For every person, a dacha is a place of relaxation. Growing crops has long ceased to be important for modern summer residents. Nowadays, the dacha is a place of relaxation. And since people come on vacation even in the cold season, in this case it is necessary to think about heating and maintaining heat in the room. To heat a country house, you need to build a fireplace stove yourself. You should also not forget that building a fireplace stove is very hard work, but if you follow the instructions and rules, it will be easy.

Do-it-yourself fireplace stove: how to choose a place

When laying out the fireplace stove, you will personally combine the elements that are present in bread stoves. These elements retain heat perfectly.

The fireplace itself has an open firebox, which can warm up the room almost instantly. And if you add a small stove to the fireplace, then you can cook on it. The main feature of the fireplace stove is the presence of 2 fireboxes and 2 chimneys. Based on this feature, the stove and fireplace can be heated separately.

Fireplace stoves have a huge amount of smoke circulation in the chimney channels. And with the help of such a quantity of smoke circulation, the heat is retained for a long time. Fuel consumption is also reduced. For heating, you can use different fuels, for example: firewood, peat, coal and other types.

When choosing a place for a fireplace stove, you need to remember that such a structure is a solid building, and it is better to think about the place where such a stove will be installed when building the country house itself, and only in this case will you do without altering the room.

You can also install a fireplace in the walls of the house, but to do this you will have to partially dismantle the floor and roof.

Which fireplace stove is better: choosing the material

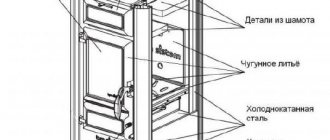

We will talk about what materials can be used to make a long-burning fireplace stove for the country house and home. In general, metal fireplaces, to protect the walls from very high temperatures, are lined (lined) with heat-resistant materials from the inside. Most often this is fireclay brick, but it can also be heat-resistant ceramics (more expensive models). This also leads to the fact that many models do not heat up much on the outside - you can easily hold your hand. The main heat is emitted through the door and this must be taken into account when choosing the location of the stove - the distance from the opposite wall should be greater, otherwise it will get very hot.

A long-burning fireplace stove for the cottage and home with ceramic cladding not only looks good, but you won’t get burned on it

To ensure that the walls of the heating device are safe, they are lined with heat-intensive materials such as natural stone, special ceramic tiles, etc. The second (cheaper) option is to install a metal casing that protects against touching the heated case.

Steel: black and structural

The most inexpensive fireplace stoves are made from ordinary black steel. The most budget option, but also the fastest to burn out. To make the furnace walls last longer, they are made of considerable thickness - 5-8 mm is not the limit. To protect against corrosion, the oven is coated with special paints.

More expensive fireplace stoves are made of structural steel. This material has increased resistance to high temperatures. Due to better heat tolerance, the wall thickness is smaller, but the cost of fireplace stoves made of structural steel is higher (due to the price of the material).

Stainless steel

The stainless steel used is heat-resistant, the wall thickness rarely exceeds 3-4 mm. The surface can be matte, polished or blackened, sometimes painted with heat-resistant powder paints.

There are very few stainless steel models

Stainless steel fireplace stoves are expensive, and their durability largely depends on the quality of the seams. To prevent alloying metals (which give the metal its stainless properties) from burning out during welding, welding must be carried out in a protective environment. And this is complex, expensive equipment. And the price of such models, all other characteristics being equal, is higher. But if the seams were welded under normal conditions, the destruction of the metal begins very quickly, since due to high heat it has ceased to be “stainless” and heat-resistant.

Cast iron

This material is one of the most durable. The walls of the ovens are quite thick and massive. So a cast iron fireplace stove takes longer to warm up, but it also takes longer to cool down. And it also takes decades for normal cast iron to “burn out.” But there is another risk of destruction: if water gets on the hot surface, the cast iron may crack. So, if you are planning to buy a cast iron fireplace stove with a stove, you will need to be very careful with it. The good news is that most of the “cast iron” is assembled from fragments using bolted connections or using the tongue/groove principle. If the stove fails, you can disassemble it, order only the required part, and replace it. But this is only possible if the model is not discontinued.

Fireplace stoves of various shapes are made from cast iron.

There is one more point: cast iron is a heavy thing.

