Setting up, adjusting the SIT gas valve

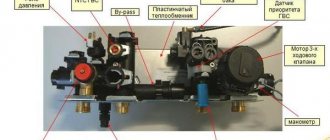

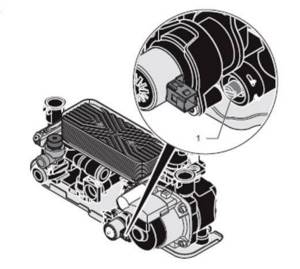

Gas valve SIT

Gas valve SIT. 1 - gas pressure measuring fitting at the valve outlet, in front of the burner; 2 — adjusting nut for maximum gas flow; 3 — adjusting screw for minimum gas flow; 4 — cover of the adjusting device; 5 - gas pressure measuring fitting at the valve inlet in the gas network.

Manufacturers of double-circuit gas boilers of many brands install a gas valve from the Italian company SIT on their boilers. The maximum and minimum power settings of the boiler burner are made by rotating the adjusting screws located on the valve body.

The boiler manufacturer Protherm Gepard (Panther) installs the SIT 845 Sigma gas valve on some versions of the boilers instead of the Honeywell gas valve. Such a gas valve is also found in gas boilers of the Vaillant series.

In the service menu of Protherm boilers with a SIT valve, lines d.52 and d.53 are missing.

How to regulate the minimum and maximum gas pressure at the outlet of the gas valve, see below in the video. The setup principle does not change.

The normal dynamic gas pressure at the gas valve inlet should be in the range of 1.3 - 2.5 kPa (13 - 25 mbar or 132 - 255 mm water column). If during measurement the dynamic pressure value falls outside the specified limits, then you must contact the gas service.

In order to eliminate boiler cycling in heating mode, reduce the minimum gas pressure at the valve outlet. screw counterclockwise .

Cycling in DHW mode is eliminated by reducing the maximum pressure. nut counterclockwise .

Automation object

Boiler equipment as an object of regulation is a complex dynamic system with many interconnected input and output parameters. Automation of boiler houses is complicated by the fact that the speed of technological processes in steam units is very high. The main adjustable quantities include:

- coolant flow and pressure (water or steam);

- vacuum in the furnace;

- level in the feed reservoir;

- In recent years, increased environmental requirements have been placed on the quality of the prepared fuel mixture and, as a consequence, on the temperature and composition of smoke removal products.

Setting up and adjusting the power of a gas boiler when operating on antifreeze

Traditional antifreezes based on ethylene glycol or propylene glycol have a higher viscosity compared to water. As a result, the movement of coolant through the boiler heat exchanger slows down. In addition, antifreezes have a lower heat capacity. All this leads to the fact that the antifreeze in the boiler heat exchanger, which is designed for water, at maximum power instantly heats up to the boiling point and boils. Boiling of antifreeze, as a result of local overheating in the heat exchanger, manifests itself in the form of loud noise, roaring and gurgling.

A gas boiler, when operating on antifreeze, can only operate at a reduced power, lower than that specified in the boiler instructions for water.

To slightly increase the power of a boiler running on antifreeze, it is recommended to dilute the antifreeze with water and also increase the pressure of the circulation pump.

For example, for heating systems with wall-mounted gas boilers, it is recommended to dilute the contents of the original packaging with water in a ratio of 1:1. As a result of diluting the antifreeze, the temperature at which crystallization begins will increase from -30 °C

to minus 10 °C.

If the crystallization temperature of diluted antifreeze is not satisfactory, then select another antifreeze.

In any case, to prevent overheating of the heat exchanger, in the settings of the service menu and gas valve it is necessary to limit the boiler power in heating mode (in lines d.00 and d.52 of the service menu), and also set the maximum coolant temperature no higher than +70 °C, (in line d.71 of the service menu). It is also recommended to increase the response pressure of the bypass valve on the boiler (how? - read below).

