Among thermal insulation materials, basalt mineral wool occupies a leading place. It is used to insulate facades, roofs, floors and utility networks of residential and industrial premises, soundproof walls in residential premises and recording studios, and provide fire protection for wooden structures from highly heated building elements, for example, a chimney.

Let's try to figure out why in industrial and residential construction they are increasingly using cotton wool based on basalt fibers for thermal insulation and whether it is worth buying this type of insulation when building a private house or renovating an apartment.

Description of material

For many visitors to the StroyGuru website it will seem surprising, but the history of using basalt wool for home insulation goes back several centuries. At the same time, there are no special mysteries: during the eruption of one of the volcanoes on the Hawaiian Islands, lava erupted in the form of a fountain, and a strong air flow turned part of the molten basalt into long, strong threads.

Local residents found them and began using them to insulate their homes. Europeans learned about this and tried to repeat the natural process artificially. In the end, the search was crowned with success, as a result of which basalt wool insulation appeared on the building materials market. Over time, they began to melt one of the types of granite - gabbro.

Cotton wool is obtained from stone using a simple technology consisting of several stages:

- basalt or gabbro is crushed;

- the crushed mixture is loaded into the oven and heated to 1500oC;

- the molten mass is fed onto rotating drums, which are blown with a strong air flow, resulting in the formation of stone threads;

- plasticizers are fed into the resulting fibers (formaldehyde resin, and from leading manufacturers - arbolo-urea resin);

- the fibers are cooled to a temperature of +200oC to start the polymerization process on the surface of the fibers of the thinnest layer of resin;

- on a special conveyor belt, the fibers are compressed (pressed) to a certain density;

- continuous tape is cut into sheets or tapes for rolls;

- the resulting insulation, if necessary, is reinforced or foil-coated.

A product produced using this technology has its advantages and disadvantages, which we will consider.

Installation

Since this insulation has different densities (hence different hardness) and is used for different surfaces (horizontal, vertical, inclined, as well as cylindrical and conical), it should be expected that installation methods may differ greatly from each other.

The easiest way is with a horizontal plane. Soft and hard insulation is laid on it - the first in cases where a screed is not necessary, the second - under a concrete screed. These can be floors or flat roofs.

Basalt wool 1000x500x50 mm. Photo Teplokontakt

On vertical and inclined surfaces, basalt insulation must be fixed. At a minimum, it is placed in a spacer - the distance between the supports is made smaller and, due to its elasticity, the insulation is compressed, after which it holds itself, and the film on both sides serves as an additional retainer.

“Fungi” can also be used - plastic dowels with wide round caps, with which the basalt insulation is attached to the wall. At the moment, this method is often combined with metal profiles, into which mats are inserted. However, profiles can be used autonomously.

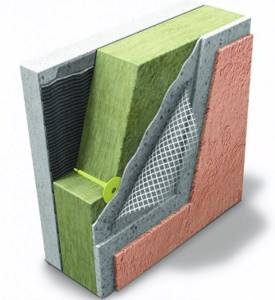

In turn, the wool under the plaster becomes a layer on which the mesh is then attached, and the plaster solution is applied to it. This places high demands on the mounting of the wool on the wall.

In addition, installation of basalt wool can be done using glue .

When wrapping pipes or other equipment, either rolls, shells, or cylinders are used. To fix the insulation, clamps or binding wire are used.

Adhesive for basalt wool

Glue for basalt wool is available either in the form of a dry mixture , which requires dilution with water, or in the form of polyurethane foam .

An interesting nuance: dry mixtures can be used as an automatic leveler . That is, you glue the insulation, and at the same time the redistribution of the glue mass corrects defects in the evenness of the wall.

Polyurethane foam is used more economically, but also costs more than the dry mixture.

In general, it is recommended to use glue from the same manufacturer whose wool you bought . If this is not possible (it does not release glue), then again take glue from well-known manufacturers - Ceresit, for example.

This video explains how to apply the adhesive solution to the surface of the basalt mat:

After gluing the insulation, it is recommended not to hesitate, but to cover it with film to protect it from atmospheric moisture.

