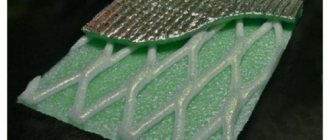

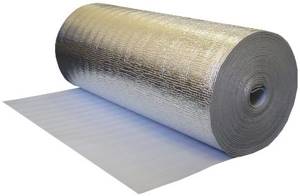

If the insulation of the floor is carried out from the side of the living room, then it is important to take into account not only the effectiveness of the thermal insulation material, but also its thickness. Often in such situations, ceiling insulation with foil insulation is used. The material has many advantages, but the main advantage is maintaining the usable volume of the room. There are many types of foil insulators on sale; we will look at the two most popular types - penofol and isolon. These materials have similarities and differences, as well as common advantages and disadvantages. Knowledge of the technology for installing foil insulation on the ceiling will help you do all the work yourself.

Advantages of foil insulation

Foil insulation qualitatively protects any surface, reflecting heat and preventing it from escaping outside. Its main advantages are:

- increased ability of foil material to reflect up to 95% of heat;

- excellent waterproofing - foil material retains moisture;

- such material does not freeze in winter and does not dry out in summer;

- provides excellent sound insulation - foil contributes to additional absorption of incoming noise;

- is an environmentally friendly material, safe for use in decoration;

- durable if installed correctly;

- An excellent solution against moisture accumulation on the ceiling.

Insulating the ceiling with foil insulation, in particular penofol , is gaining popularity every year for various reasons.

Interestingly, this material is a new ultra-thin polymer insulation , which is produced by foaming.

In this case, it is polyethylene foam welded to reflective aluminum foil. Foil insulation is excellent - and, contrary to popular belief, for this purpose you can use not only penofol or foil-isolon , but also basalt wool or polystyrene foam with metallized foil .

Useful video

Let's look at the video about the types of foil insulation:

Thus, for internal insulation of the ceiling it is best to use foil insulation. The unique characteristics of this product, elasticity and lightness ensure its demand in the market.

Polyethylene foil insulation has gained such wide popularity that the name of the famous brand – “Penofol” – has become a household name. But often homeowners and would-be craftsmen use the material thoughtlessly, violating the thermal and humidity conditions of the country house. Sellers are also cunning, greatly exaggerating the real performance of this heat insulator. Let’s clarify the situation: we’ll tell you where Penofol insulation is effectively used and describe the technology in detail according to the manufacturer’s instructions.

Ceiling insulation with isolon

Izolon is a brand under which polymer materials with a closed-cell structure for insulation, sound and noise insulation are produced. There are several product lines:

- adhesive tapes;

- Izolon 100 – non-cross-linked polyethylene foam;

- Izolon 300 – foamed chemically cross-linked polyethylene;

- Isolon 500 – physically cross-linked polyolefin foam;

- reflective insulation – foamed foil polyethylene (metalized lavsan film).

- the density of the material is 25-100 kg/m3;

- does not allow water and steam to pass through;

- has low thermal conductivity;

- foil material reflects 97% of infrared radiation.

Thermal insulation with isolon as an independent insulation gives insignificant results due to its small thickness.

In this case, in addition to auxiliary protection of heat loss, foamed polyethylene will serve as a vapor barrier . Glass wool laid on the ceiling is prone to absorbing moisture from the air, which makes insulation with isolon not so much desirable as necessary.

- mineral wool is laid between the ceiling joists;

- Izolon is fastened tensioned along the joists;

- the crown grille is stuffed;

- The final stage is laying the finishing touches.

It is permissible to lay isolon as a sound insulator directly under the finishing. To do this, the material is fixed joint to joint on the working surface using a construction stapler, and the joints are sealed with tape.

Even if there is moisture on the insulator, it will successfully evaporate without being absorbed into the finishing materials.

Scope of application

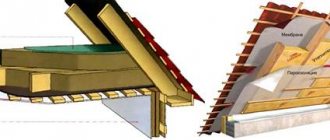

With the help of Penofol, you can significantly increase the energy efficiency of any home - a private house or apartment. Where the material is used:

- thermal insulation of the roof of an attic or cold attic;

- covering ceilings and walls from the inside - as an addition to the “pie” of basic insulation;

- under the finished floor covering laid along the joists;

- strengthening the outer thermal insulation layer;

- internal insulation of balconies and loggias;

- coating of heating pipes and ventilation ducts.

Addition. Many drivers use “penofol” type C (adhesive surface) to insulate the car body – interior floors, doors and roof. The cut blanks are glued to the metal on top of the bitumen vibration insulation.

It is not advisable to use the material as an independent insulation of external fences - you will not achieve the desired effect, only protect the building from wind blowing. An exception is products of large thickness from 20 to 150 mm of the Tepofol brand, suitable for complete insulation of a house.

Folgoizolon - foil insulation for the ceiling

Folgoizolon is a fairly new insulation on the market, providing high-quality heat, moisture and noise insulation. The basis of the material is polypropylene or foamed polyethylene. Based on this, two types of products are distinguished, designated PPE and NPE.

- lightness of the material , which makes it possible to finish any base, provided there is no need for preliminary measures to strengthen it;

- small thickness - does not reduce the dimensions of the room, maintaining its usable area;

- elasticity - unlike some insulation materials (such as polystyrene foam boards), this foil material allows you to avoid spending time on careful preliminary leveling;

- multifunctionality , or a “3 in 1” combination, contributes to a significant reduction in the costs of purchased materials (mastics, films, fasteners, etc.) and a reduction in construction or repair time;

- ease of cutting - foil isolon can be easily cut with a sharp knife, which eliminates the need to use specialized tools;

- the absence of moisture absorption is one of the most important factors that ensures the extension of the service life of not only the foil-isolon itself, but also the structural elements it covers;

- environmental safety - does not emit harmful substances even at temperatures above 100ºС. Among other things, this material will never harbor insects or rodents.

