly performs all its functions even with insignificant thickness. With proper installation, izolon can last up to 90 years. The material fully complies with modern quality standards in terms of fire and environmental safety.

Do-it-yourself insulation of a balcony with Izolon. Insulation, Waterproofing of the lodge with foamed polyethylene

Types of foil insulation

The difference between materials is related to the purpose and insulation used. If each of them has foil, then that’s where the similarities end. There are 4 types of products:

- Foil penofol;

- Mineral wool with foil;

- Expanded polystyrene;

- Basalt wool.

Foil penofol

Such insulation with foil has different names, for example, folgoizol, polyethylene foam or isolon. This product is most different from its analogues. Sold in rolls. Insulation – foamed polyethylene (crosslinked or uncrosslinked). The thickness is small - from 3 to 10 mm. As a result, the material can be rolled, bent and shaped into any shape. This is a good foil thermal insulation for pipes. The aluminum layer can be on one side or the other. There are variations with a self-adhesive base. The price is affordable.

There are variations on sale with a reinforcing layer in the form of fiberglass. Moisture absorption ranges from 0.35 to 0.7%. The layer is non-vapor permeable, the indicators are 0.001 mg/m*K. The scope of use is wide. We carry out insulation of walls from the inside with isolon, creation of warm floors (underlayment for parquet, laminate, linoleum), use in a split system, for wrapping pipes.

Foiled mineral wool

Like regular mineral wool, it is produced in the form of rigid slabs or in rolls. This is a good combination option, since cotton wool is afraid of moisture and loses its characteristics when wet. A layer of foil eliminates this disadvantage.

Otherwise, the characteristics are the same as those of mineral wool. These are excellent sound and heat insulation properties, environmental friendliness, and long service life. The foil layer is only on the outside. Maximum thickness – 100 mm. Due to its protection from elevated temperatures, it is used for places where heat resistance is required. Namely: near fireplaces, installation of chimneys, baths and steam rooms. Good foil insulation for pipes.

Styrofoam

The classic option: cheap but practical. It is a hard foam plastic that is heat resistant. The grains are tightly fused. Foil on one side. Sold in slab form. Most often used for arranging heated floors.

These special floor insulation materials have markings for the cable system inside. This simplifies installation work.

Density – from 30 to 50 kg/cm3. Thickness from 20 to 50 mm. Not afraid of moisture, dampness, temperature changes. Withstands pressure, does not rot or rust.

Basalt insulation

Ideal for use in very aggressive conditions. Remains in its original form even with temperature changes from -200 to 700 ℃. The best way to insulate and protect gas stations and other structures.

Important! To insulate a wall, floor or ceiling, you will need insulation no less than 50 mm thick. Therefore, mineral wool with a foil layer or basalt wool is most often used for walls.

Composition of isolon and its characteristics

Izolon is made by foaming polyethylene, so its structure consists of many closed air pores in the synthetic material. The material is elastic, but very soft, so it can be laid on almost any geometrically complex surface. A special feature of the production of isolon is a thin foil layer of aluminum, thanks to which heat is reflected back into the room, and because of this, the main layer of insulation can be made much thinner than the usual 50-100 mm. Izolon has an initial thickness of 2 mm, and this parameter can increase to 100 mm, depending on the application. Thus, insulating a balcony with isolon will require a layer 20-30 mm thick, since the room is always located on the street. Foamed polyethylene is sold in rolls, sheets, strips or blocks.

According to the manufacturing method, isolon is of the following types:

- Foil-coated isolon NPE (the abbreviation stands for non-crosslinked polyethylene foam). It can be of different densities and thicknesses, with a regular and self-adhesive surface. Technology – method of extrusion and foaming with butane gas;

- Foil-coated isolon PPE (the abbreviation stands for cross-linked polyethylene foam). The technology for producing NPE material differs only in the use of another reagent - porofor, which makes it more environmentally friendly due to the absence of freon.

