How is brick firing done?

There are two common methods for making bricks. The first is semi-dry and dry pressing. The plastic molding method is the second method for making bricks. The difference lies in the different amount of moisture that the raw material contains in both production methods. It should be noted that the second manufacturing method is most widely used.

Bricks made using plastic molding can be hollow or solid. The principle of production of both types of bricks is the same, the difference is that for hollow bricks the clay undergoes more thorough preparation.

The following stages of brick manufacturing can be distinguished:

- Preparation of raw materials

- Beam forming

- Drying raw bricks

- Burning

It should be noted that each stage is characterized by careful adherence to parameters. For example, in order to carry out firing, which is the final stage of manufacturing, all technical requirements must be observed. Brick firing technology requires compliance with both temperature and time conditions. Otherwise, a defective product is inevitable.

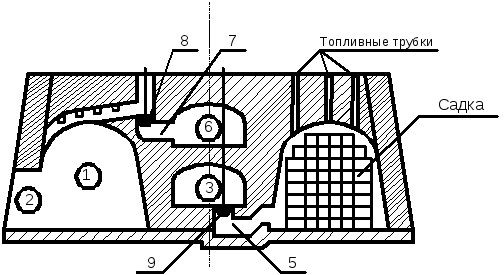

Oven operation

When the kiln is operating, the channel is almost always filled with the material being fired. Only two or three chambers remain free, through which raw bricks are loaded and finished bricks are unloaded. In these cells the walkways are open. The rest are closed. Fuel is supplied to the furnace from above through fuel pipes (backlashes)

with a diameter of 150...200mm.

If the furnace operates on gaseous fuel, then it is also supplied through the roof using a gas pipeline connected to fuel-burning devices. Solid fuel, falling on a pre-heated charge and receiving from it an initial heating impulse (activation energy), quickly ignites and, burning, heats the charge. That part of the burning channel into which fuel is loaded is called the welding (firing)

.

In this area,

the heat and smoke cones

are closed The gases formed in this zone move forward (arrow flue gases) and heat the raw material to a temperature exceeding the ignition temperature of the fuel. The area in which the raw material is heated by flue gases is called the preheating zone

or

smoke zone

.

Cooled flue gases at a temperature of 150 - 200 o C are removed from the burning channel 1

through smoke fins

5

with open

smoke cones 9

into

the smoke channel 3

. However, those smoke cones that are located closer to the firing zone remain closed so that hot gases are not removed from the kiln without releasing the body.

Disadvantages of the stove -

difficult conditions for servicing the furnace, difficulties in fully mechanizing loading and unloading. Currently, this drawback has been partially eliminated, because batch loading of bricks has been mastered, when the batch is formed in the workshop and fed into the kiln by a loader. There are stoves with a removable flat roof. In this case, when placing the raw material into the oven, the roof is removed, then the bags are loaded using a lifting device and the roof is installed in place.

Ring furnaces are characterized by uneven firing along the height of the firing channel, which is associated with temperature stratification of gas flows in their horizontal direction of movement. To ensure uniform firing across the cross section of the furnace, fuel is pressed into the raw material, which turns into a combustible briquette and the entire charge burns in the firing zone. It is recommended to press up to 80% of the total fuel consumption for firing into the raw material, but not the clay consumption

.

Design and principle of operation of a ring furnace

Such a furnace was designed by Hoffmann in 1857 in Germany. Before the invention of tunnel kilns, these installations were quite widely used for firing clay and fireclay bricks, ceramic stones and drainage pipes. The prevalence of these stoves is associated with their high thermal efficiency, the ability to burn any type of fuel, including the lowest grade varieties, as well as the ability to switch on the fly from one type of solid fuel to another without any design changes in the stove.

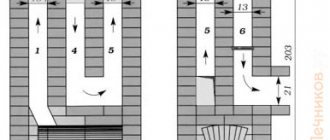

Fig.1. Scheme of a ring furnace

The main element of such a furnace is a closed through firing channel 1

, which does not have permanent partitions inside.

In the outer walls of the burning channel there are 2

called

walkers

.

Through them, raw materials are loaded into the kiln and fired bricks are unloaded. The part of the space of the burning channel between the walkers is called a chamber

.

In the inner wall of the furnace there is a smoke channel 3

, which is connected by a hole

4

with a chimney or smoke exhauster

10

.

The burning and smoke channels are connected to each other using 5 holes called smoke points

.

The chimneys are equipped with 9 smoke cones (valves)

with the help of which this channel can be connected to or disconnected from the burning channel.

Above the smoke channel there is a heat channel 6

.

