Brand history

The rights to the brand belong to the Saint-Gobain company from France. Its main office is located in Paris, and its founding date is 1665. It appeared at the direction of Louis XIV and produced glass and mirrors. The name Isover insulation is formed from the words “glass” and “insulation”. In our country, the company's products were initially known under the Uteplyaev brand.

Initial Izover products in Russia

Over more than 350 years of history, Saint-Gobain has grown into an international industrial group represented in 67 countries and employing over 170 thousand employees. Sales in 2015 amounted to 39.6 billion euros. The company is included in the following ratings:

- The hundred largest industrial enterprises according to Forbes.

- Top 100 innovative organizations in the construction sector.

- Best Employer - 2021

Experience and the latest technologies have made the company a world leader in creating a comfortable living space. The main activities of Saint-Gobain are:

- Innovative technologies in the field of high-tech products in the production of ordinary and special glass.

- Building materials represented by ISOVER, ISOTEC, ISOROC brands in insulation; GYPROC in gypsum solutions; WEBER dry mixes; ECOPHON for acoustic ceilings and panels; in siding and tiles - CERTAINTEED; RAM pipes

- Distribution activities in the field of building materials.

Saint Gobain Campaign:

The company's products have been known on the Russian market for more than 20 years. Ten years ago, a plant was opened in the Moscow region (Egoryevsk), and since 2011 in Chelyabinsk, the Minvata company began producing stone fiber insulation. All products have international environmental certificates and comply not only with internal corporate standards, but also EN 13162—ISO 9001.

Disadvantages of mineral wool

If we talk about the disadvantages of Izover mineral wool, it is worth noting the possible content of carcinogenic fractions and the harmfulness of glass dust to the respiratory system. But in order to prevent adverse effects on the body, it is enough to follow simple recommendations during the installation process:

- During installation work, demarcate the residential area and the construction site.

- Use film, plywood or drywall as a fence, which will be a good barrier to the spread of glass dust.

- Prevent the formation of drafts from the installation work area into residential premises.

- Use personal protective equipment - gloves, respirator, helmet, goggles.

Description of material

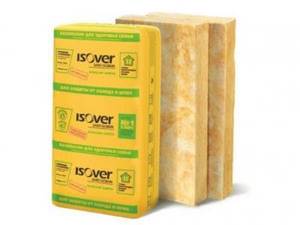

Available in rolls, as well as rigid and semi-rigid slabs. It consists of glass fibers 100-150 microns long, the thickness of which is 4-5 microns. For production, only natural ingredients are used, since mineral wool is environmentally friendly. It can be used both horizontally and vertically. Different types are designed for both indoor and outdoor use.

The insulation is made of quartz sand and broken glass (80% of the total mass). Soda, dolomite, limestone, and borax can also be used. The materials are poured into a hopper, where the process of melting the mass occurs. The filaments are formed when molten glass is blown by steam as it flies out of a centrifuge. Impregnated with an aerosol, they fall onto the rollers and are leveled, forming a “carpet”. At a temperature of 250°C, polymerization occurs. Then the mineral wool is cooled to ambient temperature and cut into mats and rolls.

Advantages and disadvantages

Advantages:

- Effective heat conservation.

- Insulation of any part of the building.

- Possibility of creating a noise-insulating layer. The sound transmission capacity is reduced when laying a 100mm double covering.

- The tight fit of the Isover insulation eliminates the need to use fasteners.

- The ability to compress is perfectly reflected in the transportation of products.

- Environmentally friendly.

- Isover thermal insulation is made using components that are not prone to fire. This is the reason to consider mineral wool non-flammable.

- It is resistant to fungus and mold.

Flaws:

- Isover is expensive.

- Use is not recommended when there is a high load on the surface of the insulation.

- Without wearing protective clothing, insulation can cause trouble to human health.

Wearing protective clothing

Main characteristics of insulation

Isover brand thermal insulation materials made from mineral wool inspire confidence and are in stable demand. Moreover, both slabs and rolls are rightfully considered one of the best thermal insulation on the market.

