Features of the material

Polystyrene foam is white sheets with low weight. If we talk about pressless PSB-S, it looks like small balls connected to each other. It contains up to 98% air. Despite this, the technical characteristics of the PSB-S 35 remain at their best.

The abbreviation is deciphered as follows. The letters "PS" stand for "polystyrene". The letter “B” is “pressless”, “C” is “self-extinguishing”. The numbers indicate maximum density. In this case, the specific gravity of the material is in the range of 25-35 kg/m3.

PSB-S 35 is capable of withstanding high loads. In this case, the slab does not sag or move. Polystyrene foam does not absorb water. Due to this, it does not change its size and shape. The mechanical, thermal insulation and technical characteristics of PSB-S 35 do not change throughout the entire service life.

Properties of popular insulation

Like many other types of foam, high-density material has similar qualities; it is necessary to list a number of its advantages .

- It has a low level of thermal conductivity due to the fact that it consists mainly of air, so it easily retains heat.

- Resistance to active chemical influences.

- Not afraid of microorganisms, not susceptible to rotting, mold and fungus formation.

- Long service life; with proper choice of insulation and work, it can last about 40 years.

- It is environmentally friendly, so it is used not only in construction, but also in other industries, for example, the food industry.

- New and modern types of material are practically not subject to combustion processes, so they can be classified as fireproof.

- Ease and simplicity of operation, which is very important when performing installation work.

- Low cost of insulation.

New and modern foam plastic is no longer so fragile, since its quality has changed for the better over the years of production. It has become stronger and more durable , so the attitude towards the material has changed.

Advantages and disadvantages

Among the positive qualities of the material are:

- Vapor tightness.

- Does not absorb water.

- Environmentally friendly.

- Prevents the development of mold and fungi.

- Doesn't rot.

- Does not react with acids, weak alkalis, alcohol and salts.

- Does not react with components of concrete mixtures and other similar building materials.

- Resistant to fire, as it is treated with a fire retardant.

- It is light in weight.

- It is convenient to work during installation (it is easy to cut without emission of dust).

- Long service life (over 35 years).

The PSB-S 35 stove also has its disadvantages. There are few of them compared to the advantages. The main disadvantage of the material is its ability to release toxic substances during combustion, which are very dangerous to human health. In addition, polystyrene foam is destroyed by exposure to solvents and bitumen-based materials. Expanded polystyrene is a good habitat for rodents (mice, rats, etc.).

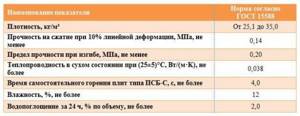

Technical characteristics of PSB-S 35

Expanded polystyrene is produced in the form of rectangular sheets of standard sizes. So, the length varies from 900 to 5000 mm. Moreover, the value increases at intervals of 50 mm. The width is 500-1300 mm (step - 50 mm). The thickness of the material changes in steps of 10 mm and is in the range of 20-500 mm.

Other technical data include:

- Density is in the range of 25.1-35.0 kg/m3.

- The material burns for less than 4 seconds.

- Humidity - up to 12%.

- During the day, the material absorbs no more than 2% of the volume.

- The limiting value of bending strength is 0.25 MPa.

- Ultimate compressive strength - 0.14 MPa.

One of the main parameters that provides a wide range of applications is the ability of foam to retain heat. The thermal conductivity of PSB-S 35 is at a very low level and amounts to no more than 0.038 W/(m*K), which is typical for the dry state.

How to determine density yourself

It is important to be able to protect yourself from unscrupulous manufacturers.

As we can see from the list of physical characteristics, such an important indicator as density varies in a fairly large range, from 25 to 35 kg/m³.

If 25-gauge foam is perfect for insulating walls, then for floor insulation you need at least 35-gauge. In this regard, as well as the dishonesty of many manufacturers, it is advisable to be able to find out the real density of the foam.

Visual inspection before purchase is required.

This is not difficult to do. It is necessary to weigh a sheet of polystyrene foam, preferably on an electronic scale, since it is light and large errors will negate all our efforts. Let us denote the weight of the sheet with the letter “m”. Let's say our sheet weighs 1200 grams, convert it to kilograms and get m = 1.2 kg.

We don't need pharmacy precision, so we can use a kitchen scale with an accuracy of up to a gram.

Next we need to determine the volume of the sheet. To do this, multiply its length (for example, 1 m) by its width (for example, 0.5 m) and by its thickness (for example, 0.1 m). We get the volume V = 1 x 0.5 x 0.1 = 0.05 m³.

