Other articles on this topic:

⇒ How to reduce the high gas consumption of a boiler for heating a house ⇒ DHW boiler for a double-circuit boiler or water heater ⇒ Setting the pressure in a heating system with a membrane expansion tank

This article describes in detail the adjustment, power settings and other parameters of BAXI wall-mounted gas boilers through the service menu. The principles of regulation and power settings described in this article are also suitable for gas boilers of many other brands and manufacturers.

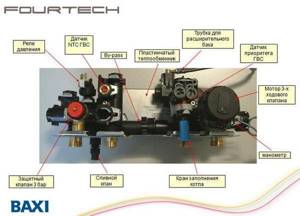

Construction of Baksi boilers

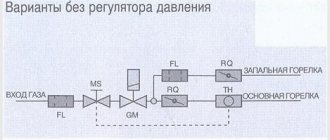

Let's look at the basic design of the Baxi boiler. The basic diagram is printed in the operating instructions for each specific model, but the main components will be the same.

There is a chimney at the top. Immediately below it there is a fan with a Venturi tube and an exhaust hood for removing combustion products. Below is the primary heat exchanger, which looks like a radiator and coil, a little to the left is a safety thermostat and an NTC heating temperature sensor.

In the center there is a combustion chamber, inside which there is a burner and electrodes for ignition and ionization of the flame. A gas train with nozzles is connected to the modulation burner, into which gas flows from the gas valve.

On the right side, a pipe goes down from the heat exchanger, connected to the expansion tank and circulation pump. The pump is equipped with an automatic air bleed valve. It ends at the bottom with a tap for draining the coolant from the apparatus and a pressure gauge; it receives water from the heating system of the house.

A pipe is lowered on the left side, on which a hydraulic pressure switch is installed and a safety valve at the end. Water comes out of it into the heating system. These pipes are connected to each other by an automatic bypass.

In double-circuit models, a secondary plate heat exchanger, a DHW priority sensor and a three-stage valve are additionally installed. The Baxi Luna 3 Combi and Nulova 3 model series are equipped with a small-volume indirect boiler.

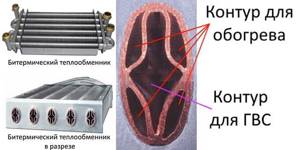

Main 5 boilers are equipped with a bithermic heat exchanger, which simultaneously heats both running water and coolant. This is realized due to the fact that inside the tube through which liquid from the heating system flows, there is another tube of a smaller diameter through which tap water flows.

An electronic control board is installed on the front. The electrical diagram printed in the operating manual shows where all the boiler elements and sensors are connected to. Using it you can understand how the electrical part of the equipment works.

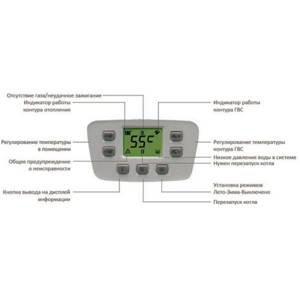

A steel casing is installed outside, on which there is an electrical control panel with power buttons and operating mode selection buttons. Modern models are equipped with a display to display technical data and error codes in the event of a malfunction.

Decoding

Parasitic flame - this is how the malfunction is described in the instructions for the boiler. Error E35 is not typical for Baksi, it is rare, and even experts find it difficult to accurately diagnose the equipment. On thematic forums, the emphasis is on the failure of the Baksi board, although failures are mainly caused by external factors: instability of power supply parameters, improper grounding, interference, and a number of others. The cost of the control unit reaches 30% of the price of the Baxi boiler, and if error E35 occurs, you do not need to immediately purchase a new board - the reason for the unit stopping is not necessarily its malfunction.

Baxi boiler control board

Principle of operation

Let's figure out the operating principle of the Baksi gas boiler. The coolant enters the apparatus system through the right pipe, driven by a circulation pump. Next it enters the heat exchanger.