Therefore, when purchasing, pay attention to the weight. Without a separate foundation, you can install stoves weighing up to 200 kg (with fuel and chimney)

And even in this case, if the floor is wooden, additional reinforcing beams may be needed.

Brick stove: laying in rows

Before you start laying, you need to draw up a correct work plan and if you stick to it, you will get the desired result.

The rows of masonry are as follows:

- We lay out the first row without mortar, leaving 5 mm gaps between the bricks. After laying out the first row, you need to check the evenness of the walls with a level or rule and measure the diagonal of the laid out rectangle. If the diagonal is the same, then the angles are right angles.

- Next, we place the 2nd row on a solution of clay and sand with bandaging of the seams. Laying the firebox of the fireplace stove begins from the 3rd row. Starting from the 9th row, the firebox window is covered with an overlap of bricks. The ceiling can be made in the shape of an arch, that is, the bricks can be laid out in a semicircle.

- We cover the 13th row with a wedge overlap. But until the 14th row is laid out, which will press the overlap, it will not hold. And it is for this reason that before laying the 13th row, it is necessary to make a wooden shield and secure it in the firebox using wooden supports at the level of the upper edge of the 12th row, and only then do the laying of the floor, that is, the 13th row.

- At the end of the ordering, you don’t have to take out the shield, as it will burn out after the first fire of the fireplace stove, but the ceiling will be held in place due to the pressure of the upper rows of masonry. And together with the overlap on the 13th row, they also begin to push the fireplace shelf forward. This shelf is pulled out by 5 cm, and on the next tier it is pulled out by 7 cm. bricks placed on the ceiling significantly increase its strength due to the bandaging of the seams.

If the description seems difficult to you, the diagram in the photo can always come to the rescue, where all the rows of masonry are indicated in detail.

Fireplace installation

After the foundation has dried, you can begin to arrange the structure. The first row is laid continuously. The second row is positioned in such a way as to outline the gas passage, the blower chamber and the place for the firebox. Next, following the drawings, you need to model the fire chamber with masonry, forming the bottom, which is the third row.

To make ceilings, you can use metal corners - they act as a support and block the door opening. With this condition, you need to lay out the fourth and fifth rows. After this there are several layers with the installation of the door. And already in the ninth row, the hole is covered with brick, laying several more rows.

On the eleventh layer it is necessary to insert a hob, so first you need to lay out the brick dry, measure the area under the slab, and only then lay it together with the structure. A few rows after - you need to lay them according to the pattern, securing the holes in the frame with wire.

On the sixteenth row you can lay the beginning of the arch under the slab, not forgetting the steel strips for support. In subsequent masonry, model the arch. On the nineteenth layer, the gap between the bricks needs to be increased for the valves and then the cleaning doors must be installed. In the next masonry, install a strip of steel on smaller valves, and in the twenty-first row, lay the strip on top of the luggage - the base of the chimney will be on it.

The chimney begins from the twenty-second level of the masonry - the channels need to be made narrower and gradually blocked. The luggage is led according to the scheme up to the twenty-sixth row, where a common latch is installed from the same steel corner.

Next comes the covering of the furnace - these are the next two rows, after which the chimney is laid. It is built according to a scheme with ligation and shifting of bricks halfway to a certain height.

After finishing, you need to dry the stove and gradually light the fireplace.

What does a fireplace stove with a bench include?

According to their design, a fireplace stove with a stove bench most often comes in several types, such as: regular Russian, Kuznetsova and teplushka.

And in the manufacture of such furnaces, the following elements stand out:

- Heating design;

- Cooking surface;

- Ash pan;

- Oven;

- Bed;

- Woodman;

- Space for kitchen utensils.

The design of a stove with a stove bench can be done with your own diagrams and drawings. Fire-resistant brick is used as a building material. Drawings and diagrams are prepared in advance. You can determine the number of bricks needed by doing the ordering. The mixture for masonry can be purchased ready-made or mixed using sand, clay and cement yourself. Also, some time before laying such a stove, you need to buy grates, valves, doors for the firebox and cast iron cooking plates.