Structure and scheme of application of isolon

Technical and operational parameters:

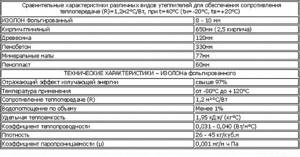

| Characteristic | Foaming ratio | ||||

| 30 | 20 | 15 | 10 | 5 | |

| Density, kg/m 3 | 33 | 50 | 66 | 100 | 5 |

| Nominal thermal conductivity, W/m•K | 0,031 | 0,033 | 0,036 | 0,039 | 0,041 |

| Water absorption, cm 3 / m 2 | 0,7 | 0,5 | 0,4 | 0,3 | 0,2 |

| Operating nominal temperature | -60°С + 100°С | ||||

| Sound absorption | at 250 Hz -7%, at 2000 Hz – 38%, at 6000 Hz – 60% | ||||

| Thermal energy reflection coefficient | from 95% to 97% | ||||

| Moisture permeability |

| ||||

Isolon vapor barrier is divided into the following brands:

- Foil insulation PPE 500, 500-L - based on polyethylene cross-linked in a vertical oven with a bonded transversely directed structure;

- PPE 500 NR – based on polyethylene cross-linked in a horizontal oven with a bonded transverse structure;

- PPE 500-300 – polyethylene chemically cross-linked in a horizontal oven;

- 100, 100-L – non-cross-linked polyethylene with a molecular structure based on EPPE (extruded polyethylene foam).

Practical use of extruded polyethylene foam for home insulation

Types of reinforced thermal insulation materials based on polyethylene foam:

- PPE with increased wettability characteristics, intended for painting and gluing;

- Izolon with increased rigidity properties;

- Insulation in a wide range of colors;

- Izolon with additives of fire retardants, as a result of which the degree of flammability of PPE is reduced.

Application options for isolon

Due to its versatility and ease of processing, regular or foil isolon is used almost everywhere - in mechanical engineering, medicine, the food industry, packaging of fragile products, production of sports equipment and many other areas. However, this material has gained the greatest popularity in the repair and construction industry, where it is used to insulate various surfaces.

Roofing work using foil insulation

Roof protection

The main percentage of roofing materials in use are metal tiles and corrugated sheets, since they are durable and affordable for most consumers. However, their main drawback is poor sound insulation. This is especially evident during rain or gusts of wind.

The use of folgoizolon can significantly reduce the level of extraneous noise and increase heat conservation. It is usually laid as an insulator under metal tiles, corrugated sheets, slate or other roofing material with a corrugated surface.

Wall insulation

After the walls are erected, increased attention is paid to the thermal insulation of these structural elements. Since the main heat losses occur as a result of insufficient insulation of external surfaces, installation of insulation in this case is mandatory. As already noted, 10 mm of this material replaces 45 mm of mineral wool. Therefore, with the same result, you can reduce the thickness of the wall.

Advice. Considering that foil-isolon practically does not absorb moisture, it is advisable to use it for insulation and waterproofing of bathhouses or other buildings with high internal humidity.

Bathroom wall insulation

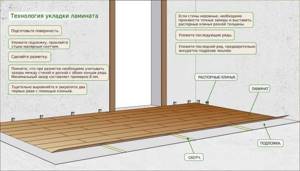

Floor construction

If the surface is constantly subject to dynamic loads, it is important to create a shock-absorbing effect, for which a so-called substrate is used. As a rule, it is laid under laminate and some types of linoleum. The use of isolon as a substrate not only softens the load, but also contributes to additional insulation of the surface.

To install heated floors, foil material is used, which acts as reflective insulation. In this case, the heating efficiency increases significantly.

Installation of a "warm floor" system

Thermal insulation of communications

Since foil insulation is easy to process and very elastic, it is convenient for them to thermally insulate individual sections of the pipeline through which coolant is transferred from heating equipment to residential premises. For example, if the boiler is located in a basement or other cold room, then without additional insulation of the pipes going into the house, its efficiency will not be very high, given the significant level of heat loss.

Thermal power engineers also recommend attaching a layer of foil-coated isolon between the heating radiator and the wall. This manipulation will stop heat dissipation through the outer wall, which will significantly increase energy saving.

Pipeline thermal insulation

Technical characteristics of using folgoizol

Typical structure of folgoizol.

For the production of foil insulation, foamed polyethylene is used; to increase the insulating qualities, this material can be covered with metallized polypropylene film on 1-2 sides. The second production option is to use foamed polyethylene and additional layers of polished aluminum foil. This insulating material combines lightness and tensile strength at the same time.

- The main technical qualities of foil insulation are due to the use of foamed polyethylene, which is known today as an excellent thermal insulation material.