Advantages and disadvantages

Stone wool for insulation stands out among its competitors with its strengths:

- durability - manufacturers indicate a service life of more than 50 years. In practice, there have been cases of material service life of 70-75 years without significant loss of heat-saving properties;

- resistance to heat - destruction of fibers begins at +1100oC and above;

- almost zero hygroscopicity - within a day, cotton wool completely immersed in water absorbs only 0.095% of moisture;

- very high thermal insulation properties;

- good soundproofing properties - absorbs up to 57 dB of airborne noise (cotton wool is powerless against structural and impact noise);

- excellent resistance to fungi and mold - microorganisms do not multiply on basalt fibers;

- versatility - used for insulating walls outside and inside the building, floors, ceilings, roofs, metal entrance doors, etc.;

- convenient transportation - easy to transport and carry;

- simple installation - installation can be done with your own hands;

- resistance to alkalis, acids and salt solutions;

- good elasticity - shapes and sizes are maintained throughout the service life;

- environmentally friendly - all components do not belong to the group of allergens and do not emit harmful substances when heated.

Attention: in insulation you can find two types of resins: arbolo-urea and formaldehyde. The first is absolutely harmless to humans, the second emits so few harmful substances when heated that the human body practically does not notice them.

In addition, two more features of stone wool should be noted:

- The ability of the material to resist rodents - they do not make passages and nests.

- When performing thermal insulation of walls from the outside and inside, decorative plaster can be applied directly over basalt wool.

Among the disadvantages, consumers note:

- high price;

- the presence of seams through which heat is lost;

- dust - is formed during cutting and laying, which requires the presence of a respirator (a new product has appeared on sale - dust-free stone insulation).

Acidity module (μ)

When assessing the quality of cotton wool, such an indicator as the acidity module, that is, the proportion between basic and acidic oxides, is very important.

The highest quality basalt wool is made from gabbro-basalt eruption products with the addition of carbonates, which regulates acidity.

If we classify the product according to this indicator, then according to GOST 4640-93 we get the following:

-A – μ > 1.6;

-B – μ > 1.4 – 1.6;

-B - μ > 1.2 -1.4.

If the indicator is high, then this indicates increased water resistance of the material, which makes it durable.

Characteristics and properties

Each type of insulation is characterized by a large number of indicators. However, the following characteristics of basalt wool are of practical importance:

- linear dimensions of products;

- fiber size;

- insulating properties;

- specific gravity (density);

- hygroscopicity;

- vapor permeability;

- strength;

- fire-resistant properties;

- environmental cleanliness.

Linear dimensions of insulation

European and Russian standards do not impose any specific requirements for the sizes of rolls and sheets. The width of the slabs can be 50-60 cm, the rolls - 100 cm. The length: slabs - 100-120 cm, rolls - 200-600 cm. The thickness ranges from 2 to 24 cm. The specific dimensions depend on the type and geometry of the insulated surface.

Fiber size

Several important parameters of insulation depend on the size of the fiber: thermal conductivity coefficient, specific gravity, elasticity and strength. On the packaging these sizes are marked: BTV (fine-fiber basalt) and BSTV (basalt with ultra-fine fiber).

For BTV, the fiber diameter is 5-15 microns, the length is 15-50 mm. The designation BSTV includes fibers with a diameter of 1 to 3 microns and a length of 50 to 70 mm.

In addition to the fiber parameters given above, thick-fiber materials are used in industrial construction, where the diameter of the threads is 25-150 microns and coarse-fiber materials with a thickness of 150-500 microns.

Thermal insulation properties

The ability of a material to retain heat is characterized by its thermal conductivity coefficient: the lower it is, the better the thermal insulation characteristics. For wool made from basalt fibers, this indicator ranges from 0.035 to 0.042 W/(m×°K). To understand how good the insulation is, let's give a simple example. Thus, a basalt mat only 5 cm thick retains heat in the same way as:

- wood 13-15 cm thick;

- brickwork made of red brick 70-80 cm thick;

- sand-lime brick and cellular concrete 1 m thick.

When compared with insulation materials, basalt wool is inferior only to polyurethane foam and has similar performance to cork, foam rubber and polystyrene foam.

The variability of the indicator is explained by the influence of the fiber diameter and the density of insulating mats on the thermal insulation characteristics. After all, it is not the fibers themselves that retain heat, but the air chambers located in the fibrous structure of the material. As a result, the more air inside the insulation, the lower the thermal conductivity of stone wool.