The boiler manufacturer usually gives its recommendations on the choice of antifreeze in the operating instructions. So, for Protherm gas boilers, the instructions say: “It is not recommended to use non-freezing liquids in heating systems with Protherm equipment installed. The use of non-freezing liquids entails a decrease in the efficiency of heat exchange, higher surface temperatures on the walls of the heat exchanger and its rapid wear, an increase in the corrosive effect and viscosity, corrosion of gaskets and fittings, both in the boiler itself and in the heating system. A boiler malfunction associated with the use of non-freezing liquids will result in a warranty denial.”

choosing a device for measuring gas pressure and adjusting the heating device

A pressure gauge exists to measure the pressure in a system. It connects with the emergency safety valve and air vent, thus guaranteeing safety.

If the pressure readings are outside the permissible limits, it means that the system is not working properly. Excessive pressure can lead to pipeline rupture and even equipment explosion.

Odnoklassniki

Classification of pressure gauges for setting up gas boilers

The operating principle of all pressure gauges is based on the fact that the measured pressure is balanced by the force of a tubular spring or a double-plate membrane.

One end of it is soldered to the holder, and the other is connected to the arrow through a special mechanism. This mechanism converts the linear movement of the sensing element into the movement of the arrow along the dial.

Exemplary

Measuring instruments that are used to calibrate others are called exemplary. This type of device is used to test equipment and accurately measure liquid and gas pressure; they have a higher accuracy class - 0.015-0.6 units. The increased measurement accuracy of these devices is due to the design features: the gear element in the transmission mechanism is made very accurately.

Electric contact

These devices monitor the pressure limit and notify the system when it is reached. Typically, this type of measuring equipment is used for gas, steam, and quiet liquids that are not prone to crystallization. The devices can control external electrical circuits when critical pressure is reached using a contact group or an optical pair.

Photo 1. Electric contact pressure gauge for a heating gas boiler. The device has a dial with divisions.

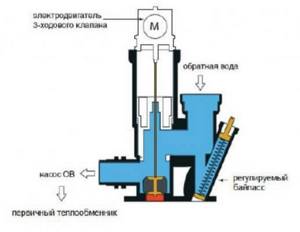

Setting, adjusting the bypass valve

In boilers, the forward and return heating pipelines are connected to each other through a bypass valve - bypass, pos. 1.

At a certain pressure difference in the forward and return pipelines, the valve opens and part of the water flows from the direct pipeline to the return pipeline. As a result, the difference in water pressure in the forward and return pipelines cannot exceed the value specified by the valve setting. The operation of the valve helps to avoid water hammer when the circulation pump is turned on. In addition, the valve setting limits the maximum speed of movement (flow) of water in the heating circuit.

The valve response pressure is determined by the position of the adjusting screw, item 1 in the figure. The screw can be rotated 10 turns from one extreme position to the other. Factory setting - the screw is set to the middle position, rotating 5 turns counterclockwise from the extreme right position. The valve opens at a pressure difference of 0.25 bar.

If the heating radiators are heated unevenly in height - the top is hot and the bottom is cold (the difference is more than 15-20 ° C), then it is necessary to increase the speed of water movement in the heating system. To do this, turn the bypass valve adjusting screw clockwise. The valve response pressure increases to 0.35 bar.

If noise is heard in the radiators or control valves during operation of the circulation pump, then the speed of water in the heating circuit should be reduced. To do this, rotate the screw counterclockwise. The valve response pressure is reduced to 0.17 bar.

The difference in pressure values that are displayed on the boiler display during operation of the circulation pump and immediately after it stops should not be more than 0.2-0.4 bar. If it is more, then you need to drain the water from the boiler, unscrew it and check the cleanliness of the bypass valve.

Three way valve for gas boiler

In DHW mode, the rod with the valve moves upward. To empty the boiler, the stem with the valve is set to the middle position through the service menu (menu line d.70).

Check before first start

If the equipment is new, then there is no need to check the deposits on combustion products; it is advisable to inspect the ventilation and remove excess debris from the chimney pipe. In these elements, I often noticed the accumulation of various insects, both small and large individuals, they can affect the productivity of the unit.

Open the chimney damper to the limit and check the draft. If you carry out the manipulations as carefully as possible, problems should not arise. But it is better to do all the work sequentially and devote the required amount of time to each moment, do all the work carefully and scrupulously, because safety directly depends on this.

Maintenance of gas boiler Protherm Gepard (Panther)

The boiler manufacturer prescribes scheduled maintenance of the equipment annually, before the start of the heating season.