- The structure of foamed polyethylene completely prevents the passage of moisture. In addition to the fact that this material retains heat, it also has high sound insulation qualities. Foamed polyethylene is made from non-toxic components; even when heated, it will not release toxins harmful to human health. Therefore, it can be used for internal thermal insulation of a room.

- To improve technical qualities, foamed polyethylene is covered with aluminum foil. In order not to damage the rather fragile material - foil, it is covered with a protective layer of polypropylene film. This film is characterized by very high strength, it is resistant to various influences of alkalis and acids. Polypropylene film protects the foil from mechanical stress and processes such as oxidation.

Folgoizol has significant differences from other thermal insulation materials. The main difference is its reflective properties. This is what keeps heat loss to a minimum. Foamed polyethylene itself also prevents the passage of heat.

What insulation and why is it better to choose?

The appearance of foil on insulation led to the differentiation of its areas of application. Materials now have a narrow specialization.

Foil polyethylene foam

Foil-rolled polyethylene foam insulation in the class of reflective insulation has the widest range of applications. It is used for insulation:

- • floor. It is used as an additional thermal insulation layer in individual construction and the main one in apartments of multi-storey buildings. At the same time, it can simultaneously perform the functions of waterproofing materials. Insulation with a thickness of 2-3 mm is used as a substrate for parquet, laminate or linoleum floors;

- walls and ceilings. The material is especially in demand in conditions of limited space (balcony, loggia), since the small thickness of thermal insulation minimally “steals” the usable area;

- roofs. Used alone or in combination with other types of insulation;

- baths At the same time, it performs two functions: heat and vapor barrier, protecting walls and ceilings from heat loss and waterlogging. But there are exceptions: they cannot be used in steam rooms and saunas, as they become deformed due to high temperatures.

Another area of application available only to this type of insulation is heat-reflecting screens behind heating devices: radiators, air heaters, infrared films located on the walls and ceiling. This measure allows you to save thermal resources, and in significant quantities.

Foiled polystyrene foam

The main task of foil foam is to direct the downward heat flows of all types of “warm floors” back into the room. It is not used for other purposes, although the instructions do not prohibit it. The reason is the prices. With almost the same effect, you can insulate the walls with polystyrene foam without foil, which will cost about two to three times less.

The use of foil polyethylene foam is not limited to construction. It can be found in agriculture (insulation of calf barns, incubators), automotive (insulation and sound insulation of passenger car interiors) and footwear (warm insoles) industries.

Foil glass wool (mineral wool)

Like foam plastic, foiled glass wool has a narrow specialization - it is the main type of insulation for baths (primarily steam rooms) and saunas, although nothing prevents you from insulating a roof or attic with wool and foil.

The high heat resistance (+300oC) of glass wool with a foil side has made it possible to increase the scope of its application. It is widely used for thermal insulation of boilers, boilers, and pipelines. At the same time, collapsible cylinders or half-cylinders of different sizes, both in length and diameter, are produced specifically for pipes.

Foil basalt wool

The excellent thermal insulation properties of basalt wool do not require a layer of foil when insulating residential premises. This type of insulation can only be afforded by consumers with unlimited financial capabilities. Therefore, foiled stone wool is used mainly for insulating buildings with a high level of fire danger (withstands up to +700oC), for example, gas stations. In this case, the external walls (facade) are insulated.

Subtleties of laying diagonally

Sand concrete for floor screed: what is it, composition of mixtures

Diagonal installation is one of the popular ways of laying laminate flooring. How to lay a covering with your own hands in this way? When calculating the amount of material, it is necessary to add 7-8% to the total area of the room.

Diagonal laying of the laminate begins in the same way as longitudinal or transverse laying - from the corner near the window. Before installation begins, a fishing line is pulled from the corner at an angle of 45° to the wall: the rows of coating will subsequently be aligned along it.

Using the diagonal method, the edges of the first panel are cut at an angle of 45°, and wedges are installed between it and the wall for a gap. After this, it is necessary to measure two strips of laminate so that the joint between them is in the middle of the first row, and the edges cut at an angle are near the wall. The entire floor is filled in this way.

Many videos “Installing laminate flooring with your own hands” show that first, solid pieces are installed, and then the panels are cut and the space near the walls is filled. With this method, you will avoid the risk of unevenness at the joints of adjacent rows.

