Waterproofing walls is necessary in order to protect the house from the destructive effects of moisture and provide it with a comfortable microclimate. To protect your home from precipitation and groundwater, you need reliable waterproofing of facades. Internal walls should be insulated from condensation and water in rooms with high humidity - these are kitchens and bathrooms, and in private houses also basements.

Waterproofing is a mandatory procedure

Types of materials for waterproofing walls

To extend the life of a home, it is necessary to protect its structure from moisture . Water penetrating into walls contributes to the destruction of the materials from which they are made. And it doesn't matter what material the building is made of, they all need the same waterproof barrier.

Recently, underground space has been actively used, where excess moisture is also caused by uneven soil pressure, shrinkage of walls and foundations. Penetrating into the basement, water rises through an unprotected wall into the living room. To avoid these phenomena, you simply need to waterproof the walls.

There are special rules for wall insulation - SNiP (regulatory documents that establish all the important requirements for waterproofing connections, sealing mixtures and technologies).

Waterproofing of external and internal walls is carried out with the following materials:

- Expanding cement - as the mixture hardens, it will expand in volume, filling joints and cracks.

- Penetrating mixtures - for example, liquid glass, bitumen, cement, quartz sand with active additives. Can be used inside a building.

- An insulating membrane is a specific film of varying density with an antioxidant and other components that improve technical characteristics. The thickness of the tape can be from 0.5 to 3 mm. The densest membranes are not as elastic.

Which side to perform from?

To ensure reliable protection of walls from moisture, waterproofing should be done not only from the outside, but also from the inside. The optimal solution can be considered an integrated approach to waterproofing walls, carried out on the external base of the building and in internal areas.

Unfortunately, installing external waterproofing is only possible during the construction of the building, otherwise it will be necessary to excavate the foundation; this is quite a large-scale work that requires not only physical effort, but also the availability of special equipment. In principle, nothing is impossible if the house is surrounded by land, but what to do if the foundation is surrounded by communications and roads with asphalt or concrete pavement?

Such work is not only labor-intensive, but also expensive due to the fact that you will first have to remove the coating, excavate, perform waterproofing, and then restore the surfaces again. The only correct solution would be to produce internal waterproofing of the walls, which we will discuss in more detail.

Methods for protecting buildings from moisture

Waterproofing methods for civil and industrial buildings are classified according to the technology of application to the surface. You need to choose the most suitable method.

The following methods are distinguished:

- gluing;

- painting;

- lubricant;

- plaster;

- penetration;

- impregnation and other methods.

Having tested various waterproofing methods, experts recommend impregnating surfaces exposed to moisture.

Industrial and folk remedies for mold control

In modern conditions, with a large number of counterfeit products on store shelves and advertising of ineffective mold treatment products, you can waste money and time and not get positive results from your work. Therefore, it is so important to know proven and effective antiseptics manufactured in industrial conditions. But time-tested mold control products can also help eliminate it.

Industrial means to combat mycelium

When purchasing, be sure to consult with the manager and study the instructions. It may be that the wall dampness solution is designed to combat a specific type of mold and is not suitable for you. In this case, it is better to purchase a universal product that kills all types of fungus. When purchasing a dry mixture, do not forget to buy a diluting agent. Depending on the type of substance, it can be dissolved in turpentine, white spirit and ordinary water. The most popular drugs are given in the following list. Only proven and high-quality antiseptics and fungicides are presented here:

- Atlas Mykos. This material fights not only fungus, but also moss and lichen formed on the outer walls. Sold in concentrated form. After dilution, according to the instructions, it is used to treat facades and any rooms with humid air and extensive mycelium colonies. Diluted with water according to instructions. For processing minerals, the ratio is 1 to 5; in all other cases, the ratio of substance to water is 1 to 2.

- Spectrum Fungicide. This is a universal material that can eliminate mold from a wooden surface. Works well on plaster and paint. The universal product works on interior and exterior wall surfaces with high moisture content.

- Xiolate. With the help of this drug, the molecular structure of the mycelium is destroyed. It is able to penetrate deep into the structure of walls or furniture. It is especially effective in advanced cases - it can kill deep-seated mold.

- Teflex. A very effective anti-mold substance that is absolutely harmless to humans and animals. When treated, the walls are protected for a long time.

- FILASMUFFY. This spray effectively removes fresh mycelium formations. Particularly effective for small stains on wallpaper, concrete or brick surfaces.

- Snezhka Impregnation. Effectively fights mold, moss, and algae. Treat all types of surfaces in rooms with high humidity and outside the building.

Important. Any product will reliably and efficiently remove mold from walls, if the problem is detected and dealt with in a timely manner. When purchasing, be sure to check the drug certificate, beware of counterfeits.

