Stone wool is a type of insulation made from gabbro-basalt rocks, which allows for thermal and sound insulation of various structures or fire protection.

Due to its physical and chemical properties, this type of insulation serves as the main energy-saving technology for finishing facades, roofs, floors and utility networks of both industrial, semi-industrial and domestic facilities.

Which is better polystyrene foam, basalt wool or mineral wool?

| Type of insulation | Advantages | Flaws |

| Expanded polystyrene | + moisture resistance + lightness + low price + good adhesion | – vapor tightness – breaks and crumbles easily – afraid of ultraviolet radiation |

| Basalt wool | + environmental friendliness + low thermal conductivity + fire safety + variety of packaging | - high price – rodents form nests – low moisture resistance |

| Mineral wool | + affordable price + rich assortment + versatility + fire resistance | – poor adhesion – dangerous to human health – caking |

Raw materials[edit | edit code]

One of the main components of raw materials for the production of stone wool are rocks, as a rule, these are igneous rocks of the gabbro-basalt group and metamorphic rocks similar in chemical composition, as well as marls.

Approximate chemical composition of raw materials:

- SiO2 45–65%

- Al2O3 10–20%

- CaO 5–15%

- MgO 5–10%

- Fe2O3 + FeO 5–15%

- Na2O + K2O 1–3%

One of the main indicators of the quality of stone wool fiber is the acidity modulus - the ratio between acidic and basic oxides.

The highest quality stone wool can be obtained from mountain gabbro-basalt rocks, with the introduction of carbonate rock additives to regulate the acidity modulus.

According to the acidity modulus value, stone wool can be classified according to GOST 4640-93 “Mineral wool. Specifications", as follows (3 types):

- A is the acidity modulus of St. 1.6

- B - acidity module St. 1.4 to 1.6

- B - acidity module St. 1.2 to 1.4

Wool with a higher acidity modulus is more water resistant and therefore more durable.

One of the components of stone wool insulation is a binder, which holds the fibers together, thereby providing the products with the specified parameters of shape and density. Types of binder:

- Bitumen binders

- Synthetic binders. As a rule, these are phenol alcohols, phenol-formaldehyde, and urea resins.

- Composite binders (binders consisting of several components).

- Bentonite clays.

Currently, the most common use is a composite synthetic binder consisting of phenol-formaldehyde resins and water-repellent additives, because this type of binder provides the best thermal insulation characteristics. In the finished product, phenol and formaldehyde are less than 2% by weight, the substances are in a coherent state, the binder is inert to the environment.

Line for the production of cellulose insulation

Production consists of several cycles: packaging of raw materials (waste paper is separated from unsuitable types of paper and foreign objects such as files, wrappers, etc.), a fully automatic processing process (primary crushing, mixing, removal of small metal objects using a powerful magnet, such as staples, paper clips). Then an industrial shredder is used to crush it into smaller fragments.

Next, the resulting mass goes into a special container, where an antiseptic and boric acid are added to it. After this, the disperser carries out the final completion of the process - it forms ready-made blocks. The entire cycle described above will take about five to ten minutes, of course, provided that a high-tech and modern installation is used for the production of this type of insulation.

Types of mineral wool

There are only four types produced by factories - slag wool, basalt wool, stone wool and glass wool. Each group has its own distinctive properties, but basalt and stone have the highest quality parameters. The remaining types are budget material.

Slag wool is similar to glass wool and also has serious disadvantages. The material has residual acidity. It easily interacts with metal and oxidizes it. Also, cotton wool quickly absorbs moisture and is not suitable for insulating rooms, metal and plastic pipes. Slag is prickly and very inconvenient to use.

Glass wool is the most popular insulation material. It is elastic and durable. Requires special care during use. Damaged fiberglass is easily inhaled by humans and deposits on the lungs. To work with such cotton wool, you must use protective clothing, goggles, a respirator and gloves.

Rock wool - made from diabase and gabbro. Its properties are similar to slag wool. The material is not scratchy, so it does not cause inconvenience during installation. Stone wool practically does not absorb moisture and is well suited for insulating a room.

Basalt wool is also made from diabase and gabbro. The composition does not include blast furnace slag and other impurities. The material is produced in rolls, which does not in any way affect its structure and quality parameters. The properties of basalt wool are optimal for the use of insulation in many areas. This type of mineral wool is difficult to set on fire. When in contact with fire, its fiber will only melt.

