Previously, bathhouses were built only from natural wood; no additional internal or external cladding was made. The wooden walls “breathed,” which allowed them to constantly maintain optimal relative humidity values. In addition, during washing, the internal surfaces of the walls were heated to high temperatures, which prevented the appearance of dew points on them even at a relative humidity of 100%. All building structures (not only wooden ones) are afraid not so much of steam as of water, and water is condensation.

Vapor barrier for a bath

Why is vapor barrier necessary?

Currently, most bathhouses have interior walls lined - this is beautiful, useful and prestigious. The walls are usually covered with natural clapboard. From the designer’s point of view, everything is great, but from the builder’s point of view, there are big problems.

- An additional “heat-protective” wall is formed between the load-bearing wall and the steam room. This is good, it minimizes heat losses, but it causes condensation.

- Due to the low thermal conductivity of wood, the temperature difference between the lining and the wall is large. This situation needs to be looked at from two sides. The good thing is that the steam room retains heat. The bad thing is that steam easily passes into the forcing joints, and the relative humidity of the wood increases.

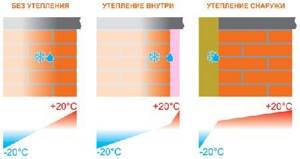

Now we come to the main problem. If the temperature of the lining is so high that condensation does not form given the existing humidity, then the wall temperature is below the dew point. Condensation forms on cold walls and is absorbed into all materials of external walls: wood blocks, brick. Due to the fact that natural ventilation between the sheathing and the wall is almost completely absent, water does not evaporate. As a result, the wood begins to rot, the red brick crumbles, and the concrete materials transfer moisture through micropores to all adjacent structures.

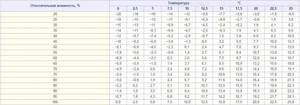

Dew point table

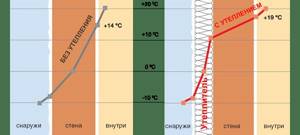

Dew point in the wall

Here you can clearly see how the dew point in the wall of the house will shift

Vapor barrier and wall insulation

But these are not all the reasons why you should use a vapor barrier. Let's touch on the issue of insulating the bathhouse. Insulating the outside is a waste of money and time. Until the insulation “shows its effectiveness,” no one will wash in the bathhouse. The heating time for the sheathing and walls is several hours. Only then will the internal heat “reach” the insulation outside the external walls and it will be able to “work”. The effect will no longer be during the heating of the steam room, but during its cooling after washing. To “enjoy” the effectiveness of external thermal insulation, you need to stay overnight in the steam room.

It is necessary to insulate the bathhouse from the inside

This means that for steam rooms, insulation needs to be installed only inside. But here too a problem arises. Most often, mineral wool, glass wool or polystyrene foam are used as insulation. The latter is not environmentally friendly and emits harmful chemical compounds, especially during heating. Sanitary authorities categorically do not recommend using it for steam rooms. What remains is mineral wool or glass wool.

Mineral wool has two “unpleasant” properties. First, with increasing relative humidity, thermal conductivity characteristics decrease significantly. This is what some “experts” write, although the characteristics increase, thermal conductivity increases, and heat saving decreases. Do you feel the difference? Three times - cotton wool takes a very long time to dry, there is almost no air movement in it. Which is natural, otherwise the heat would not be retained in the room. Insulation is always attached to the walls, regardless of the material they are made of. And prolonged contact with wet wool has an extremely negative effect on all building materials. Here is another reason why you need to use a vapor barrier in a bathhouse.

If you understand these issues, you can familiarize yourself with various vapor barrier materials and their physical characteristics.

Materials for vapor barrier of baths

Based on the fact that the installation of heat and vapor barriers is aimed at avoiding the occurrence of condensation, different materials can be used for this. The cheapest and most popular option is a mixture of clay and sawdust. It applies perfectly, dries quickly and hardly crumbles.

The downside of this material can be considered the time spent on surface treatment and the dirt that remains after this stage of work.

You can also use filling the clay screed with a mixture of perlite and peat, and then covering the whole thing with foil or polyethylene.

One of the best options for vapor barrier of a bathhouse is stizol, ordinary type or self-adhesive. The properties of these two types of material are identical, the only difference is that self-adhesive material is easier to work with.

In addition to vapor barrier, stizol helps retain heat in the room, so such a purchase is profitable from an economic point of view. This material can withstand severe thermal loads, so it is ideal for a steam room. It is also resistant to humidity and temperature changes. Thanks to stizol, the bathhouse quickly heats up and maintains the optimal temperature for a long time, while heat losses are insignificant.

Today, vapor barrier films such as Isoltex and Armitex are becoming increasingly popular. Armitex film is placed inside the bathhouse, under the casing, and Isoltex film is placed on top of the thermal insulation, outside the bathhouse.

For vapor barrier of a bath, you can also use materials laminated with foil. For example, foamed polypropylene Penotherm NPP LF. It perfectly reflects heat rays, keeping them indoors, and at the same time perfectly performs the function of vapor insulation. The main properties of this material include:

- application temperature from -50 to +150 degrees

- powerful thermal insulation, vapor barrier and sound insulation properties

- ease of installation (easily cut with a knife, mounted with a furniture stapler, small nails, can be glued with tape)

- not subject to corrosion, rotting

- environmental friendliness

Izospan (for example, Izospan FB) is a foil material based on kraft paper, which is also used to insulate baths, saunas and other wooden structures from steam and moisture. For an example of Izospan installation, see this video:

Cost of various materials for vapor barrier of baths and saunas:

| Name | units change | Price |

| Izospan FB (width 1.2 m) | 1 PC. (35 m2) | 722-900 |

| Isoltex V vapor barrier 1.6 m | 1 PC. | 618-1120 |

| Penotherm NPP LF 2 mm | 1 roll | 2550-3120 |

Rest rooms and locker rooms can be decorated with craft paper. It is breathable, durable, easy to install and has a presentable appearance. Kraft paper is one type of material that combines the best option in cost and quality.