And here are the recipes for traditional methods of fighting fungus. Therefore, in the early stage of mycelium development, such treatment will not only save money on the family budget, but will reliably and efficiently solve it.

Insulation outside and inside

Home protection from water is better integrated . Waterproofing of walls should be carried out on the external areas of the structure and its internal surfaces. In the absence of an external waterproofing layer, mold and dampness are guaranteed in the housing. In order for the protection to be complete, the base should be treated with connections both outside and inside: on the ground floor with ground contacts on both sides.

The difficulty of implementing external waterproofing lies in the fact that this work must be carried out during the construction of the building. If it is already built, waterproofing the walls requires excavating the foundation.

If the building is surrounded by earth, it will need to be dismantled by digging trenches along the basement and waterproofing, then burying the trenches again. Therefore, waterproofing the external walls of an already constructed building will be expensive. Then it is better to insulate from the inside.

In the modern market of construction materials, there are many different means for introducing waterproofing.

The following popular types can be listed:

- bitumen mastic;

- impregnated sheet or roll material;

- cement-polymer mixtures;

- rubber-based hydrobarrier.

Do not use polyethylene-based film materials. Such materials used for waterproofing do not have sufficient vapor permeability, unlike those listed.

Types of insulating materials

Manufacturers of waterproofing materials offer many products. Depending on the local climate conditions, composition, water saturation of the soil, insulation is chosen.

Injectable

Injection solutions based on polyurethane, minerals, epoxy resin, and other substances are popular. Application of the composition requires equipment that, under pressure, forces the mixture into concrete pores. Gradually the introduced solution will fill and impregnate a layer of 5-10 cm with a waterproof coating, enough to prevent contact with moisture.

How injection insulation works

It is used when it is impossible to approach the foundation wall with other material, or it is impossible to excavate the base, all that remains is to make a cutoff at the horizontal level.

Penetrating type

The protective layer of the penetrating direction is a mixture of a cement base with fine sand and chemically active components. The product is suitable for working inside basements and treating foundation structures.

The substance is applied to the concrete surface and allowed to dry. When the base comes into contact with groundwater, the waterproofing will enter into a chemical reaction and crystallize.

An outer protective layer is created, crystallization occurs inside the capillaries, creating a maximum water-repellent layer. The effect of “self-healing” of concrete is created.

It is recommended to apply a penetrating coating to a freshly poured foundation; it may react poorly on an old foundation.

Coating insulation

For internal processing, liquid mastics based on bitumen are suitable, which are produced in two formats - cold and hot.

Cold formulations are a set of individual components that are mixed before direct use. Simply stir the solution thoroughly and you can begin processing.

Coating mixture

Hot mastic needs to be heated to 70 - 90 degrees (depending on the manufacturer's instructions). The mixture is distributed in a heated state, after cooling, hardening begins immediately. A dense, seamless coating will soon form, effectively repelling water.

The material is rarely recommended as independent protection; it is better to take mastic with a denser coating.

Spray protection

Liquid insulation can be so diluted that it can be sprayed. Working with a spray gun will significantly speed up the process, without affecting the quality of the result.

This category includes liquid rubber, which dries quickly, creating a dense layer. Analogues - synthetic rubber, inopaz H2O, elastomix.

The advantages of the liquid composition are the absence of joints, filling the pores of the structure, speed, and ease of application.

Disadvantage: limited application. Spray-on insulation is suitable for exterior applications only. It should be at least +5 degrees outside, the main surface should be moistened with water before work, the wind can affect the uniformity of spraying.

Raw materials are expensive and require the involvement of special equipment and experts in working with equipment.

Pasting material

Forms a thick protective barrier that adheres tightly to the base. To fix the sheathing, you can use bitumen mastic, a material with a layer of bitumen applied to the back side. The bitumen treatment is heated with a gas burner, and the piece is immediately glued to the desired location.

Working with adhesive coating

The coating fits well on vertical and horizontal surfaces, but is used more often for external insulation and roofing.

New types of products with durable additives, with antiseptic properties.

Regardless of the base material, the pasting cut will be firmly fixed.

However, before use, it is necessary to level the walls, observe the temperature regime (from +10 degrees), you need to be careful when working - punctures and cuts appear almost instantly. The product is completely unstable to mechanical damage.

Film coating

A simple option is a polyethylene film that does not allow water to pass through, does not absorb, and if the joints are properly sealed, does not allow leakage.

However, the material does not allow air or steam to pass through at all. Not suitable for wall cladding, but can be used on roofs, ceilings, and foundations.

If you use film, you immediately need to purchase a substrate - geotextiles.

The polyethylene is laid overlapping, the seams are taped with simple tape.