A corner stove will be an excellent decoration for your home; its construction and installation are practically no different from the standard type. Like all other stoves, such a stove requires a foundation, since the total weight of the stove will be approximately 10 tons. You can make such a foundation yourself on the basis that every 50 mm is approximately one ton of weight and the area of the foundation should be 15% larger than the base of the stove.

After determining the size of the foundation and digging it out, the bottom is covered with a layer of crushed stone, formwork is made and concrete is poured just below floor level. The concrete sets within 2 weeks and only after that waterproofing is carried out. This is done to prevent moisture from entering the oven.

And so we move on to laying out the oven in rows. To begin with, we lay several rows of bricks horizontally and with right angles on the foundation. It is important that the distance between the stove and the wall should be at least 150 millimeters. Next, laying out the next rows involves laying the blower and air ducts. You can see above how the masonry is done.

Important criteria for preparatory work

In order to complete all the preparatory work, avoiding the most common mistakes, which are very difficult to correct later, the following instructions will help you:

- Due to the large mass of brick kilns, there is a need to build a separate foundation. At the same time, it is not tied to the house, since subsequently it will undergo mandatory shrinkage, which should not appear on other elements of the building;

- The size of the foundation should be slightly larger than the fireplace itself on all sides (10-25 centimeters);

- To perform masonry work, you will need to buy both cheaper ceramic bricks, from which the main part of the structure will be made, and fire-resistant fireclay bricks. The second is needed to lay the elements of the firebox and chimney, which are subject to the most intense heat. It is worth noting that the price of fireclay bricks is quite high, and a lot of material will be needed;

- The seams between ceramic and fireclay bricks must be at least 5 millimeters, and the adhesive mortar itself is mixed based on clay and heat-resistant cement;

Stick to the same thickness of seams: optimally 5-7 millimeters

Stick to the same thickness of seams: optimally 5-7 millimeters

Corresponding recesses are left for each decorative element and fittings

Corresponding recesses are left for each decorative element and fittings

- Additional fittings and components (grate, ash pan, doors) are installed according to the diagram and are pre-purchased in a specialized store or made to order;

- For additional fixation of the doors, grate or ash pan, you will need to use annealed wire, which is installed between the bricks, after which it is filled with a solution for additional fixation and adhesion (preliminarily threaded into specially prepared holes and twisted with a bundle);

- In order to avoid too much variation in temperature conditions in the area of the combustion chamber, before installing it, be sure to extend a special asbestos cord between it and the bricks;

- In order to save effort and free time, the chimney can not be laid out with bricks, but give preference to a ceramic block variation (sold in a fully assembled state);

- If the brick does not have a very attractive appearance, you should take care of finishing such a surface. For these purposes, you can use any fireproof materials (tiles, ceramics, decorative plaster, heat-resistant paint, natural and artificial stone). Finishing a fireplace is not only a way to give the unit a unique style and individuality, it can also significantly increase the overall efficiency of the stove.

A brick fireplace stove for a summer cottage is an excellent opportunity to quickly and economically heat both a small and a two-story house with several rooms. In order to familiarize yourself with the variations of ready-made arrangements, we also recommend reading the article “Corner brick fireplace stove.”

The main elements of a fireplace stove with increased heat capacity are in the following order:

A fireplace stove can replace any heating appliances and can become an excellent oven. You can learn how to install it at your dacha from the video. It is the winding serpentine air duct that allows the heated air in the firebox to rise, pass through the entire structure of the stove and thereby heat the stove bench. On the 9th and 8th rows, overlap is performed on the firebox and bed. Next are the rows for the hob and oven, and another row that separates the oven from the wall. After the lintel has been laid out, it is necessary to use simple or, if desired, decorative masonry above the oven chamber: with a wedge or an arch. Next, a metal corner is used above the stove for cooking, and a decorative shelf is made from it. Subsequent rows will combine all the chimneys into one and windows will be made on the walls of the stove.

The summer window is necessary to maintain combustion in the warm season and is located under the oven chamber, and those windows that are located above are intended for stronger heating in cold weather.

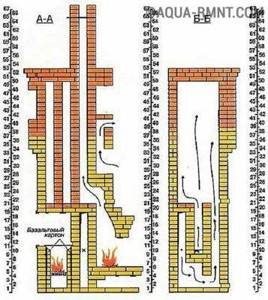

Next we lay out the pipe. It has a square shape, and the optimal pipe laying will be 2 and a half bricks. The ceiling through which the pipe passes is insulated using basalt slabs in several layers.