In the Russian Federation, there are “Rules for the use of gas in terms of ensuring safety during the use and maintenance of in-house and intra-apartment equipment when providing public gas supply services”, approved by Decree of the Government of the Russian Federation No. 410 of May 14, 2013.

In accordance with current rules, in order to ensure the safety of gas-using equipment, household consumers must enter into a maintenance agreement with a specialized organization.

In December 2021, the Code of the Russian Federation on Administrative Offenses was supplemented with Article 9.23, which provides for punishment in the form of a fine of up to 30 thousand rubles for individuals for violating the rules for ensuring the safe use and maintenance of indoor and indoor gas equipment.

Fines are provided for:

- avoidance of concluding a mandatory contract for the maintenance and repair of gas equipment in homes;

- refusal to admit a representative of the organization to perform maintenance;

- avoidance of concluding an agreement on the performance of work on diagnosing gas equipment;

- avoidance of replacing gas equipment;

- actions that led to an accident or an immediate threat of harm to human life and health;

- untimely or poor-quality performance of work on maintenance and repair of in-house or in-apartment gas equipment.

I do not advise home craftsmen to carry out work on the gas path of the boiler.

If necessary, a home mechanic can do some simple work that is recommended to be performed when servicing the boiler.

Check serviceability and correct operation:

DHW (hot water) flow sensor. Open line d.36 of the service menu, which displays the readings of this sensor. Open the hot water tap and, filling a vessel of a known capacity with water, note the time of its filling. Check that the flow rate sensor is measuring l/min correctly. Then check that the boiler burner is turned on to heat up the hot water supply at a flow rate of 1.5 l/min.

Ionization electrode for flame control system. Open line d.44 of the service menu, which displays the ionization quality parameter. When burning gas in a burner, ionization is considered good if the quality parameter is less than 300 units, and mediocre if the parameter value is in the range of 300 - 1000 units. If the parameter is more than 1000 units and/or the readings fluctuate greatly, then the operation of the flame control system is unsatisfactory and requires urgent repairs, for example, cleaning the electrode. The ionization electrode is located on the right side of the burner.

Correct connection of the boiler to the electrical network. The Protherm Gepard (Panther) boiler must be connected to the electrical network through a plug socket with a grounding contact, which eliminates a “zero-phase” connection error. The mains power phase must be connected to the phase wire of the boiler. To avoid confusion, identify and color-code the phase contacts on the plug and socket. The boiler must not be connected to a plug socket without a grounding conductor. Failure to comply with these rules may impair the operation of the ionization flame control electrode.

Membrane expansion tank on the rear wall of the gas boiler

Expansion tank (built into the boiler and external, if any). The water pressure in the heating system in the heated state should be 0.5 bar greater than the pressure in the cold state. , no more. The pressure gauge readings on the display are recorded during the period when the circulation pump is not working. If the pressure difference is greater, then it is necessary to check the serviceability or adjust the air pressure in the expansion tank. Check whether the volume of the expansion tank is sufficient for the given volume of water in the heating system.

Read more: “ Setting the pressure in a heating system with a membrane expansion tank ”

Check the dynamic gas pressure at the gas valve inlet. For the measurement method and permissible pressure range, see above, in the settings of the SIT gas valve. The gas pressure in the gas network to which the boiler is connected may change over time for various reasons. For example, as a result of connecting new consumers to the gas network, as well as during severe frosts due to high gas consumption, the pressure in the network may drop unacceptably. For this reason, the boiler stops or its power decreases. If the pressure value is outside the permissible range, then it is necessary to require the gas service to correct the deficiencies.

Check the presence of natural draft in the ventilation duct annually. The room in which the gas boiler is installed must have a separate natural ventilation channel.

Preventive cleaning of the chimney, the air supply channel to the boiler and the room ventilation channel is done every five years.

Gas boiler cleaning

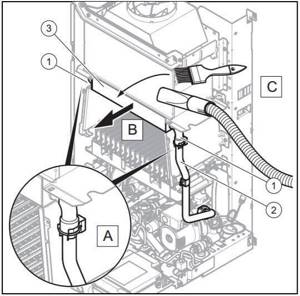

Carry out regular brushing and vacuum cleaning of the surfaces in the combustion chamber - the gas burner and the primary heat exchanger.