It is designed to move hot air, which is formed during cooling of baked bricks. The heat channel is also connected to the burning channel using heat pins 7

equipped

with heat cones 8

.

Types of furnaces

Special kilns are used for firing ceramics and producing fired, including ceramic, bricks. They come in 2 types:

- tunnel;

- ring.

Return to contents

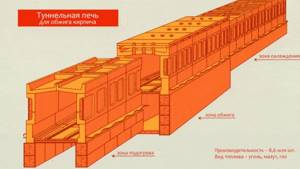

Tunnel oven

A tunnel type device is a long, tunnel-shaped gas brick kiln. Inside there are 3 chambers and rails. Metal trolleys move along them with the help of automatic pushers. Unfired bricks are loaded before entering the kiln. The entrance and exit are sealed hermetically. After drying in chamber 1, the brick blocks are moved to chamber 2 for firing. It is provided by gas burners that constantly maintain the temperature at 920-980 degrees. The brick then enters a third zone with a lower temperature, where it is cooled. After the mode is completed, the pushers roll out the trolleys from the furnace and the brick blocks cool completely outside of the furnace.

Tunnel ovens in bakery and confectionery production

In order to buy a tunnel oven intended for baking bakery products, you can familiarize yourself with the catalogs located on the Internet on specialized sites. There you can buy a unit that runs on one specific or several interchangeable types of fuel.

Dimensions, functionality, power, performance, and the ability to load such equipment play a big role. The most economical furnaces are those that can fully utilize their own resources, including steam. Some innovative models even operate on steam generated by a boiler located at the production site.

Important: it is recommended that the selected tunnel oven operates almost 24 hours a day, without interruptions.

In the food industry, each piece of equipment is made not only from heat-resistant materials, but also from materials that are safe for health. The basis of any equipment is special stainless steel, which can be easily cleaned of any contamination with a simple detergent based on a disinfectant.

Basic configurations:

- A conveyor belt along which products are moved through certain zones that have a characteristic, required length and heating temperature. This equipment is quite long. In order to save free space, such equipment can consist of several tiers, which allows you to profitably save free space;

- Multi-tiered equipment is primarily intended for baking bread based on components such as rye flour, wheat. The finished product has a certain shape: loaf, loaf, baguette. Baking is possible both on special trays, baking sheets, and on the surface of the equipment itself.

Its full automation makes it easy to use. Tunnel ovens are able to independently control the set temperature, intensity, and speed of the conveyor belt. In the event of failures and malfunctions, the firing unit will begin to emit a characteristic sound warning and may automatically turn off.

The most expensive and multifunctional is German equipment

One unit can simultaneously accommodate a large amount of bricks

Tunnel ovens fully cope with the task and do not fail

To improve overall performance, several such furnaces can be installed in production at once.

In order to control the work process, the design is equipped with a special controller that is capable of storing several operating modes in its memory. Thus, even the largest production will be fully automated.

Firing bricks at home

As a rule, industrial production of bricks is characterized by large mass production, which is not always economically profitable.

Attention: Such production must be 100% loaded in order for there to be a tangible economic effect. Currently, there is a tendency to move from large volumes of production to small volumes, when high-quality control of the products is possible.

- If desired, you can organize brick firing at home. This option is suitable when you need a little brick, and the brick offered by the manufacturer does not have the appropriate quality. To do this, you can take a regular 200 liter barrel and cut out the bottom and top of it.

- In this case, you can get by with a very ordinary fire, but first you need to dig a hole, about 50 cm deep. Above this hole, a barrel is installed on special supports, ensuring the height of the barrel rolls is about 20 cm above ground level. At the bottom of the barrel there is a metal grate on which the brick will be stacked.

- After the barrel is filled with brick, it is advisable to close it with a lid to reduce energy loss. In the process of filling the barrel, you should pay attention to leaving a gap of about 5 mm between each brick, then there will be a more uniform heating of all bricks.

- Depending on the characteristics of the clay solution, firing can last for 20 hours.

- At the same time, this time should be divided into three parts so that each part of the time corresponds to one technological cycle: one part of the time is allocated for a gradual increase in temperature, the other part of the time for firing and the third part of the time for slow cooling. Only in this case can you obtain a high-quality final product.

Raw brick production

There are two methods for producing bricks from clay:

- unfired (so-called raw brick),

- burned.

Made using technology and from good clay, unfired building material can compete almost equally with fired construction material. It is successfully used in the construction of small buildings on the site: one-story buildings, ancillary buildings - sheds, saunas, etc. Let's look at the method of producing raw bricks.

