There are always a lot of questions about what and how to cut mineral wool. Especially for those who are going to build housing on their own (for example, frame housing, which involves assembling it yourself). After all, in its structure it is a fibrous material, which also has a certain thickness. Ordinary table knives or scissors designed for cutting cardboard or thick fabrics are completely unsuitable here.

However, before you start cutting mineral wool, it is important to deliver it correctly to the construction site. Indeed, otherwise, the material, brought to the state of defect, will not have to be cut, but simply replaced with a new one. And these are additional costs.

Overview of mineral wool cutting tools

There are always many questions about what, how and how to cut mineral wool. Especially for those who are going to build housing without the help of others (for example, frame housing, which involves assembly by their own employees).

After all, in its structure it is a fibrous material, in addition having a certain thickness. Ordinary table knives or scissors designed for cutting cardboard or thick fabrics are completely unsuitable here.

But before you start cutting mineral wool, it is important to deliver it correctly to the construction site. After all, otherwise, material brought to the point of being defective will not have to be cut, but simply replaced with a new one. As is clear - additional costs.

How to transport insulation correctly

The science is simple, but very principled. What is necessary:

- slabs and mats are transported horizontally;

- the truck is expected to have a protective awning;

- transportation is provided only in packaged form;

- during transportation, loading and unloading operations, it is important not to compress the heat insulator too much;

- unpack the mineral wool just before starting insulation work.

Safety is ok

Stone wool is made from natural raw materials – the mineral basalt. Its fibers are bonded using formaldehyde resin. It gives the material the necessary strength characteristics, in addition making it more dense. Although they say that phenol is dangerous, but not in this case.

READ Screwdriver Lithium Battery Replacement

After all, it is not capable of being released from basalt wool, since it is completely neutralized during the production of the material. In general, at the production stage of this mineral heat insulator, phenolic fumes are very small - much less than the permissible limit of 0.05 milligrams per m2/hour.

In contrast to glass wool fibers, basalt fibers do not irritate the skin, do not prick, and do not cause allergies.

At the moment, the construction market has decent volumes of stone wool brands of various densities, the technical characteristics of which are somewhat different.

But what remains for our client to do? The types of basalt heat insulator are distinguished by their strength and a couple of years of operation.

Operational features of basalt wool

Basalt and other rocks of its group are used for production. Thin fibers are taken, into the melt of which limestone (10-15%) or charge is added. Additives increase the resistance of the material to excessively high temperatures and aggressive environments. The result is an insulation material with fairly high performance characteristics:

Scheme of basalt insulation.

- thermal insulation and hydrophobization. The first parameter is from 0.042 to 0.048 W/mK. Other well-known insulation materials (for example, polystyrene foam, polyurethane foam) have approximately the same characteristics. Mineral wool is not able to accumulate moisture (hygroscopicity is less than 1%), which makes its weight unchanged. A distinctive feature is vapor permeability, which guarantees insulation and at the same time intense moisture exchange between the external environment and the walls of the building;

- density, strength. The insulation has sufficient density (from 30 to 100 kg/cubic m), which guarantees high thermal insulation properties with optimal strength. The rigidity of the material is ensured by the direction of the fibers; they are located in horizontal and vertical directions;

- soundproofing. Good noise protection characteristics are achieved due to the porous structure of the wool;

- resistance to aggressive environments. Vata is “indifferent” to alkali and acids; does not rot, is not affected by fungus. Rodents also avoid this insulation;

- fire resistance. Basalt wool can withstand heating up to +700°C. This protects the structure from complete destruction in a fire and gives time for residents to evacuate;

- health safety. In production, resins containing harmful substances (formaldehyde, phenol) are used. However, adherence to the technology requires their introduction into the insulation composition in a chemically bound state. The substances become completely neutral in relation to the environment and do not pose a danger to humans.

However, if mineral wool is produced by handicraft methods, then there is a health hazard. Therefore, it is more advisable to purchase material from trusted manufacturers.

How to cut mineral wool?

A distinctive feature of a mineral heat insulator is its structure consisting of fibers, which must become solid to ensure thermal insulation. Based on these reasons, special attention should be paid to the cutting process. You cannot use cardboard scissors, as fabric is also called, or ordinary table knives to cut the material. These tools are not intended for such material, because they can spoil its appearance and impair its useful properties. It is very useful for novice repairmen and builders to know which tools are suitable for this purpose.

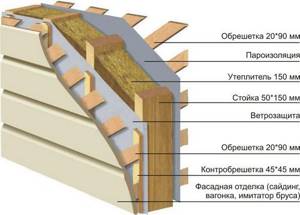

Technology of wall insulation with basalt

Inside with sheathing

Refers to the simplest option for insulating a private home and industrial structures. The essence of the method is to create a sheathing frame. Assembly is made from wooden beams or metal profiles. The width of the mats is first measured and, subtracting 5-7 cm from the obtained values, the sheathing is assembled.