It is worth noting that the more combined materials you choose to work with, the more effective the result will be.

By drawing up a plan for vapor barrier, insulating the bathhouse and choosing the right materials for the work, you can accomplish two tasks at once: ensure the long service life and efficiency of the bathhouse, and also save your budget. A serious approach to business and a little hard work will allow you to build a bathhouse that will bring you and your dear people pleasure for many years.

Types and characteristics of vapor barrier materials

There are quite a few of them; we will focus only on a few of the most frequently used ones. Let's start again with a little “educational education”. Some amateur builders do not fully understand the difference between vapor barrier and waterproofing materials. After all, steam is the same as water. Why should some materials be used for vapor barrier and others for waterproofing?

Vapor barrier and waterproofing. Differences and Similarities

The fact is that water molecules and steam molecules have different sizes. Based on these characteristics, manufacturers produce materials with different micropore diameters. Some do not allow steam molecules to pass through (vapor barrier), while others do not allow water molecules to pass through. This means that vapor barrier materials can also be used as waterproofing, but the latter cannot be used in the same way. Recently, the production of vapor-waterproofing fabrics has begun; they consist of two layers with different micropore diameters. When installing such materials, you need to monitor the location of these sides so as not to install “exactly the opposite.”

What vapor barrier materials are produced?

Ordinary polyethylene film.

| Material | Description |

| The cheapest, but pretty good option. It has another significant advantage. The films are produced in sleeves with double walls, the sleeve width is up to three meters. By cutting the sleeve in half, you get a sheet of continuous film more than five meters wide - quite enough to cover the wall of a bathhouse with a continuous material without overlays. | |

| Glassine, roofing felt and other bituminous materials. | They are rarely used in baths due to the likelihood of unpleasant odors. |

| Pure aluminum foil and aluminum coated multi-component materials. | Used most often, multi-component materials have a small layer of thermal protection or special fibers to prevent condensation from draining. |

| An excellent vapor barrier material that can be applied to surfaces of any complexity and configuration. | |

| Liquid polyurethane foam insulation. | In addition to their main tasks of insulation, they have a sealed outer surface that does not allow steam to pass through. Universally applicable, characterized by high performance characteristics. |

Types of materials

There is a huge range of vapor barrier materials on the market. So, you can choose:

- membrane hydro- and vapor barrier;

- foil;

- various mixtures applied to the surface;

- film.

They all have their strengths and weaknesses. To make a decision, it is worth taking a closer look at all the types.

Film

Most often, film is used when arranging a bathhouse. Several manufacturers offer this material. It may vary in thickness, color, and performance characteristics. The surface can be completely smooth or rough.

Reinforced film is also available. It has a higher cost. At the same time, the products are durable and reliable.

Using film you can finish various surfaces. Budget models are chosen for walls. For floors and ceilings, you can purchase more expensive products.

pros

The film has many advantages:

Price. This is the main advantage of the material. The cost of film is much lower than the price of modern materials.- Efficiency. Even the cheapest film protects thermal insulation materials well from getting wet.

- Moisture resistant. The film does not get wet. It is not afraid of exposure to water and does not deteriorate under its influence for a long time.

The service life of polyethylene depends on its quality, density and other parameters.

Minuses

Despite the abundance of positive aspects, film, like any other material, has its drawbacks. The disadvantages of polyethylene include:

- Fear of high temperatures. Under the influence of temperature, the film is destroyed. Therefore, it is not recommended to use it for finishing a steam room. It is better to use the material in rest rooms and other rooms.

- Quality. Cheap types of material cannot boast of high performance characteristics.

- Elasticity. The material stretches. During prolonged use, the film sags, which leads to its damage.

In order not to purchase low-quality products that will quickly become unusable, it is recommended to check the material before purchasing. The film should not spread in your hands. When bent and unbent, it should quickly return to its previous shape. There should be no creases left on the surface.

To avoid repeated repairs after just a few years, it is better to purchase polypropylene material. It is much more resistant to high temperatures and is not afraid of ultraviolet rays. This makes it possible to use products not only for interior but also for exterior decoration.

The cost of such material is higher, but the difference is insignificant. Especially considering the long service life.

Polypropylene film is made from viscose or cellulose. Due to the porous structure, the product is able to retain a significant amount of water. In this case, moisture does not penetrate through the pores and the insulation does not get wet.

Membrane

To protect the thermal insulation material from moisture, membrane vapor barrier is actively used. This is a non-woven fiber that is often used in the manufacture of sportswear.

The material allows air to pass through well and at the same time effectively retains moisture. When using it, it is possible to achieve a unique microclimate in the steam room or the entire building.

The membrane can be single- or double-sided. When installing it yourself, it is important to take into account the variety and place the material correctly. Otherwise, the wrong side will breathe. Thus, the material will be of little use.

The installation method is usually indicated on the packaging. If this information is not available, the material should be placed with the porous side facing the inside of the room. This applies exclusively to single-sided products. Double-sided can be laid in any direction.

The material may have one or more layers. The second type accumulates moisture inside itself. When dry, the membrane slowly releases water. This way it does not get on the insulation, and the material itself subsequently becomes dry.

The so-called “smart” membrane performs several functions at once. It effectively retains moisture and at the same time prevents heat loss. In addition, the material is used as waterproofing.

Membrane fiber is highly expensive. However, taking into account the characteristics of the material, the price is completely justified. When using such products, you can save money on waterproofing, as well as use less insulation or completely abandon it. However, the first option is more preferable.

Foil

A material whose surface is covered with foil or metallized synthetic fiber additionally performs a thermal insulation function. It helps retain heat in the room. Foil is capable of reflecting thermal radiation. As a result, it is sent back into the room. This increases the energy efficiency of the bath.