In residential premises there are many difficult places to install the coating, for example, heating pipes, doorways, etc.

Features of using foil insulation

The use of materials with foil for insulation depends on a couple of indicators: the properties of a particular heat insulator and the place where it will be used. In general, with the help of such thermal insulation, floor structures are insulated, the heat transfer of heating radiators is increased, and air ducts and pipelines are finished. Thermal insulation of entrance doors of verandas, loggias, porches and balconies also gives excellent results

When installing foil-type insulation, you need to acquire all the necessary tools for the job:

- Construction stapler.

- Small carnations with large heads.

- Nail puller and hammer.

- Construction tape with foil coating.

- Direct insulation with foil.

The most common mistake many builders make is incorrect installation of the material with the foil surface facing outward. Due to the fact that the foil is a reflector, it is designed to return heat to the room. But if you place the insulating material on the wrong side, you won’t be able to achieve this effect.

When laying foil insulation , it is recommended to enclose it in a wood sheathing.

Slabs, rolls or sheets of material must not be laid overlapping. They must be installed strictly on the same plane, secured with nails or construction staples.

Material with an adhesive surface does not need to be secured with additional fasteners, but to increase service life it is still better to use small nails. In the absence of an adhesive coating, rubber or acrylic adhesive can be used to fix the material on the surface.

After installing and securing all layers of heat insulation, the joints between them must be treated with foil tape. This completes the installation.

When installing a heat insulator on vertical surfaces that have mold, wallpaper or dirt on them, they must first be cleaned, otherwise the fixation will be very unreliable, and the material will simply fall off over time. In addition, it is recommended to treat the surface with antiseptic agents.

Easy to use and very high-quality foil insulation will save money and keep your home cozy and warm.

Advantages of foil isolon: photo

Foil-coated isolon has excellent technical characteristics, which sets it apart from other thermal insulation materials. The material is equipped with a reflective surface, which contributes to the release of 97% of heat, and retains only 3%. The surface of the insulation does not heat up, as it reflects heat.

In rolls, sheets, different widths, single-layer and multi-layer and different colors, Izolon can really solve your problems in the house

Izolon consists of environmentally friendly polyethylene foam that is safe for the environment and health.

Small cells filled with air. Don't let the heat escape. Thanks to this, the living space remains warm. It is very effective to use the material for insulating floors between floors. The material is lightweight, which makes it easy to use.

Advantages of the material:

- It is an excellent noise insulating material.

- It is characterized by elasticity and flexibility.

- If proper care and use are followed, it can last for many years.

- The material is not susceptible to chemical influences.

- Does not absorb water.

- It has a high vapor barrier coefficient.

The use of isolon makes the use of other vapor barrier and waterproofing materials unnecessary. It is worth noting that isolon is afraid of mechanical influences. Therefore, you need to work with it very carefully. Depending on the material used for it, the methods of its installation may be different.

Installation features

One of the main disadvantages of foamed polyethylene is its lack of rigidity, this narrows the scope of its use and imposes certain restrictions when carrying out installation work, the basic rules for which are:

- The insulation should be placed on the aluminum foil side from the inside of the room - with this arrangement, the reflection of the infrared spectrum of thermal radiation is maximum.

- Considering that the material is quite soft, self-adhesive varieties or installation using lathing made of wooden slats or metal profiles for drywall are used for installation on vertical and horizontal planes.

- To avoid cold bridges, rolls or sheets are laid with an overlap, and the joints are sealed with adhesive tape.

- Folgoizol is not used together with finishing building materials - it does not adhere to plaster, wallpaper, and cannot be painted. Therefore, the interior decoration above the insulation must be made of durable, rigid materials - most often they use lining, plastic panels, plasterboard (gypsum fiber) sheets, particle boards and fibreboards (chipboard, fiberboard, MDF).

Laying schemes for Folgoizol

- Folgoizolon is flammable; when ignited, it emits caustic, toxic smoke, therefore, to increase safety, it is advisable to use it in non-residential or outdoor residential premises - baths, saunas, attics, roof slopes, facade walls of houses.

- The thermal conductivity of Folgoizolon is slightly less than that of polystyrene foam, that is, to provide the same thermal protection as 50 mm polystyrene foam, you will need to use a 60 mm layer of polyethylene foam, which is technically difficult to implement with a maximum thickness of Folgoizolon of 15 mm and is also economically unprofitable. Therefore, foil polyethylene foam for high-quality insulation is often used together with other cheaper types of insulation to ensure low vapor permeability and obtain water-repellent surfaces for laying subsequent layers of thermal insulation materials.