Next, mineral wool is tightly inserted into the cells of the frame, filling the entire space. A vapor barrier membrane must be attached on top of the insulation.

Lathing

Insulation of walls using the “well” method

If the house design involves laying facing bricks, then the best insulation option would be “well”.

Consider the composition of the “well” pie:

- Bearing wall. As a rule, it is brickwork laid out in one row. Although other materials are also used for load-bearing structures. Depending on the required load-bearing capacity, the walls are laid out in half a brick, a brick and a half or two.

- Insulation. In this case, basalt wool is used. Fastening to the surface is done using umbrella dowels.

- Facing wall. Masonry begins after complete installation of the insulation or as the inner layer builds up. Ceramic or silicate brick is used as the outer layer. The usual installation method is half a brick. A prerequisite for laying facing bricks is the presence of a concrete base.

- Ventilation gap. Since the appearance of condensation on the inside of the insulation is undesirable, a ventilation gap is created for this purpose to ensure sufficient ventilation.

Well method

Attention! If for some reason it is not possible to create a ventilation gap, then it is better to abandon the well method of insulation altogether. This applies to mineral wool.

Wet insulation of walls

The method is used for plastering, because with the “wet” method of insulation, lathing is not provided. Since a high load will be applied to the mineral wool, it is recommended to use high-density mineral wool.

Wet method

Basalt wool fastening technology:

- Following the instructions supplied by the manufacturer on bags of glue, we prepare a liquid solution.

- Apply the prepared mixture onto the mineral coating with a notched trowel. The glue is applied in a continuous layer without coating the end part, which can lead to a decrease in the level of thermal insulation.

- We install mineral mats on the basement of the building and press them against the wall. To increase adhesion, it is necessary to smooth the surface using pressing movements, applying little force. Installation of basalt wool is done from bottom to top. The next row is laid with an offset of half the mat. The same applies to places near window and door openings.

- External and internal corners are reinforced with plaster corner plates.

- We fix the mineral wool with umbrella dowels - 5 fasteners per sheet.

- Using an adhesive solution, we attach the reinforced fiberglass mesh. Make sure that the material overlaps each other by 15-20 cm.

- At the final stage, plastering is carried out.

Machine for cutting mini-slabs - without intermediaries.

How to cut thermal insulation? Mineral wool is one of the best, most common and widespread materials for insulation and sound insulation of walls and ceilings today, and is also known in some other areas of application. In addition, it is easy to install, in other words, you can create room insulation without the help of others. Most people do not know how to cut mineral wool correctly without disturbing its structure; in this matter, the material will be examined; our client only needs to know how to properly cut mineral wool, and we will advise the tools that are best suited for this purpose.

Sawdust as insulation for the home

Sawdust is wood processing waste in the form of small shavings and wood dust. This well-known material has been used as insulation for a very long time, since it retains heat well, releases wood resins and is an excellent leavening agent.

Application area

The beginning of the history of using sawdust in low-rise construction goes back to those distant times, when they began to be added to clay and used to build floors from this mixture in village houses.

Such floors can be called ideal: they served for a very long time, were not damaged in any way, had no disadvantages and had very significant advantages - low cost and high thermal insulation.

Taking this ancient technology as a basis, modern industry began to produce the same high-quality building materials - granules, wood concrete, concrete with sawdust, wooden blocks.

Sawdust also continues to be used in low-rise construction. Private developers are especially interested in this material, who insulate walls, floors, ceilings with sawdust, and also use them for other purposes as needed.

Are there any nuances in transportation and storage?

Cotton wool should only be stored horizontally

When transporting, you should follow the same rules: transport the cotton wool horizontally and in a dry truck bed. It is also necessary to provide the material with protection from mechanical stress and precipitation. When loading and unloading material, do not compress it too much.

Unpacking a mineral thermal insulator also requires certain qualities. The material should be removed from the packaging only before work, which will reduce the risk of damage to the heat insulator. When laying out the material for cutting, use its packaging as a bedding. Thus, the product will not get dirty. Also, packaging is also used to collect other waste at a construction site.

Rock wool or glass wool?

When placing cotton wool, you should wear gloves and a long-sleeved robe.

Despite fairly similar technical characteristics, basalt insulation has a number of significant differences from glass wool. These differences will help us understand which is better - glass wool or stone wool.

First, let's take the basalt insulation slab by the corner and try to shake it.

After the test, the sheet remained intact.