Making molds (manual and mechanical)

The first option is to make it with improvised means. We will need the dimensions of the forms that need to be made, usually these are the dimensions of an ordinary brick 250-120x62 mm. The material for them can be boards with a thickness of about 25 mm; it will also be necessary to use additional sheets of plywood.

The inner surface of the mold is smooth. To form voids in the brick, the lids must be made with protrusions. The protrusions are made with a slope to facilitate the process of removing the finished product.

The components of the mold are nailed together with nails 50–60 mm long, ensuring free removal of the top cover. We recommend making several identical molds - this will intensify your small production.

The second option is if you are planning a large-scale construction project, it is better to rent a machine for fast and efficient brick production.

Loading forms

We wet the inner parts of the molds with water before loading the mixture, and then sprinkle them with fine dust or cement - this will make removing the products much easier. Fill the molds, shaking occasionally so that the mixture fills the entire volume. The protruding excess is cut off with any convenient metal device.

Closing the mold with the top lid, let it sit for some time. We remove the lid, turn the mold over and, carefully lifting it up, remove the contents to the platform for drying.

Drying

Drying workpieces is a rather complex and important process. They should be dried on racks that have a canopy to protect the blocks from solar radiation and precipitation.

If drying is carried out in a utility room, for example, in a barn, then the material must be kept indoors for three days, and then ventilation must be organized.

If you plan to dry outside, then first prepare the area for placing the bricks - you need to make a wooden floor or fill the area with dry sand. As the liquid evaporates, the workpieces shrink, resulting in a loss of up to 15% of the original volume.

Important: the outside air temperature when drying outside must be at least 10 °C.

The duration of drying can be influenced by many atmospheric factors: temperature, humidity and the speed of movement of air masses. The process is long and can last from 6 to 15 days. The unfired brick is ready, you can begin construction work.

Important: the resistance of bricks obtained in this way to water is very low. This must be taken into account when constructing buildings.

Is it possible to secure such a brick? There are a number of standard methods that help protect the material from moisture:

- the roof overhang must be at least 0.6 m long,

- door and window openings must be located at a distance of at least 1.5 m from the corners of buildings,

- the seams of the masonry must be well tied,

- finished walls must be plastered; they can also be lined with facing bricks or other modern building materials.

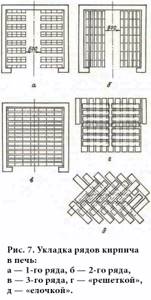

Cage (laying)

In addition, insufficiently dried raw materials produce up to 80% of rejects. The main reason for the defect is that excess moisture, turning into steam, seeks a way out and leads to cracking of the brick.

The laying of raw bricks in the furnace (see Fig. 7 ) is carried out so that in the first 3-4 rows of laid bricks the gaps between them are (for bricks located directly near the firebox) 10-15 mm, and as they move away (further from the firebox) increased to 25 mm.

The rows can be laid in any way, for example, “lattice” or “herringbone”. Methods can be alternated.

The main thing to remember is that each brick must be accessible to flue gases flowing around it.

The distance between the cage bricks and the furnace walls should be within 20-25 mm.

Difficulties that may arise during the process

diagram of a home mini brick kiln

The characteristics of the tunnel brick kiln can be familiarized with during assembly or use, but at the same time it is fraught with some difficulties. Before each new start of work, you must monitor

- the way fuel is consumed. Now, as you know, fuel is very expensive. And if several ignitions are required at maximum temperature, then its consumption will be enormous. Most manufacturers try to fit the entire batch of goods into the first ignition. If you do it as expected, the price of brick will increase many times over.

- furnace performance. If you lay 30 pcs per day. goods, then it will not be possible to obtain any benefit from this entire process. How to make a brick kiln is no longer the first question, because most production uses a cyclic method.

- Because many craftsmen claim that it is no longer profitable to fire clay products, the best way is to produce silicate under the M150 brand.

- temperature and always compare it taking into account partings, although this process is complicated because such high-quality and expensive equipment requires increased attention.

Tunnel oven

Most brick factories producing single solid bricks and ceramic stones are equipped with kilns of this type. They are a tunnel along which trolleys or a conveyor belt with raw materials move. Their workspace may have one or two channels, located in a straight line or having a closed, ring-shaped shape.

Principle of operation

Unlike ring installations, here everything happens the other way around: the material moves through the remaining stationary, clearly demarcated zones of heating, annealing and cooling. The material moves sequentially from zone to zone. In such a furnace there is only one entrance and one discharge zone. They are located at opposite ends of the tunnel and are equipped with mechanisms that hermetically seal the interior of the furnace during loading and unloading of material. Sealing occurs automatically, which avoids excess coolant consumption. The space above the floor, under the conveyor or the bottom of the trolleys, also does not warm up, since it is fenced off with a sand barrier.