However, do not rush to buy loose insulation labeled BSTV. It has one problem: low strength, due to which the heat insulator cakes on horizontal planes and settles on vertical surfaces. In both cases, the thermal insulation properties of basalt wool are lost to a significant extent.

Insulation weight

The weight of the insulation depends on its density, which is associated with the weight load on the insulated structures. However, this is a one-sided approach to the problem. The strength (rigidity) of the mats also depends on the indicator, which in many cases is the determining criterion when choosing a thermal insulation material, and its thermal conductivity.

The density of basalt slabs used for insulation ranges from 30 to 300 kg/m3, which allows you to choose your own type of insulation for a specific situation. Among the main brands that take into account the density of insulation:

- PT-250, PT-220, PT-300 (hard mats) with a specific gravity of 220-300 kg/m3;

- PPZh-160, PPZh-180, PPZh-200 (slabs with increased rigidity) - the density indicator reaches 160-210 kg/m3;

- PM-50, PM-40 - the most popular sheets with a density of 30-55 kg/m3;

- PZh-120, PZh-100, PZh-140 - rigid insulation with a specific gravity from 100 to 150 kg/m3;

- PP-80, PP-70, PP-60 - semi-rigid mats weighing 60-90 kg/m3.

Hygroscopicity

The problem with insulation materials is always their hygroscopicity - wet insulation materials deteriorate their thermal insulation properties. Basalt fibers have virtually zero moisture absorption.

So, when conducting an experiment to determine the wettability of a basalt mat, it was immersed in water for 24 hours. As a result, the following data was obtained:

- only 0.095% of water was absorbed;

- the inside of the cut mat was absolutely dry.

If you are constantly in a damp room, moisture absorption does not exceed 1-2%, which allows you to use cotton wool for thermal insulation of baths, saunas and foundations.

Vapor permeability

The presence or absence of vapor permeability of any finishing material determines whether the walls will “breathe” or not. To find out, let's do a little experiment. Place a container of water on the stove and bring it to a boil, then cover the boiling water with a piece of basalt-based insulation. After 1-2 minutes we observe the effect: steam begins to pass freely through the insulation. The result of the experiment: the vapor permeability of the insulation is 0.25-0.35 mg/m2 x h x Pa.

Strength

The strength of the material is characterized by a number of indicators:

- compressive strength - 8-60 kPa;

- for layer separation - 80 kPa;

- bending - 0.15 MPa.

To understand what this means in practice, here are two examples.

1. A car drove onto the mat, creating a pressure of 100 kPa. There were no visible traces left - the fibers completely restored their previous shape after removing the load.

2.Plates were glued to the top and bottom of the slab and tried to tear the layers of insulation. As can be seen in the photo, the efforts will be crowned with success only after applying forces of more than 80 kPa.

Fireproof properties

Basalt wool refers to fire-resistant materials (not to be confused with fire resistance - these are different terms). The experiment shows that when the insulation is heated with autogenous heat to +700-800oC, nothing happens to the fiber: it does not ignite or collapse.

If you touch the heated area with your bare palm from the back, you will not feel any sensations of the heated surface - only 15-25oC, which corresponds to natural heating from the environment. This experience confirms not only the fire resistance of the material, but also the excellent thermal insulation properties of basalt wool.

Strength characteristics - about insulation performance

The peculiarity of thermal insulation based on stone wool is the special arrangement of fibers inside in a chaotic order, partially in a vertical position. Due to this, mineral insulation is able to cope with noticeable loads.

For example, in the case of 10% deformation of stone wool, the insulator exhibits compressive strength limits of up to 80 kilopascals. The final performance is affected by the density of the material. In general, it can be noted that due to the special strength characteristics of stone wool, its service life is extended to 50 years while maintaining its geometric shape and, accordingly, functionality.

Is basalt wool harmful?

Many experts believe that basalt wool is harmful to health. They explain their point of view by the presence of formaldehyde resin, which releases harmful substances when heated. However, it is difficult to agree with this for two reasons.

- Leading manufacturers of stone wool have switched to arbolo-urea resins, which are harmless to human health.