Now let's do the same with glass wool. The result is radically different.

The corner of the glass wool could not stand it and came off.

Now fold the sheet of basalt wool in half.

We folded the basalt slab in half - it lends itself well.

We perform the same manipulations with glass wool. The result is again strikingly different from the previous experience.

A sheet of glass wool broke in half.

Remember how we walked on stone wool slabs with our feet? Let's walk through the glass wool slabs. The result is different again.

Footprints are clearly visible on the glass wool.

In addition to this visual demonstration, you can recall the well-known feature of fiberglass insulation:

- This material causes severe itching upon contact with skin;

- In case of contact with eyes, seek medical attention;

- If you inhale glass wool dust, you can get bronchitis or asthma, and in some cases, lung cancer.

If we take slag wool or mineral wool based on basalt with admixtures of dolomite and limestone, we will see that basalt insulation is superior to all these types in almost all respects.

Fire-resistant basalt fiber mat.

The difference between fiber-based insulation can be quite significant. One turns out to be a safe and durable product that demonstrates unexpected properties, the other is a source of disease and simply a low-quality material.

What is the best way to cut mineral wool?

To separate canvases and rolls, craftsmen use a special machine. But some people ask the question: “What is the best way to cut mineral wool into slabs at home in order to save money?”

In everyday life, a mounting knife is used to cut the canvas. This commonly heard tool has one drawback: due to the small blade, it is difficult for them to cut thick slabs. Therefore, I recommend using a stationery knife only for thin sheets. If this condition is not observed, then the canvas will naturally become unusable.

Saw, Shura! HOW TO CUT mineral stone wool TO INSULATE a house. Part 4

Cutting mineral wool with a knife

Tools that are significantly more reliable for cutting mineral heat insulators:

- A knife whose blade is made of carbon steel. This product is very easy to cut, now its blade sharpens well and quickly. This knife needs careful care to avoid rust. The basic rule of care is to wipe the blade after washing.

- A knife whose blade is made of steel. Each side has teeth of different lengths, so it is very easy to cut mineral insulation of various sizes and thicknesses. The blade quickly sinks into the slab and cuts it perfectly. The sharp tip will make even indirect cuts.

- Special machines. Such tools are capable of cutting blades along an even cutting line and along a bend. A similar feature is highly valued in industry. If you need to cut the cotton wool only once, then it is stupid to buy precious equipment - the tool that you have at home will do.

Cutting mineral wool with a special saw

To cut wool, it is advisable to use a special hacksaw for heat insulators or for metal. It is used for cutting material whose thickness does not exceed 5 cm.

The blades of the tool you use to cut cotton wool should always be kept perfectly sharp. In this case, the cotton wool fibers will not stretch enough. Russian manufacturers advise cutting cotton wool without performing a high-quality installation, like unrolling a roll.

READ Which glass cutter is better to cut a mirror with your own hands?

Main characteristics:

- coefficient of thermal conductivity

- mechanical characteristics

Mineral wool has high thermal resistance. The thermal conductivity of mineral wool depends on the geometry of the fibers of the material. The ideal choice is a material with randomly directed fibers. According to the degree of rigidity (density indicator) and, accordingly, according to the areas of application, materials can be divided into 5 types:

- Soft (light) grades: from 40 to 55 kg/m3, grade PM-40 and PM-50 (used in frame structures, for insulating walls, pitched roofs - where there is no load on the insulation)

- Semi-rigid: from 60 to 90 kg/m3, grade PP-60, PP-70, PP-80 (wall partitions, pitched roofs, multi-layer systems)

- Hard: from 100 to 150 kg/m3, grade PZh-100, PZh-120, PZh-140 (plaster facades, flat roofs, floors - where there is a load on the insulation)

- Plates of increased rigidity: from 160 to 210 kg/m3, grade PPZh-160, PPZh-180, PPZh-200

- Solid slabs: from 220 to 300 kg/m3, brands PT-220, PT-250, PT-300.

The weight of mineral wool depends on its base. Fiberglass-based materials are lighter than stone wool-based materials. You can choose different sizes of insulation. The thickness of mineral wool varies from 25 mm to 150 mm. The width and length of the material are also varied. The dimensions are usually dictated by the distance between the frame posts into which the insulation boards will be inserted.

Thus, the melting point of stone wool fiber is over 1000 C⁰. At high temperatures, the minislab does not deform, its properties are preserved, and it resists the spread of fire. Therefore, basalt wool is often the only possible solution when choosing thermal insulation for structures, taking into account the strict requirements of fire safety standards. Basalt wool is an absolutely safe product; it is not classified as a carcinogen, but wool requires the use of personal protective equipment (PPE) during installation. The microparticles that make up mineral wool can cause damage to the respiratory and visual organs if they are not protected.