Natural gas is used as a coolant. Sometimes they are modified to run on fuel oil, diesel fuel, heating oil, or electrical energy. A combination of options is possible.

The oven operates around the clock. Gas burners direct torches of burning gas onto the brick mass directly (in open-design kilns) or through protective screens (in muffle kilns). Fans and smoke traps are installed along the entire channel, directing the required amount of heated air and flue gases to the required zones of the furnace through special circulation channels. These devices operate independently of each other and are controlled remotely by the operator. Loading the furnace is carried out by workers manually, and unloading is mechanized.

The firing technology is as automated as possible. Special computer programs, using numerous sensors, monitor the technological process and issue control commands:

- temperature conditions in all zones.

- air pressure

- speed of movement of trolleys.

The selection of the furnace operating mode is carried out automatically and depends on the initial parameters of the raw brick (type, shape, size, humidity level, type of setting). The controller stores all possible modes in memory and selects the most optimal one. Quality control of finished products is also automated. The duration of the technological cycle for solid products is from 36 to 40 hours; hollow stones are ready within 24 hours.

Advantages and disadvantages

The most important advantage of tunnel installations is the ability to minimize manual labor and automate the control process. All workers loading the kiln and unloading products are located away from the hottest firing zone. They work in good sanitary and hygienic conditions (acceptable air temperature, good lighting). An automated control system allows you to adjust the installation to produce products of the highest possible quality.

Disadvantages of tunnel ovens:

- work mainly on expensive coolants.

- large temperature differences in adjacent zones, threatening the appearance of material defects.

- contamination of products with ash when using coal in open furnaces.

- high cost of some production equipment (protective couplings, radiant panels) and automation systems.

- rapid breakdown of their rolling stock.

Good brick can be made from any of these types of kilns. In ring plants, high quality products are ensured by the hard work and skill of the burners, who manually feed the fuel and regulate the process at their discretion. In more modern tunnel structures, often even advanced automation cannot protect goods from deformations, cracks, and non-compliance with specified parameters. When choosing a brick, you should not pay much attention to the method of firing it. Just take a closer look at the material.

Experts' comments

Anatoly Smirnov, stove maker, designer stoves and fireplaces:

“The selection of bricks for building a fireplace is important for both the master and the owner. A lot depends on the correct selection: the strength of the fireplace, the duration of its safe operation, the aesthetics of appearance, efficiency, etc.

The craftsman has at his disposal a variety of types of bricks: ordinary, ceramic, fire-resistant, oven, for external use. The chemically aggressive environment in the combustion chamber and the high temperature (700–1000°C) place special demands on the bricks used to lay the firebox. Red solid ceramic brick, if it is not intended for this purpose, begins to peel off over time in layers of 3–7 mm. Ceramic samples with water absorption below 10% can only be used in the firebox.

Unlike ceramic red bricks, fire-resistant analogues are made on the basis of quartz sand, therefore, at a temperature of 580°C, a melt is formed inside them - a glassy mass that prevents the penetration of gaseous chemical compounds. However, if the rules for operating the fireplace are violated, the fireclay brick can also be subject to destruction, because the glass that appears in its body during the firing process is, as is known, a fragile material that cannot withstand sudden cooling.

Thus, both fireclay and ordinary ceramic bricks can be used in the firebox of an open fireplace. Application of various coatings followed by firing, as well as impregnation with “liquid glass” reduce the gas permeability of the material and help increase its service life. It is not advisable to use ceramic bricks in the fireboxes of household stoves, and if for some reason this is impossible, then in any case the ability of the material to accumulate (absorb) water should not exceed 10%. In order to avoid premature destruction of the structure, the customer should obtain detailed written instructions on the rules for operating the fireplace.”

Kirill Rinne, director of the Brunner representative office in Russia:

“Together with Brunner fireplaces, fireclay products from Ortner are supplied to Russia, which, among other products, produces reliable, heat-resistant, efficient and durable KMS modular systems designed for long-term heat accumulation.

The weight of this design depends on the volume of wood burned in the firebox and is designed to achieve maximum combustion efficiency and heat transfer. The specific gravity of the material used is over 2.7 t/m, which makes it possible to maintain the required temperature in the heated room throughout the day after the flame in the furnace goes out, and in terms of reliability and durability it is noticeably superior to both brick and natural stone. In addition, there are no right angles inside the smoke channels organized here, which enhances and stabilizes the draft, and also prevents the accumulation of soot.”