One of the best options for using Folgoizol is to lay it first on the inner surface of a wall or roof slope with the foil layer facing outwards, then mineral or glass wool is placed on it. This provides steam and moisture protection to mineral wool that absorbs water well and significantly reduces heat loss from infrared radiation.

Outdoor mounting option

Balcony insulation

Insulation of a balcony or loggia is done using foil insulation with a polyethylene base. Polyethylene is foamed, after which aluminum foil is glued onto it. The thickness of foamed polyethylene can reach 10 mm. The canvas acts not only as reinforcement and damper, but also can prevent heat loss.

Most users know this material under the name penofol. There is one-sided and two-sided material, the foil of which can have a smooth or corrugated surface. Products with auxiliary protection in the form of polyethylene film are also produced. The layer is applied using lamination.

Insulating a balcony without auxiliary insulation is not effective and does not allow achieving the desired result. For this reason, penofol should be used in conjunction with polystyrene foam or cotton wool.

The easiest way to work with foam is using self-adhesive foam adhesive. Externally, it is similar to simple mounting foam and you can use a mounting gun to apply it.

Insulation is carried out according to the following scheme:

- The foam must be glued to the prepared base from the inside.

- Penofol is laid on a layer of polystyrene foam.

- Wooden blocks that will be used for finishing should be fixed on top.

- Then you need to sew up the resulting “pie” with any finishing material. You can use plaster, siding or block house.

- Overlapping foam foam is not allowed. The joints are sealed using special aluminum tape.

To insulate the floor, you will need to position the guides according to the level, and then place foam plastic between them. Penofol should be placed on the guides. Then there are two installation methods:

- the floor is installed directly on the foam foam layer;

- the second level of sheathing should be installed, and then the floors should be laid.

Experts recommend using the second method, since using the first method it is impossible to obtain the ventilation gap necessary to reflect the insulation. If you exclude the arrangement of a ventilation gap, penofol is not needed, since it will not be of any use.

Thermal insulation of pipes

Foil thermal insulation for pipelines is used during the installation of communications underground or by air. To reduce heat losses from pipes, foil insulation is used even in unheated rooms located on the ground floors of suburban buildings.

Installation does not require special instructions, since installation of insulation with foil is easy. It is enough to put the shell on the desired area and in some places remove the protective coating from the adhesive layer, which is located at the ends of the longitudinal cuts

Due to the reflective surface, communications are provided with protection from solar radiation if the reflective shell is located only on the outside. If a reflective coating is present on the inside, it helps transfer heat back to the pipe.

Foil insulation is used for interior decoration, and can also be used to insulate communications that are located on the street. Mineral wool, expanded polystyrene or foamed polyethylene are used as the basis for the heat-insulating material. Wool and foam insulation is used as the key insulation layer, and the reflective shell is used as an auxiliary barrier.

Bath protection

If you plan to insulate a bathhouse, it is recommended to purchase rolled materials. This is due to the fact that it is easier for an untrained person to work with rolls. For these purposes, you can use foamed polyethylene or mineral wool of medium thickness.

Most often, wooden buildings are insulated. Installation begins from the ceiling, moving to the walls. Thermal insulation material with foil for the floor is laid last. To work, you will also need parchment, which is glued to the ceiling paired with mineral wool.

The foil insulation is attached to the wall according to the following scheme:

- First of all, you need to create a wooden sheathing. Rolls are placed in it. Glue must be used for fixation.

- If the foil insulation is torn, the damaged area can be repaired using metal tape. Experts advise using basalt wool with foil, which rarely breaks.

- Then you should attach the strips to the sheathing. They are later joined by a ceiling covering. The foil film is secured with slats.

- If foiled basalt wool is not available, it can be replaced with another thermal insulation material with foil. Installation of products is carried out in the same way as installation of wool.

- The easiest way to install foamed polyethylene. To install it, you just need to cut the roll into the necessary parts and cover the ceiling. Heat-resistant tape is applied to the seams.