Basalt wool is ideal for interior work, because... subsequently it will not emit harmful substances when heated, as happens, for example, with expanded polystyrene. When heated above 35-40 degrees, it releases toxic substances, albeit in minute quantities.

If the question arises about how to cut mineral wool, then there will be no problems with the answer. Any mineral wool can be easily cut to give the desired shape and size: soft wool is cut with a knife, and harder wool is cut with a hacksaw.

Cotton wool can be placed on any surface, as it easily takes on the desired shape. To fasten the wool, frame structures (rafters, floor beams, plasterboard profiles, etc.), glue for mineral wool or an adhesive composition with dowels are installed. The best fasteners for mineral wool are plastic dowels; plastic does not conduct cold well. The length of the fastener must be calculated based on the thickness of the slab + 5...7 cm for the fastener to enter the wall.

There are also metal dowels, but there is no point in using them for thermal insulation; they are used for fire protection; for thermal insulation, metal fasteners will be a “cold bridge.”

The biological and chemical resistance of wool is also an important characteristic. Thus, stone wool is immune to fungi. To the question whether mice live in mineral wool, one can answer that the environment is attractive for rodents to live in if the density of mineral wool is low, then mice even build nests there. But they do not live in mineral wool with a density of 100 kg/m3 and higher; they simply cannot chew through it.

Characteristics and properties of the material

Before starting construction or repair work, the owner of the premises thinks about the question of what nuances should be used to choose materials. Nowadays, the range of sales is replete with different canvases, differing in raw materials, prices, scope of implementation, and features of operation.

The term “mineral wool” implies three types of materials, and directly:

- basalt (stone);

- slag;

- glass wool

Glass wool (made from fiberglass) is characterized by low density and high hygroscopicity. The material does not have the characteristics of water resistance, and it is not recommended to expect heat resistance from it: when the heating temperature reaches a high temperature (about 300 degrees), the wool fibers melt, and the material no longer functions as an insulator. Glass wool is sold in rolls.

Glass wool is made by blowing: an industrial centrifuge produces air flows that go directly into the raw material. Using the air flow method, fibers appear from threads; however, they have different lengths, directions and thicknesses.

Mineral wool has low thermal conductivity, allows steam to pass through the cell structure and does not actually absorb water. Not counting the base in the composition than the connecting parts, which allows it to withstand high temperature properties. The material is widely used as sound insulation and heat insulator for various substrates and surfaces. It is made in sheets that vary in strength.

How to cut mineral wool

Slag wool for room insulation

Slag wool is a cheaper option for insulation. The material consists of fibers that are waste from blast furnaces; it is not dense and does not have good heat resistance. If you overheat slag wool, it will sinter. Therefore, the material is not suitable for insulating rooms adjacent to heat sources, and is also not recommended for building houses.

The structure of the horizontal layer of all types of mineral wool is created in the direction of the fiber. The formation of vertical sections occurs using the method of parts that are arranged randomly. Each type of material has its own characteristics and external differences.

Mineral wool production technology and manufacturers

Development of basalt wool technology began back in the 60s; they were dictated by the need to create a particularly high-quality material for the manufacture of rocketry. Costs were high, so mass production required the creation of new and improved installations.

New developments have made it possible to establish mass production of Izovol, TechnoNikol, Rockwool. Since 2011, a new brand “Baswool” has appeared on the Russian market - a derivative located in the city of Blagoveshchensk (Bashkortostan). Local raw materials are used as the basis for Bashkir basalt wool; production is highly automated.

In special furnaces, basalt rock is melted, passed through dies and, at high temperatures, inflated with powerful streams of compressed air. As a result, the fiber is ultra-thin, its diameter is 1-3 microns. The fibers are formed into pressed mats, then they are heat treated and cut into slabs.

To give the material strength and durability, additives from carbonate rocks are used, which increase its acidity. The higher the acidity, the better the water resistance. Composite, bitumen, bentonite and synthetic clays are added to bind the fibers, and they also give the wool the desired shape.

Product Types

Mats are widely used: stitched, with one-sided or double-sided facings, as well as options without facings. Slabs are no less in demand; here slabs are distinguished by rigidity: rigid, semi-rigid, soft, with increased rigidity, hard slabs. When choosing, you should pay attention to modifications, sizes, brands of the product - the scope of its application depends on this. Material specifications:

- low thermal conductivity;

- excellent sound insulation;

- good vapor permeability;

- resistance to aggressive environments;

- fire resistance, creates fire protection, as it can withstand melting temperatures of more than 1000 degrees;

- preservation of geometric dimensions during compression, if subjected to significant loads; - does not rot or be affected by fungi.