When the liquid temperature drops below the one set in the control panel settings, the gas valve supplies fuel to the burner and the ignition electrode is activated. A flame ignites and heats the heat exchanger. When heated, the coolant expands and its excess enters the expansion tank.

The coolant exits through the left pipe, passing through the temperature sensor. When the water has heated to the set level, the gas supply to the burner is cut off. An external room thermostat can also regulate the operation of the boiler; in this case, the operating cycles will be tied to the room temperature.

In dual-circuit series, a three-stage valve changes the priority of domestic hot water and heating depending on the needs of the consumer.

Baxi Three Stage Gas Valve

The wiring of such a boiler is quite simple, since all functional elements are configured and located inside the housing. You need to calculate the required number of radiators, draw a diagram, and then connect them to each other and bring all the pipes to the device.

How often should it turn on?

The frequency of turning on the boiler depends on several factors:

- Unit power.

- Correct boiler settings.

- Availability of a room thermostat.

If the power is excessive, the installation quickly heats up the heating agent and turns off. The circulation pump ensures the flow of new portions of cooled coolant, the temperature sensor is triggered and starts the boiler again.

Power can be reduced programmatically . It is also necessary to reconfigure the boiler, in particular, increase parameter F11 (waiting time before restarting) to the maximum, which is 10 minutes.

Using a thermostat allows you to significantly increase the time between starts of the unit, since the air cools and heats up much more slowly.

Series and their features

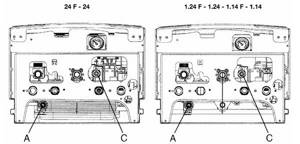

To be able to determine the type of boiler by its name, let’s look at the markings. The symbol “F” or “Fi” indicates that the boiler is turbocharged with a closed combustion chamber. Atmospheric vehicles have the letter “i”. The word “Comfort” means that the kit comes with a remote control panel; the mark “Air” means that this panel is remote.

The first number after the name of the series reflects the generation of boilers, and the second number reflects the power. For example, the fourth generation Baxi Eco Four 24 F with a closed combustion chamber and a power of 24 kW.

Boiler Baxi Eco Four 24 F

The fifth generation Main 5 series is the next stage in the development of the Baxi Main Four 240 F boilers. It includes three wall-mounted models with a power of 14, 18 and 24 kW. All of them are double-circuit due to the installed bithermic heat exchanger, and have electronic protection against scale. Equipped with a closed combustion chamber. The configuration is very adaptive, the boiler operates at a reduced gas pressure of up to 4 bar and power voltage drops from 170 to 270 V.

Boiler panel Baxi Main Four 240

The development of the outdated Eco 3 Compact series became the ECO Four (Ecofor), Eco 4s and Eco 5 Compact lines. Baxi Eco Compact devices are small in size due to the optimized internal arrangement of the main components. They include single-circuit and double-circuit devices with a secondary stainless steel plate heat exchanger.

Boiler Baxi Eco Compact 4s

The hydraulic system includes an economical circulation pump with automatic air bleed. The lines include 18 models with closed and open combustion chambers with power from 14 to 25 kW. They have a liquid crystal display. Eco 5 Compact devices can be connected to an integrated solar circuit.

The Baxi Four Tech (Fortech) line is a cheaper analogue of the Eco Four series due to plastic water supply pipes. The Luna 3 and Luna 3 Comfort editions offer single and dual circuit units from 24 to 31 kW. Can run on liquefied gas. The burners have continuous electronic flame modulation.

Boiler Baxi Four Tech

The electronic board has a self-diagnosis function and weekly programming capabilities. The Comfort series is equipped with a remote control panel with a built-in room temperature sensor. In Luna 3 Combi devices, DHW is provided by a built-in eighty-liter indirect heating boiler made of Combi 80 stainless steel.

Baxi Slim floor-standing boilers have very compact dimensions, a stylish gray body with a black control panel and are equipped with a cast iron heat exchanger. Slim 2 models have an indirect heating boiler of 50 or 60 liters.