The main characteristics of insulation include:

- Thermal conductivity.

- Soundproofing.

- Flammability.

- Vapor permeability.

- Long service life.

- Environmentally friendly.

- Convenient release form.

- Light weight.

As a heat insulator, Izover insulation has managed to prove itself from the best side precisely thanks to its thermal conductivity coefficient equal to 0.041 watts per meter per Kelvin. The coefficient does not change during the operation of the insulation throughout its entire life; the fibers do an excellent job of accumulating and retaining air, preventing heat loss.

The material has excellent sound insulation properties. Fiberglass insulation with an air gap absorbs noise, guaranteeing an optimal level of silence, especially if you use specially adapted types of insulation to create a sound insulation layer.

The flammability index also matters. Thermal insulation materials with technical characteristics indicating a density of up to 30 kilograms per cubic meter are classified as non-flammable. The materials are successfully used in premises of any type and purpose, without fear of the spread of fire in the event of a fire.

Thermal insulation boards made of mineral wool with special technical characteristics indicating the presence of an additional layer based on aluminum foil or fiberglass are classified as slightly flammable.

Such materials are used subject to certain restrictions, which in fact are nothing more than a convention. In practice, insulators are appropriate almost everywhere; the main thing is to follow the fire safety requirements for structures prescribed in SNIP.

An important item on the list of technical characteristics of thermal insulation is vapor permeability. The insulation is able to maintain functionality even after contact with moisture. Unlike many modern analogs for thermal insulation, Izover products based on stone wool simply and effectively cope with the problem of moisture penetration inside the thermal insulation layer.

The insulation releases the absorbed moisture as quickly as it receives it; the main thing is to leave a small gap (2-3 cm) between it and the wall to maintain ventilation.

Neglecting this simple rule will lead to disruption of the material’s ability to remove moisture, which over time will negatively affect the ability to retain heat. Izover insulation materials have optimal vapor permeability values - from 0.50 to 0.55 mg/mchPa.

Analysis of the technical characteristics of the material also implies mention of such an important parameter as service life. The material not only does not allow heat to pass through, but is also able to serve properly for several decades. The manufacturer claims a service life for thermal insulation boards and rolls of 50 years with full preservation of functionality.

A special feature of the material is that it contains water repellents that can repel moisture, preventing the proliferation of insects, fungi and the formation of mold, which in turn ensures safety throughout the entire period of use.

Insulation release form

There are also single-layer and two-layer Izover. In the first case, the thickness reaches 5–10 centimeters. The two-layer material does not differ too much in thickness, since here the dimensions of one layer are about 5 centimeters. The slabs can be about a meter in size, or more precisely, this is the standard that can most often be found on the construction market, but there are exceptions when ordering insulation on websites or from dealers.

One roll of Izover insulation is about 16–20 square meters, that is, quite large in size. The roll width reaches 1.2 meters, while its length can vary from 7 to 14 meters. It goes without saying that the technical characteristics will differ slightly depending on the choice of material size.

Advantages and disadvantages

Among the advantages of building materials, the following factors are worth noting:

- High-quality thermal insulation. Izover is used in particular for facade insulation, which allows significant savings on heating a house in the winter.

- Resistance to extreme temperatures.

- Fire safety. Mineral wool does not burn, so it is used for insulating multi-story buildings, where the spread of fire would have very serious consequences, as well as for roofs and attic floors, the structure of which consists of wooden elements.

- Resistance to mechanical and chemical influences.

- Tensile strength and no compressive deformation.

- Excellent sound insulation allows the products to be used in plasterboard partitions.

- Resistance to the negative effects of rodents.

- Easy to install.

However, this material has its drawbacks. During installation, it is necessary to use a full set of personal protective equipment: goggles, gloves, a respirator, long-sleeved clothing that completely covers the body.

Even if it is very hot outside, you cannot neglect the above remedies, because the fibers cause irritation and itching when they come into contact with the skin.