When we build brick ovens, we need to know all the nuances and have designs; even the smallest detail can disrupt the design.

Device and principle of operation

The fireplace stove is installed on a foundation slab, arranged on a drainage pad made of sand and crushed stone. The structure has two combustion chambers. The one that forms the working area of the fireplace has an increased height and can be equipped with a glass door. Often it has a curved shape - this way it is possible to increase the area of the reflective surface.

Scheme of gas movement inside a combined type heating device

The firebox is made in both rectangular and trapezoidal shapes. In the latter case, it tapers to the rear wall, which is inclined, with a small threshold - a fireplace tooth or a gas threshold. Its purpose is to hold carbon deposits that settle on the walls of the chimney. Above the firebox there is a smoke collector, which goes into a direct gas channel.

The firebox has reduced dimensions and lower air supply. Depending on the configuration of the heating device, the roof of the firebox is equipped with a hob or covered with brickwork. Combustion products from the firebox rise into vertical channels arranged in accordance with the schemes of Dutch or Swedish stoves.

Internal structure of the fireplace stove

To prevent combustion products from entering the room, the smoke ducts of both devices are equipped with valves, which are closed as necessary. In addition, the chimney is equipped with an additional damper, which prevents heat from escaping after the fuel has completely burned out.

Review of the best domestic fireplace models

Russian is very noticeable on the fireplace stove market. Consumers leave positive reviews about the company's products. The best assembly is considered to be the stoves from the Ardenfire series. The products use some elements from the best foreign manufacturers: Germany, France and Japan, and are assembled using unique technologies. Each series is characterized by being equipped with heat-resistant glass, sufficient power up to 12 kW and compactness.

Corner stove-fireplace "Amur" - wood-burning

The stove is designed to heat 90 sq. m area. The manufacturing technology is combined: the firebox is laid with fireclay bricks and lined with high-quality steel. The brick is designed for 5 years, after which it should be replaced. The firebox door has high-quality heat-resistant glass of Japanese origin. There is excellent heat flow through the door and good visibility of the fire. Glass is self-cleaning and can withstand high temperatures.

Corner stove-fireplace “Cupid”

The firebox has a volume of 73 liters and can provide power up to 10 kW. The weight of the entire structure is 157 kg, which allows you to quickly install the fireplace stove. High efficiency 3 kg of firewood allows you to keep the room warm for 8 hours.

Attention! This is a wood-burning model of a corner stove-fireplace for a summer cottage; it cannot be heated with coal. Guarantee of at least 10 years of work. Guarantee of at least 10 years of work

Guarantee of at least 10 years of work.

Corner fireplace-stove "Neva" - wood-burning

A very compact model with a height of 87 cm and a width of 64 cm. The small size of the fireplace allows it to be installed in the smallest cottage. The model has gained well-deserved popularity among domestic consumers.

Corner fireplace-stove "Neva"

The power is enough to fire 60 square meters. m. of housing. This compact model warms up the home in 3 hours; you will need to add 3 kg of firewood to keep the room warm for 8 hours.

The weight of the structure is 95 kg, allowing installation to be completed in a couple of hours by connecting the pipe to the chimney. The manufacturer provides a 1-year guarantee of flawless operation.

The group's products produce products that comply with European standards, but are designed specifically for our climatic conditions.

Corner wood stove fireplace "Bavaria"

The domestic manufacturer Ecofireplace produces long-burning stoves that are popular with private homeowners. The company supplies a wide variety of models of heating structures, including high-quality options for corner wood-burning stoves and fireplaces for country houses.

Fireplace stove "Bavaria"

A sample of European quality, with small dimensions, it is capable of heating a room of 80 square meters. m. Made of high quality steel, the grate is made of cast iron, the self-cleaning system is heat-resistant glass. It has a very stylish look: the glass is framed by black steel doors, the side panels are trimmed with ceramics.

The design is equipped with a hob, without an oven. The depth of the firebox allows you to place wood logs up to half a meter, while the height of the fireplace is 86 centimeters. As on almost all Bavaria models, the corner fireplace stove has an economical fuel consumption mode.