Advantages and disadvantages of stone wool

Having considered the main characteristics of this material, we can draw conclusions about its advantages and disadvantages.

The positive qualities of mineral wool include:

- High thermal insulation ability;

- Good vapor transmission;

- Fire safety;

- Biostability;

- Environmental friendliness;

- Durability;

- Easy to install.

The main disadvantage of basalt wool appears at the installation stage. When working with it, dust is formed, consisting of small particles of stone fibers. They enter the respiratory system, causing coughing and irritation. Eliminating the damage caused by dust is not difficult. To do this, you should use standard personal protective equipment (masks or respirators). Also, negative factors include the considerable cost of the material.

Production line for the production of penoizol

Equipment for the production of insulation includes a wide variety of devices that work with each other. This is a gas-liquid installation, molds that are used to make blocks, a compressor, as well as various containers for storing raw materials. One of the most important components of the production line is the installation that cuts the blocks.

The manufacturing technology of this material is not very expensive. And the purchased equipment for the production of insulation is characterized by a high level of productivity, efficiency, and ease of installation. In addition, the installation is quite compact, which allows it to be installed on a small technical site. The production of penoizol has a high degree of return on investment.

Properties[edit | edit code]

Stone wool is a non-flammable material. Stone wool fibers are able to withstand temperatures without melting at temperatures reaching 870ºC. Stone wool does not burn, but at a temperature of 600-700 degrees it disintegrates, forming hot dust. [ clarify

] Stone wool products have heat and sound insulation properties due to their open porosity. The thermal conductivity coefficient of stone wool is in the range of 0.035 - 0.039 W/m•K. The air enclosed in the pores of wool has low thermal conductivity and is in a static state, which is what determines its excellent thermal insulation qualities. Thanks to the open porosity, stone wool is a vapor-permeable material, the vapor permeability is approximately 0.25 - 0.35 mg/m²•h•Pa .

The density of stone wool can vary widely from approximately 30 kg/m³ to 220 kg/m³, therefore, the physical and mechanical characteristics also differ. Thus, rigid slabs can withstand a distributed load of 70 kPa (700 kg/m²!).

Products can be produced with a coating of aluminum foil, kraft paper, fiberglass, etc.

The positive aspects of stone wool are: environmental friendliness, biological resistance, durability, ease of installation, sufficient vapor transmission, fire safety, good thermal insulation ability.

Equipment selection

Before you begin searching and selecting the equipment you will need, you need to clearly define and formulate the requirements for the selected equipment: minimum time for setup and preparation for work; stable power; performance adjustment; compactness; accuracy of dosing of raw materials and components; light weight; maintainability, easy replacement of worn mechanisms, etc.

Installation rules

Most often, mineral wool is used for external insulation of walls, attic floors and roofs. For thermal insulation of the foundation, foam plastic is better suited - an inexpensive and fairly rigid material that does not allow water to pass through.

Failure to comply with technology is costly!

Stone wool for the facade of a wooden house is installed after treating the walls with an antiseptic, which protects them from rotting. Before insulation, the surface of foam concrete and brick is cleaned of old paint and peeling plaster. The work of installing insulation is best done during the warm season on dry walls.

All window sills and door trims must be removed before installation. Since the thickness of the walls will increase after covering with mineral wool, you will have to buy new elements of window and door cladding.

Dry installation of insulation into the frame

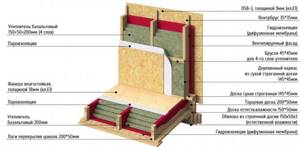

There are two ways to insulate with stone wool: dry and “wet”. The first involves the use of a wooden or steel frame (lathing), in the cells of which insulation is placed. In the second method, the slabs are attached to walls without a frame using glue and disc dowels.

"Wet" installation option

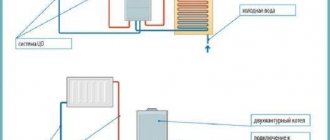

It should be noted that installation in a frame is most often used when constructing a ventilated facade. The lathing allows you to create a gap between the insulation and the outer cladding (4-6 cm), through which water vapor is released into the atmosphere.

The disc dowel is used for both dry and “wet” installation

Mineral wool is placed on glue and dowels in cases where a finishing layer (plaster, putty) will be applied to its surface.

Business registration

When registering a business, it is advisable to choose the form of LLC management with the involvement of capital from investors. If you want to cooperate with large construction companies and sell goods through a retail chain, you must choose a general form of taxation.