Foil-based waterproofing can be of various types. Thus, the following products are presented on the market:

- On paper made from lightly boiled long-fiber sulphate pulp. This insulation is stronger than traditional foil. It is convenient and easy to use. At the same time, the material accumulates moisture greatly. This leads to its rapid destruction. Fungus may form on the surface.

- Synthetic on kraft pulp paper. According to numerous manufacturers, the products can be used in areas with high temperatures. However, this material is not very popular. This is due to its synthetic composition. This violates the environmental friendliness of the bathhouse. At the same time, synthetics flare up quickly and burn well. This reduces the safety of the building.

- On fiberglass. The material has a long service life. It has high strength and resistance to rotting. Vapor barrier additionally prevents heat loss. The only disadvantage of such products is the high cost. However, taking into account the service life, the disadvantage is completely eliminated.

Also, a number of manufacturers offer products that combine vapor and thermal insulation. It is a kind of cake made of several layers, including insulation and foil. Such products are highly efficient and make it possible to save time and money on the installation of several different materials.

Surface treatment compounds

Also, for protection, compositions that are applied with a brush or roller can be used. They are used to treat ceilings, floors, and walls. It's a kind of liquid rubber. To improve performance, manufacturers additionally use polymer additives that provide a film on the treated surface. In this way, vapor barrier is achieved.

pros

Such compositions have a number of advantages:

- The coating provides good heat and sound insulation characteristics of the room.

- The material is easy to use. It can be quickly applied to the surface.

- Vapor barrier can be applied to almost any surface. It is used for processing natural wood, concrete floors, bricks, etc.

Most modern formulations are non-toxic. This allows them to be used in steam rooms. When heated, they do not release hazardous substances into the air.

Some general tips for laying vapor barrier materials in a bathhouse

You can find advice from “experts” who encourage making small holes in vapor barrier materials through which air will pass, and the structure supposedly will not suffer from high humidity. There is nothing to say, it is better to remain silent. When installing a vapor barrier, the main condition for effectiveness is the complete absence of gaps ; overlapping materials must be sealed with ordinary tape (cheaper option) or special metallized tape (more expensive option). The presence of any cracks nullifies all activities.

Laying the material strictly without gaps

The fewer holes the material has during fixation, the better the protection. If possible, try to use double-sided tape or silicone glue. Of course, the choice of adhesive composition must correspond to the physical characteristics of the vapor barrier material. Now we will consider two options for performing the work: for a bathhouse with brick walls and for a ceiling.

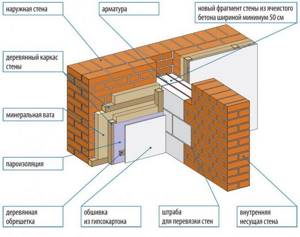

Vapor barrier for brick walls

Such baths are very rare and belong to elite and expensive buildings. Their vapor barrier is quite complex, in most cases two-layer. Brick baths must have insulation on the walls, and it is highly desirable on the interior. We have already explained why this is so.

Brick wall insulation scheme

Step 1. Selection and calculation of the quantity of materials. The quantity is easy to calculate: measure the quadrature of all surfaces and increase the resulting number by ten percent. It is more difficult with the selection of materials. As we have already noted, only materials that are safe for health can be used for thermal insulation of indoor baths. Not “environmentally friendly”, as it is now fashionable to say, but safe.

What is it for?

The main purpose of this structural element of the ceiling cake is to protect its remaining elements from getting wet.

Everything seems to be clear. However, a logical question arises: is it needed in the entire bathhouse or can it be limited to the rooms that are the most humid - the steam room and the washing room?

The answer to this is simple: no, you cannot limit yourself to a steam room and a washing room, because vapor barrier is part of the standard ceiling pie, regardless of the room in which it is being built. Why is that?

Because the main element that needs protection is the thermal insulation material , which lies at a higher level. Since in most cases this is mineral wool, the mats of which are most affordable and easy to install, one must also take into account the property of this material, such as sensitivity to the accumulation of condensate in its thickness.

The fact is that moisture accumulating between the fibers of stone wool significantly reduces its thermal insulation properties. After all, the main heat insulator is always air. We simply create a heat-resistant environment for it in the form of thin mineral wool fibers or clay partitions in expanded clay balls. Water, on the contrary, connects the fibers (this does not apply to expanded clay, the clay is baked there, and water does not get inside the balls), improving the conductivity of heat through this medium .

Condensation forms not only when the room is very humid, but also when there is a temperature difference between what is inside and what is outside. And humidity is present in any room and outside it; it is a natural component of the air.

In the Russian steam room

In terms of the amount of steam, the Russian steam room is second only to the Turkish hammam, but it is usually finished with tiles or mosaics, which makes it less sensitive. The Russian steam room is traditionally finished with wood, and if its surface layer, for example, lining, is inevitably sacrificed and takes on all the blows of increased temperature and humidity, then the inner layers can (and should) be protected.

We will talk about the methods of vapor barrier of the ceiling in a bathhouse a little lower, but for now it is important to draw conclusions - a Russian steam room clearly needs a well-thought-out and powerful vapor barrier. Does the same apply to the sauna?

In the sauna

It is not for nothing that the Finnish sauna is called “dry air”. In the orthodox version, the humidity in the sauna is minimal, amounting to no more than 5-15%. The Finns don’t pour much water on the stones, which is understandable - they either lay them out in a mound on top of the stove, or in a mesh covering the body, and this does not give the stones the heat needed to produce light, fine steam. Instead, the steam is thick and heavy.

In addition, the high temperatures of the Finnish steam room do not allow a person to easily absorb excess steam.

The third essential property of a sauna is vigorous air exchange , which is achieved using natural or forced ventilation.