- Installation of insulation on the surface of the walls occurs in a similar way. The difference is that you need to provide an overlap of five centimeters, which should overlap the floor and ceiling. Thus, steam will not be able to escape from the room. There should be a small gap between the inner wall and the foil layer.

- Hot air vapor rises to the top, so special attention should be paid to the ceiling. Many users lay basalt wool in two layers.

Outside the building

It is best to insulate wooden houses from the inside, since such an event allows you to retain heat. However, if internal insulation is not possible, external cladding is allowed. For these purposes, it is necessary to purchase foil-coated mineral wool with an average layer thickness.

To ensure quality work, you will need:

- adhesive;

- gun for construction work;

- set of dowels;

- wind protection film;

- sanding brush.

Laying foil insulation for exterior wall finishing is done as follows:

- Work begins with the installation of a metal cornice, which is fixed using dowels. A cornice is required to ensure that the mineral wool slabs are level.

- You need to apply glue to the back of the basalt wool and press the slab to the wall surface. Plastic dowels can be used as an auxiliary fastening.

- The surface should be leveled using a sanding brush.

- A windproof film is laid on top of the insulation.

- The process is completed with priming and external finishing of the structure.

Also, external wall decoration can be done using penofol. It is easy to install and has an affordable price range. For these works, it is better to purchase perforated penofol. The product can protect the surface from getting wet.

When insulating a wooden house, you should use antiseptics to treat the walls. The corners of the building need to be treated more carefully.

Insulation with penofol consists of several steps:

- It is necessary to build a structure from slats. Penofol sheets are subsequently attached to it.

- The joints should be masked using metal tape.

- If external cladding is being carried out, it is recommended to use an additional frame.

- Laying foil insulation outside is allowed only at positive temperatures and in dry weather

Internal wall insulation

With the help of penofol, you can insulate walls outside and inside. Installation of products is accessible even to a beginner. The layer thickness is 5 mm. If the building is located in a region with harsh winters, an additional insulation layer will be required for insulation. Experts recommend using foiled mineral wool in rolls.

Laying insulation consists of the following steps:

- the material should be cut in such a way that the length of the product matches the dimensions of the walls;

- penofol is attached to the wall using a stapler;

- after the installation of penofol is completed, the joints should be sealed with tape;

- GKL is laid on top of the insulating layer.

You can replace penofol with foil basalt insulation. However, its installation is accompanied by additional conveniences due to the need to arrange an auxiliary frame.

For roofing

To work with the roof, basalt slabs with foil are used.

Step-by-step guide to roof insulation:

- All cracks on the roof need to be repaired. To do this, you can use polyurethane foam or tow.

- Then you should create a vapor barrier layer. Glassine secured with a stapler is suitable for it.

- The next layer is waterproofing. Since basalt wool with wood construction can begin to rot, it is necessary to use polyethylene.

- The foil insulation is installed last. It will require special formwork. Installation of the material is carried out by surprise, followed by fixation with a cord.

Tips for installing film flooring

Experts advise laying film flooring following a number of rules:

- do not connect rolled film to the network;

- Installation of heated floors should be done at a humidity of no more than 60% and a positive temperature;

- if damage is detected on the graphite surface of the film, the hole must be insulated on both sides;

- Installing a film floor under a laminate cannot be done on a damp surface;

- if the heated floor is flooded, you need to quickly unplug it and let it dry naturally;

- install the temperature sensor in free access so that it is easy to change if necessary;

- save the layout of the film floor.

Infrared film is very popular today, as it can heat both an apartment and a house. By adhering to the installation rules, you can easily and quickly install this heating system with your own hands. In addition, if she has the right attitude, it will not be financially costly.

Approximate cost (in Russia)

There are various types of Folgoizolon sold on the market, the price of which depends on its parameters - the thickness of polyethylene foam, reflective film made of aluminum foil, manufacturing technology, the cost of some brands:

- Folgoizolon SRF-0.1-200 is a corrugated polyethylene foam with a density of 200 kg/m2, on one side of which a fiberglass coating is applied, and on the other, aluminum foil 100 microns thick, its approximate price is 170 rubles. per m2. Insulation with a thinner foil layer of the SRF 0.05-200 brand costs 140 rubles. per m2, the specified Folgoizol SRF is sold in rolls 1 m wide and 20 m long.