- Indeed, when formaldehyde resin is heated, hazardous substances are released into the surrounding space. But their size is so small that they do not harm the human body (the insulation contains only 3% resin, and the resin, in turn, releases about 3% of harmful substances when burned). It should not be forgotten that doctors prescribe medications containing 0.5% formaldehyde to patients, considering this dose to be safe.

What is basalt and how did you come up with the idea of making insulation?

What is basalt wool made of? The answer is simple - from basalt. Basalt is a volcanic rock. Simply put, a stone that once came out of a volcano. This breed is very common on our planet - almost the entire bottom of the world's oceans is covered with it. And often entire islands grow from basalt - for example, Hawaiian and Galapagos.

Basalt appears from the depths of the earth. The main sources are volcanoes, eruptive basaltic flows and ocean ridges. And sometimes it happens that basalt lava rises into the air, and the wind blows out individual drops and pulls them into thin threads. This results in something vaguely similar to modern basalt wool.

Such bundles of “hair” made of basalt threads were often found in the Hawaiian Islands - they were called “Pele’s hair” in honor of the local goddess. And in Iceland they are called witch hair.

This is how nature itself simply suggested to man how to use basalt for insulation.

Application area

Basalt wool is used in various sectors of the national economy. It can be found in fine and coarse water purification filters, in the composition of soil for drip irrigation, pipeline transport, etc. However, the main area of application is industrial and residential construction. Here the material is used for insulation:

- flat roofs;

- attic space;

- floor bases;

- interfloor floors and ceilings;

- external and internal walls;

- foundation from inside the building;

- walls with multi-layer masonry;

- frame houses made of sandwich panels.

In addition, such material properties as fire resistance, fire resistance and the ability to absorb airborne noise are used. Therefore, on sale you can find:

- basalt wool for the chimney - protects flammable elements of the building from contact with an overheated chimney;

- soundproofing mats for recording studios;

- rigid slabs for constructing a “wet” facade, on which you can immediately plaster.

Where is basalt insulation used?

The excellent technical characteristics of basalt insulation allow it to be used in all types of buildings. Most often, this material is used for thermal insulation:

- facades;

- roofing;

- walls and partitions;

- floors and ceilings.

In addition, basalt thermal insulation is used for laying pipelines, the temperature of which varies greatly. It is also used as a fire barrier - the material perfectly protects building structures from fire.

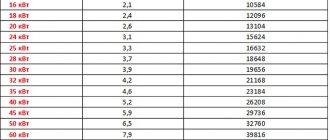

Important: to calculate the required layer of thermal insulation, you need to contact specialists, since many factors need to be taken into account. This may be the climate of your region, the type of facade, structural features, the duration of the heating season, the amount of precipitation in winter, the thermal capacity of coatings, the area of the premises, the amount of glazing, wind strength and even the number of sunny days per year.

Manufacturers and prices

An analysis of the preferences of Russians showed that the best manufacturers of basalt slabs are:

Rockwool. The Danish company (“Rockwool”) has many factories in Russia and the CIS countries, which allows it to offer European quality products at affordable prices on the building materials market (the price does not include transportation costs, customs clearance and higher wages for foreign workers).

Basalt mats are characterized by:

- fire resistance - one of the few enterprises whose wool can withstand heating up to +1000oC (for European consumers the norm is +600oC);

- durability - not only linear dimensions are preserved, but also insulating properties;

- environmental friendliness, as confirmed by the “EcoMaterial Green” certificate;

- good noise and heat protection properties.

Price for 1 m3 is about 7,000 rubles.

Paroc. There is practically not a single construction forum dedicated to thermal insulation where Finnish products (Parok) are not discussed. The company's products:

- high heat-saving properties, allowing you to save on heating the room;

- good acoustic insulation - basalt wool is used to protect recording studios from extraneous noise;

- excellent fireproof characteristics.

But, before choosing Parok products, it’s still worth looking at how much stone wool from Finland costs. After all, the price is quite high and amounts to 9,400-10,750 rubles/m3.

IZOVOL. IZOVOL is a Russian manufacturer of insulation made from basalt fibers. Affordable products are in good demand for insulating walls, roofs and ventilated facades.

The line of brands for thermal insulation of pitched roofs and attics is especially popular. Technical and operational characteristics of the product comply with European and Russian standards:

- the insulation has a low thermal conductivity coefficient - 0.035 W/(m×°K);

- standard indicators of durability, sound insulation, etc.

