Insulating the ceiling with mineral wool is a good way to make your home warmer, improve comfort and reduce heating costs. Mineral wool is an environmentally friendly material and has undeniable advantages: low thermal conductivity and excellent heat-saving abilities.

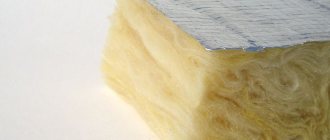

Mineral wool consists of thin glassy fibers, between which air pores are formed, constituting 95% of the volume of the entire material. This is what gives mineral wool such exceptional thermal insulation properties.

Manufacturers produce mineral wool: in the form of slabs and rolls. Both slabs and rolls allow you to create a continuous layer without gaps.

For long-term and trouble-free operation of mineral wool, it is necessary to take care of reliable protection from moisture. The effectiveness of this insulation material decreases by several orders of magnitude even when a minimal amount of liquid gets in. And completely wet cotton wool is practically useless. Installing a hydro and vapor barrier will help protect against moisture.

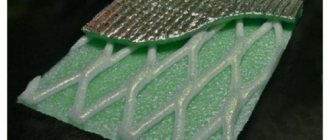

When using foil plates, insulation is ideal: they retain heat well and reflect back thermal infrared radiation.

Benefits of mineral wool

Mineral wool has many advantages over other insulation materials:

- Low thermal conductivity coefficient.

- Excellent soundproofing characteristics.

- Air conductivity. This property allows the use of mineral wool for insulation in wooden houses.

- Wide operating temperature range.

- Light weight, easy handling and quick installation.

- Non-flammability: does not emit toxic substances in case of fire.

- Modern types of mineral wool are resistant to water; when wet, they dry quickly and restore their properties.

- Resistant to chemical and biological influences.

- Elasticity: after compression several times, it quickly restores its original volume.

- Environmental Safety.

How to attach mineral wool to the ceiling

Residents of private houses often get very cold in winter. After all, heat escapes through windows and doorways, cracks in the floor, as well as walls. To solve this problem, mineral wool for insulating the ceiling helps a lot.

Below in the article a video of do-it-yourself ceiling insulation with mineral wool is published, as well as the main nuances of installing this building material.

Features of ceiling insulation with mineral wool

Mineral wool is considered a good ceiling insulation. This building material covers the attic area or living space.

Mineral wool is made from the following materials:

- cullet;

- sand;

- blast furnace slag;

- rocks (basalt).

Mineral wool is considered the most popular building material for ceiling insulation. You can insulate the ceiling in a wooden house with the following mineral wool:

- slag;

- glass wool;

- basalt (stone) wool.

However, many homeowners still use mineral wool as ceiling insulation. After all, this mineral building material has various advantages and has few disadvantages compared to its analogues.

Foil slabs made of mineral wool of the smallest thickness take up little space in a living room and provide good thermal insulation. Fire-resistant mineral wool reflects the heat going outside back into the room.

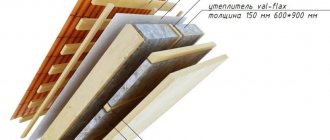

If there is an unheated cold attic in a cottage or private house, then a thick layer of mineral wool is needed to insulate the ceiling. Then fire-resistant mineral wool 15 cm thick is attached to the top. If there are radiators upstairs in the attic of a cottage or private house, then the ceiling covering is sheathed with insulation boards of the same thickness - 10 cm.

Another important criterion when choosing a certain thickness of mineral wool is the density of the building material. The higher the indicator, the thinner the mineral slab.

Advantages of mineral wool insulation on the ceiling

Mineral wool as a thermal insulating ceiling building material has the following advantages:

- minimal thermal conductivity, all rooms of a private house have a comfortable temperature all year round;

- ease of installation, in addition to specialists in this matter, the ceiling is covered with mineral wool by the residents themselves, so they significantly reduce the cost of installation work;

- accessibility - mineral wool is cheaper than many similar thermal insulation materials;

- non-flammable, mineral wool can withstand significant heat, up to 1000 degrees;

- environmental friendliness - mineral wool fully meets all hygienic standards;

- high sound insulation;

- chemical and biological resistance.

However, before fixing the insulation to the ceiling, you need to know not only the advantages, but also the disadvantages of all types of mineral wool. The main ones are listed below.