Let's summarize: the sauna has good ventilation and high temperature, both of which help eliminate excess moisture, so even the surface layer of the ceiling will not suffer much during the procedures. However, insulation of the ceiling is mandatory, which means you need to make sure that the insulation does not accumulate condensation even due to temperature differences. Therefore, it still needs to be insulated , except that the vapor barrier itself can be standard, but (since the temperature in the sauna is high) it must be designed for exposure to heat.

Proper waterproofing of the top of the insulation will also help, but more on that later.

Vapor barrier of bath walls

As soon as the work on the ceiling is completed, you can proceed to the vapor barrier of the bathhouse walls. The material for work is selected only after a waterproofing, thermal insulation and vapor barrier plan has been drawn up. If you miss some little detail at this stage, then you will not achieve your main goal - to save heat in the room.

To avoid the formation of condensation, polyethylene film, glassine or aluminum foil are used to decorate the walls.

It is not recommended to use roofing felt and roofing felt in the steam room. Because during operation they emit toxic substances that have an unpleasant odor and are harmful to health. To decorate the walls in the steam room, it is better to choose foil that copes with the task and is safe for health.

Often, polyethylene film with a thickness of no more than 140 millimeters is used to decorate the washing room and steam room. As for the locker room and recreation areas, the walls can be decorated with kraft paper.

As an economical option for vapor barrier of bath walls, you can use rolled fiberglass or foil. These materials have a similar structure, fit perfectly and are affordable.

As soon as the installation of the vapor barrier of the walls is completed, you can start sealing the seams. This is done with aluminum foil and tape to completely eliminate the possibility of drafts.

The vapor barrier of the walls of the bathhouse is hidden, as it were, inside the wall, and only aspen or linden boards remain on the surface. The interior of the bathhouse looks attractive, and at the same time preserves its healing properties, extending its service life.

What is the difference between vapor barrier and waterproofing

Now this is an interesting question. In essence, in both cases we are talking about the effect of moisture, it’s just that in the first case an increased temperature is added to it. Therefore, it would be correct to use these concepts and related materials something like this:

- vapor barrier is done from the inside of the room so that water vapor that arises inside does not turn into condensation when faced with the cold of the external environment;

- waterproofing is done primarily to protect against moisture coming from outside, and it can be in the form of water vapor or precipitation.

When it comes to ceiling insulation, vapor barrier is the bottom layer, waterproofing is the top layer. However, if the bathhouse has a second floor with a residential attic, then the term “waterproofing” becomes somewhat arbitrary, because protection is carried out from the same vapors, only found in the insulation.

Hence, probably, the constant confusion that can often be found in descriptions.

Everything is clear with the roof: the layer located directly under the roofing material is waterproofing, because precipitation can seep into it, and the layer that is made from the inside on top of the insulation is a vapor barrier .

See the article When is it necessary to insulate the roof of a bathhouse and when is there no point? Roof thermal insulation technology

Why is vapor barrier needed?

In the bathhouse, like in no other building, there is a lot of water and the humidity is very high. All this cannot but have a negative impact on the materials of the walls, ceiling and floor of the bathhouse. Water causes mold and mildew to appear on all parts of the building. Wooden parts will begin to rot from the water, and the insulating layer, under the influence of water, will simply stop fulfilling its main task - to retain heat inside the bathhouse.

Particular attention to ceiling insulation is due to the fact that, according to the law of physics, all warm air rises. It is here that one can expect the maximum concentration of wet vapors and, naturally, their negative effect on the structure of the building.

To avoid the negative effects of humidity, high-quality vapor barrier of the bathhouse ceiling, as well as its walls and floor is necessary. A layer of vapor barrier coating protects the laid insulation, as well as all other elements of the bath structure, from the negative consequences of contact with wet steam.

The main task of a vapor barrier is to protect against moisture and prevent the accumulation of water in the insulating material and the appearance of condensation.

[custom_ads_shortcode2]

What types can be found on sale?

And again, it’s interesting to figure out what a vapor barrier film for the ceiling is, what can they offer us in the store? In general, it’s probably worth clarifying right away that the class of vapor barrier films is not all that can be found on sale. It is worth talking about such a popular foil, and about foil materials, and much more.

Vapor barrier films

There are polyethylene and polypropylene. The difference, as you understand, is in the polymers. Polypropylene is more expensive, its melting point is 40 degrees higher than polyethylene (better for a bath), but it is more fragile and can withstand frost 10 times worse (PE - up to -50, and PP - up to -5), PP more elastic, but still less durable.

Also, the film may or may not have perforations. Since we are talking about vapor barrier, it cannot be perforated and single-layer. Therefore, perforation is allowed only in the second layer.

The advantages of perforation are questionable - during operation, these holes are easily clogged with dust.

Reinforced and not reinforced . An ordinary film is not reinforced with anything, but you can easily distinguish a reinforced film - it has a thread base made of a different material. The film is reinforced for the sole purpose of increasing its strength. And this really helps, it is more difficult to damage mechanically.

Reflective foil vapor barrier film

Another way to improve the properties of conventional films is foiling. A thin layer of metal makes such a film reflect infrared radiation. On the other hand, fragile foil with a polymer base becomes more durable.

As for anti-condensation films, they are not for vapor barriers and not for ceilings - they are for roof waterproofing.

Foil

But this is generally a favorite of those bathhouse owners who want to both retain heat and provide a reliable barrier to steam. Aluminum foil is completely impenetrable to steam. However, the rolls have a limited width, so you have to overlap and seal the joints, and the seams are always imperfect. So, if any moisture penetrates into the insulation, it will not be the fault of the foil itself.

Many people do not like to cover the ceiling in a bathhouse with foil in its pure form because of its fragility - it breaks easily, in addition, it is easy to cut yourself on it; this material requires great care in working.

combined on sale - foil increases the operating temperature range of the films used, and they, in turn, protect it from ruptures. In addition, the presence of a polymer backing allows you to make the foil layer thinner - in its pure form you simply would not be able to lay it with such a thickness.