If the insulation is moistened by 1%, its thermal insulation properties deteriorate by 10%. Therefore, when using the material on the roof and attic, it is necessary to carry out waterproofing work, because getting wet will lead to a loss of thermal insulation properties. And when installing slabs on the facade of a building, it must be immediately covered with mesh or plastered to avoid moisture due to precipitation.

Characteristics and scope

The material is produced in slabs and rolls and is characterized by high thermal efficiency, elasticity, density and light weight. Refers to non-combustible materials.

The main competitors in the mineral insulation market are Ursa, Izovol, Rockwool, Parok, Knauf. Isover mineral wool has a wide range of applications in general construction work. For industrial work, the Izover company produces insulation under the Isotek brand.

Isover is used for the following types of work:

- thermal insulation and sound protection of external walls;

- roof insulation;

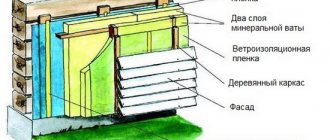

- ventilated facade systems, multi-layer walls;

- for sound insulation of internal partitions;

- in industry - for insulation of pipelines, ventilation, etc.

Isover, like other insulation, has its advantages and disadvantages.

The advantages of Izover include:

- Ease of transportation and storage - the manufacturer compresses the insulation 5-6 times when packaging it. Izover restores its shape 100%.

- Product lines with different technical characteristics are intended for different areas of construction. For example, Isover Sound Protection or Isover Pitched Roof.

- High elasticity. The insulation is superior to other mineral wool in this indicator, thanks to the special TEL technology with which it is produced.

- High energy efficiency - 5 cm of mineral wool is equal in thermal conductivity to 1 m of brickwork.

- Refers to non-combustible materials. The use of mineral wool for thermal insulation of a house does not increase its fire hazard class.

- Noise protection. Due to the fact that there is air between the fibers of the insulation, it does not transmit sounds well.

- The warranty period declared by the manufacturer is 50 years.

- Resistant to biological and chemical influences.

- Light weight – 28-60 kg/m3.

- Convenient to work. To insulate the surface, you just need to roll out the roll.

- Does not shrink during use.

- Environmentally friendly material. Holder of the EcoMaterial Absolute eco-label and ISO 14001:2004 international environmental management certificate.

- Heat resistant.

- High density and rigidity, which allows you to install insulation without additional fasteners.

The disadvantages of Izover include:

- The soft structure of wool limits its scope of application.

- Absorbs moisture well. A ventilation gap is required during installation. If this is not done, the cotton wool can become saturated with moisture and lose its technical characteristics, and even freeze completely in winter.

Varieties

The manufacturer Izovera produces mineral wool in rolls, mats and slabs.

Plates

Slab models come in the following types:

- Isover Optimal whose density is 28-37 kg/m3. It is used for frame structures and installation of sound insulation for interior partitions and floors. They can insulate roofs, floors, and walls. Slab dimensions - 60*100 cm, thickness - 5 cm or 10 cm, in a package of 4 slabs (10 cm) or 8 slabs (5 cm);

- Isover Standard. It is used to insulate external walls before finishing them with siding or facing bricks. The geometry of the plates is identical to Izover Optimal. Among the characteristics of Izover Standard, it is worth noting low compressibility under a specific load of 2 kPa - 10%;

- Izover Façade, whose density is 145 kg/m3, is used for facades with a thin layer of plaster. Fire resistance, as well as the absence of the influence of rodents, are the undoubted advantages of this model when insulating a building.

Rolls

Among the many roll options for this insulation, the following can be distinguished:

- Isover Warm Roof. The technical characteristics of this model allow it to be used for pitched roofs, since this material has high water-repellent properties;

- Isover Warm House is convenient to use on large horizontal surfaces. It allows you to save on heating your home by 64%;

- Isover Sauna combines a steam barrier. The presence of a layer of foil allows you to maintain a high room temperature for a long time;

- Isover Frame-M37 is used for serial construction;

- Isover Frame-M40-AL has a layer of aluminum foil, which allows you to increase the rate of heating of the room and save heat for a long time;

- Isover Frame-M40 is used for thermal insulation of floors.