The simplified form of tax payment limits cooperation with companies for which the calculation of value added tax is mandatory. For the optimal selection of tax benefits, legal advice is required during the process of registering an enterprise. It is better to generally entrust them with preparing the necessary documentation for submission to the Federal Tax Service.

What is the density of mineral wool influenced by?

The density of the cotton filler is measured in kg/m3. Stone wool density indicators vary from 20 to 220 kg/m3. These numbers indicate the degree of rigidity, the weight of a cubic meter of material, and resistance to vertical loads. Cotton wool with a density of 220 kg/m3 can withstand loads of up to 700 -750 kg per m2.

The lighter the material, the lower its resistance to compression, the better its elasticity, which are necessary qualities for insulating shaped, asymmetrical elements of a building.

Application[edit | edit code]

The use of stone wool as insulation has become widespread since the beginning of the 20th century due to the fact that this natural material (approximately 95% consisting of stone) is non-flammable and durable. Stone wool is mainly used as insulation for building envelopes (facades) , roofs). Thanks to its thermal insulation abilities, the material allows you to prevent heat loss through surfaces during the cold season and keep the room cool during the warm season. Currently, stone wool is widely used in the following structures:

- Walls. In ventilated facade systems, facades with a thin or thick layer of plaster, lightweight external frame structures, three-layer brick walls, reinforced concrete wall panels, metal sandwich panels, element-by-element assembly panels.

- Partitions. Indoors as sound insulation in partitions in office and residential premises.

- Floors. For insulating floors on joists or floor slabs, with the possibility of installing screeds. For sound insulation in floating floor structures.

- Roofs (pitched, flat). It is possible to lay insulation on flat roofs on reinforced concrete slabs or profiled decking with further waterproofing with bituminous materials or PVC membranes.

- Fire protection of steel load-bearing columns and beams, transit air ducts, reinforced concrete floors, pipe and cable penetrations

Insulation of equipment and pipelines. Thanks to its non-flammability and high melting point of fibers, stone wool can be used to insulate surfaces with temperatures up to +700 ºС.

To isolate curved surfaces, cylinders, segments or mats (for large radii) can be used.

What raw materials will need to be purchased?

The production process will require regular purchases of raw materials. To avoid equipment downtime, find wholesale suppliers - analyze prices on the market and choose the appropriate option for your future workshop. The list of components will depend on the range that you plan to offer to customers. Mineral wool comes in several types:

- The shape is mats, slabs rolled into cylinders.

- By density - hard, semi-hard, soft.

- Processing: foil-coated, hydrophobized.

There are also special types of heat insulator - fire-resistant, hydrophobic. Such products, due to improved performance characteristics, are somewhat more expensive. At the same time, the manufacturing process differs insignificantly. The benefit for the entrepreneur is obvious.

Try to expand the range of products offered to the maximum so that each consumer finds “their” material from you.

Raw materials for mineral wool can be divided into groups:

- Stone – dolomite, diabase, limestone, basalt.

- Slag – waste from metallurgical production.

It is believed that insulation based on stone raw materials is much better in terms of quality characteristics. But the specific recipe will be prepared by a technologist. It is unlikely that you will be able to “get” a ready-made composition of the raw material mixture, since each enterprise has its own approaches to production. It will take both time and money to develop the recipe. You will find more customers if you certify your products, which will also require some investment.

General recommendations

When choosing equipment for the production of insulation, you can turn to folk wisdom for help:

1. “Measure seven times and cut once.” Approach your choice thoughtfully and carefully, because it is not easy to make jewelry work with a rough tool.

2. “You can’t even take a fish out of a pond without difficulty.” Even if you purchase an expensive and automatic device, it will not do the job on its own. Much will depend on you.

3. “All that glitters is not gold.” No matter how much the equipment is praised, it will in any case have disadvantages. It is better to find out about them before making a transaction, so as not to bite your elbows later.

4. “The miser pays twice.” Remember that savings must be reasonable. It should not be at odds with quality; the price will be forgotten, but the quality will remain.

5. “Beer in a new bottle is the same beer.” If the characteristics of the presented equipment remain unchanged, and only the appearance has changed, then it is the same “beer”.

6. “Nothing lasts forever under the sun.” The operation of any equipment sooner or later leads to breakdowns. Be prepared for this.

Merge

Stone wool and basalt fiber

Stone wool

— heat and sound insulation, made mainly from the melt of igneous rocks. A type of mineral wool.