So, is it possible to insulate the ceiling with foil insulation? Taking into account the material above, we can safely give a positive answer.

Finally, about other use cases

Home craftsmen use insulation made from foamed polyethylene for a wide variety of purposes:

- protection of heating and hot water pipes from freezing;

- interior decoration of entrance door leaves;

- reflective screen glued to the outer wall behind the heating radiators;

- inexpensive thermal insulation of outbuildings - sheds, workshops, garages;

- exotic – shoe insoles made of 3 mm thin sheet insulation.

Polymer insulator "Penofol" is a material that deserves attention. If applied according to the instructions, it will serve as a good insulator. But do not try to save money and solve all thermal insulation problems using thin polyethylene alone; use other effective insulation materials.

Today we will tell you on what principle reflective insulation works and which side to lay the insulation with foil. These two aspects simply cannot be separated, because if installed incorrectly, foil insulation simply does not work. In addition, we will tell you about the most important aspects of installation and their impact on heat loss and the microclimate in the room. And naturally, we will conduct our educational program separately for each type of insulation with foil. These include polystyrene foam in sheets, mineral wool in sheets and rolls, foamed polyethylene in rolls, as well as shells for insulating pipes made of polystyrene foam and mineral wool.

Ceiling insulation with foil-isolon

Sheets of foil-isolon should be spread over the surface of the ceiling so that the foil “looks” into the room. After this, the insulation must be pressed with a clamp strip. The foil layer serves to reflect thermal radiation, which can be used as an additional advantage if foil isolon is used together with penoplex or polystyrene foam. In this case, the foil material will act as a vapor barrier.

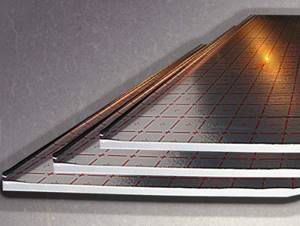

How to properly lay polystyrene foam with foil

Expanded polystyrene mats for floor insulation and subsequent installation of a low-temperature “warm floor” system.

It is necessary to consider which side to lay the insulation with foam foil in the narrow direction of installation of low-temperature heating systems, that is, heated floors. Now you can find on sale special foam mats (sheets), which are covered with foil on one side. In addition, markings are applied to the foil for laying polymer pipes or electrical cables. As you know, heat sources when installing heated floors must be at a certain distance from each other for the system to work correctly.

In this case, the most important role is played by insulation with foil; how to fix it correctly is a key point. The essence of reflective insulation is to reflect infrared rays, that is, heat. Like a mirror, it reflects up to 97% of all IR radiation. Naturally, the reflected rays must return back into the room, so the logical conclusion on how to lay foil insulation suggests itself. Of course, with the reflective surface inward.

Methodology for laying insulation with foil for heated floors:

- the subfloor is leveled;

- foam boards with foil are glued with construction adhesive;

- Cable or pipes are laid according to the markings;

- everything is filled with screed with reinforcing mesh.

Another important point is how to correctly lay insulation with foil: the slabs must fit snugly to the floor. It happens that due to the unevenness of the mats themselves, they lie unevenly on the floor, even if it is perfectly flat. To correct the situation in places where the thermal insulation does not fit tightly, it is simply cut. That is, several smaller ones are made from one sheet, and the operation is carried out locally, after the mats are laid.

Considering the principle by which foil insulation works, figuring out which side to put is as easy as shelling pears. Reflective insulation should reflect IR radiation into the room; accordingly, it is placed with the shiny side in the middle.

Such slabs are used only for floor insulation; they are not used for walls and ceilings, since there are thermal insulation options specifically designed for this. These include:

- mineral wool in mats and rolls with one-sided or double-sided foil;

- foamed polyethylene with foil.

By the way, ordinary foam plastic or its extruded analogue in tandem with penofol perfectly replaces mats for insulating floors and further laying a low-temperature heated floor system. The only inconvenience is the lack of markings.

If you are going to build a private house, then water heating will be the best option for heating it. There are, of course, air, steam and electric heating, but they cannot compete with a liquid coolant circuit.

The two-pipe water heating scheme for a two-story house can be vertical and horizontal. Drawings with explanations here.

Types of foil insulation

Nowadays, there are several types of this material. They differ from each other not only in the density of the top layer, but also in the type of heat insulator.

The main types of foil-based insulation:

- Polyethylene foam (isolon, penofol, folgoizol) . This type is produced in rolls. The material is distinguished by its low price. Foamed polyethylene is used to create insulation. It can be either stitched or unstitched. The thickness of the canvas ranges from 3-10 mm. A distinctive feature is the presence of a self-adhesive surface. Some types of foil polyethylene foam have a reinforced layer, which is made from fiberglass mesh. As for the foil layer, it can be on one or both sides.

- Mineral wool . The material is distinguished by high levels of moisture resistance. Foil-coated mineral wool is sold not only in rolls, but also in the form of slabs. Basalt is often used for its production. Thanks to it, the service life of the canvas increases significantly. The material is used everywhere. This is due to good thermal conductivity and fire safety.

- Styrofoam . This foil insulation is intended for the “warm floor” system. Its density ranges from 30-50 kg/m. Available in the form of rolls 50 cm wide. The thickness of the canvas ranges from 3-5 mm.