Mats

Pro - used indoors and outdoors, a universal material that is popular. Thickness 50, 100 and 150 mm. Classic – thickness 50 mm, 2 mats wound in a roll. It is used for insulation of floors, roofs along joists, and ceilings along lathing. M37 frame - thickness options 40, 50, 60, 100 and 150 mm. It is used to fill the space between walls when insulating frame houses. Frame M34 – thickness 50 mm, less dense than M37. Frame M40AL – foil insulation with a thickness of 50, 100 and 150 mm.

Types of thermal insulation

All materials produced under the Isover brand differ from each other in functional purpose and physical properties. Industrial and household categories of insulation are supplied separately. There are several of the most popular varieties of products from Saint-Gobain.

Types of thermal insulation Izover:

Minvata Izover KL 34

This is a mineral plate 5 or 10 centimeters thick. It is used in frame construction and does not require additional fastening with dowels. These products are characterized by high elasticity, which maximizes the scope of application.

The insulation is packaged in a bag. After opening, it instantly takes on its original appearance and is ready for installation. Another advantage of this modification is low shrinkage. Among the technical characteristics it should be noted:

- Thermal conductivity – 0.034 W/μ.

- Vapor permeability – 0.53 mg/mchPa.

- Nominal compression at 2 thousand Pa – 60%.

- Return to normal state – 98%.

Thermal insulation of walls and floors:

This material is completely non-flammable with operating temperatures from -70 to +250 degrees. If it is completely immersed in water, it will absorb moisture no more than 5% of its mass, and when wetted - no more than 1%.

Pitched roof

This modification is intended for use as roof insulation. Available in the form of mats measuring 117x61 centimeters and 5-10 cm thick. It is almost one hundred percent hydrophobic. This is its main advantage over its competitors - the ability to use it in conditions of high humidity without loss of properties.

Stamps

Isover's lines of thermal insulating products include several dozen items and are designed to solve specific problems. They all differ in delivery form, thickness, density and size.

Please note: since all brands have the same base, they are interchangeable.

For general construction work

Izover Profi. A universal material with increased elasticity.

Provides the highest level of thermal protection among the brand's retail materials. Supplied in rolls, plate thickness – 50, 100 and 150 mm. Does not require additional fasteners during installation; can be installed by surprise. Received positive reviews from builders.

Used for insulation and sound protection:

- external walls inside and outside the house;

- pitched roofs;

- interfloor ceilings;

- frame walls;

- internal partitions;

- ventilated facades.

Classic. Supplied in rolls, material thickness – 50 mm.

Can be installed by surprise. Application area:

- insulation of suspended ceilings;

- interfloor ceilings - the material lies between the joists;

- attic spaces.

Isover Classic stove. The shape of mineral wool is slab. Size – 610*1170 mm, thickness 50 and 100 mm. Packaging 5 and 10 m2.

Installation of thermal protection

A wide range of uses implies several options for working with Izover materials. There are 4 technological options in total:

- Metal frame structure.

- Wooden building.

- Using staples.

- On the plinth.

When installing thermal protection, seek help from a specialist

When assembling a thermal insulation complex, the physical properties of the materials should be taken into account. It is worth providing additional protection from moisture using special films. When laying a roofing or wall pie, a certain order of layers should be observed. The vapor barrier is usually pulled from the inside to prevent the formation of condensation. The waterproofing is installed outside to protect against precipitation.

It is very difficult to choose the best of the many varieties of Izover products. Each type has its pros and cons. However, due to the diversity of the assortment and the optimal price-quality ratio, this product is recognized as the most popular.

All about insulation and thermal insulation Izover:

Throughout the entire existence of man on Earth, people have always strived to improve their living conditions. One of the primary tasks was to ensure that housing met all needs. Creating a warm and cozy “nest” became possible with the advent of modern building materials.