Now we determine the density using the formula:

Formula for calculating the density of a substance.

Density is 1.2/0.05 = 24 kg/m³.

If you bought material with grade 35, look at GOST 15588-86 and make sure that you were deceived, since PSB-25-S has this density characteristic.

Characteristic values according to GOST.

PPS PSB-25-S is most often used for wall insulation.

You can be sure that you are using material with the density that corresponds to the calculations. After all, if you are insulating a critical facility, and the specific gravity of the insulation, according to the documentation, must be at least 32 kg/m³, then the PSB-35-S foam plastic you purchased can have a specific gravity of one cubic meter equal to, say, 28 kg on completely legal grounds.

Application area

Due to its technical characteristics, expanded polystyrene PSB-S 35 is ideal for use in regions with severe climatic conditions. It is used to insulate the foundation, ground floor, basement, pipelines (and other communications located underground), roofs (both flat and gable). But the main area of application is thermal insulation of walls and floors (including with a heating system).

The material is used in a wide temperature range - from minus 200 to plus 85 degrees. In areas with very high temperatures, the use of polystyrene foam is prohibited.

Foam is easily cut with a regular knife in any direction. In addition, it reduces vibration levels during transportation, thereby protecting the goods. Therefore, it is widely used as packaging material. It is used for packaging breakable goods (glass, ceramics), electronics, and so on.

Installation features

Thermal insulation of walls will be done efficiently if you take into account a few simple points. First you need to choose the right material. You should not purchase polystyrene foam that is stored outdoors. Expanded polystyrene should be white, without stains or faded areas. The plate is elastic and soft. Its balls are approximately the same in diameter.

The slabs are mounted on previously prepared surfaces. So, the walls need to be leveled and treated with a primer that will protect against mold (and mildew). Glue is used to attach the boards. The sheets are laid according to the principle of brickwork, that is, between the three sheets the seams form the shape of the letter “T”. The glue should dry within a few days (depending on the weather).

After the glue has completely dried, the polystyrene foam is attached using “umbrellas” (dowels with a very large head). Initially, holes are prepared into which dowels are inserted. “Umbrellas” are driven inside. Dowel umbrellas are chosen to be plastic, since metal ones allow the cold to pass through. This stage of work is carried out in order to increase the reliability of the connection between the wall and the foam.

The next stage involves gluing the reinforcing mesh. This is done using an adhesive that completely covers the mesh. The mesh is rolled out over the entire surface of the wall. Its individual parts are overlapped. Particular attention is paid to the corners. The glue should completely hide the mesh. After it dries, the wall is sanded using sandpaper. The surface must be flat.

Next, a layer of putty is applied. After it dries, the wall is primed. At this point, the surface is considered ready for application of the topcoat. This can be paint, wallpaper and any other materials.

Expanded polystyrene PSB-S 35 can be considered a universal material that has found its use as a heat and sound insulating layer in the construction of buildings and structures for various purposes. The material is used in regions with different climatic conditions.

Why do buyers choose this brand of foam?

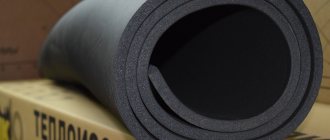

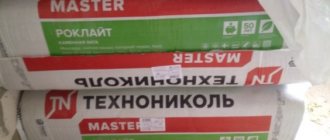

Packaging of self-extinguishing polystyrene foam PSB-35.

I will not list the advantages of polystyrene foam as insulation. Those interested can familiarize themselves with them in my other articles on the site. I would like to highlight the differences specifically in the 35th PSB-S.

Another example of PSB-S products.

In short, we can say that this is in a sense a universal material that will suit:

- for wall insulation;

- will not be “afraid” of the foundation or septic tank;

- and can also be used to insulate floors inside an apartment or house.

This is a kind of substitute for an extrusion machine, but cheaper.

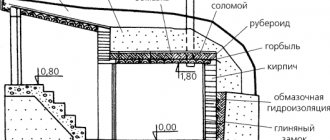

Do-it-yourself thermal insulation of the base.

The strength of these sheets is sufficient for use in the construction of heated roads and parking lots, runways, protection of soils from swelling, strengthening of slopes, etc. The instructions allow you to use PSB-S of the thirty-fifth series for these purposes, although personally I would play it safe and buy a PSB-S-50.

In regions with harsh climates, the material can be used on walls.