Foil foam with markings

Important! Any type of material acts as an excellent sound insulator.

When used correctly, each type of foil insulation will perform its functions to the maximum. To get what you want, you just need to follow simple rules.

What is Penofol and its analogues

Thin polymer insulation is made from the following materials:

- The main insulating layer is foamed polyethylene 3...10 mm thick with closed air pores. The thermal conductivity coefficient λ of this layer lies in the range of 0.037–0.051 W/(m • °C) depending on operating conditions.

- The outer reflective layer is aluminum foil 14 microns thick, securely glued to a polymer base.

- The third layer on the back side of the polyethylene can be glue for ease of installation or the same aluminum.

Reference. All given characteristics are taken from the official website of the manufacturer. Thermal insulation parameters of other brands may vary. For example, the thickness of a similar material reaches 150 mm.

A special feature of the material is its impermeability to moisture, the declared indicator is simply scanty - 0.001 mg/m • h • Pa. The insulation is quite light - the density ranges from 16...35 kg/m³, and is sold in rolls. Thanks to these parameters, the material serves well as an internal vapor barrier.

"Penofol" is available in 3 versions:

- double layer type A;

- three-layer – the base is coated with aluminum on both sides (type B);

- the same, with an adhesive layer - Type C.

The foil side works as a reflector of the radiant (infrared) component, polyethylene foam resists direct heat transfer. For exterior wall cladding, a perforated version of Penofol, shown in the photo, is offered. Many small holes are designed to allow water vapor to escape from the thickness of building structures.

External wall cladding is made with special insulation with perforation

Features of using foil insulation

The reflective properties of foil help retain heat inside the building. To do this, the sheets are mounted with the foil surface facing the room. To get maximum results, the canvases need to be attached end-to-end.

Also, to increase characteristics you should:

- Tape the seams. To do this, use a special metallized type of tape.

- Create an air cushion. It is formed on both sides of the laid material. A sheathing is first made, on which the canvas will later be attached.

Important! It is strictly forbidden to install this material overlapping. Such fastening reduces its thermal insulation ability. There is also a high probability of the resulting condensation draining into the room.

Each type of material has its own installation characteristics. As for polyethylene foam, its installation is the simplest. The canvases are secured using construction staples. Since such insulation with foil is the thinnest, when laying it you can allow overlap within 10 centimeters. Ventilation gaps should be left on both sides. Their optimal size should be 1 to 2 centimeters.

Before installing foil insulation on the ceiling and walls, you need to pay special attention to insulating the wiring. For this you can use both corrugated pipes and plastic channels.

As for laying insulation based on mineral wool, the sheets should be fixed as tightly as possible. Compliance with this rule will avoid the formation of bridges. It is not worth using force in such work, since the rather fragile sheets can be deformed.

Technologies

Since the materials have different structures and shapes, the methods of their installation differ.

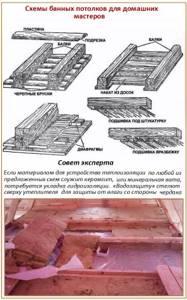

Method one: insulation from above (from the attic)

The ceiling insulation installed from the attic side can be absolutely anything, because this material does not have to be fixed. It is only necessary to cover the plane as tightly as possible so that there are no cracks or gaps left. This mainly applies to bulk materials.

In this case, the question: “What is the best way to insulate the ceiling?” is not particularly relevant. This may well be a type of insulation that has a lower price. And which will have the required level of thermal insulation. Basically, mineral wool or expanded clay is used as insulation on the attic side.

Another way

To install ceiling insulation from the bottom side, you need either a special hanging-type frame or fastenings. After all, you will have to attach the material to the ceiling, as they say, by weight. The simplest way may be to fill the space between the main ceiling and the suspended ceiling with insulation.

In this case, no matter what kind of heat insulator is used, it is pushed through the hangers of the ceiling frame, after which the profiles (made of metal or wood) are installed in place. True, this method is good only when it is possible to lower the suspended ceiling so much that material can be mounted in the resulting space.

We use polyethylene foam

A material such as foil polyethylene foam can be used as insulation on almost any type of ceiling. After all, it can be secured with double-sided tape, and then, right through it, the hangers and frame can be strengthened.

- In addition, materials can be laid in the spaces inside the frame, between metal (wooden) profiles.

- However, when laying rigid products, such as polystyrene foam or extruded polystyrene foam, there may be gaps that are best filled with foam.

- By the way, for insulation, especially if it is an attic floor or attic ceiling, you can also use foam materials.

- They are not as popular in comparison with the materials mentioned above, as much because of the price as because you cannot do without the appropriate equipment, and you cannot do such work with your own hands.

The thickness of the material is selected based on its type and operating conditions of the room. Instructions for installing heat insulators of any type, as well as a video, can easily be found on the Internet. After watching the video, it will be easier for you to cope with the task and decide which material is best to use in this particular case.

Advantages of foil insulation

An important advantage of such insulation is the foam base. Thanks to it, a layer of air is securely retained, which has minimal thermal conductivity. This is what allows maximum retention of warm air inside the room.

It is not necessary to level the surface before using insulation

Other advantages that insulation has:

- The material is not flammable. This makes it possible to safely use it indoors in any room. Including residential ones.

- High sound insulation rate. Foil insulation is often used as additional protection against noise penetration into the room.

- Lightweight and thin. These characteristics allow the installation of canvases in conditions where other types of insulation cannot be installed.

- The structure of the material allows moisture and steam to pass through. Thanks to these indicators, there is no need to use additional moisture insulation around the insulation.