The downside is a slight shedding during the work process, which greatly affects the rating. You can buy “IZOVOL” for 3,999-4,900 rubles/m3.

TechnoNIKOL. Another manufacturer of basalt insulation from Russia is. The brand's products are produced in Lithuania, Belarus, England, the Czech Republic and other countries. Cotton wool is distinguished by good quality and affordable price. For the first time in the world, the company's enterprises began to produce dust-free wool (Rocklight brand), which simplifies the insulation process.

In terms of production volume, the holding is among the TOP 5 largest producers of mineral wool. Prices vary in the range of 2,350-3,780 rubles/m3.

Isover. Isover, a French multinational company producing basalt insulation, has built its enterprises in Russia. The products have the best balance between price and quality, which allows the brand to be a sales leader in most countries of the world.

The price for 1 m3 ranges from 3,999 to 5,240 rubles.

Origin

The main raw materials are rocks of the gabbro-basalt group, as well as other rocks and marls with similar chemical and physical properties.

A material such as basalt wool has the following technical characteristics and approximate composition:

-sodium dioxide – 65-45%;

- aluminum oxide -20-10%;

- calcium oxide – 15-5%;

-magnesium oxide -10-5%;

-magnetite – 15-10%.

Basalt wool insulation technology

When working with basalt insulation, the technology of thermal insulation of various building elements has its own nuances that need to be taken into account.

Roof insulation

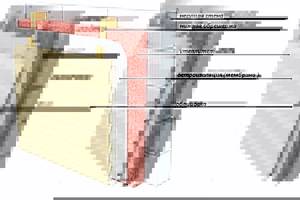

When insulating the roof, it is necessary to take into account that here the probability of condensation formation is the highest. Therefore, all work must be performed in the following sequence:

- the bottom of the rafters is filled with lathing, on which the insulation will be laid;

- a vapor barrier film made of polyethylene 0.5-0.1 mm thick is overlapped over the sheathing and rafter system so that moist air from the room does not enter the insulation layer;

- joints are glued with construction tape or masking tape;

- 18-20 cm thick basalt mats are laid on the film between the rafters (ideally, the thickness of the mat should correspond to the width of the timber in the rafter system);

- A vapor barrier (sometimes they write and say - windproof) class B membrane (for a pitched roof) is attached to the insulating layer. In this case, it is necessary to lay it with the smooth side to the insulating layer, the rough side to the roof;

- the counter-lattice is stuffed;

- boards are nailed to the rafters to secure the roofing material and create a ventilation gap between the roof and the insulation;

- roofing material is attached.

If there is an attic under the roof, then instead of lathing, OSB or plywood sheets are attached to the rafters below.

Floor insulation

Having high compressive strength, rigid mats made of basalt fibers can be used for floor insulation using the “floating” screed principle. Here the work is performed in the following order:

- the base of the floor is repaired and then thoroughly removed from debris;

- waterproofing work is carried out to prevent moisture from entering the insulation from below;

- Thermal insulation mats are laid. It is advisable to seal the connecting seams with tape or masking tape;

- a reinforcing film is laid on top of the insulation;

- the screed is poured.

In practice, basalt insulation is mainly laid directly under the finishing floor covering. In this case, the work algorithm is as follows:

- A polyethylene film with a thickness of about 200-500 microns is laid over the screed;

- a sheathing with a height of 20-50 mm is arranged (it is advisable to make the cells a few millimeters smaller than the size of the mats);

- insulation is installed in the sheathing;

- a wooden floor or rough plywood or OSB flooring under laminate, tile, parquet, etc. is laid over the lathing.

Wall insulation

Stone wool insulation is attached differently to the walls inside and outside the building. The indoor work algorithm is as follows:

- the wall is cleared of old finishing, after which it is inspected and, if necessary, repaired;

- removes dirty and greasy stains;

- a layer of penetrating primer is applied;

- a vertical frame is mounted in increments equal to the width of the mat;

- Insulation is laid between the vertical posts. At the same time, the slightest cracks and gaps are not allowed - they will conduct cold;

- the resulting gaps between the slats and the cotton wool are foamed with polyurethane foam;

- the lathing is covered with sheets of plasterboard.