Many film companies have expanded their range to include foil materials, so when we get to specific names, just keep in mind that they most likely have them.

Now is not the time to argue about whether foil is needed in the bathhouse or not. In essence, all questions of this kind can be reduced to one thing: does a person know the materials enough to get exactly the desired effect or does he not know. And the circumstances can be very different.

Ruberoid or glassine

Both are the result of impregnation of cardboard with petroleum bitumen . Both can, in principle, be used for vapor barrier of a bath ceiling, but we still would not recommend these two materials over the steam room .

However, you may not listen to our opinion, because the temperatures in the steam room are different for everyone, and the ceilings themselves will not be the same, so in some cases such a vapor barrier may turn out to be quite acceptable.

Since we are talking about fairly cheap materials, they can be used in budget construction, when, for example, a flat ceiling scheme is used. In this case, roofing felt or glassine is placed directly on the flooring boards from the attic side and serves as a backing for the insulation.

Kraft paper

This is an excellent option for those who decide to insulate themselves with ecowool. Vapor barrier kraft paper is a type of cardboard that can be single-layer or double-layer. The coating with a polymer film can be on one side of a single-layer cardboard or between two layers of a two-layer cardboard. , reinforcing mesh can be added , which is also located between the layers of cardboard.

This paper is produced in Finland and is intended for insulating environmentally friendly insulation materials made from cellulose or flax fiber.

Can kraft paper be used with other types of insulation, such as mineral wool? Yes, you can.

Izospan

We inquired about the recommendations given by the manufacturer of these products. Izospan RS (aka B) as a vapor barrier there

Well, let's see what he is. This is a material that consists of three layers of polymers, two of them are exactly polypropylene. The first layer of polypropylene is a regular film, it is smooth. In the middle (second layer) there is a reinforcing mesh, the material of which is not specified. The third layer is non-woven material, all made from the same polymer. Non-woven materials (= something like felt) are usually used to create an anti-condensation layer, in this case its use is not entirely clear.

Izospan B for a bath on the ceiling

However, in addition to vapor barrier of ceiling insulation, this type of film can also be used for waterproofing, for example, floors and roofs. Let's classify the rough third layer as waterproofing. Although this is a little strange - if the film is vapor barrier, then it is impenetrable to vapors, if it is waterproofing, it is permeable. What is a universal film, suitable here and there? Mystery. At least for us.

The technical specifications say that Izospan B is vapor-tight, its temperature range is -60+80 degrees. In terms of temperature characteristics, it is not particularly suitable for a steam room. In other rooms, if desired, you can use it.

A little about the manufacturers and their products

Armitex-75 is an analogue of Izospan V. Only without reinforcing mesh, apparently. It has smooth and rough sides. The manufacturer advises facing the rough side towards the insulation.

The Czechs produce films under the Jutafol . They have several types of films only as a vapor barrier, they are all included in the Yutafol N . Among other things, you can find films with a reagent that leads to the extinction of the flame, preventing a fire. Some are reinforced, some are foil.

The Luxembourg company DuPont produces a foil vapor barrier called AirGuard® Reflective .

The Poles make Folder in the following varieties: Minima H 98, Silver H 98 and Alum H 90. The numbers mean grams per square meter. The latter is foil, suitable for baths and saunas. Others, however, are also suitable. Minima is not as durable as Silver.

Russian-Polish film Optima B is suitable for insulating insulation. This is a two-layer film with a density of 75 g/m2, with smooth and rough sides.

The company that produces the popular roofing material ondulin also produces roofing films. There are also vapor barrier ones among them. These are Ondutis R 70, RV, RS and Thermo. The latter is foil, RV does not have reinforcement, but RS does, and RS can be considered an analogue of Yutafol standard 110. Thermo is suitable for steam room ceilings, because the foil there is protected by a layer of polyester with a melting point of 200 degrees!

Bathroom floor installation: flooring, heating and vapor barrier

This article, accompanied by a video about the installation and installation of heated floors, will tell you how to install insulation and vapor barrier depending on the design features of the floor and create a heating system.

The design of bathhouse floors has a number of specific features. The floor in the steam room is raised, and in the shower room it is lower than the level of the finishing coating in the dressing room and the relaxation area of the bathhouse.

Floor installation

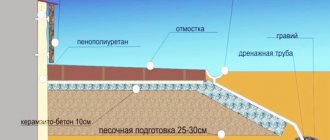

To obtain an elevation in the paired compartment, backing beams measuring 70x100 mm are used as the basis for the floor joists. In addition, the flooring receives an additional margin of safety, since the beams act as a support and partially absorb the main load. The entire installation process is controlled by a horizontal building level to avoid distortion. All wooden structural elements must be treated with an antiseptic before starting assembly.

The basic procedure for arranging floors in a bathhouse comes down to the following actions, which require accuracy and precise execution. Such work, as a rule, does not require professional skills:

- Before laying the backing beams, the strip foundation is covered with a double layer of insulation. In this case, roofing material can be used.

- The ends of the beams rest on the foundation walls at the shortest distance from wall to wall, and its central part rests on 2 support pillars.

- The logs are cut 20 mm towards the central part on both sides and laid on top of the support beams. From the bottom, skull blocks are nailed to them, on which the rough covering will be installed.

- The waterproofing is laid on the rough covering with an allowance of up to 200-250 mm on each wall to connect with the waterproofing layer from the wall.

- The insulation layer is placed tightly, but without deformation, on the insulating layer.

- Hydro- and vapor barrier is installed layer by layer on the top of the insulating material.

- The finishing coating is a finishing flooring made from edged or tongue-and-groove boards.

It's important to know that

Providing a ventilation gap of only 20 mm between the inner surface of the finished floor and the insulating layers will ensure the safety of the insulation cake for many years.

If mineral or basalt wool was used as an insulation material, then they need high-quality vapor barrier, since dampness is detrimental to mineral insulation. They lose their properties when moisture penetrates internally.