- Good elasticity. Most types of foil insulation have a similar indicator. This saves time on leveling the surface.

- Environmentally friendly. All types of foil-based insulation are absolutely safe for human life. The fabrics are not able to emit harmful fumes during the entire period of operation.

- Relative ease of installation. To attach material, it is not necessary to have special skills or involve specialists. You can do this kind of work yourself. To carry out installation, it is enough to prepare a minimum set of tools (stapler, scissors, stationery knife, tape measure, pencil).

Which side to attach polyethylene foam with foil

When the question arises about how to attach foil insulation to a wall, most often we are talking about penofol. This is insulation that consists of two layers. The first layer is polyethylene foam, and the second layer is foil. In addition, there are products in which the foil is on both sides. The reflective surface can be glossy, like a mirror, or crumpled (embossed). It is believed that the relief allows you to slightly increase the reflection area, but not critically, so there is not much difference.

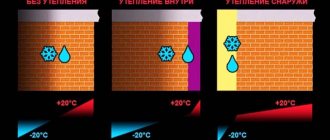

Unlike mats for floor insulation, regarding penofol, the answer to the question: “Which side should we attach the insulation with foil?” sounds like this: with a base (foamed polyethylene) to a wall or other insulation.

The thing is that this material is used for both internal and external insulation. It turns out that during thermal insulation of the facade, it will not be possible to put penofol with the shiny side inward; it will look outward. What will this give us:

- Such insulation will not reflect heat from the room, since there is no ventilation gap between the foil and polyethylene;

- the insulation will not let summer heat into the house.

Two-layer reflective insulation, where polyethylene foam acts as a damper and reinforcement.

It is precisely because of the absence of any significant shifts towards increasing the thermal insulation qualities of the room that experts do not use penofol for external insulation. How to properly lay foil penofol insulation:

- should be placed from inside the room with the shiny side facing the heat source;

- there must be an air buffer zone (ventilated gap) between the foil and the finish;

- the material is laid end-to-end;

- secured either with nails or staples;

- The joints are glued with aluminum (not ordinary, but aluminum) tape.

These manipulations are performed in order to create a sealed reflective screen, which additionally acts as a vapor barrier, since it does not allow steam or moisture to pass through. Why, when answering the question of how to properly lay insulation with foil, do we focus on the ventilation gap? The fact is that without it the material will not perform its functions. The air space allows the foil to repel IR radiation from structures in front (plasterboard, lining, siding, whatever).

If there is no air gap, then heat will be transferred to the foil not through IR rays, but through direct contact of the materials. Aluminum's thermal conductivity is exceptionally high, so the process of transferring heat outside the room will even speed up in this case. A thin layer of foamed polyethylene does not create a special barrier to heat loss, and its main function is different: it acts as a damper and reinforcement for the foil, everything else is indirect.

This will cause an undesirable side effect – condensation. The foil does not allow steam to pass through, and it settles on it in the form of condensation. If there is a ventilation gap, then micro droplets of moisture simply evaporate. In the absence of a buffer air zone, moisture collects and is absorbed into the finish, causing fungus to appear. This is what can lead to not knowing which side to put insulation with foil on.

Despite the fact that there is plenty of information about heating a house from sip panels, many can still decide on the method of heating a house made from this material. Although there are quite a lot of approaches that have a lot of advantages and benefits.

You can find all the necessary information about convector heating at home with photos and video files on our website by following this link.

Procedure and rules for insulating premises with penofol

To insulate rooms internally using such material, the first thing you need to do is install a layer of the same foam foam with the minimum possible thickness. It is secured using wooden slats. If installed correctly, you will get a sheathing that will act as the basis for fixing the main layer of insulation.

Canvases applied later can be secured in the same way or using a construction stapler.

This method will provide better thermal insulation to the room. This will be achieved not only thanks to the double layer of insulation, but also due to the air cushion that appears. It will also allow air to circulate freely, preventing the accumulation of moisture and condensation.

Lathing for attaching the second layer of insulation

Advice! To increase the energy efficiency of the insulated ceilings of a house, you can use penofol with other types of insulation.

Method of installing penofol with other materials:

- Mineral wool. Initially, you need to assemble the sheathing, as for a plasterboard structure. Cotton wool is placed between the guides. Penofol is attached on top of the frame and fixed to the supporting profile using self-tapping screws. The canvas should be laid with the foil side in the room. The material is laid end-to-end and glued with metal-containing tape. The structure is sheathed on top with sheets of plasterboard or other type of material.

- Mineral wool and double layer of penofol. In this way, the insulation effect can be improved and sound insulation can be increased. In this case, on top of the first layer of foam material, the second is laid with foil to the top. So the insulation also acts as a vapor barrier for mineral wool.

- Penofol and penoplex. A similar design is often used to insulate partitions between floors. At the initial stages, extruded polystyrene foam in sheets is glued to the ceiling. The size is chosen based on the parameters of the room. Fastening is done using dowels. During the work, you must try to build the structure in such a way that you end up with the most even horizontal surface possible.

Laying penofol on mineral wool

Penofol is placed on top of the penoplex. The seams are insulated with special tape. Wooden slats are installed on top of the foil. To fix them, use 15 mm dowels. Next, PVC panels or plasterboard sheets are placed. You can also use plastic elements and wooden lining.

Penofol is also used to add sound insulation to the room. In this case, before installing the sheathing, material must be laid under the ceiling slab so that the aluminum film touches the surface. Often this need arises in apartment buildings where neighbors live above, and a thin partition does not eliminate loud extraneous sounds.