Varieties of mineral wool

Mineral wool, depending on the material of manufacture, comes in three types:

- Glass wool

Glass wool is popular because it has the lowest cost. Quartz sand or cullet is used in production. Therefore, glass wool contains small glass fibers that are harmful to human health. Today, glass wool is practically not used for indoor insulation. Most often used for thermal insulation outside the room.

- Slag

In the production of slag wool, waste from blast furnace metallurgy is used. It contains brittle and thorny fibers that adversely affect human health. Of all types, it has the lowest thermal conductivity. It absorbs moisture well, but is short-lived: its service life is no more than 15 years. Of the advantages of this material, only one can be named - low price.

- Basalt

Basalt mineral wool has unique technical characteristics. Molten basalt is used in production. This is a material of volcanic rocks that has technical characteristics valuable for insulation. Basalt mineral wool is rightfully considered the best thermal insulation material for insulation. This insulation can be used both outside and indoors.

To achieve high-quality and maximum insulation, it is recommended to choose insulation material from well-established and well-known manufacturers.

How to attach stone wool to the ceiling?

Advantages and disadvantages of insulating ceilings with stone wool, options for placing an insulator on the ceiling, rules for choosing a material, technology for performing work.

articles:

- Features of thermal insulation

- Advantages and disadvantages

- Insulation technology

- Preparatory work

- Selection of stone wool

- Installation from inside

- Installation outside

Ceiling insulation with stone wool is an inexpensive way to prevent heat loss through the ceiling, whether installed inside or outside the room. The quality of work depends on competently performed operations, so in this article we will consider the rules for placing and attaching the insulator to the surface in various situations. Using our recommendations, you can avoid unnecessary financial costs and common mistakes when insulating.

Features of thermal insulation of ceilings with stone wool

Stone wool is a fibrous insulator made from basalt. To improve its characteristics, various substances, including hydrophobic ones, are introduced into its composition. The material is quite loose, saturated with an inert substance, and does not allow heat to pass through.

The ceiling is insulated due to large air leakage through the ceiling, which can reach 20%. This product is used in the following cases: if the house has an attic that is poorly protected from the cold; if the attic of the mansion is not insulated; if the apartment is on the top floor and it is damp; if there are noisy neighbors upstairs.

The ceiling is insulated in two ways: from the inside and from the outside (from the attic). The second method is more convenient and economical. It is allowed to mount the insulator from below if the room has sufficient height to accommodate it. For insulation on the room side, cotton wool is used, shaped as slabs, and on the attic side - in the form of rolls. The thickness of the sheets ranges from 10-100 mm; if necessary, they can be laid in two rows.

The material absorbs moisture well, so the insulating “pie” includes waterproof materials - polyethylene or polypropylene film.

Fibers can have a harmful effect on humans, so when working, follow the safety rules:

- To avoid skin irritation, wear thick clothing with long sleeves and gloves. To protect your eyes and respiratory system, wear goggles and a respirator. After work, change your clothes.

- Keep the product away from children.

- There should be no food in the room.

- Make sure that the insulation threads do not scatter throughout the house. Remove any remaining material promptly.

It is often said that cotton wool is very dangerous, but this statement is not true. Modern technologies completely isolate the coating from the living space, and it will not bring trouble to anyone.

Advantages and disadvantages of ceiling insulation with stone wool

The fibrous material has unique characteristics, thanks to which it is considered the best among similar products.

Its main advantages include the following:

- Very low thermal conductivity, which creates a comfortable indoor environment.

Users should be aware of the problems that sometimes arise when operating a room insulated with cotton wool:

Technology for installing stone wool on the ceiling

Thermal insulation is a complex job and requires compliance with the order of operations. Deviation from the technology will lead to the appearance of bridges of cold and dampness, and the formation of black mold.

Preparatory work

Before insulating the ceiling with stone wool, inspect it for defects and eliminate any deficiencies. The insulator is not afraid of irregularities less than 3 mm; more serious defects will have to be removed.

On the surface, work is performed as follows:

- Clean the ceiling from decorative coating and plaster.

Selection of stone wool

The components of the insulating “pie” must be of high quality. In order not to doubt the purchased product, control the following points:

- Storage conditions for stone wool for ceilings. The ideal option is to store the product in a dry room.

For thermal insulation, purchase products with the following technical characteristics:

- Density

_ Not less than 80 g/m 3. The higher the value, the greater the mechanical load the coating can withstand. The value is relevant for insulation from the attic side.