In the 20th century, glass wool was often used to insulate houses. This material has proven itself well and it was on its basis, with the help of the latest developments, that a completely new product was created that shook the construction products market - Isover insulation, competitors KNAUF, TechnoNIKOL.

Thermal insulation materials Izover are also made on the basis of stone fibers, and are better known as basalt insulation.

Technical characteristics, properties and a wide range of applications allow Izover thermal insulation materials to occupy a leading position among world analogues. The choice in favor of the products of this manufacturer is evidenced by numerous positive customer reviews. According to statistics, during the construction of every third European house, Izover products were used, for example, for insulating walls, floors or ceilings.

The lineup

Like any building material, isover insulation is available on the market in several types. Each of them is designed for specific building structures:

Isover product line

- “Sound protection” is intended for finishing partitions and walls.

- For frame construction, insulation of the “ Framework ” model is used.

- “Profi” is used for insulating attics and pitched roofs. This is high quality insulation. Profi is offered on the market in rolls of thickness 50, 100 and 150 mm.

- The classic is widely used. He can insulate floors, joists, attic floors and other complex objects. Although Classic is a roll material, it can be used to cover huge areas at a time. Usually two layers of 50 mm are laid in a roll. So you can safely divide it or use it as is.

- Classic Plus . This heat insulator is used to insulate the external and internal surfaces of walls. Has high thermal insulation characteristics. A magnificent example.

Important . Many models are classified as “interchangeable”. That is, one is freely replaced by another. In this regard, Pro and Classic Plus are universal insulation materials.

The sound protection model has increasingly become used in rooms where there is a need to reduce the penetration of noise from the outside. Sound protection is two in one. Therefore, for those who no longer want to hear their neighbors’ steps overhead, it is recommended to install Izover Sound Protection under suspended or suspended ceiling structures.

Fiberglass construction wool from a Finnish manufacturer is today a leader in the “thermal insulation” category. Excellent quality characteristics plus an affordable price for the mass consumer. This is enough to achieve the excellent qualities of a 100% insulated house.

Mineral wool insulation Isover (Izover) Venti 100

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):82 kg/m3

- Packed area: 2.16 m2

792 RUR

Mineral wool insulation Isover (Izover) Venti 150

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):82 kg/m3

- Packed area: 1.44 m2

775 RUR

Mineral wool insulation Isover (Izover) Light 100

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):38 kg/m3

- Packed area: 2.88 m2

563 RUR

Mineral wool insulation Isover (Izover) Optimal 100

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):34 kg/m3

- Packed area: 2.88 m2

117 RUR

Mineral wool insulation Isover (Izover) Optimal 50

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):34 kg/m3

- Packed area: 5.76 m2

363 RUR

Mineral wool insulation Isover (Izover) Venti 30

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):103 kg/m3

- Packed area: 5.76 m2

692 RUR

Mineral wool insulation Isover (Izover) Venti 50

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):85 kg/m3

- Packed area: 4.32 m2

792 RUR

Mineral wool insulation Isover (Izover) Light 50

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):38 kg/m3

- Packed area: 5.76 m2

563 RUR

Mineral wool insulation Isover (Izover) Facade 100

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):145 kg/m3

- Packed area: 1.44 m2

854 RUR

Against the backdrop of many proposals for new insulating materials, mineral wool “Isover plaster facade” and other types of “Isover” remain recognized classics. Fiberglass is processed using a special patented technology to produce insulating materials with strictly specified properties. If high adhesion to adhesives is required for external wall insulation, we recommend using “Isover façade”.

In addition to chemical resistance to plaster mixtures, this type of material has a zero ignition rate. According to the area of application, Izover is divided into the following types:

- For light thermal insulation;

- For general building insulation;

- For special purposes;

- Lightweight insulation.