How to cut mineral wool?

The material has a fibrous structure, so during cutting, small particles of glass wool fly in the space. Therefore, it is necessary to prevent contact of hazardous parts with the skin and respiratory tract.

Before cutting the heat insulator, the following conditions must be observed:

- The room should be well ventilated.

- When working, it is imperative to introduce protective equipment and special clothing. We are talking about gloves, a respirator, a mask, overalls and safety glasses.

- When the material is cut, it is recommended to wash your face and hands under cold water.

To ensure that the least amount of glass wool particles are formed in the air, you should use a well-sharpened tool.

The insulation should be cut without unrolling the roll.

To obtain strips of cotton wool that are identical in width, you should cut the material directly from the roll. If the wool is in the form of slabs, then you need to cut them one at a time.

In order for the strips of cotton wool, cut without the help of others without the help of others, to come out even and similar, they should be divided correctly according to the marks. Also, use a ruler to cut the cutting line.

When cutting, leave allowances along the edges. If it is a roll, then the indicator should be 0.5 cm, if it is a slab , then 4 cm. This cutting feature is needed so that the mineral wool element completely fills the required space.

Let us remind you that mineral wool slabs are cut one at a time, and the material is cut in rolls without unrolling.

Types of metallized insulation

There are a huge number of insulation materials with a foil layer.

Almost every manufacturer of thermal insulation materials has a line with foil coating, and everyone calls their products differently; accordingly, the same material can have a different name. Folgoizol, foil plastic, energoizol, all this is practically the same material. Let's look at the most popular types of metal-coated insulation.

Foiled polyethylene foam

The most popular foil-coated material is made from polyethylene foam. It can be two or three layers.

It is used everywhere in the construction of houses, baths, saunas. Also used for sound insulation and insulation of cars. Can be used as a backing for laminate and other floor coverings.

The thickness of the foil coating rarely exceeds 15 microns. The foil layer can be applied on both sides of the insulation, due to which the material is able to reflect both internal heat and cold penetrating from the outside of the room.

The base made of foamed polyethylene is environmentally friendly, does not rot and resists moisture well. It has internal pores filled with air, due to which it has good thermal insulation characteristics.

Foamed polyethylene with foil coating is produced by the following companies:

It is worth noting that there are several technologies for the production of foamed polyethylene:

- The usual, inexpensive one is produced using foaming technology, after which it does not undergo additional processing; as a result, its resistance to dynamic loads is not high enough. Simply put, the material is subject to shrinkage.

- The second method is cross-linked polyethylene, after production it undergoes special processing, due to which it becomes denser and, after removing the load, tends to restore its original shape and size.

To install such thermal insulation, no specific skills are required:

- It is enough to unroll the roll, cut off the required amount of material and secure it to the insulated surface.

- For fastening, you can use a construction stapler.

The second option for fixing the “shiny” is to press it down with laths for siding or lining. The insulation is laid with an overlap of no more than 10 cm, the joints are glued with metallized tape and pressed with a lath or fixed with staples.

Foiled mineral wool

Another type of insulation with a metal coating is mineral wool.

It is mainly used for external insulation or for thermal insulation of attic rooms. Mineral wool (glass wool), even without a metal layer, has good thermal insulation qualities. The presence of a metal layer on the surface only enhances its effectiveness.

Mineral wool also has its disadvantages. First of all, it is afraid of moisture, so for interior work it is used only for dry rooms, mainly for insulating roofs. The second feature that must be taken into account is almost zero load resistance. This means that even a slight weight of the load can compress the mineral wool, as a result of which the thermal insulation properties are sharply reduced. Using mineral wool for floor insulation is not effective.

Often, mineral wool with a metallized coating is used for insulation of pipelines and chimneys. This is due to the low flammability of the material and the ability to withstand temperatures up to 300 degrees.

Installing such insulation is a little more difficult than the previous one:

For fastening to concrete, brick and gas-block bases, special dowels for insulating materials are used, the head of which is wide, due to which it does not break the loose structure of the insulation.

Foiled polystyrene foam (with double-sided foil)

The material is used in damp rooms. Thanks to the foil layer, it reflects heat and prevents moisture from entering the material.

Expanded polystyrene is a derivative of polystyrene foam. The structure is dense, finely porous, due to this it resists external loads well. It can easily support the weight of an adult, so you can step on it during installation. The material is recommended by manufacturers as a basis for laying a heated floor system.