. Within 0.036. It characterizes the ability of cotton wool to retain heat. The lower the value, the more noticeable the effect.

. For ease of installation from the inside, the insulation should be 500×1000 or 600×1200 mm. For outdoor use, size does not play a special role.

. Not less than 40 mm. The resistance of the material to high temperatures depends on it.

Features of installation of mineral wool

Modern types of mineral wool are completely safe and do not emit any harmful substances during operation. But during installation you must follow certain rules.

With any type of mineral wool, microscopic fibers are separated during installation. They can get into a person's eyes and lungs, and penetrate under clothing. Glass wool is especially harmful to health, since the smallest glass needles do not dissolve in the lungs and can provoke the development of complex pulmonary diseases.

Therefore, it is recommended to work with mineral wool in a closed suit, gloves, goggles and a respirator. At the end of the work, you need to take a shower, throw away your clothes or wash them thoroughly.

Features of fastening to different bases

When talking about how to properly insulate a ceiling, it is impossible not to mention: the method of fastening depends on the base material.

- If it is wood, the work of constructing the frame and installing supporting “umbrellas” will be easy to handle with only a screwdriver or even a screwdriver.

Advice. Before insulation, treat all wooden floor elements with fire-retardant compounds.

- With concrete floors it is more difficult: to drill holes in them you will need a hammer drill. And to assemble the frame - screws with plastic dowels.

You will find a fairly detailed description of the construction of suspended ceilings in other materials on the site; we will not dwell on this here.

Options for insulating the ceiling with mineral wool

There are two insulation options:

- Internal insulation.

Most often it is performed in cases where it is not possible to insulate the attic or when the ceilings of the room are sufficiently high. Depending on the roof structure, temperature changes and the type of mineral wool, the thickness of the insulation will be from 15 to 40 cm.

- Attic insulation

This method is much more convenient, allows you to use cheaper insulation and will help maintain the height of the room.

Polyethylene foam and polyplex

In addition to attaching mineral wool to the ceiling, thermal insulation of the ceiling can be done using other materials:

- Foil polyethylene foam. This insulation is made of polyethylene foam in a special way and then glued to aluminum foil. It is sold in rolls, the width of which is standard and reaches one meter, and the thickness varies from one to 20 centimeters. The material is used both independently and together with mineral wool to improve the thermal barrier.

- Polyplex is produced by extruding polystyrene foam. It is sold in the form of sheets measuring 60x120 centimeters, the thickness of which varies from one to 20 centimeters. Among the advantages, it should be noted the increased density, due to which polyplex is used as insulation and a rough base for laying putty.

Rules for insulating the ceiling with mineral wool

With any method, certain rules must be followed:

- in a cold attic, the thickness of the insulation should be at least 300 mm;

- installation of vapor barrier and insulation must be carried out carefully and carefully;

- Mineral wool should not shrink when used: it should not be pressed tightly with OSB boards or slag should be poured on top;

- to ensure good sound insulation, mineral wool must have a high density;

- It is necessary to lay a vapor barrier film for any type of mineral wool;

- vapor barrier is performed on the warm side of the room from below the insulation;

- The vapor barrier film is installed on one side only.

Foam plastic and expanded clay

The structure of polystyrene foam resembles foamed plastic material with a cellular structure. Most often it is found in the form of square sheets measuring 1mx1m. Its peculiarity is that it is used not only as an internal insulation, but also as an external one. The thickness of the foam varies from 20 to 100 cm. It is also used as a base for putty. When the ceiling is insulated from the inside with polystyrene foam, it can perfectly level the surface. This material has a number of other advantages:

- universal;

- has a low price;

- durable;

- reliable;

- provides a good level of thermal insulation.

Expanded clay is made from clay; in appearance it resembles balls. The principle of installing expanded clay on the ceiling is to pour it on the floor of the attic. Therefore, this method of insulation is applicable only for private houses. But at the same time it has the following advantages:

- does not decompose;

- fire resistant and fireproof;

- eliminates the possibility of insects and rodents appearing in the material;

- has good sound insulation;

- waterproof and frost-resistant;

- has good heat dissipation;

- has an affordable price.

If you are planning to insulate your ceiling with expanded clay, pay attention to the following recommendations:

- Before laying expanded clay, you should take care of the waterproofing layer on which the material will be poured.

- The first thing to cover is the rafters and chimney.