The raw materials for the production of stone wool fiber are gabbro-basalt rocks.

Manufacturers and prices

In recent years, a whole “cage” of manufacturers of high-quality stone wool has formed on the market. These are foreign brands Isover (Izover), Rockwool (Rockwool), Paroc (Parok). TechnoNIKOL competes with them on equal terms . Izovol have also earned a good reputation .

The range of products they produce covers all areas of insulation, from the basement to the roof.

For a correct comparison, consider the price for 1 m2 of insulation with a thickness of 10 cm for universal use, offered by different companies:

- Rockwool LIGHT BUTTS SCANDIC (37 kg/m3) 170-190 RUR/m2;

- Isover MASTER OF WARM WALLS (38-48 kg/m3) 160-200 RUR/m2;

- Paroc EXTRA (30-34 kg/m3) from 200/m2;

- TechnoNIKOL ROCKLITE (30-40 kg/m3) from 160/m2;

- Izovol L-35 (35 kg/m3) from 160/m2.

Application in frame housing construction

Basalt slabs are actively used in frame housing construction. This is an excellent non-flammable insulation for walls and other structural elements. The choice of density is determined based on the direct purpose of thermal insulation:

- external wall insulation – slab thickness 100 mm, density – 80 kg/cu.m. m;

- insulation of interior partitions - sufficient material with a thickness of 50 mm and a density of 50 kg/cu. m;

- for ceilings and floors, insulation with a density of 35 kg/cubic meter is suitable;

- thermal insulation of the sloping roof - mineral wool with a density of 40 kg/cu.m. m.

Basalt roll material and slabs serve as a reliable fire barrier, protecting building structures and ventilation ducts.

Useful: Frame garage: step-by-step construction instructions

Stone wool is harmful to health

There are many different myths and speculations around stone wool, including those about its harm to humans. However, scientists have proven that if only high-quality raw materials and approved chemical additives are used in the manufacture of the material, then the harm from such insulation will be minimized. Thus, basalt, from which this thermal insulation is made, is considered an environmentally friendly natural material. Formaldehyde and phenolic resins are used to bind its fibers, but their content is negligible.

Some people confuse glass wool and stone wool, and believe that the dust emitted by the materials is harmful to human health. These are two completely different insulation materials, the first of which is made from broken glass and is truly unsafe, but the second is made from natural basalt rock and its dust does not have such a harmful effect on humans. However, only branded thermal insulation products are considered harmless.

Cellulose insulation

This thermal insulation material is better known in our country as ecowool. This is a fairly effective insulation with low air tightness and thermal conductivity, and high sound absorption. There is no shrinkage or moisture. Consists of 81 percent prepared cellulose and 19 percent natural boron components (borates).

The advantage of this technology is that ordinary newsprint can be used as a raw material. Modern installations for the production of cellulose make it possible to process any type of waste paper, which indicates the economic benefits of the material. As a result, such insulation production in Russia is constantly increasing.

Financial calculations

Start-up capital

To set up mineral wool production, the average initial investment will be 870,000 rubles.

Costs are shown in the table

| Flow type | Amount, rub |

| Paperwork | 30 000 |

| Rent of production premises (200 m²) | 120 000 |

| Repair | 60 000 |

| Purchase of raw materials | 150 000 |

| Equipment | 420 000 |

| 70 000 | |

| other expenses | 20 000 |

| Total | 870 000 |

Monthly expenses

| Flow type | Amount, rub |

| Rent | 120 000 |

| Staff salaries | 150 000 |

| 15 000 | |

| Raw materials | 100 000 |

| other expenses | 10 000 |

| Total | 395 000 |

How much can you earn?

The amount of net profit depends on the volume of goods produced by the enterprise and its sales. For example, the price for one roll of thermal insulation will be at least 1,400 rubles. Customers prefer to make wholesale purchases, so they will purchase the material in batches. In a week, the company will be able to sell 300-350 rolls of insulation worth approximately 490,000 rubles. Taking into account monthly expenses, the net profit will be 95,000 rubles.

Equipment for the production of flax-based insulation

The production line for this type of thermal insulation material is controlled entirely by computer. It consists of a machine, a conveyor, a slicing machine and a comprehensive filtration system. All this equipment is made in the form of the letter L, its long part is thirty meters, and the short part is eighteen.

The line's operating staff is five people, the productivity is eight cubic meters per hour. The equipment forms block mats with a thickness of 40 to 180 mm, size – 1000x625 mm.