Vapor barrier of floors in the bathhouse

Materials that retain steam are represented in two segments on the modern market. The first of these is numerous film materials, including membrane-type vapor barriers. Fundamentally opposite products are representatives of the second segment. These are liquid and mastic-like vapor barriers that carry the properties of waterproofing agents. As a result, the second segment is represented by “Two in One” products, which is very beneficial in modern construction of buildings and structures, especially wooden baths.

A typical representative of such materials is liquid rubber. With its 100% water impermeability, it provides 100% vapor impermeability. This material is mainly used in wooden construction. In this case, it is very appropriate to use it as a vapor barrier when installing wooden floors in a bathhouse or sauna.

Vapor barrier for wooden flooring

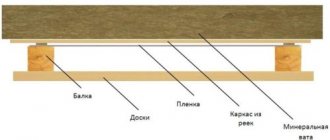

The structure of the wooden floor in the bathhouse consists of layers of insulation cake:

- subfloor as an independent wooden structure;

- logs laid directly on the foundation;

- vapor barrier laid on the joists and protecting the plane of the subfloor;

- insulation tightly laid between the joists;

- top layer of vapor barrier protecting the layer of insulation material;

- thick plywood or fiberboard, which take on and distribute the entire load onto the logs;

- finishing surface made from edged or tongue-and-groove boards.

In order to prevent heat loss through the ceilings, be it walls, ceiling or floor, especially if the bathhouse operates throughout all weather seasons, and therefore is heated in winter, it is necessary to build high-quality insulation in it. Full operation of the insulation over a long period of operation will not be achieved if the insulating layer is not provided with hydro- and vapor barrier, especially if a vapor-permeable material is used as insulation.

As a rule, various types of rolled film material are used as vapor insulators. It is spread out and secured with an overlap. To prevent the formation of cracks, the film is glued together using sealants or construction tape. Methods and methods of installation are different, but do not always give the result for which this technique is designed. During installation, air vents may form, which will allow moisture to enter the inner layer of insulation. It is almost impossible to identify this right away, and only in the third or fourth season from the start of the bathhouse’s operation can one say how well the vapor barrier was laid.

Today, industrialists are proposing a completely new method of laying a vapor barrier layer for floors in wooden buildings, including bathhouses and saunas. It is characterized by 100% coverage of the entire surface, including hard-to-reach places.

We are talking about liquid rubber and its analogues, materials made on a bitumen-polymer basis. Such material is capable of not only covering the surface of the ceiling without the formation of seams, but also tightly attaching to the surface, with a sufficient amount of adhesion for every square millimeter.

The formed film, thanks to the use of liquid rubber or its analogues, will not allow a drop of moisture to penetrate into the insulating layer over a very long period of operation. As you know, rubber has strong molecular bonds, which neither hot air, nor dampness, nor heating have any effect on, and its service life is unlimited.

Heating in the bathhouse

In the entire room, as a rule, there is one stove located in a steam compartment. But its functions are limited. In winter, the firebox is unable to heat either the dressing room or the locker room, not to mention the relaxation area. In order to avoid discomfort after taking the procedures while resting, it is necessary to take care of the heating of the rooms associated with the steam room.

You can heat a bathhouse using any method used in residential buildings. The only difference is in the frequency of heat supply to the room - at the time of receiving the procedures. A wood-burning stove is not suitable for these purposes, since it is not heated regularly, and it is advisable to maintain heat in the bathhouse constantly, especially in winter. Conducting steam heating is quite an expensive pleasure. It is possible to install heaters, but the floor in the bathhouse will remain cold, which will seriously affect the enjoyment of the procedures.

Underfloor heating system

The autonomous system of arranging heating built into the floor, used as the main and additional heating, has gained enormous popularity today. It can be installed in absolutely any premises, but requires compliance with certain safety regulations, both during assembly and during operation.

Since the bathhouse has some design features, they must be taken into account before installing an electric or water floor.

Warm electric floor

The device is characterized by its simple design and ease of installation. It is located under the outer floor covering in a concrete screed. The basis of the device is an electric heating cable made of high-resistance alloys. The cable is located on the mounting tape and laid under the external floor covering at the time of installation of the screed.

Floor heating occurs by converting electric current into heat waves. Each system is equipped with a thermostat that adjusts the level of heat supplied to a level that is optimally comfortable for the consumer.

There are two types of underfloor heating system models:

- Using a single-core cable equipped with two couplings in the design.

- Using a two-core shielded cable in its design. This model is equipped with one coupling and a pair of plugs located at both ends of the cable. This design has protection in the form of a metal screen and shell.

For ease of installation, each cable of a certain length is packaged in a mat corresponding to its parameters. Thanks to this packaging, you can install a thermal electrical cable yourself without having any specific skills. It is only necessary to observe the safety measures specified in the accompanying instructions for laying the device. For cables packed in a mat, a concrete screed is not required. The device is simply spread under the flooring.

Video about installing a warm electric floor under a concrete screed:

Infrared floor

Easy to install under parquet, laminate or ceramic tiles. Its special properties include uniform thermal radiation from the entire surface of the device. The degree of radiation belongs to the far infrared spectrum, completely harmless to the human body. In the form of sensations, the radiation resembles the heat emanating from the sun.

An infrared heated floor is a device in the form of a film heater. Its carbon heating elements are covered on all sides in electrical polyester, more often in special-purpose polyethylene, in this case used as an electrical device. This coating prevents any moisture from entering the structure, ensuring its complete tightness and reliable protection against electrical sparks. The device is ideal for use as the main or additional heating for a bathhouse.

Infrared heating devices can also be used as wall heating.

Rod mats with a self-regulating system

Warm infrared floors, which are based not on heating films, but on flexible carbon rods based on graphite and silver. The system became available as a result of innovative developments in the field of alternative provision of thermal energy to the population.