The raw material is fragile, the slightest damage will damage the integrity of the protective layer. Slots, through holes of different diameters, easy separation are the most likely results of physical interaction with a person or object.

Paint protection

Waterproofing and cladding at the same time is a liquid paint composition. The material has a neutral light shade, which is tinted.

The product is suitable for coating inside and outside the structure; the dried layer is reliable, elastic, seamless protection.

Paint barrier

Insulation - bitumen-based mastic with the addition of synthetic resins, asbestos, talc.

The simple composition, budget cost, and ease of use attract attention, but the safe coating will not last long, a maximum of 5-6 years. After the expiration of the period, you need to clean the walls and carry out the procedure again.

A detailed overview of waterproofing raw materials can be seen in the following video:

Autonomous waterproofing of walls

For independent work, it is better to choose a combination of materials, such as bitumen mastic and any other rolled material impregnated with bitumen. It is in this combination that they will allow you to properly build a waterproofing system and ensure the durability of the protective and finishing layer of the room.

Waterproofing walls from the inside and outside is carried out in the following ways:

- Horizontal waterproofing is a method in which, after cutting the walls in a horizontal plane, the space is filled with waterproof material. In some cases, an injection method is used in which the capillaries are blocked and the walls become hydrophobic.

- Vertical waterproofing is not as effective because, while preventing moisture from penetrating into the building, it cannot completely protect the walls from increased moisture at height, creating a favorable environment for the appearance of fungus. This method is used more effectively in difficult cases.

Although any structures require waterproofing, this issue remains most relevant when it comes to a brick house. Brick is an affordable and popular building material, which is characterized by a porous structure that absorbs water and destroys walls. This applies to both private and multi-storey buildings.

Waterproofing with penetrating and injection agents

For waterproofing concrete walls, penetrating or injection composites are considered the best option. Concrete is a building material that contains the necessary components to initiate the chemical crystallization reaction.

Before starting work, the wall is generously moistened with water, after which a penetrating solution is applied to it. When the solution penetrates deep into the concrete, it crystallizes, forming a protective layer. At the same time, the structure of concrete itself changes - it becomes stronger and more durable. This method works best on recently constructed walls, where the concrete has not yet dried well.

For repairing and waterproofing old walls, the injection method has proven itself to be better. Such moisture protection can only be done by specialists with special equipment. To create it, holes are drilled in the wall through which the solution is fed deep into the material. It is important to correctly calculate the frequency of “injections” so that, on the one hand, the strength of the structure is not compromised, and on the other, to ensure a continuous insulating layer. But if all the manipulations are carried out correctly, then the wall reinforced by the injection method becomes a real monolith, which is 100% waterproof.

Protection from moisture in a brick house

It is not surprising that brick buildings must be protected from moisture, and the sooner this is done, the better, since the brick immediately begins to absorb moisture from the environment. The waterproof layer, which protects the surface of walls and ceilings, is usually applied externally, but in some cases an integrated approach is used where waterproofing materials are used both internally and externally .

The highest quality and most effective option for insulation builders is a penetrating mixture, which is used from the accessible side. These impregnations applied to external walls completely prevent moisture, creating an excellent water lock that is resistant to damage.

Preparing a brick wall before applying impregnation involves thoroughly cleaning it from dirt and dust, leveling the surface and repairing areas. If cracks are found in the masonry, they must be closed. To perform the work you need a protective suit, gloves and a mask.

A primer is applied to the surface for better adhesion , after which a waterproofing composition is applied to the moistened surface. You can use a brush or roller for this. Typically, the penetrating mixture is applied in several layers - to find out the number, read the instructions. Please note that already at the purchase stage you must select a specific composition designed for your type of wall.

When carrying out waterproofing work in a high-rise building, pay special attention to air joints. If we are talking about a private house, then you will have to work a lot: partially dig the foundation, clear it of soil and apply a special primer, as well as waterproof the bitumen. Sometimes roll materials are used, which strengthen the waterproofing material. Experts recommend planning for insulation early in construction.

Protecting walls with special plaster

In historical premises, the walls are made of brick and often have high humidity. To effectively remove this moisture, sanitizing plaster is used. This is a special plaster composition with a large-porous structure that effectively sucks moisture out of the wall and actively evaporates it without visible traces. Apply indoors in a layer of 2 cm.

This type of plasters can be painted in any color, but it is necessary to use vapor-permeable paint for mineral substrates.

Selection of materials

- The coating composition is sold in all construction stores; each manufacturer offers its products upon purchase, which should be ensured that there are documents confirming the quality and origin of the material.

- To treat wooden surfaces, use a waterproofing compound with additives that prevent the development of fungi and mold. Surface treatment should be carried out immediately after completion of construction. If mold appears on the wall, disinfect the area, clean it and treat it with an antiseptic as soon as possible.