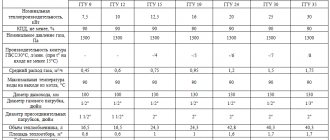

Characteristics of Baxi eco four 24

The eco gas boiler is a double-circuit wall-mounted boiler with an automatic control system. The number 24 indicates the maximum developed thermal power in kW (minimum - 9 kW). At the same time, the maximum power consumption of the electrical network is 25.8 kW, and the largest heating area is 240 square meters. If the gas boiler is also marked with the index F, it will be equipped with a turbine for supplying air and a coaxial pipe for exhaust gases to exit the house. It is good to buy such a boiler when there is no chimney in the house, or a boiler cannot be connected to it, or if you live in an apartment.

As the instructions say, the Baksi Ecofor 240 gas boiler has the following main characteristics.

- It has the function of continuous electronic modulation, independent regulation of its power, depending on the temperature, according to the specified parameters. In other words, you set the required coolant temperature and hot water temperature (DHW) using the keys, and the boiler maintains it in such a way that the clocking (frequency of switching on and off) of the boiler is minimal.

- When operating in heating mode, the smooth electronic ignition function operates. The equipment reaches the specified maximum power gradually, at a minimum flame, which reduces the noise from its operation.

- Availability of flame dividers made of stainless steel.

- An original system for supplying the air necessary for combustion.

- Possibility of working on liquefied gas after reconfiguration.

- The heat exchange device is bithermal. This means that in one thermomechanical device, both OM (coolant water) and DHW flow through two different pipe systems made according to the appropriate design.

- The circulation pump is designed in an energy-saving mode, with automatic removal of air from the system.

- The presence of a filter on the DHW supply water pipeline to remove suspended particles. This filter will not protect the pipes from damage from the inside if the water is too hard. If the amount of hardness salts in the water exceeds 20º F, you will have to purchase additional water softening equipment, for example, purchase a polyphosphate dispenser.

- Pump post-circulation. This function is available for eco for 240 if a thermostat is connected. In a room where it is necessary to maintain a certain microclimate, a thermostat device is mounted on the wall at a level of 1.5 m and connected via wires to the corresponding terminals on the eco boiler. The required maximum temperature is set, upon reaching which the gas supply will turn off on its own, but the pump will continue to circulate the coolant through the pipes for another three minutes, then it will turn off.

- The gas boiler of this modification has a self-diagnosis function. If there is a malfunction, the automation itself determines the probable cause and displays an error code on the electronic display. By looking at the instructions, you can find out what malfunction this code corresponds to.

- The ability to configure one of two main modes for regulating the temperature of the coolant: normal (35-80 degrees) and mode (35-45 degrees), which helps save energy when there is a “warm floor”.

- Anti-icing system. If the boiler has been turned off for a long time and the temperature drops to critical, the automation will automatically turn on the burners and the circulation pump, which will protect the entire system from freezing. This function will operate in any mode (“winter”, “summer”), unless the power supply is turned off.

- You can connect a sensor that will measure the outside air temperature.

- Displaying water temperature on the display screen.

- Possibility of connecting a timer that can be programmed.

- Flame control ionized.

- Sensor for monitoring the vacuum at the outlet of combustion products from the boiler.

- The gas boiler has a kind of inspector of normal operating conditions - a pressure switch that turns off the gas supply when the water pressure drops, which is additional protection against overheating of equipment elements.

In the photo you can see the location of the various parts under the cover.

Temperature adjustment

To increase or decrease the heating agent temperature, there are “+” and “-” buttons to the right and left of the display (on older models there is a special regulator; turning clockwise increases the temperature and vice versa).

If a room thermostat is used, adjustments are made from it, and only limit values are set on the boiler.

When setting the temperature, do not change the parameters in large increments . It is necessary to change the mode smoothly, giving some time to overcome the inertia of the system. This will soften the transition to another mode and extend the life of the boiler.

Pressure setting

To increase the pressure, a make-up valve is used, and to release the pressure, a drain valve is used.