Externally, the rod mat is a flexible thermoplastic with flexible electrically conductive tires built into it at the edges. Orange-colored heating rods made of composite material are located between the tires like sleepers. The rods are placed on the mat with a step width of 10 cm.

The design features include the fact that if one rod fails, this failure does not affect the entire device as a whole. Rod mats are not afraid of kinks or being blocked by furniture, and the mats are not afraid of overheating. The device has a high degree of fire safety.

Warm water floor

Allows you to maintain a constant temperature throughout the entire bathhouse without any special financial costs. A device consisting of water pipes of a certain cross-section, connected to a double-circuit heating boiler and laid under the external flooring, will simultaneously heat the bathhouse and provide hot water in the shower compartment.

A water heated floor is installed directly into a concrete screed, only its thickness will be slightly greater than when laying an electric heated floor, since the pipes carrying water are much thicker than the electric cable.

Pipes are laid in two ways: in the form of a “snake”, or in a spiral – “snail”. The laying step depends on the thickness of the concrete screed. With a thickness of 100 mm, the pitch will be 200 mm. The thicker the layer, the shorter the step and the higher the energy consumption.

Before laying polyethylene pipes, they must be filled with water to prevent deformation under the influence of a heavy solution. If the pipe is rigid, metal-plastic, then it does not need to be filled with water.

Traditional insulation methods and materials

Progress has both disadvantages and advantages. But when it comes to vapor barriers, traditional methods of making ceilings vapor-tight turn out to be very questionable when compared with what modern technology has given us.

Just for reference: in Russia, ceilings in log buildings were made on three beams attached to opposite walls of the log house. Poles were placed across these beams - these were logs or half-logs. They formed the basis of the then ceiling. Of course, gaps formed between the poles .

So, the only analogue of a vapor barrier in the construction of floors at that time could be covering these cracks with clay . Yes, but as insulation they put everything on top of them - straw, and even hay, and yarn, and hemp, and flax, and twigs, and dry leaves... In general, they put what was at hand.

For reference, we studied part of an archaeological book about construction in Rus' in the 10th-11th centuries. Now think for yourself - why bother so much when even with the smallest budget you can buy plastic film and protect the attic space from steam with it?

Useful video

This video will help you distinguish between different types of film materials for protecting ceilings and roofs:

Let's summarize: if we had insulation at our disposal that would not suffer at all from moisture getting into it, the entire technology for constructing a standard ceiling and roof in a bathhouse would change. But while we are relying on mineral wool, we will have to do vapor barrier and waterproofing. Foam plastics, of course, do not suffer from moisture, but they try not to use them in the bathhouse.

In order for a bathhouse, and especially a steam room, to hold steam well, the ceiling in the bathhouse must be insulated and vapor-proofed. Wood is a “breathing” natural material, so vapor barrier for a ceiling in a wooden floor has a number of specific features that are characteristic only of this type of structure.

What happens to the heated air in the baths?

The vapor barrier of the bathhouse ceiling made of natural materials could not protect the wood 100% from steam, but after washing, the heat remained in the bathhouse, and the moisture accumulated in the log evaporated during this time. The bath heated up and cooled down slowly. There was no sharp temperature difference inside the bathhouse and on the surface of the ceiling, just as there were no prerequisites for creating a dew point - the temperature at which warm air saturated with moisture cools down and cannot retain moisture that condenses on cold surfaces. Even if moisture appears on the surface of the ceiling, it will not penetrate deep into the wood, but will form drops on the ceiling, which will stop dripping onto the floor as soon as the bathhouse warms up.

In modern baths, the finishing materials are made of moisture-resistant wood , but the design of the stove, in most modern baths, is designed to quickly heat the steam room. Now imagine what happens during warming up if there is no vapor barrier on the ceiling and walls. The stove gives off heat almost instantly. The walls and ceiling that have not yet been heated take on the heated hot air; Some of the wet steam finds the dew point on the surface of the cold walls and ceiling and condenses on them in the form of droplets.

The dew point does not stand still, it moves as the walls and ceiling heat up. What happens if there is no vapor barrier on the ceiling in the bathhouse? Warm air penetrates behind the sheathing and encounters insulation, which has a temperature lower than the warm air entering. A condition of temperature difference may be created in which moisture condensation occurs directly in the insulation (internal condensation), and since the insulation has low thermal conductivity, the dew point in it can be maintained for a long time and the insulation will become wet, like a sponge, absorbing moisture.

This is the difference between an ancient Russian bathhouse and a modern one. For an old Russian bath, there are practically no conditions for condensation of warm air, or they are reduced to a minimum (surface condensation). A modern bathhouse must have steam protection . Moreover, this protection is based on specific conditions, which take into account:

- Stove type: with an open type heater and a constant firebox, and a closed type with an intermittent firebox and high heat capacity;

- Features of the room design;

- Construction material.

Based on these conditions, choose a protection method:

- Maximum insulated room with impenetrable vapor barrier, protection against internal condensation;

- Partial vapor barrier, eliminating the formation of dew point in the bath structure.

[custom_ads_shortcode1]

The principle of heat retention for a bath ceiling

The bathhouse can be classified as a building with special operating conditions. Due to the fact that this is most often an unheated room, with occasional heating of air masses to high temperatures and a large amount of steam, the ceiling, which absorbs maximum temperature influences, can quickly become unusable.

Depending on the budget and capabilities of the owner, the bathhouse can be a whole complex of several rooms for undressing and relaxation and a steam room itself, or a small building with a steam room and a dressing room. Regardless of the area, the ceiling must be properly insulated with a mandatory vapor barrier device.

The most common method of producing steam for a Russian bath is the construction of a heater stove. A large amount of steam released due to temperature changes and excess humidity will settle in the form of condensation on the ceiling lining, up to the formation of large drops that fall down. An unsuccessful vapor barrier in a wooden house will lead to soaking of the insulation, loss of its qualities, and ultimately to excessive fuel consumption and an uncomfortable stay in the steam room.