- Before gluing the rolled material, a brick or concrete wall is treated with a primer to increase adhesion.

- When choosing any material, it is better to give preference to well-known brands, even if the price is slightly higher than analogues.

Waterproofing walls helps to increase the life of the building; in this matter, you should not skimp on the choice of protective coating. It is better to carry out high-quality waterproofing once than to spend additional funds annually on repairs and eliminating the consequences of water penetration into the premises.

Need for work inside

In every home, the temperature regime inside is necessarily different from the regime outside. To create a good comfortable environment in the summer we try to ventilate more, and in the winter we turn on different heating.

As a result, moisture condensation occurs, especially on indoor surfaces. Probably, at least everyone has paid attention to wet wallpaper and windows at least once; this can lead to various undesirable consequences:

- Since most building materials are capable of absorbing moisture, this can greatly reduce their lifespan.

- Most main services are made of metal and will therefore be corrosive in humid conditions.

- Over time, dampness begins to appear.

- The microclimate is disrupted.

- Mold begins to appear and this is not good for human health.

Thus, we can conclude that protection from moisture indoors is just as necessary as outside.

Impregnation of a brick wall

Protecting bricks from moisture - applying mortar to the masonry

It is recommended to protect bricks from moisture by impregnation with hydrophobic substances.

To ensure that the solution is well absorbed by the brick, it is recommended to do this in warm, sunny weather. When processing brick, the following happens: the substance included in this preparation closes the pores of the brick and construction joints.

An invisible, transparent film is created on the surface of the wall, which will protect your brick from harmful influences and factors. Another feature of this film is that it does not collapse for a long time, which will allow you to avoid returning to this process for a long time.

Also, protecting the brick with a water repellent helps to increase frost resistance and increases its strength by about 30%.

As mentioned above, this method is very easy to use and incredibly effective. The drug has many advantages over other protective agents:

- The water repellent does not create a sticky film visible to the eye, which could cause the accumulation of dirt and insects on it.

- The product does not contain harmful chemicals, so it can be called environmentally friendly.

- It does not spoil or change the appearance of the wall. The wall remains the same as it was before using the drug.

- The water repellent is durable and also has a low cost.

Consumables and tools

For injection waterproofing you will need:

- Hammer. Creates holes for packers.

- Packers. Special tips that are inserted into the hole on one side and a pump with gel is connected on the other.

- Pump.

- Repair compound to seal holes after treatment.

After finishing work indoors, it is recommended to use an impregnating waterproofing compound as an addition to injections.

For adhesive insulation you may need:

- gas-burner;

- plumb line (check if the surface is level);

- plaster mixture;

- water;

- spatula, usually graters, smoothers;

- primer;

- bitumen mastic or polymer glue for processing joints (you will need a ladle for them);

- knife, scraper;

- containers for water, mastic.

For the coating you will need:

- brushes, scrapers for cleaning walls;

- cement mixture for eliminating cracks and failures;

- primer;

- roller, spatula or spray gun;

- waterproofing tape or reinforcing fiberglass mesh (for forming corners in problem areas);

- containers for diluting the composition;

- plumb and level.

To create a vapor barrier you will additionally need:

- brushes, scrapers for cleaning walls;

- metallized tape.

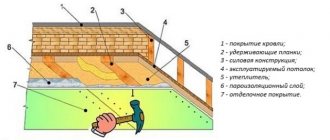

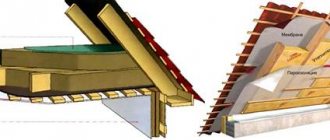

A layer of insulation is installed between the waterproofing and vapor barrier. The steam protection layer is attached directly to it.

Treating walls with antiseptic

Before applying antiseptic to the wall, it should be properly prepared. First of all, it is necessary to remove all finishing from the affected areas - old wallpaper, plaster, putty down to the bare wall.

Old finishing material contaminated with fungus should be disposed of in a trash bin, carefully collecting it. The fact is that fungal spores are very tenacious and, if construction waste is not properly disposed of, can again cause its development.

To remove the old finish, you can use any available tools: a spatula, a hammer, a chisel, an old hatchet, etc. To make old wallpaper come off easier, they should be thoroughly moistened with warm water and left for half an hour. We also completely dismantle and dispose of plaster permeated with mycelium.

After the wall is completely free of interior decoration, you should carefully inspect it. If it is damp to the touch, you will need to dry it thoroughly using a heat gun or hair dryer. Then these places are treated with chemical compounds with antifungal and antimicrobial components.

If you don’t have them at hand, you can make do with folk, time-tested remedies. This could be chlorine bleach or bleach. A solution of copper sulfate (20 grams per liter of water) or baking soda (1 tablespoon per half liter) is also suitable.