- The price of roll materials is determined by the characteristics of Folgoizol, the main of which are the thickness of the aluminum foil coating and polyethylene foam, the approximate cost depending on the thickness for Folgoizol for a bath is as follows: 2 mm - 55 rubles, 3 mm - 60 rubles, 5 mm - 70 rub., 8 mm - 80 rub., 10 mm - 90 rub. per square meter when purchased in rolls of 50 m2.

- Self-adhesive Folgoizolon in rolls is more expensive; its length and price for the above standard sizes and thicknesses from 2 to 10 mm range from 100 to 200 rubles. per m2.

Price listFoil insulation Izolon. Excellent insulation for the home Watch this video on YouTube

Folgoizolon is one of the many brands of insulation based on polyethylene foam widely represented on the domestic market, which has earned positive reviews from consumers; its use is advisable as an auxiliary insulation to reflect the infrared spectrum of thermal radiation, as well as in places where the thickness of the layer plays a significant role. Most often, the material is used on floors as a heat-reflecting substrate under laminate, boards, water heating pipelines or electrical wiring of heaters for heated floors.

Which polycarbonate is better for a greenhouse?

The coating experiences fairly large snow and wind loads, UV radiation, and temperature changes. In order for the material to last as long as possible, when choosing, you need to adhere to the following parameters:

- thickness is at least 3.5, and preferably 4 mm;

- weight per square meter - 0.8-1.3 kg;

- the presence of not only vertical, but also diagonal stiffeners;

- wall thickness 0.56-0.8 mm;

- UV protective film on the surface;

- Manufacturer's warranty 10-15 years.

Unlike cheap low-density material, high-quality polycarbonate does not deform the edge when pressed with fingers. This coating can withstand snow, hail, temperature fluctuations, and is not damaged or blooms during the entire warranty period.

Cellular (cellular) suitable for year-round greenhouses

On one of the surfaces of the sheets there must be a marking indicating the presence of a protective layer. When installing, they must be turned to the sun with this side.

Seasonal greenhouses are covered with monolithic polycarbonate

Sellers may claim that UV protection is included in the polymer itself, but this is not enough. Such material will quickly crack and become unusable.

Manufacturers produce budget options at a relatively low price, but provide a guarantee of no more than 6 years. You need to be aware that such material will not last long.

Examples

The following models of foil insulation can be found on sale:

- TFP-3.5:

| Specifications | Values |

| The basis | Fiberglass |

| Upper layer | Aluminium foil |

| Waterproof at a pressure of 100 Pa for 72 hours | Absolute |

| Roll dimensions | 10 by 1 m |

| Price | 207 rubles |

TFP-3.5 has the highest performance properties and cost in comparison with other samples of foil insulation

- HMAP-3.5:

| Specifications | Values |

| The basis | Fiberglass |

| Upper layer | Metallized film |

| Waterproof at a pressure of 100 Pa for 72 hours | Absolute |

| Roll dimensions | 10 by 1 m |

| Price | 121 ruble |

The KhMAP-3.5 model is simplified by using a metal coating instead of a foil coating, due to which it costs less

DIY crafts from isolon

Master class on making a lamp in the shape of an owl from isolon

To work, we will need a thin sheet of isolon, which must first be prepared, namely, cut into squares, 3 × 3 cm², forming “feathers”.

The procedure can be seen more clearly in the photo instructions. To work, we will need a small lampshade, which must first be disassembled into 2 parts, isolon, scissors, and glue. In addition, we will need wire with which we will make the frame of the wings

Please note that the wire will have to support a fairly large number of feathers. Be sure to use an LED lamp as a backlight, it is more durable, and you will not need to open the structure often

| Illustration | Description of action |

| Cut the isolon into squares. It's okay if the squares aren't perfectly straight. To speed up work, it is best to roll the isolon sheets in several layers | |

| Next, we give these squares a petal shape approximately like this. We cut each leaf so that we get a fringe. | |

| To make the head we will need foil and corrugated paper. We roll the corrugated paper noodles, cut into thin strips about 1.5 cm wide, into a ball and wrap them with foil. We got this blank for the head | |

| We wrap it with a sheet of heated isolon so that we get such a round blank, tighten the base with tape or an elastic band for banknotes. Cut off the excess. The diameter of our head for the owl turned out to be approximately 10-12 cm | |

| We attach the head with hot glue, in fact, it turns out to be such a snowman. Carefully glue the workpiece in a circle | |