Cutting mineral wool, how and how to cut mineral wool in rolls and slabs

A distinctive feature of a mineral heat insulator is its structure consisting of fibers, which should preferably be solid to ensure thermal insulation. Based on these reasons, special attention should be paid to the cutting process. You cannot use cardboard scissors, as fabric is also called, or ordinary table knives to cut the material. These tools are not intended for such material, because they can spoil its appearance and impair its useful properties. It is very useful for novice repairmen and builders to know which tools are suitable for this purpose for your job.

What are leftover mineral wool useful for?

The remains of the insulator do not need to be thrown away: they are also useful for the pantry or utility room. They probably strive for economical insulation, so they use scraps and leftover material.

Waste mineral wool can be recycled for later use. Special machines are used here.

In order for the process of insulating a room to go well, you should know what you need to use to cut mineral wool and how to do it. If you follow simple rules for working with this heat insulator, you will achieve good results.

READ How to Repair the Interskol Screwdriver Battery

External wall insulation technology

Insulating the façade with cotton wool is done using glue and special dowels with a large head. The material is supplied in the form of rolls or slabs, which are cut into pieces of the required size. You will also need a metal profile or wooden blocks between which the insulation will be fixed. You can cut the material with an ordinary sharpened knife. However, if the density is high enough (80-100 kg/cubic m), then you will have to cut it using a hacksaw. Insulation of the facade is carried out in the following order:

- a vapor barrier film is attached to the wall; it must release moisture under the mineral wool slabs and prevent cold air from entering the house;

- Then wooden blocks or a metal profile are attached to the wall in a vertical position. Their width should correspond to the thickness of the insulation. The interval between the posts should be such that the mineral wool is inserted with little effort;

- The insulation is fastened with glue and special dowels if the wall is stone, or with nails (screws) with large washers if the surface is wooden. For 1 sq. m you need 5-6 pieces;

- It is recommended to lay a windproof membrane on the fixed basalt wool, the joints of which are taped with adhesive tape;

- To ensure ventilation under the subsequent decorative coating, it is advisable to make a counter-lattice over the slabs from wooden blocks or a metal profile 10-15 mm high.

Insulation scheme using basalt wool.

This technology is suitable when facade insulation under siding is required. However, in some cases, for example, in multi-story buildings, it is necessary to secure the insulation more firmly. In this case, it is additionally fixed to the surface with glue, and reinforcement is carried out at the same time. This operation strengthens the structure and dampens the thermal expansion of the material, which can contribute to the formation of cracks and increase thermal conductivity.

Reinforcement is made on the already installed insulation using special glue and mesh that is resistant to alkali. First, glue is applied on which the mesh is laid, then it is covered with another layer of adhesive. The final decorative finishing can be done using facade paint and decorative plaster.

Return to contents

How to cut?

When cutting mineral wool, it is important to maintain the shape and density of the material, avoid injury and make do with inexpensive purchases. Therefore, it is important to follow the following tips:

- during independent construction, when the workers do not have sufficient experience, it is advisable to consult with the craftsmen before cutting, especially if the presence of pieces of complex shapes is expected. This will help prevent unnecessary consumption of heat insulator;

- the cutting tool can be perfectly sharpened so that the mineral wool does not tear into fibers and generates less dust;

- when cutting a heat insulator, it should be taken into account that in order to ensure a tight covering of the insulated area with mineral wool, allowances of about 5 cm must be left;

- It is better to cut rolled mineral wool before unrolling it;

- mineral wool slabs must be removed from the packaging and cut one at a time;

- It is not recommended to cut mineral wool “for future use” - right away, completely for the amount of work. This increases the risk of accidental damage to its shape when additionally moving it to different places, or, in other words, stacking pieces on top of each other.

Tips for cutting insulation

To prevent the material from tearing when cutting, creating a large amount of dust and waste, the tool must be sharp. Due to the nature of the insulation, consisting of stone or glass fibers, it quickly becomes dull and requires frequent sharpening. Or, in the case of a utility knife, replacing the blade.

Before cutting mineral wool in slabs, markings are applied to them, an even strip is pressed against it and the cut is made by pressing the tool blade against the guide and holding it vertically.

To cut rolled insulation, markings are made directly on the packaging, gluing masking tape around its circumference.

How to cut mineral wool in slabs?

There are always many questions about what, how and how to cut mineral wool. Especially for those who are going to build housing without the help of others (for example, frame housing, which involves assembly by their own employees). After all, in its structure it is a fibrous material, which also has a certain thickness. Ordinary table knives, or scissors, designed for cutting cardboard or thick fabrics, are completely unsuitable here.

But before we start cutting mineral wool, it is important to deliver it correctly to the construction site. After all, otherwise, material brought to the point of being defective will not have to be cut, but simply replaced with a new one. This amounts to additional costs.