- To ensure high-quality thermal insulation, the expanded clay layer must be at least 16 cm.

How to insulate a ceiling with mineral wool from the inside of your home

When insulating the ceiling surface in a private house, tiled mineral wool is best suited.

Installation consists of several stages:

- Lay a special waterproofing film or any other insulating materials.

- Assemble and secure the frame using a hammer drill and dowels - nails. The frame can be wooden or metal.

- Place mineral wool. The insulation is glued to the ceiling. You can use tile adhesive for this.

- Cover the structure with plasterboard or boards.

When covering, it is better to use self-tapping screws made of hardened steel: they have high strength and can withstand heavy loads.

Glue option

Everything will be much simpler here. There is no need to assemble the sheathing or frame - all the slabs are simply glued to the base and then further strengthened using plastic dowels. However, before starting work, it is imperative to prime the ceiling and, if necessary, create a waterproofing layer.

The glue must be spread both on the surface and on the slab. Some adhesive compositions can only be applied to the part being glued - be sure to clarify this point in the instructions for the glue. When all the slabs are glued and secured with dowels, they proceed to the final stage - covering the mineral wool with non-woven fabric, vapor barrier or polymer mesh.

A vapor barrier or non-woven fabric prevents cotton wool particles from getting into the air. If they come into contact with the skin, they can cause itching and other unpleasant sensations, and if they get into the lungs they can pose a certain threat to health. That is why all work with mineral wool must be done in a respirator and gloves. The mesh is glued to the surface of mineral wool slabs so that the surface can later be plastered or puttied, and also protects the air in the room from the appearance of insulation particles in it.

How to insulate the ceiling with mineral wool in your home from the outside

Installation steps:

- Clear the attic of debris and belongings.

- Lay a vapor barrier film or any other vapor barrier material on the ceiling.

- Seal the joints with special tape.

- Lay rolled mineral wool on the vapor barrier film between the wooden beams. Do not leave gaps between the beams and the insulation! There is no need to cover the mineral wool on top with anything.

- Lay boards or drywall over the beams.

After installation, mineral wool takes on its final size in 15-20 minutes. If it is located above the beams, then it is necessary to fill the beams with additional blocks to the height of the insulation.

How to put mineral wool on the ceiling?

Residents of private houses often get very cold in winter. After all, heat escapes through windows and doorways, cracks in the floor, as well as walls. To solve this problem, mineral wool for insulating the ceiling helps a lot.

Below in the article a video of do-it-yourself ceiling insulation with mineral wool is published, as well as the main nuances of installing this building material.

How to fix insulation to the ceiling from the inside

How you can insulate a ceiling with mineral wool from the inside depends on the specific type of insulation chosen. For example, when using polystyrene foam, the lathing is not installed on the ceiling, because the building material is firmly held on by glue and mastic.

Mineral fire-resistant wool is attached under suspended ceiling structures. In damp residential areas, metal profiles are installed, and in the rest - wooden ones.

When installing mineral wool ceiling insulation from the inside, perform the following steps:

- after insulation of the ceilings, decorative finishing is carried out;

- the profile is mounted taking into account the dimensions of the building material;

- film or glassine is used as waterproofing;

- building materials are laid without gaps.

The second level of waterproofing is also hermetically sealed. When using foil material, such a layer is placed as a reflector inside the living space. The lattice, with which fire-resistant mineral wool is fixed, is also used as a strong support for decorative ceiling decoration.

How to attach mineral wool to the ceiling from the attic side

When covering the ceiling with mineral wool, the necessary microclimate is created in the attic of a cottage or private house. This prevents the formation of various pathogens (for example, fungus).

Important! Mineral wool is a unique thermal insulation building material. However, before carrying out external installation work, first provide free access to all ceiling surfaces.

When installing ceiling insulation in a private household from the attic side, the following installation work must be performed:

- Install a vapor barrier. If there are several joists in the attic, a film is laid on top.

- Mineral wool slabs are laid between the joists.

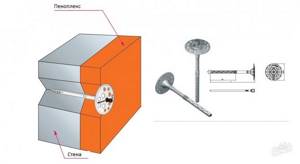

- After completion of the installation construction work, the insulation is attached to the ceiling with several dowels with large heads.

- A waterproofing ceiling layer is laid.

- The ceiling is insulated with sheets of plasterboard.

Source: https://arthouse188.com/kak-polozhit-minvatu-na-potolok/