The optimal value is considered to be a range of 0.7-1 mbar . Usually Baxi boilers independently maintain the desired value, but sometimes failures occur. If there is a constant drop that does not disappear after the system is recharged, then there is an OM leak somewhere.

This could mean either leaking pipes or radiators, underfloor heating systems or other external elements.

Often the problem occurs due to a faulty bleed valve . An abnormal increase in pressure may be due to a malfunction or open make-up valve or damage to the expansion tank membrane.

Optimal operating mode

The optimal operating mode of the boiler is described in detail in the user manual.

Its parameters:

- Ambient temperature is 70-75°.

- Water pressure - 0.7-1 mbar.

- Parameters F08 and F10 are adjusted to the minimum and maximum values respectively.

Adjustments are made during commissioning; additional adjustments are made periodically during annual maintenance or after repair work.

How to turn it on

The boiler is connected to the power supply network only after connecting all pipelines supplying water, heating agent and gas.

It is necessary to carefully check the correct connections, paying special attention to the gas pipeline.

Using a soap solution, check for leaks; if any deficiencies are found, immediately correct them yourself or with the involvement of specialists of the appropriate profile. After this, the boiler can be filled with water by opening the feed tap.

The pressure should be between 0.7 and 1 mbar. When the pressure reaches the desired value, the boiler can be started .

Download instructions

Download instructions for Baxi boilers.

Self-diagnosis

Self-diagnosis is an automatic continuous process that starts immediately when the boiler is turned on for the first time..

It does not require any special actions and runs constantly in the background. Any error is immediately registered by the corresponding sensor, which displays it on the display, and the control board blocks the operation of the unit. To reset the error and restart the boiler, press the “R” button and hold it for several seconds.

First start

After connecting all communications and power supplies, you can turn on the boiler.

Procedure:

- Open the gas tap.

- Set the heating and DHW supply mode (or only DHW). These modes correspond to the designations “Winter” and “Summer”.

- Set the desired temperature by pressing the “+” or “-” buttons.

After this, the burner will start and the boiler will begin to operate. Often, after the first start, an error immediately appears on the display and the boiler is blocked.

This is due to air remaining in the pipes. By pressing the “R” button and holding it for several seconds, the error is reset and the unit is restarted. Several repetitions of this situation may occur before the air is completely removed.

IMPORTANT!

The air can be released more quickly by opening the pump and loosening the screw. The procedure is performed with the power off. The air will come out from under the pump cover as soon as water comes out, the screw will immediately be tightened again and the equipment will start again.

Connecting a room thermostat

Most models of Baxi boilers have the ability to connect a room thermostat. The idea is that the boiler will turn on only by a signal from the thermostat when the air temperature in the room drops below the set one.

Of course, everything is quite individual, and a lot depends on the type and balance of the heating system as a whole, and using only one room thermostat will have a certain inertia.

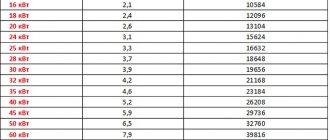

Programmable thermostats allow you to flexibly set different temperatures throughout the day. Reducing the room temperature by 1 degree throughout the year will result in gas savings of about 4-5%.

In some EU countries, where energy efficiency issues are more meticulous, installing a room thermostat is a mandatory requirement.

Error E01

The most typical malfunction of a boiler from absolutely any manufacturer, which is probably why it is indicated by the first serial number. Error E01 occurs when it is impossible to ignite the boiler gas burner normally. Ignition is controlled by a special device - a flame ionization sensor (or a flame presence electrode). In some boiler models it can be combined in one electrode (for example, in ECOFOUR), in others - separately. This electrode records microcurrents that arise precisely during gas combustion between the electrode and the burner. Normal gas combustion corresponds only to a certain microcurrent value, therefore, if the control board detects deviations from the nominal values, error E01 will appear and the boiler will stop.