Almost weightless Izover mineral wool slabs eliminate the load on the base. The slabs are used in the reconstruction and construction of residential buildings and industrial facilities. This is a well-proven insulation of floors, roofs, walls, attics, and ceilings between floors. The slabs are available in optimal sizes. Thanks to this, 20% less time is spent on installation. Our company’s specialists will tell you what is best for you to buy - “Isover Facade” or other products of this brand.

General building insulation.

Izover fiberglass rolls are mounted without fastenings and fit tightly to the base. They have proven themselves to be excellent for thermal insulation of partitions, walls, floors and more. You can buy Izover stone wool with aluminum film for vapor barrier.

In the production of mineral wool of this class, particularly enhanced moisture resistance and fire safety properties are imparted. Insulation is widely used for arranging pitched roofs of houses, insulating floors, insulating water pipes and ventilation pipes. To protect against external airborne noise, “Isover sound protection” is used. The level of protection is confirmed by acoustic tests.

Basalt insulation Isover

Izover insulation materials of this group are made from natural raw materials of volcanic origin. It belongs to the basalt group, which determined the name of mineral wool thermal insulation. Isover basalt insulation is not presented in such a wide range as quartz. But even among them, materials are distinguished by purpose and type of construction.

Mineral wool for walls and frame structures

Basalt mineral wool has improved strength characteristics, vapor permeability and resistance to the negative effects of moisture.

For frame structures, external and internal walls, Izover offers:

- Izover Frame House. Universal insulation for any frame structures both in the house and in the apartment.

- Isover Master of Warm Walls.

- Isover Optimal. Universal insulation for walls, roofs, interfloor ceilings, floors along joists, partitions. Elastic, holds its shape well and does not require the use of additional fasteners.

- Isover Light. This is mineral wool for partitions, frame structures, suspended ceilings. Provides additional sound insulation and is characterized by increased elasticity.

- Isover Flor. At the same time, it serves as heat and sound insulation for floors, reducing the level of impact noise to 35 dB .

The standard thickness of these insulation materials is 50 or 100 mm. And only Izover Floor has 25 mm.

Basalt thermal insulation for facades

Due to their properties, Izover basalt insulation materials are ideal for insulating ventilated facades and facades under plaster, siding, and brick. Thus, Isover FACADE-MASTER is designed for insulating external walls under a thin-layer plaster facade. Features high adhesion .

Isover Facade are slabs with high mechanical strength and uniform structure. The thickness of the slab can reach 200 mm. Isover Standard is used for insulation of external walls under brick, block house, siding. It is characterized by high elasticity and chemical resistance to elements of the insulated structure. Isover Venti and Isover Venti Optimal are suitable for ventilated facades.

Basalt mineral wool for roofing

Izover produces insulation for both pitched and flat roofs.

For a pitched roof, you can use one of the universal insulation options or a special one - Isover Master of Warm Roofs. Plates of this material help minimize heat loss during the cold season and keep rooms cool in summer.

For insulating flat roofs, Isover has the Isover Roof series. These are slabs of various sizes that are compatible with most building materials and can withstand loads of up to 7 tons per 1 sq.m.

The production of insulation from two types of raw materials and a naturally large assortment make Isover a leader in the market of thermal insulation materials. Not only professionals, but also inexperienced craftsmen who want to do the insulation work themselves can find the right solution.

Wall insulation with ISOVER materials

The use of ISOVER thermal insulation improves the quality of life of the whole family:

- increases the efficiency of heating and air conditioning systems,

- helps reduce associated costs,

- prevents noise from entering the house from the street.

ISOVER thermal insulation materials are non-flammable and do not emit toxic substances even at the highest temperatures. Interesting to know Thermal insulation 10 cm thick can replace massive walls made of brick or timber in terms of thermal protection. Insulating the facades of Kyiv houses will not be difficult with ISOVER products, since the materials have optimal geometric shapes and low weight.