About installation methods

Stone wool is used for all types of work, external and internal

For each climate zone, it is important to separately calculate the coefficient below which the thermal resistance should not fall

To do this, the thickness of the structure in meters is divided by the thermal conductivity coefficient that distinguishes this or that material. Each of them is counted separately, then the indicators are added to each other. This way you can calculate the optimal performance of basalt slabs, and it is easier to control the technical characteristics.

Wall insulation

Due to their composition, basalt insulation is not able to absorb moisture. But it is better to take care of a tight vapor barrier when the material is installed indoors. Then all the moisture from the room will be retained in the walls.

The layers of material, starting from the deepest, are in the following order:

- Interior finishing.

- Minimal ventilation gap.

- Vapor barrier.

- Stone wool.

- The wall is outside.

Exterior finishing is best done from materials that can breathe. This will protect against moisture from escaping from the insulation. 50 kilograms per m3 is the optimal density for work when using basalt insulation.

Facades

Cotton wool is also excellent for long-term insulation of facades, because the total service life, if all requirements are met, reaches seven decades. For a ventilation facade or plaster – you can choose any method to complete the project. In the case of plaster, the situation is simpler.

It is enough to connect the insulation sheets to the wall, then use plastic dowels or mushrooms for fastening. After this, the tile will retain its parameters for a long time.

The top of the wall is plastered and a reinforcing mesh is used.

Creating ventilated facades will be more difficult:

Wall Mounting Rails

It is important to take care of the indentation 2 centimeters less than the width of the wool. The insulation itself is placed between the guides. The soft layer must be laid against the wall if there are several layers themselves. The wind barrier is laid directly on the cotton wool, close to each other. The finishing guides are filled with the following

The ventilation gap is created during this same stage. Finally, everything ends with stuffing the trim.

Treatment of floor and ceiling

A vapor barrier is an element that is required in any case

It doesn’t matter whether we are talking about floor or ceiling coverings. Basalt wool does not absorb moisture, but this does not mean that you can abandon such solutions completely

Using a vapor-proof membrane to cover the top of the insulation is an even worse mistake.

Complete insulation of materials is impossible; some moisture will still get inside. Using a vapor barrier on top leads to the formation of fungus. The reason is that all the moisture accumulates inside the cotton wool itself.

Here are some simple tips that will help you understand the further work:

- It is recommended to install the vapor barrier on the inside of the room, under the insulation. This is true in the case of floors.

- Waterproofing protects against moisture, but is capable of allowing steam to pass through. These types of materials must go above the insulation. Then moisture will not get inside, and steam will come out.

- Wind protection. Protects the top layers of materials from air ingress. Thanks to this, the ability to protect the base at the original level is maintained for a long time. This option is used only by owners of ventilated facades.

A ventilation technical gap between films and finishing materials must be present in any case. Between foam and insulation, this arrangement option will also not be superfluous. 35 kilograms per cubic meter is a suitable density for work in this case.

Roof

A vapor barrier is laid between the insulation and the room. This is done so that the vapor barrier layer does not let moisture in in large quantities. The waterproofing membrane must lie behind the stone wool. She's missing steam. The main breed does not matter.

Without ventilation gaps, mold appears along with condensation. Insulating films do not allow direct exposure to sunlight; they must be constantly protected from this. This is what insulation is for.

What are we going to cut?

There is an option to do this using different devices, depending on the thickness of the mineral wool.

Thin materials (less than 50 mm):

- kitchen loaf knife with serrated edge;

- assembly construction knife;

- stationery knife.

Denser and thicker materials:

- special knives about 300 mm long. They are often offered by Russian manufacturers of insulation materials. Such a tool has teeth of different sizes for cutting mineral wool of different thicknesses and densities;

- saws with straight teeth;

- hacksaw for metal;

- cutting machines. Used when cutting parts of complex shapes. But for independent construction of your own house, in other words, for one-time use, it is not practical to obtain such expensive equipment - you will have to adapt to the capabilities of other tools.

Cutting tool

How to cut mineral wool depends on the thickness and density of the insulation

The scope of work should also be taken into account. If it is small or thermal insulation work is carried out once, you can get by with a regular cutting tool

If you have to insulate several objects, it is better not to waste money on a professional one.

Regular tool

Before cutting the mineral wool insulation, determine the thickness of the slab or mat. If it is less than or equal to 5 cm, for cutting you can use:

- construction knife;

- stationery or wallpaper knife.

Construction knife with a retractable segment bladeSource ozone.ru

The main thing is that the length of the blade exceeds the thickness of the material being cut, otherwise it will wrinkle and the cut will be torn.