Therefore, the cause of error E01 can be either improper gas combustion:

- insufficient pressure at the outlet of the gas valve

- lack of gas supply

- insufficient air supply to the combustion chamber

or malfunction of actuators:

- state of the flame control electrode (position relative to the burner, contamination)

- connection of the sensor to the control unit

- failure of the control board (ignition unit)

In most cases, the user will be able to independently check only the position and condition of the ionization sensor (the gap size is given in the instructions for each model) and try to reset the error (on Baxi boilers, hold down the R button for more than 2 seconds).

To adjust the gas valve or diagnose the electronic board of the boiler, you will need the help of a qualified specialist, because it is performed using a special device - a differential pressure gauge.

There are cases when it is possible to visually determine fault E01. Watch the video below; with the lid open, you can see why the boiler cannot start: apparently the insulation of the electrode supply wire was broken and the spark struck in the wrong place where it was necessary:

The board is the very last device on the list because it is diagnosed after all other possible causes of error E01

. This is a technically complex electronic device, the diagnosis of which requires special knowledge and equipment, and there are not many specialists who can carry out repairs.

If you are immediately offered to buy a new board, I recommend reading our material on repairing baxi electronic boards. Most likely you will be able to save a decent amount of money.

Zonal control system

Such a system provides for individual temperature control in each room separately by installing controlled thermal heads on each radiator. That is, depending on the air temperature in a particular room, the amount of coolant in the radiator will be regulated, and the boiler will turn on only when necessary. The use of such regulation will provide maximum savings (about 30%) and comfort in the room. The only disadvantage of such a system is its cost.

Savings and regular equipment maintenance

The basic structure of a traditional gas boiler is almost the same, regardless of the manufacturer. Thermal energy from gas combustion is transferred to the coolant through a heat exchanger. There can be either one or two heat exchangers in the boiler. During operation of any gas boiler, the heat removal surface becomes contaminated with soot deposits from the outside and scale from the inside.

From practice, we can say that it is extremely rare that the system is filled with special prepared water or the water supply system is equipped with a water treatment system. This is especially true for apartment buildings, in which the owners receive a ready-made heating system along with the apartment.

The formation of scale and soot on the walls of the heat exchanger will gradually reduce the heat transfer performance, and more energy will be consumed for heating.

Therefore, annual regular maintenance will definitely affect the efficiency of equipment operation for the better! This especially applies to boilers with bithermic heat exchangers, which, due to their design, are difficult to clean.

What to do if there is a sudden power cut?

UPS for gas boiler Baxi

Many people install generators to protect themselves and their expensive equipment. Of course, this is a good solution. But there is a much simpler and less expensive solution to the issue.

All that is required is to install a five percent Stihl thyristor stabilizer with a power of 1.2 kW and SmartUps 1000. Next, we replace the 24-volt internal battery installed in the uninterruptible power supply with two 12V car batteries, each of which has a capacity of 75 A/ h. We connect the batteries to each other in series. As a result, we get an additional energy reserve of 150A/h.

Note that when the fan, circulation pump and boiler are operating at full power, the battery charge will be enough for approximately 11–12 hours of operation, which is quite enough for the emergency situation to be resolved.

BAXI gas boiler service menu commands

In the service menu lines you can change some settings for the operating mode parameters of the Baxi gas boiler.

BAXI Main Four | BAXI Eco Four | BAXI Four Tech:

Line F06 - setting the maximum temperature (°C) of the heating system: 00 = 76°C (burner switches off at 80°C); 01 = 45°C. Factory setting = 00.

Line F08 - maximum net power of the heating system (0-100%): 80 - natural gas; 100 - liquefied gas. Factory setting = 80.

Line F09 - maximum useful power of the hot water supply system (0-100%): 80 - natural gas; 100 - liquefied gas. Factory setting = 80.

Line F10 - minimum useful power of the heating system (0-100%): 20 - natural gas; 00 - liquefied gas. Factory setting = 20.

Line F11 - burner waiting time between two starts (01-10 min): 00=10 sec. Factory setting = 03.

Only BAXI Main Four:

Line F14 - test to check the correct position of the hot water sensor: 00 - off; 01 - always on. Factory setting = 01.