If you decide to use penofol, then to improve the insulating characteristics it will be enough to select a fabric with maximum thickness. Better yet, use a material with a double layer of foil. This will allow for excellent insulation of the ceiling of buildings, if the temperature outside the room does not drop to too low a level. Otherwise, it is worth using a combined version of penofol insulation with other types of thermal insulation materials.

Ceiling insulation with penofol is one of the modern generation materials designed to reduce heat loss. The insulation has highly effective properties when exposed to outside temperatures in the range of 0°C. If work is carried out in a region with negative temperatures, an auxiliary heat insulator must be added to the penofol.

How is thermal insulation performed with isolon?

Insulation of the floor in a house made of timber can be done in three ways. Below we will look at each option separately.

First way

Extruded polystyrene foam slabs are laid on the leveled ground, and the seams between the sheets are foamed with polyurethane foam.

A concrete screed is placed on top of the insulation. It is necessary that the concrete base is level, without cracks or other defects. If there are cracks, they must be filled with putty and then sanded.

After cleaning the surface from dust, rolls of isolon are placed on it (the protective film must first be removed from the material), which are fixed to the floor with glue or dowels. The sheets are glued together with foil tape.

Second way

The pre-leveled soil is covered with a waterproof membrane, then mineral wool slabs are placed on it. A waterproofing film is also laid on top. The lower hydromembrane protects the insulation from moisture coming from the ground, and the upper one does not allow it to enter the room.

Distinctive characteristics of ceiling insulation work with penofol

Penofol is a material made from synthetic products and has several layers. The insulation is based on polyethylene foam, which, due to its characteristics, is considered an unusual heat insulator. So, on the outside it is covered with aluminum foil 10 microns thick. The main function is to reflect heat in the direction where it is needed. It is noteworthy that the mirror-shaped surface retains up to 97% of heat.

Penfol is also divided into several groups of modifications, distinguished by a metallized shell on one or both sides, as well as the presence of an adhesive layer.

Penofol insulation has unique characteristics that prevent heat loss through convection, conduction and infrared radiation. At the same time, other types of modifications do not have such a degree of protective properties. It is noteworthy that penofol has the ability to replace several other types of heat insulator at once, or one, but with greater thickness.

Please note: the average thickness of penofol is from 2 to 10 mm. There are also more massive models on the market, but experts note that installation is inconvenient.

This insulation is used in everyday life and production as both a primary heat insulator and an additional one. In addition to the main functionality, it also solves the problem of vapor barrier. Because of this, it is used in hammam, bathhouse, sauna and steam rooms.

Real thermal insulation characteristics

At the beginning of the publication, we mentioned the overestimation of the performance parameters of the material by unscrupulous sellers. Common myths about the properties of an insulator look like this:

- Innovative insulation "Penofol" has the best thermal insulation characteristics. The thermal resistance R of a 4 mm thick sheet reaches 1.2 m² • °C/W, which is comparable to 0.67 meter red brick masonry or 46 mm polystyrene foam.

- The Penofol layer serves as excellent sound insulation.

- The insulation can be freely filled with cement-sand screed, turning the foil up.

Material with an adhesive layer on the back side (type C)

Reference. The manufacturer claims: for the most effective operation, the heat insulator must be placed inside a closed air gap. When installed close to other materials, the aluminum coating will not perform its function of reflecting radiant heat. Infrared waves can penetrate open space, but not thick concrete.

The heat transfer resistance of one insulating layer can be easily calculated using the classic formula from the building thermal physics course:

- R – the value of the thermal resistance of the material, m² • °C/W;

- δ – insulation thickness, m;

- λ – coefficient of specific thermal conductivity, W/(m • °C).

Substituting the manufacturer's data into the formula (we take the optimal option), we get R = 0.004 mm / 0.037 W/(m • °C) ≈ 0.11 m² • °C/W. Knowing the thermal conductivity of the foam (λ = 0.043), it is easy to determine the appropriate layer thickness: 0.11 x 0.043 = 0.0047 m = 4.7 mm. Roughly speaking, 5 mm of polystyrene foam and 4 mm of polyethylene foam will retain the same amount of heat; there is no talk of 46 mm.

Pros and cons of ceiling insulation

Penofol for the ceiling today is a popular material due to its versatility and easy installation. In addition, construction specialists value insulation for such parameters as:

- Light in weight, due to which the material can be worked at any height.

- To fix the insulation, no additional tools or devices are required.

- The coating is not water- and vapor-proof, incl. not subject to destruction under the influence of precipitation.

- Insulation performs several functions. So, when fixed to the ceiling, it prevents heat loss and absorbs noise. Often used in conjunction with other insulators to improve properties.

- When exposed to high temperatures, it does not release toxins. In the manufacturing process of the material, polyethylene and foil are used, which are used in food production.

- After installing the heat insulator, there is no significant loss of usable area. Because of this, penofol is often used in rooms with low ceilings.

- The material is sold in roll form, which makes the work much easier.

- The products are not subject to combustion and are resistant to rodents.

As for the disadvantages of insulation, there are few of them. Thus, these include a high price tag and the need to use secondary heat insulators to improve the properties of the first one. The second significant disadvantage is the use of glue as fasteners, which also increases the financial burden. Third, the material has a soft structure, so it cannot be used in rooms where you plan to wallpaper the ceiling.

Characteristics and advantages of isolon

The material has the following properties:

- High reflectivity. Thanks to this, heat loss in the room is significantly reduced.

- Moisture-proof. The insulation does not absorb moisture at all, which ensures its long-term operation without loss of heat-insulating properties. This characteristic is especially important when laying in wooden houses.