Due to the design features of the roof, log baths or baths made of timber can be divided into two types: with and without an overhead “attic” space.

Depending on this, the vapor barrier device will be designed differently.

Is it necessary to protect the bathhouse from exposure to steam?

The service life of structures and buildings made from any modern construction material depends on a number of factors, many of which have an extremely negative impact on the elements of the structure. It is very important to neutralize them already at the stage of creating a construction project. Everyone knows that high temperature and humidity are mandatory attributes of a bath.

Humidity in the bath

When a person takes water procedures, they have a beneficial effect. But for the construction itself, it’s the other way around. Over time, moisture destroys the ceiling and walls of the bathhouse. These phenomena should be combated with the help of measures that provide high-quality protection from steam. It is worth considering that the baths consist of several compartments, characterized by their own level of humidity. The most moisture is always found in the steam room, where, in addition, very hot air circulates.

Slightly less water vapor in the shower room. And the “dryest” room in the bathhouse is the room for relaxation and rest, but even there the moisture level is always quite high. Materials for vapor barrier measures are selected so that the most reliable of them are installed in the steam room. But less effective means of steam protection can be used in the rest room and shower. This will save you money, and at the same time you will be able to make a high-quality vapor barrier with your own hands.

Materials for vapor barrier measures

As a rule, bathhouses these days are lined with wood materials on the inside. Through the cracks in such finishing, hot steam will penetrate to the insulation with each wash, destroying both it and the structure itself.

To avoid this, they perform a vapor barrier, installing it between the heat-insulating layer and the wooden sheathing. The walls and ceiling of the building need protection from steam. They are the ones who are susceptible to the negative effects of high humidity. Floors also require protection from condensation and water. But here we are no longer talking about vapor barrier, but about other operations - about waterproofing and drainage for a bathhouse.

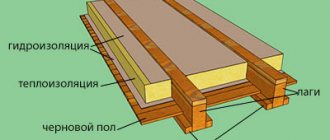

Protecting a wooden ceiling from excess moisture - which vapor barrier is better

The air gap under the roof slopes will prevent heat loss, but without additional insulation with a vapor barrier, the bathhouse ceiling will get wet from excess humidity and the wood will deteriorate. This can cause individual deck boards to dry out due to temperature changes and cause mold to form. A properly executed vapor barrier for a bathhouse ceiling involves installing two vapor barriers on both sides of the insulation with a small air gap between them.

If the insulation is not made with fibrous or slab materials, but with bulk material, for example, expanded clay, the vapor barrier is laid on top of the intermediate wooden flooring, from the side of the above-ceiling space.

To lay slab insulation, it is enough to arrange a sheathing of timber with a two-layer membrane-type vapor barrier laid over it, with the rough (absorbing) side down.

It is not advisable to use the following as a vapor barrier for a bath:

- Polyethylene film, due to its excessive tightness;

- Roofing felt and its varieties under the general name “euroroofing felt”, due to the possible leakage of bitumen impregnation through the ceiling due to high temperatures;

- All types of coating vapor barrier, except for places where chimneys pass through the ceiling.

The best choice is breathable two- or three-layer membranes or foil membranes. The reflective layer of such a vapor barrier, due to the reflection of heat waves, will significantly improve the temperature in the bathhouse and reduce the cost of fuel for the stove.

An economical option is to lay craft cardboard impregnated with drying oil.

Vapor barrier of the ceiling in a bathroom in a wooden house is carried out using the same technology, but since maintaining a high temperature in such a room is less important, you can save on installing a foil vapor barrier.

Required tools and materials

Vapor barrier film Adhesive tape Construction nails Lath Hammer

Properly executed vapor barrier of a bathhouse provides the room for water procedures with the necessary humidity and air temperature. In addition, it protects this structure from premature aging.

- 2 Materials for vapor barrier – which ones to choose?

- 3 Izospan - excellent protection for walls

- 4 How to protect the ceiling and walls of a bathhouse from steam - pro tips

Vapor barrier for the ceiling of a wooden bath

A bathhouse without an overhead space, usually a structure with a flat roof with a slight slope, due to the lack of an air gap, requires significantly greater efforts to insulate and vapor barrier the false ceiling. Let's take a closer look at this process.

- The vapor barrier is attached over the entire surface of the rough ceiling, extending onto the walls by 15-20mm. It is advisable to seal the junctions with the walls with sealing tapes. The vapor barrier can be installed directly on the rough ceiling or on wooden dies nailed to it in small (no more than 1 m) increments;

- If the width of the vapor barrier panels is not enough to cover the entire ceiling, they are attached with an overlap of at least 15-20 mm. For installation, nails with a wide head or staples of a construction stapler are used. It is advisable to place cardboard washers or any other sealing gaskets, for example, cut from the remains of a vapor barrier or any other film, at the fastening points, in order to prevent ruptures of the vapor barrier at the points of contact with the fasteners.

- Insulation is laid on top of the vapor barrier. This can be expanded polystyrene (cheaper foam for a bath is not desirable due to its high flammability and release of toxic smoke when ignited), mineral wool, glass wool, slab basalt insulation;

- The insulation layer must once again be protected by a vapor barrier to protect against internal moisture;

- A wooden sheathing is installed with a gap of 40-50 cm from the ceiling to secure the finishing ceiling lining.

A common finish for the ceiling of a wooden house is lining with wooden clapboard. It is also appropriate to use it in a log bathhouse. The only difference is that for lining the bathhouse ceiling it is better to use wooden lining made from hardwood.

Using coniferous lining, on the one hand, will give an unforgettable forest aroma due to the release of resin when heated, on the other hand, the release of resin will gradually lead to warping of the wooden lining. There are no such restrictions for other rooms of a wooden house.