8 advantages of ISOVER materials

| Thermal insulation Reliable thermal protection due to low thermal conductivity coefficient. |

| Service life - 50 years Maintain operational capabilities throughout the entire shelf life. |

| Fire safety Reduce the risk of fire: materials do not burn even in direct contact with fire. |

| Environmentally friendly Materials are made from natural ingredients: sand, soda, limestone. Recommended for use in children's and medical institutions according to the EcoMaterial Absolute certificate. |

| Ease of installation Thanks to their flexibility and special dimensions, the slabs can be easily installed into a structure without requiring fasteners. |

| Renewability Once unpacked, slabs and rolls are guaranteed to be restored to the correct dimensions. |

| Convenience of delivery Materials are delivered in compressed form, which reduces the cost of delivery and storage by up to 5 times. The slabs are produced in sealed packaging and can be stored in open areas. |

| Quality guarantee Product quality is controlled in accordance with the European standard EN13162, the international standard ISO 9001 and the standards of the Saint-Gobain group. |

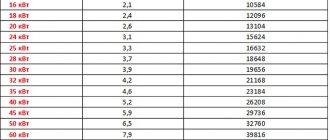

How quickly wall insulation will pay for itself

Before buying ISOVER thermal insulation materials, you need to understand whether it is profitable to insulate a house at all and what type of insulation is needed for the walls (inside or outside). Therefore, we conducted a small experiment - we compared the gas and electric meter readings in insulated and non-insulated houses with an area of 352 m2. And this is what came out of it.

| In an uninsulated house: | In an insulated house: |

|

|

Materials used for insulation:

- Facade - 18 m3 of ISOVER Profi material (wall insulation in a Kiev house was carried out with slabs 150 mm thick).

- Roofing - 20 m3 of ISOVER Profi material (insulation layer 120 mm).

- Floor - 7 m3 of ISOVER Profi material (insulation layer 100 mm).

In total you need 45 m3 of ISOVER Profi material ≈ 20,850 UAH. *At the price of gas for a private home, 7,188 UAH/m3 (as of March 1, 2016). **The price for electricity for a private home is 1.56 UAH/kW/year (as of March 1, 2021). You can calculate your home heating savings using an energy efficiency calculator. Insulation of facades is the price of warmth and comfort in your home.

Safety

The safety of stone wool for health is evidenced by its natural origin , production method and the conclusion based on the results of product testing and audit of the enterprise . It is no coincidence that professional builders use mineral insulation in the construction or reconstruction of even children's, medical and sports institutions . ISOVER stone wool creates a comfortable temperature in the building of the Federal Center for Cardiovascular Surgery (Chelyabinsk), in an emergency hospital (Kazan), in many kindergartens in Moscow, St. Petersburg and other Russian cities. This material is chosen when it is important to use a safe product with a positive experience of use, the quality of which can be trusted. Fire safety Mineral wool belongs to the group of non-combustible materials. Therefore, it does not burn, does not spread fire and does not emit harmful substances not only when in contact with an open fire, but also simply when heated.

Environmentally friendly and harmless

Fiberglass materials of this type are absolutely harmless to human health and life. During their operation, no harmful substances are released. Finnish scientists have been checking this fact for half a century. No danger was detected - this verdict was repeatedly made by specialists from the Institute of Cancer Problems.

Rules for working with stone wool

Manufacturers of stone wool recommend installing stone wool in accordance with the rules for working with any building material, i.e. wearing gloves and a respirator.

Insulation weight

If we compare Izover with other heat insulators in terms of weight, it will turn out to be much lighter than the others. Therefore, in those buildings whose walls are made of not very durable materials or excessive load is unacceptable, the use of Izover will be an excellent way out.

Disadvantages of using Izover

The main drawback of Izover insulation, which many sites are silent about, is, of course, the fiberglass structure , which has very fine glass chips.

Because of it, installing insulation is quite inconvenient and dangerous, because if a large amount of such glass dust gets into the body, undesirable negative consequences for the body can begin. To ensure that there are no health consequences when installing insulation, you need to use gloves, goggles and a respirator . Many may think this is an unnecessary safety feature, but simply looking at the fiberglass in good sunlight will reveal all the glass dust.