- It has a small thickness - from 2 to 15 mm, and does not bear additional load on the structural elements of the log house. Excellent for floor insulation in rooms with low ceilings, saving usable room space. Despite its small thickness, its thermal insulation qualities are comparable to those of a brick wall.

- Environmental Safety. The material does not contain or emit harmful components, making it completely harmless to humans and can be used in any room.

- It has a long service life and retains its properties at temperatures from -80 to +120 degrees.

- Resistant to biological factors, not subject to decomposition and rotting.

- Has good soundproofing characteristics.

The material is produced in the form of rolls or sheets of standard sizes.

For those who are interested in whether it is possible to insulate a floor with isolon, you need to give a definite answer: “Yes,” since the material combines perfectly with wood and is the best choice for thermal insulation of floors in houses made of logs and timber. Izolon is also excellent for insulating ceilings, walls and other structural elements from inside the house.

Technology for installing penofol to the ceiling with glue

The use of an adhesive solution reduces the installation work of penofol to the ceiling from inside the room. This method does not require specific fasteners and is easy to use. Due to the fact that the material is light in weight, there is no need to calculate the volume of glue. If you plan to use penofol as the only insulation, it is recommended to choose a product with sufficient thickness.

- Cleaning the ceiling surface from old plaster and coating. A flat surface should be achieved and, if necessary, treated with sandpaper and plaster.

- Pathogenic microorganisms should be scraped off with a spatula. Then the treated area is doused with a hot stream of air and treated with antiseptic solutions.

- If there are stains of grease and oil, wipe with a solvent.

- Cracks, chips and gaps in the ceiling are sealed with a mortar of cement and sand.

- If the ceiling is made of wood and there are gaps, then they are filled with caulking; large cracks are eliminated with tow and PVC film.

- Wooden elements are coated with protective anti-flammable and anti-rotting agents. Each new layer is applied after the previous one has dried 100%.

- All sharp protruding elements that could damage the integrity of the foil are eliminated.

- Next, the ceiling is treated with a primer that is suitable in composition for the adhesive for fixing penofol. This stage is mandatory, because allows you to improve the quality of adhesion to the surface.

- Preparation of glue. If you choose a material with a sticky base, then it is enough to remove the protective film and then carefully attach the penofol to the ceiling.

- If a regular material is chosen, then a thin layer of adhesive solution is applied to its surface. At the same time, the work is carried out evenly, without gaps. Carefully coat the edges and leave for 1 minute.

- Then, the foam sheet is pressed against the ceiling or the first layer of insulation. Gently smooth out until it sticks. The joints are fixed with reinforced tape or sealant with a silicone base. Joints must not be left untreated.

During installation, you must ensure that the canvas ends in the corner of the room. It is prohibited to install the material overlapping. Additionally, you should monitor the contact points between the wiring and the foil. This is due to the fact that foil is an excellent conductor of current. In view of this, you should make sure that the wires close to the insulation are insulated.

Finally, decorative work is carried out. For example, this could be the installation of a suspended ceiling structure.

User reviews about Penofol

It must be admitted that on popular forums there are quite a variety of responses and opinions of homeowners about reflective polyethylene insulation. We would venture to assume that the negative or positive in the comments depends on the correct use of the material.

Let's give a few examples, discarding obviously purchased reviews:

Vyacheslav, Donetsk, Ukraine.

Recently, for the purpose of repairs, I had to open the plasterboard lining of the wall inside the room. Behind it was foil-coated Penofol covering a plastered cinder block wall. There was dampness and black mold under the insulation; all the sheathing had to be dismantled and the walls dried.

Ivan, Veliky Ustyug, Russian Federation.

I lined a cold veranda made of plank with 5 mm Penofol. I stapled it to the walls and ceilings, laying down sheets of chipboard. This winter I calmly opened the door to the veranda, without fear of freezing the house; the temperature outside was minus 40 degrees. Sometimes he heated the extension with a potbelly stove to dry the walls.

Natalia, Lipetsk, Russian Federation

No matter how they insulated the northern wall of my private house, it was impossible to get rid of the mold. We tried cotton wool, polystyrene foam, all kinds of waterproofing. My father-in-law, a builder, came to visit, remodeled everything and covered it with this shiny material. The result after opening (a year later) is that the wall is dry.

While looking for video material to publish, we came across an interesting point that confirmed our assumptions. Installers are well aware of the recommended methods of using Penofol, but in practice the technology is constantly being violated. The reason is clear: installing double lathing for the sake of a thin layer of insulation is not economically feasible. It would be better to install full-fledged thermal insulation from basalt wool or Penoplex on the subsystem without any frame.

Review of vapor barrier materials ↑

In search of an answer to the question: what vapor barrier to choose for the walls and ceiling of a bathhouse, it is necessary to study the properties of all available materials. They can be divided into the following groups:

- various films;

- membrane materials such as isospan;

- kraft paper;

- insulation with vapor barrier properties;

- coating vapor barrier.

Ordinary polyethylene film ↑

This is the cheapest material. The good thing about the film is that it is sold in sheets ranging from 3 to 6 meters wide. Thanks to this, it is possible to cover the walls and ceiling with a minimum of seams. In a six-meter sheet, the film is sold folded in half, that is, the actual width is three meters. In this folded form, it can be mounted on walls to create a double layer.

However, the film is short-lived. After a few years, it will begin to deteriorate under the influence of high temperatures. Therefore, in modern construction it is used less and less. If you still decide to cover the bathhouse with film, choose the thickest sheet - at least 100 microns thick.