Evgeny Nikitin, stove maker at Wolfshоher Tonwerke:

“I have long and willingly used fireclay as a material that perfectly accumulates heat. It certainly needs to be used in heat storage furnaces. This summer I completed one project where the external lining of the fireplace insert was fireclay slabs, and the fireplace was tiled on top. The heat from wood burned in the fireplace is accumulated by the structure, which continues to heat the room for 6 hours after the fire goes out, which reduces fuel costs.

Installation of large format slabs occurs quite quickly. It is also important to use the appropriate mixture recommended by the manufacturer. In this case, I used fireclay from the Wolfshоher Tonwerke company with a mixture of the XKM brand, which has the same coefficient of linear expansion, does not contain cement, adheres well and allows the master to work without the use of protective gloves.”

How to determine the unsuitability of a brick?

If you perform firing for the first time and without the help of a professional, you can make a number of mistakes that will significantly affect the quality of the building material. Even by the appearance of the brick you can determine the defect:

- If the technology was followed during firing, the resulting brick should have an orange-red color. Its shape should be clear and resemble a rectangle. If you hit such a brick with a hammer, it will make a clear sound, while a defective one will make a dull sound. This defect occurs due to the low temperature during firing.

- Light red bricks with an uneven shade at the fractures will indicate that the firing process was incorrect. This means the temperature was insufficient. If the workpiece is dark gray or blue-black in color, then this indicates that it has been “burnt.”

- Damage to edges. Such defects can occur in case of careless handling of bricks or careless removal from molds. Any distortion of the surface indicates that the brick was not dried enough before being fired. Cracks, as mentioned above, are formed due to sudden temperature changes.

It should be remembered that any construction must begin with soaking the brick, otherwise it will draw water from the binder mortar. In the future, if this preparatory stage is bypassed, the constructed building may be unreliable. Therefore, it is important not only to make the brick correctly, but also to responsibly prepare it for future masonry.

How to build a brick oven - nuances?

Experienced people suggest that it is best to hire a professional stove-maker for this purpose. But if you decide to do the stove masonry yourself, start with a project. It is important to provide for all the functions that you expect to receive from the stove: cooking, baking, keeping warm, sleeping place if necessary, etc. Provide detailed order. This will help you not only during the work process, but also in calculating building materials before purchasing.

Remember that a stove, like a house, needs a separate foundation, and it should not be connected to the foundation of the house. After the stove foundation has hardened well, lay the waterproofing and begin laying.

Raw clay brick

The most important stage in the production of raw meat is drying. The shrinkage of the brick will be at least 12-15%, and cracks are possible, and such a brick will not be durable and is only suitable for garden paths and possibly for septic tanks (the second row of masonry). Drying technology is based on providing the raw material with conditions: shade or partial shade, absence of direct sun and wind, protection from atmospheric moisture (including dew). It would seem that such conditions are easy to create, but in practice it often turns out that an ordinary canopy is not enough - a closed room is required, but at the same time well ventilated. It will also not be possible to properly dry raw bricks under trees in the garden or under the wall of a house, since the drying time is long - from 6-7 days to two or more weeks, and throughout this period it is necessary to provide the bricks with optimal conditions in terms of temperature and air humidity, and the only a downpour will be fatal for the molded raw materials. Heat and sun do not speed up the drying of clay, but only lead to cracking of the outer layers and deterioration of the material.

- Wooden block molds or single molds are moistened from the inside and sprinkled with cement powder;

- Lay out the clay batch into the molds in a “slide” and compact (shake, ensuring that the mixture fills the mold completely), excess clay is removed from above flush with the sides with a spatula or wooden slats; Cover the molds with lids and leave to dry at normal temperature, in a shaded place.

After the bricks have dried (after 1-3 days), continue drying with the mold lids removed for another 24 hours or more. Next, turn the block molds over, carefully shake out the raw material and leave it to dry completely. Drying time depends on weather conditions, air humidity, quality and type of clay and filler.

What is this process and features of the technology

The heat treatment of clay building materials under high temperatures is called firing. This is the final stage of brick block production. The firing technology includes 3 stages:

At the first stage, the brick is heated to a temperature of 120 degrees in order to evaporate the water from it. Then, to burn out impurities of organic origin and finally remove the liquid, it is heated to 600 degrees. At the next stage, the brick firing temperature is 920-980 degrees. At the same time, the clay begins to shrink and strength is acquired. Under conditions of constant maximum temperature, the brick block is hardened and languishes for some time. At the final stage, the resulting clay building material is cooled. If there was no violation of technology during heat treatment, the color of the block will be orange-red and the structure will be uniform. To obtain glazed brick, repeated firing will be required.

In order to ultimately obtain durable and high-quality fired bricks without cracks, the heat treatment process requires strict temperature control