The service life of Bavaria stoves is at least 10 years.

A fireplace is very useful for any home, and it is unlikely to get in the way or spoil the appearance. Such heating structures have many advantages that owners of home fireplaces enjoy. External energy independence of housing; if gas or electricity is turned off, the house will remain warm due to heating by the fireplace. It has high performance and can be used as the main source of heat for a summer residence. Fuel can be purchased as needed, at any time of the year.

Design Features

Having heard about fireplace stoves for the first time, owners of country houses often shrug their shoulders: why waste effort on building a heating device of such a design, if you can build one of the well-proven stoves such as a Dutch oven, a Swede stove, a kolpakovka stove, etc. That’s all. the fact is that they do not know the operating features of fireplace stoves, but during their development they combined all the best from two completely different heating devices.

Combining a stove with a fireplace allows you not only to heat the room efficiently, but also to make its interior unforgettable

The main advantage can be considered that to heat the room, you can use two modes of operation of the dual heat generator.

Fireplace mode

In this case, the smoke from the fireplace will be directed through a special smoke collector into a flue located on the rear wall of the heating device and then directly into the chimney. The construction of an almost straight channel avoids a decrease in draft, so the intensity of firewood combustion will be maximum.

Using a heating unit as a fireplace is very convenient for irregular fires, for example, in a country house or in country houses, where people visit only on weekends in winter. In this case, the temperature in the room will become comfortable literally within one hour.

Advantages of the stove

Combustion products do not “fly out into the chimney,” as is the case with a fireplace, but are redirected into additional channels located on the sides of the heating device, where they transfer all the heat to the walls of the structure. The duration of combustion of the same amount of fuel during furnace combustion increases significantly, since the operation of the unit most often occurs at the border of smoldering. This is achieved by adjusting the air flow through the blower. Thanks to the expansion of the furnace array, it has improved heat-accumulating properties and allows the accumulated heat to be released for a long time even after complete combustion of the fuel.

If irregular operation is expected, then most often the heat generator is operated according to the following scheme:

- When kindling, a vertical channel is opened, which switches the unit to fireplace mode.

- After the temperature in the room rises to a comfortable level, close the valve of the vertical channel and close the ash door to maximize the combustion duration.

As you can see, the fireplace stove is a successful symbiosis of several heating devices. However, its advantages do not end there.

Using a fireplace cassette increases the hygiene of the design and facilitates the construction of the heating device

Heating devices can be made with either an open or closed fireplace insert. In the latter case, a door made of heat-resistant glass or a special cast-iron cassette (liner) is used. Limiting the amount of incoming air allows you to increase the operating time of the fireplace and increase its efficiency.

Option for a bath

Most modern owners of country and country houses build bathhouses on their property, which also include the installation of a stove. You should understand this issue well and not make hasty decisions. Therefore, before we choose the right stove, let's look at their main characteristics.

Many stove makers agree that a heater stove is most suitable for a bathhouse. However, such a structure can only be mounted on a previously poured foundation. This is necessary because the initial weight of the structure is about 700 kg. This is not suitable for every bath, because sometimes steam rooms are very small.

Bath stove option

Such stoves for summer cottages are capable of raising the temperature to 600°C degrees, despite the fact that it will take about four hours to heat it. The disadvantage of the structure, naturally, is its significant mass, as well as large dimensions, which eat up useful space. But at the same time, they are able to heat not only the steam room of the bathhouse, but also the adjacent room, which is very important in the cold season.

If you need to heat a building using a more modern method, then choose structures made of high-quality steel or cast iron. The cost of such products is reasonable, and the level of heat maintenance is sufficient, and if you place stones in a special tank, the heat will be released much longer and more evenly.

The choice of stove is made on the basis that 1 kW of power is required for each square of space. If you need to further increase the period of maintaining a high temperature in the steam room, then metal stoves are lined with bricks.

In addition, modern baths can be equipped with electrical products. Such models are easy to use, have a heat regulation function, an on/off timer, and do not require the construction of a chimney, while being able to maintain a comfortable level of humidity.

In conclusion, it is worth saying that everyone should choose a heating device for their home or cottage, because there is no ideal formula, and what is suitable for one may be completely unacceptable for another.