Construction cardboard or kraft paper ↑

In rooms where there is no high humidity, it is quite acceptable to use thick construction cardboard, the so-called kraft paper. In its pure form it is now rarely used; modifications with foil or lavsan coating are more popular.

Plain and foil kraft paper without a polyethylene layer absolutely do not tolerate contact with water, so they are used only for covering a dressing room or rest room. Kraft paper with a lavsan coating or a polyethylene layer is a more durable material, suitable for both dry saunas and steam rooms.

On sale you can find the following vapor barrier for a bathhouse based on kraft paper:

- Izospan FB - cardboard with lavsan coating;

- Megaflex KF - similar material from another manufacturer;

- Alurcraft, Izolar - three-layer vapor barrier consisting of kraft paper, polyethylene film and foil;

- Rufizol S is a foil vapor barrier based on kraft paper.

Foamed polyethylene isolon ↑

This material is widely used for vapor barrier of baths and saunas. In addition to hydro- and vapor barrier properties, it has a warming effect. It is a flexible fabric made of foamed polyethylene.

The most popular is isolon with foil coating. It withstands extreme steam room temperatures well, does not allow moisture to pass through, and retains heat. The thicker the foam layer, the more pronounced the insulating properties. For baths, it is advisable to use foil-coated isolon with a thickness of at least 3 mm.

Foil-coated mineral wool ↑

When deciding which foil is best to choose for a bath, you should take a closer look at such a universal material as foiled mineral wool. This is a modern vapor barrier with excellent insulating properties.

Essentially, it is insulation covered with a heat-reflecting, moisture-resistant layer. This foil vapor barrier is ideal for insulating a bathhouse. It is mounted on the ceiling and walls with the heat-insulating layer on the inside and the foil on the outside.

To cover a bathhouse, you should choose a coating with a thickness of at least 50 mm. Foil-coated mineral wool is sold in rolls. In construction stores you can find mineral wool from the following manufacturers:

- Rockwool Lamella MAT - natural foiled stone wool with a fiber arrangement perpendicular to the coating, which ensures the strength and flexibility of the material;

- Knauf Insulation LMF Alur is a foiled mineral wool that can withstand temperatures up to 600 degrees, but the temperature of the air in contact with the foil should not exceed 100 degrees;

- Isover (Izover) Sauna - a covering made of glass wool and foil, created specifically for baths and saunas;

- URSA M-11 F is another coating designed for insulation and vapor barrier of wet rooms.

Vapor barrier coating “Izospan” ↑

"Izospan" is one of the modern materials. The product line is represented by a wide variety of coatings. However, they all have one thing in common - they are polypropylene films of different thicknesses and strengths, designed to protect against moisture.

Izospan vapor barrier, which can be used on the ceiling and walls of a bathhouse, does not allow not only steam to pass through, but also water. Therefore, steam rooms and shower rooms can be sheathed with materials from this company.

The following brands are best suited for cladding bath rooms:

- foiled "Izospan FS" - polypropylene membrane with a metal coating. Absolutely steam and waterproof. Reflects up to 90% of heat, which contributes to energy saving;

- foil “Izospan FX” on a foam base. A universal product with which you can not only protect walls from moisture, but also insulate them;

- metallized “Izospan FB” with a kraft paper base, it is preferable to use it for the ceiling of a bathhouse. Like other foil products, it reflects most of the thermal energy, keeping it indoors.

How to lay insulation with foil for pipes

Shells for insulating communications are made of polystyrene foam and mineral wool.

In addition to thermal insulation for floors, horizontal ceilings and walls, there is also insulation with a reflective layer for pipe insulation. These are shells that are made of polystyrene foam or mineral wool. The former are lighter and are not afraid of moisture, while the latter can withstand high temperatures, which is appropriate when insulating chimney pipes. Considering the fact that the material is already produced in the form of a pipe, the question of whether to put the insulation with foil on the outside or inside is not worth it. There is a shell that you put on the pipe and that’s it, you can’t turn it inside out.

At the same time, there is always a choice when purchasing, since they are also produced with one (outer) or two (outer and inner) layers of foil. Such shells are used for:

- laying pipelines by air;

- laying highways underground;

- laying pipelines in unheated rooms;

- insulation of chimneys.

In some cases, they are used to insulate pipes so that the coolant does not lose its temperature even in heated rooms. For example, in industries where the first and last heat exchanger of one circulation ring are installed at a great distance from each other.

Principles of thermal insulation of bath ceilings

Based on the design features of the roof, bathhouses made of logs or timber can be divided into two types: buildings with and without attic space. In the path of warm air flowing out of bathhouses with attics, there will be a much more powerful ceiling, into the layer cake of which thermal insulation material is usually laid during the construction process.

The under-roof space itself, filled with an air mass, also inhibits the leakage of thermal energy, and the insulation of the roof structure also slightly moderates the agility of the “escaping” heat.

However, this does not mean that insulation of the ceiling in a bathhouse with an attic or attic is not necessary. Increasing the thermal insulation characteristics in it is no less necessary than in a building without an attic, where the heat leaking out encounters few and too weak barriers in its path.

Specifics of the vapor barrier device

In both cases, regardless of the roof structure, a vapor barrier is laid on the bathhouse ceiling before laying the heat-insulating layer. To equip a building without an attic space, you can use aluminum foil, compacted cardboard, generously impregnated with drying oil, or wax paper as a vapor barrier layer.

In bathhouses with an attic, the same materials are used, but most often the ceiling boards on the roof side are coated with a two-centimeter layer of clay.

Of the options offered by the industry, the following are used:

- standard polyethylene film (as for greenhouses 0.4 mm with variations) - a type of vapor barrier that is not very popular due to the greenhouse effect;

Note. The use of polyethylene film as insulation requires leaving a gap necessary for condensation to evaporate.