Line F16 - minimum useful power of the hot water supply system (0-100%): 20 - natural gas; 00 - liquefied gas. Factory setting = 20.

BAXI Main 5:

Line F06 - Setting the maximum supply water temperature to the heating circuit (°C) 000=76 °C (burner shutdown at 81 °C) 001=45 °C (burner shutdown at 50 °C). Factory setting =000.

Line F08 - Max. power in heating mode (0-100%). Factory setting for boiler model 24F =055; for model 18F =100; for model 14F =050.

Line F09 - Max. power in DHW mode (0-100%). Factory setting =100.

Installation subtleties and configuration nuances

We have already noted that the installation, connection, first start-up and adjustment of the operating parameters of the Baksi gas boiler should be carried out by a specialist from the organization with which an agreement has been concluded for the supply of blue fuel and for the maintenance of gas processing units. After applying your own efforts to implement the above steps, you will no longer be able to benefit from the warranty.

All steps of the installation cycle of work are documented. Boiler owners are given papers indicating who installed and connected what. If a malfunction is detected, the contractor will deal with it. If a manufacturing defect is detected, which is extremely rare, all replacement and repair problems are resolved by the gas service.

Please note that these gas heat generators can be installed in heating circuits with any heating appliances. Heated floors are no exception, but for them to work, the boiler power should be set to 65ºC at the inlet to the supply pipe. They are suitable for both one- and two-pipe heating circuits, for tee and radial options.

Steps to connect the boiler to communications

Let us list step by step what gas workers must do during the installation and connection of a Baksi gas boiler.

Conventionally, the entire cycle of work can be divided into three main parts, these are:

- Preparation of building structures and communications. Strengthening structures as needed. Laying lines for connection, if necessary.

- Hanging the boiler on the wall and connecting to communications. Purely mechanical work that requires strict adherence to the diagram and recommendations of the unit manufacturer.

- Performing the first launch and setting up operating parameters. Carrying out the first launch is the responsibility of representatives of the gas company. The user can set the settings himself.

All actions are carried out in a thoroughly thought-out and clearly worked out manner by the boiler manufacturer.

The manufacturer of equipment for heating coolant and hot water supplies the installation diagram with the unit. When connecting communications, you must strictly follow the instructions

The preparatory period includes:

- Inspection of the premises to confirm the possibility of installing equipment using gas.

- Drawing up a contract for the work, attaching a connection diagram for a gas boiler with the Baksi logo and an accurately calculated estimate. It should indicate the prices for the work and the cost of materials purchased by the company for the installation of the thermal energy generator.

- Cleaning used heating and hot water systems from mineral deposits and contaminants deposited on the walls of pipelines and devices during operation. Produced by any available chemical.

- Laying communications to the boiler installation site. Only heating and gas supply lines are connected to single-circuit ones, and heating, gas and water supply lines are connected to double-circuit ones.

- Installation of shut-off valves on each communication line. They are needed to shut down the unit in case of repair, accident, or replacement.

- Installation of a dirt filter on the return pipe of the heating system. It is required to collect mineral deposits that may remain after cleaning and will form when the water heats up.

- Connection of a separate power supply line. It is used to ensure that other electrical equipment is not connected in parallel with the device, which creates the risk of a short circuit with fire hazardous consequences.

Connection of communication systems is carried out with the mandatory use of seals. All work must be carried out in accordance with plumbing standards.

The optimal location of the electrical outlet relative to the gas boiler is 30-50 cm from the body. Its installation and laying of the power supply branch is carried out in accordance with the PUE. In addition, the equipment must be grounded using a three-core cable with a grounding wire.

Since the operation of the hot water heater and coolant from Baksi requires power, it is necessary to lay a separate power line to the installation site of the boiler. It should pass at a distance of 30-50 cm from the body

The list of measures for installing the boiler includes:

- Boiler mounting. It is made on a wall with sufficient load-bearing capacity. Fix the unit with anchor bolts; if necessary, cover the wall with non-combustible finishing if it is made of flammable materials.