Facade insulation

To insulate the facade, it is best to use specialized facade insulation made from basalt. In this case, thermal insulation work is carried out using three different technologies:

- “well” system;

- with a ventilated facade;

- "wet" method.

"Well" system

A feature of this method of insulation is the presence of 2 walls: load-bearing and decorative, between which the insulation is laid. In this case, the supporting structure is laid first, then the façade is insulated, and only after that a wall of facing bricks is laid out: the schematic diagram is shown in the photo.

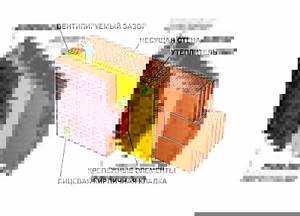

With ventilated facade

The installation of a ventilated facade is carried out as follows:

- a frame is placed on the wall with a distance between vertical posts equal to the width of the slabs. Horizontal slats are attached at intervals that are a multiple of the length of the insulating mats. The width of the beam should be slightly larger than the thickness of the insulating mats - this way a small ventilation gap is formed between the heat-insulating layer and the facade cladding;

- sheets of insulation are placed in the cells of the sheathing, after which they are fastened with special screws to the wall or staples to the slats;

- a windproof (vapor barrier) membrane is attached on top of the insulation;

- the counter-lattice is attached;

- the façade is covered.

"Wet" method

When constructing private houses, the most common method is the “wet” method of insulating facades. Its essence is that first the basalt slabs are very rigidly fixed to the wall using glue and 5 special dowels, after which a reinforcing mesh is attached to the wool. The technical process is completed by applying a layer of decorative plaster.

Dimensions

The dimensions of basalt wool are determined by the manufacturer. Unfortunately, there has been no standardization , so you should always familiarize yourself in advance with the products of the company that you plan to purchase for your needs - its dimensions will determine the pitch of the joists and rafters, as well as wall sheathing or niches in the frame.

If the material has elasticity (this does not apply to very rigid slabs), then for better fixation of basalt wool in the allotted space, the distance between the limiting elements is made 1-2 cm less than the width of the wool.

We borrowed from our colleagues examples of sizes of several popular manufacturers:

Insulation of facades:

| Manufacturer | Brand | View | Dimensions, mm | Density, kg/m3 |

| TechnoNikol | TECHNOFAS | plate | 600×1200, 50 (100) | 145 |

| TECHNOVENT STANDARD | 600×1200, 50 (100) | 80 | ||

| Knauf | Insulation FKD | plate | 600×1200, 20-160 | 140-150 |

| Insulation FKD-S | plate | 600×1200, 60-180 | 140-160 | |

| Insulation FKL | plate | 200×1000, 20-200 | 85 | |

| Insulation HTB | plate | 1000×500, 20-180 | 35-150 | |

| Rockwool | Fasrock | roll | 1000×600Х100 | 135 |

| Panelrock | plate | 1000x600x50-100 | 65 | |

| Wentirock max | roll | 1000x600x50 | 50-90 |

Insulation of partitions and walls:

| Manufacturer | Brand | View | Dimensions, mm | Density, kg/m3 |

| TechnoNikol | Mat TechnoNIKOL regular | roll | 1000x4000, 50 (100) | up to 30 |

| ROCKLIGHT | plate | 600×1200, 50 (100) | 30 | |

| TECHNOLITE EXTRA | plate | 600×1200, 50 (100) | 30 | |

| TECHNOLITE OPTIMA | plate | 600×1200, 50 (100) | 35 | |

| TECHNOBLOCK STANDARD | plate | 600×1200, 50 (100) | 45 | |

| Knauf | Insulation LMF Alur | roll | 1000×2500, 20-100 | 35-90 |

| Rockwool | Domrock | roll | 4750×1000, 200 | 20 |

| Superrock | roll | 1000x600x50 | 35 |

Thermal insulation of floors:

| Manufacturer | Brand | View | Dimensions, mm | Density, kg/m3 |

| TechnoNikol | ROCKLIGHT | plate | 600×1200, 50 (100) | 30 |

| Heatroll | roll | 4000Х1000, 50 (100) | 30 | |

| Knauf | Insulation LMF Alur | roll | 1000×2500, 20-100 | 35-90 |

| Insulation PVT | plate | 600×1000, 20-120 | 175 | |

| Rockwool | Rockmin Plus | plate | 1000x600x50 | 31 |

| Rockton | plate | 1000x600x50-120 | 50 | |

| Superrock | roll | 1000x600x50 | 35 |

Thermal insulation of roofs:

| Manufacturer | Brand | View | Dimensions, mm | Density, kg/m3 |

| TechnoNikol | ROCKLIGHT | plate | 600×1200, 50 (100) | 30 |

| TECHNOLITE EXTRA | plate | 600×1200, 50 (100) | 30 | |

| TECHNOLITE OPTIMA | plate | 600×1200, 50 (100) | 35 | |

| TECHNOBLOCK STANDARD | plate | 600×1200, 50 (100) | 45 | |

| Knauf | Insulation DDP | plate | 600×1200, 20-180 | 150-200 |

| Insulation DDP-K | plate | 600×1200, 40-160 | 105-110 | |

| Rockwool | Dachrock max | plate | 2000×1200, 40-200 | 130-210 |

| Domrock | roll | 4750×1000, 200 | 20 | |

| Megarock | roll | 3000(6000)x1000x200(100) | 28 | |

| Monrock | plate | 2000x1200x50-200 | 115-200 | |

| Rockmin Plus | plate | 1000x600x50 | 31 | |

| Rockton | plate | 1000x600x50-120 | 50 | |

| Superrock | roll | 1000x600x50 | 35 |

Thickness

Despite the fact that the tables above indicate the thickness of basalt wool for each mentioned case, let us clarify that this parameter is still variable . It is quite possible to find a manufacturer who will take a thickness of 60 mm as a basis, after which the following thicknesses will be multiples of this value: 120 mm, 180 mm.

However, most manufacturers still adhere to the basic value of 50 mm and produce insulation with a thickness of: 50, 100, 150, 200 mm.

Insulation Rockwool Standard 50 mm. Photo by Leroy Merlin

The thickness should be chosen according to thermal calculations of the dew point, and if we are talking about premises of periodic use, then one must be guided by the climatic conditions of the area . The layer of wool can reach 300 mm in particularly harsh areas.

As for sound insulation, 50 mm may be enough .

Basalt wool 100 mm

The thickness of 100 mm basalt wool is one of the most popular sizes, almost universal. There are many cases when this thickness is enough to solve problems with thermal insulation.

However, it is worth noting that if according to the plan the insulation thickness is 100 mm, then you have two solutions at your disposal:

- in the first case, the problem is solved head-on - packages of cotton wool with a thickness of 100 mm ;

- 50 mm thick insulation , after which he lays it in two layers, moving the seam of the second layer to the middle of the mat of the first layer.

TechnoNIKOL insulation for walls 100 mm 6 slabs 600x1200 mm. Photo by Leroy Merlin

The second decision can be considered more competent, but there are many factors that can influence the choice, so there is no point in insisting.

Binder

This insulation product always contains a binder. It binds the fibers and gives the desired density and shape. Types of binder:

— bitumen;

- synthetic, usually phenol-formaldehyde, phenol alcohols or urea resins.

- compositional (complex composition of several substances).

- bentonite clays.

Manufacturers most often use a composite binder. This is a synthetic composition that includes plasticizing and water-repellent additives, as well as phenol-formaldehyde resins. In the final material, formaldehyde and phenol are combined, and the binder is completely inert.

Production

The method of manufacturing such a material as basalt wool, the characteristics of which are indicated above, was suggested to man by nature itself. The thinnest threads of volcanic rocks found (after a volcanic eruption) became the prototype of a modern, sought-after material.

The first batch of hard wool was produced in the USA. Modern manufacturers produce cotton wool in furnaces where the temperature is extremely high and reaches 1500 degrees. This heat melts the rocks into artificial “lava” and then transforms them into fibres.

Methods for obtaining fiber:

— blowing;

-centrifugal roller;

-centrifugal-blast;

-centrifugal-spun-blown;

-other.

After obtaining the desired fibers, the binder is introduced in different ways. The mass with a binder applied to it undergoes heat treatment, during which a polycondensation reaction of the binder occurs. The finished product usually contains about three percent organic substances. The final stage of production is cutting, packaging and storage of products.