- a special vapor barrier film made of polyethylene with fibers to retain condensation;

- membrane type vapor barrier material.

Vapor barrier is necessary to prevent the transit of wet vapors and their settling in the insulation. After all, water accumulated in the thermal insulation material will shorten its service life, increase the weight of the multilayer ceiling system and, if we return to the physics course, reduce its insulating qualities.

Three functions of bath ceiling insulation

The hotter the room temperature is required, the more difficult it is to build a barrier to retain heat. To solve this difficult problem, those who want to know how to insulate the ceiling of a bathhouse should familiarize themselves with the three main leak patterns:

- movement of heated air through the cracks in the ceiling;

- gradual transition of heat from heated objects to cold ones;

- intersection of homogeneous barriers by thermal waves.

Laying thermal insulation material in a multi-layer roofing system prevents all types of thermal leaks. Properly done insulation will adequately perform all the work assigned to it. Due to poor thermal insulation, condensation will settle on the ceiling, it will take much longer to warm up the room, and more fuel resources will be spent.

Selection of materials for insulation

Before deciding how to insulate the ceiling in a bathhouse, you need to consider all options for suitable thermal insulation materials.

- “Classic” mineral wool is used most often. In its chaotic interweaving of fibers melted from basalt there are billions of air-filled voids, each of which works responsibly to retain heat. Disadvantage: loss of insulating properties when wet.

Note. When using mineral wool to insulate the ceiling in bath buildings, it is recommended to lay a waterproofing layer on top of the insulation if the roof is not sufficiently protected from atmospheric water leaks. A thermal insulation gap must be created between the waterproofing layer and the insulation.

- Super-light polypropylene foam - penotherm - is also often installed on the ceiling of a bathhouse. The foil-laminated material was developed specifically for arranging bath buildings and saunas. In addition to its intended function of insulation, its foil side reflects the flow of thermal energy. Working on the mirror principle, penotherm allows you to reduce the heating time of the steam room by 2-3 times.

- Expanded clay is suitable for large-sized bath structures. The layer sufficient to insulate the ceiling should be 30 cm. Although the material is relatively lightweight, it will inevitably increase the weight of the building. Its porous granules, like mineral wool, are susceptible to moisture. Waterproofing is also necessary.

- "People's" heat insulator. The first element is a 2 cm layer of crumpled clay. Instead, a mix of black soil and peat, wood shavings filled with cement mortar, a mixture of clay, sand or sawdust are suitable. A “carpet” of dry sawdust or leaves (preferably oak) is laid on top of the laid layer, and the insulation is completed by laying a layer of dry earth 15 cm thick.

- Growing aerated concrete, for pouring which a simple formwork is arranged. The video will clearly depict how this insulation of the bathhouse ceiling is carried out: the video demonstrates the simple technology in detail.

It is difficult to recommend the thickness of the insulation layer offhand, without knowing the actual size of heat loss and the technical parameters of the structure. The figures are approximate throughout, variations are allowed. Much depends on the climate zone, because the ceiling insulation in a bathhouse is not only a barrier to heat, but also protection from external temperature factors. If the ceiling freezes from the outside, moisture will certainly condense on the ceiling. In such cases, the thermal insulation layer is simply increased.

The main requirements for materials and raw materials: insulation for a bathhouse on the ceiling, which is better and more reliable

Photo from the site: kak-uteplit.ru

When the entire structure has already been built, and all systems have been well thought out, it is worthwhile to take up insulation, especially if you plan to use the bathhouse throughout the year, regardless of the season. Moreover, in the sultry summer and cold winter, this will be equally useful and simple if all the calculations for insulation are correctly made, especially the ceiling, from where the lion's share of the heat from inside the room can be ventilated. To begin with, before you figure out how you can insulate the ceiling in a bathhouse, you need to understand that this material must meet special requirements, otherwise it’s simply not worth taking it, it will be wasted funds, and now is not the time to risk your own money.

It is worth understanding that, first and foremost, the insulation in a bathhouse on the ceiling, the builders forum is replete with similar statements from real professionals, must be moisture resistant, since all the hot steam first rises. Moreover, you should not hope that vulnerable material that absorbs water can be reliably hidden under a vapor barrier. It will, of course, help a little, but such an insulator can still become unusable and completely lose its properties in just a couple of years, due to the regular appearance of condensation, which is inevitable with temperature changes.

- Also, the insulation for a bathhouse on the ceiling must be completely harmless and not dangerous to human health and life. That is, it should not release toxins, aldehydes, or other dangerous substances, even under the influence of high temperatures that will regularly occur in the bathhouse.

- Fire safety is another important factor that insulation for the ceiling in a bathhouse must have, and which one is better under this criterion, they will help you figure it out, for example, in a store.

- We should not forget about sudden changes in temperature, which the thermal insulation indoors must withstand without much reaction, and over a long period of several years.

- Biological and chemical inertness, as well as resistance to the development of various microorganisms, fungi and other “living creatures” of the material for bath insulation is also extremely important.

Photo from the site: info-potolki.ru

Among other things, I would like to definitely note that the heat-insulating layer must be sufficiently tight and elastic, but such that, for example, it itself will not sag over time. Therefore, in order not to be too tormented by the question of which insulation to choose for the ceiling of a bathhouse, it is worth purchasing one that is relatively inexpensive, but in terms of performance and properties is at its best. Moreover, it is worth understanding that this can be done using natural materials, or you can choose synthetic ones, which also “work” quite well.