- Connecting pipelines to the boiler. It is carried out in accordance with the diagram attached to the technical passport by the manufacturer.

- Chimney assembly. The connection of chimneys to Baksi boilers is made only with fasteners supplied by the manufacturer of the unit.

For turbocharged models equipped with a closed combustion chamber, either a coaxial pipe or a regular pipe is connected together with an air supply pipe to the closed burner. The first option is simpler, but more expensive in terms of purchasing a coaxial system. However, it is not a fact that installing two channels for air supply and smoke removal will ultimately cost less.

A conventional chimney is connected to atmospheric models with an open combustion chamber. The products of blue fuel processing are discharged either through a wall into the street space or into the collective chimney of an apartment building.

Chimneys are connected to gas boilers with the Baksi logo using the fasteners included with the device. Turbine models are equipped with coaxial types of chimneys, atmospheric ones are equipped with conventional ones, which are recommended to be supplemented with condensate collectors

Chimney elbows allow this channel to be brought out in any direction through the wall. Let us note that exits through the walls are mainly in high-rise buildings, the number of storeys of which does not exceed five levels. In private houses, it is preferable to build vertical smoke channels.

Upon completion of the installation work, they proceed to the first launch and configuration.

Launch and commissioning activities

For the first start-up, the gas boiler and the circuits it processes are filled with the medium transported through them. Unlike most wall-mounted models, which can only heat water as a coolant, Baksi units can be filled with antifreeze - an aqueous solution of propylene glycol with antifreeze additives.

The process of filling the boiler and heating circuit with coolant is carried out through a pipe located in the lower part of the unit. After filling, bleed off the air, then, if necessary, replenish the coolant volume in the same way.

After connecting the boiler to the communication lines, it and the associated systems are filled with water. Then they connect to the electrical network and open access to gas. Now you can configure

Recommendations for reducing operating costs

If all operational settings are made in accordance with the tabular data given by the manufacturer, then the equipment will consume energy very economically, generating the necessary heat in the volume required by the owners.

To do this you should:

- For systems with radiators or thermosiphons, select the temperature of the coolant at the boiler outlet +60ºС. It is worth increasing it only if, during operation of the unit, comfortable heat in the room was not obtained.

- Adjust temperature conditions in accordance with the manufacturer’s instructions and the purpose of the room. To heat bedrooms and other rarely visited rooms, the heating temperature can be set below average.

- Do not exceed the temperature background recommended by the manufacturers of the heating devices included in the circuit.

- Use indoor and outdoor temperature sensors that record temperature increases/decrease. The thermostat connected to them will independently start/stop the boiler as needed.

- Adjust the temperature of the coolant by the hour using a timer. At night, for example, it can be lowered by 3-5 ºС.

It should be remembered that by increasing the temperature in the room being treated by just 1º, we immediately increase costs by approximately 6%.

In order not to constantly change the coolant temperature settings during the difficult autumn-spring period, it is better to install an outdoor temperature sensor. If you don’t find a suitable model or don’t have the funds to buy the original, you can build a homemade device like this:

In case of prolonged absence, it is better to disconnect the boiler from the power supply, but you should not turn off the frost protection system. It is turned off only for the summer period, during which the heating function is abandoned, completely turning off the single-circuit model and switching to the dual-circuit version for the supply of hot water.

In order to save on heating, you should not cover radiators with screens and heavy curtains. They will disrupt normal air circulation and force the boiler to work at full capacity for no apparent reason.

Also, the equipment manufacturer does not recommend micro-ventilation in rooms, keeping the transoms constantly ajar. It is better to open the window wide and ventilate in one gulp than to artificially lower the readings of the room temperature sensor for a long time. It has been proven in practice that it is more economical.

When using the water preparation function, it is better to initially select a temperature that is comfortable for use, without counting on mixing heated and cold water in the mixer. Believe me, thanks to this solution, the thermal energy generated by the generator will not be wasted. In addition, limescale will not settle on the inner walls.