| We begin to cover our blank with feathers from the bottom up so that we have a fluffy body. The higher you go to the head, the smaller the feathers should be. We glue the next row in relation to the previous one in a checkerboard pattern. | |

| Having reached the head, we begin by gluing the area under the eyes. This needs to be done at the very beginning, otherwise you simply won’t be able to make them on top of the glued row later. | |

| For the eyes, we chose a ready-made option, which can be bought on AliExpress or in any craft store | |

| Next, we continue to work according to the usual pattern - checkerboard, trying to avoid gaps | |

| Now it's time to start decorating the wings. We attach the blanks to the base. The process of creating voluminous feathers is similar to the design of the body. | |

| Our owl is almost ready. Now it's time to make the ears. To do this, we wind the isolon tape into a small skein, glue the base and make a fringe | |

| We attach our ears to glue, slightly fluffing the tops. Now all that remains is to complete the final finishing by covering the rest of the head with makeshift feathers. To give our lamp the appearance of natural plumage, you can slightly fluff the feathers by directing the warm jet of a hairdryer | |

| This is how our volumetric lamp made of isolon in the shape of an owl turned out |

You can watch all the stages of work in more detail in this video:

Watch this video on YouTube

Lamps in the form of flowers from isolon

Izolon is most often used to make beautiful jewelry and decorative flowers. These masterpieces are almost indistinguishable from the real thing. Despite the apparent complexity of the work, giant plants made from isolon are the simplest craft that a novice craftsman can complete.

For work we use familiar objects:

- 5 strips of isolon 1 m long, 15, 15, 23, 30, 33 cm wide;

- plastic container with lid;

- cartridge;

- glue gun

Watch the video in which the author explains in detail how to make a flower from isolon with your own hands. He got a huge rose. You can decorate your garden plot with it. If you are starting a renovation, save some isolon to make this luxurious flower.

Watch this video on YouTube

Master class on making a lamp in the shape of a doll from isolon

Almost any lamp can be made in this way. For example, the author of the following video explains in detail how you can make an unusual lamp for a child in the shape of a doll. This idea will make your child absolutely delighted.

Watch this video on YouTube

Thermal insulation in rolls based on mineral wool

No less popular is foiled mineral wool - a type of insulation based on mineral wool, including basalt and fiberglass wool in the form of rolls and slabs. The latter option is less convenient for transportation and installation, and limits the possibilities for insulating surfaces with complex terrain.

Thermal insulating mineral wool with fiberglass-based foil is used for thermal insulation of walls, roofs, and floors between floors. The material is also suitable for installing a vapor barrier layer, as well as insulating floors, walls and ceilings in baths and saunas. In rooms insulated with mineral wool and foil, heat is retained an order of magnitude longer precisely due to the features of the foil layer.

On the domestic market, foiled mineral wool is most often represented by the brands Knauf, Izover and others. At the same time, each manufacturer focuses on such important properties for heat-insulating materials as environmental friendliness, durability, optimal thickness level and ease of installation.

Regarding the safety of mineral foil insulation based on basalt wool, the opinions of experts and users are contradictory. On the one hand, they talk about the complete environmental friendliness of the material, on the other hand, they mention the phenol included in the composition, which negatively affects human health.

Use of cross-linked polyethylene foam

Thanks to its sanitary and epidemiological qualities and unique technical properties, the range of applications of this material is constantly expanding. The installation of such a product is often used in the engineering industry to insulate heat-reflecting screens, refrigerators, isothermal cabinets and climate control equipment. Isolon is also in demand in construction, where it is used for the following purposes:

- waterproofing of basements and foundations;

- protection of communications;

- heat and vapor insulation of rooms with high humidity (bathrooms, saunas);

- insulation and waterproofing of partitions, roofs, walls, ceilings, ceilings and floors.

This thermal insulation material is often used in the automotive industry. This product is used to cover the interior for sound insulation and also to reduce vibrations. Among other things, it is used as a sealant, a protective element against corrosion, and a damping gasket.

The material in question is used in medicine to make elastic products for specialized purposes, thermal blankets, insoles, as well as orthopedic products.

Isolon foil material has increased moisture resistance

A variety of things for tourism and sports are made from this versatile material. These mainly include gloves, mats, life jackets, punching bags, mats, helmets and swimming boards.