It is better to cut thicker insulation with other tools that you will probably find on the farm.

- A long kitchen knife, better for cutting bread with a serrated edge.

- Metal hacksaw with fine teeth.

- A hand saw or hacksaw with straight, fine teeth.

You can cut the insulation with a fine-toothed wood sawSource stroyday.ru

Professional tool

When choosing how to cut mineral wool in thick slabs, experts advise not to skimp on special tools. Of course, we are not talking about buying special machines - it is justified only if you are going to do thermal insulation work professionally and on an ongoing basis. But if the amount of work to be done is considerable, you can think about buying professional tools - knives and saws, the cost of which varies between 500-1500 rubles.

Knives for cutting insulation have a smooth, wavy or serrated blade with a length of 28 cm. Some models have double-sided sharpening with different edge relief: a serrated edge cuts cotton insulation, a wavy edge cuts polystyrene foam.

Knife with a double-sided bladeSource allegroimg.com

For professionals, a similar tool is available in the form of a cordless hacksaw.

Rolled insulation is often cut crosswise before removing the packaging, without unwinding. In this case, the cut is smooth along the entire length, and tightly twisted material is easier to cut. If you need to decide how to cut basalt insulation in rolls, preference is given to knives with a long blade length or special saws for fiber insulation. Their length usually starts from 50 cm.

In principle, such insulation is easy to process, and it can be cut with any sharp tool. Even with thin steel wire, with handles attached to the ends.

It is important to create a safe working environment

This is truly fundamental. Just as in any business, following light safety precautions will preserve your health and carry out work in the optimal time frame at a high quality level. Where to pay attention:

- It is better to cut the heat insulator in cool weather, because to perform the work it is necessary to wear a protective suit made of dense material, which will prevent skin contact with the mineral wool fibers and its irritation;

- To protect your hands, wear special gloves - with silicone or rubber coating on the palms;

- To protect your eyes you will need special glasses;

- The respiratory system will be protected by a respirator.

It is necessary to observe such measures, because when cutting the heat insulator, particles of material rise into the air from under the knives. Which naturally get into the eyes, respiratory tract, and additionally become a prerequisite for skin irritation.

Right now, it’s important to keep in mind:

- while working with this type of heat insulator, you need to periodically take a break, during which you need to ventilate the room;

- the cut pieces must be rearranged carefully, without throwing them, in order to reduce the amount of fibrous suspension in the air;

- Then there is no need to make children at the construction site, even in protective equipment.

As can be seen from all of the above, there is nothing overly complicated in cutting mineral wool. If you follow the indicated rules, it will be easy to complete the work efficiently and safely.

Sources:

https://znatoktepla.ru/utepliteli/rezka-mineralnoj-vaty.html https://chudoogorod.ru/prochee-dacha/chem-rezat-minvatu-v-plitax.html

Installation methods

Installation of basalt heat insulator

There are three ways to install stone wool or any other insulation. Two of them involve the use of drywall, the third - simply in the wall.

For the method without drywall you need:

- calculated amount of insulation;

- base for constructing a profile;

- staples for easy fastening of cotton wool;

- tape measure and scissors.

Operating procedure:

- Attach the brackets to the wall every 50 cm. Mineral wool insulation will be placed on them.

- Unwind the rolls and cut with scissors to the height of the walls. You can take it with a margin of 3 cm in case of deformation.

- Place the pieces on the staples so that the layers overlap.

- Attach the profiles and press the material against the wall.

In some cases, the cotton wool is covered with a vapor-permeable film. It's also good to keep particles out of your eyes and skin.

Second way:

- Knock down the plasterboard profile so that its width is no less than the thickness of the mineral wool.

- Screw the profile to the wall and insert roll insulation into it. Sometimes they make square holes in the profile and put mineral wool slabs there.

- Sew up the cotton wool with sheets of drywall.

If you do not plan to make plasterboard walls, you can use denser slabs and glue them to the wall, after first cleaning off any remaining plaster. There are special adhesives for this. In the same way, basalt wool is installed on ceilings or roofs, even if a frame is previously constructed.

The most popular way to cover a wall with insulation is to attach the slabs with dowels, after placing a square plate of dense material, such as plastic or wood, under the cap.

How to cut insulation

Knife for cutting mineral wool

When cutting mineral wool insulation, there is a risk of damage to the fibers, which will affect the thermal insulation properties. The most suitable tool is a mounting knife, but it has a short blade - it will not cut thick slabs.

In the kitchen you can find a serrated knife for cutting bread. It needs to be sharpened before work.

In construction supermarkets you can find special knives made of stainless steel or carbon fiber, which are designed for cutting insulation. A hacksaw is a good cheap alternative.