To clean the primary heat exchanger, it is better to remove it from the boiler:

- Switch off and empty the boiler.

- Open the front lining of the combustion chamber.

- Fold out the electronics unit and protect it from water.

- Remove the brackets - clamps on the supply and return pipes (1).

- Disconnect the upper supply and return pipes (2).

- Pull the heat exchanger (3) forward.

- Clean the heat exchanger fins from combustion products using a stiff brush and vacuum cleaner.

- Reinstall the heat exchanger.

- Connect the flow and return pipes (2).

- Attach the brackets to the flow and return pipes (1).

- Close the combustion chamber with a lid and replace the electronics unit.

The surface of the gas burner is cleaned of combustion products on site, without removing it from the boiler. For cleaning use a stiff brush and a vacuum cleaner.

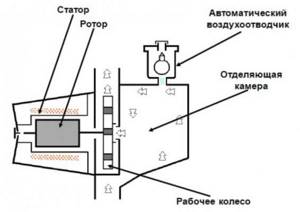

To remove the fan you only need to unscrew one screw

Remove the fan from the boiler every 3-5 years, clean the impeller and other surfaces from dirt, and lubricate the bearings with a few drops of oil. Don't wait until the noise from the fan becomes unbearable. Pay attention to the condition of the gasket between the fan and the chimney.

Circulation pump

The automatic air vent cap should be opened by turning it two turns.

During long periods of inactivity of the boiler, the rotor of the circulation pump sometimes “sours” due to deposits, and the pump cannot start when the boiler is turned on. Before turning on the boiler after a long period of inactivity, loosen and remove the rotor plug screw and use a screwdriver to turn the shaft. The location of the pump rotor on the housing is closed with a yellow plug. If the shaft creates a lot of resistance when turning, it is necessary to dismantle the pump motor and clean it of dirt.

Benefits of remote control

Not all home appliance users are supporters of new technologies. Many are quite satisfied with the usual mechanical control - simple, accessible, without unnecessary bells and whistles.

But before making final conclusions, we suggest considering the advantages of “smart” equipment, which not only makes life easier and more comfortable, but also allows you to significantly reduce costs.

By controlling a gas boiler from a distance, you can save from 20 to 50% of your total home heating costs by simply changing the operating mode or choosing the appropriate program

The main advantage of remote control of a gas boiler is hidden in the method itself: you do not need to be constantly present in the house, “communication” with the equipment occurs at any distance.

Moreover, it is two-way - you send commands to the unit, which it executes and, in turn, notifies you about the current parameters and instantly signals about failures and irregularities in operation.

The programming capabilities of heating equipment are limited, but still quite wide. Today, having a gas boiler with remote control, you can schedule the heating mode while at work, visiting or even on a long trip

Users who have successfully tested the remote control system highlight the following advantages:

- Increasing the service life of the boiler due to the optimal choice of mode, reducing the number of switching off/on, and, in general, more careful use.

- A long-term absence no longer threatens to return to a cold cottage - on the way home you can set the desired temperature.

- If external weather sensors are installed, you won’t even have to interfere with the operation of the boiler during a thaw or frost - the temperature will be adjusted automatically.

- From a distance, you can select a more comfortable “night” mode for sleeping.

- If an emergency occurs or any part fails, you will know about it right away.

Of course, a lot depends on the nuances of installation and the complexity of the heating system.

The advantage is that from a smartphone you can control not only the simplest, but also an extensive network - with radiator or convector heating, or a “warm floor” system.

On the open market you can find equipment for climate zoning, which will allow you to adjust a comfortable temperature in the rooms: in the bedroom or kitchen - lower, in the living room or children's room - higher

Some functions of the system start automatically, that is, you don’t even need to select a mode on your phone - the equipment will switch itself based on sensor signals.

Gas boiler does not heat hot water

The DHW water flow (flow) sensor is a rotating turbine with blades, the rotation speed of which depends on the intensity of water flow. From the operating experience of Protherm Gepard (Panther) gas boilers, it is known that a frequent cause of failure of the DHW heating function in these boilers is the turbine stopping due to foreign particles entering it. Although the turbine is protected from clogging by a mesh filter, it does not always cope with its task.

If, when you open the hot water tap, the boiler burner does not ignite and cold water flows from the tap, then check the serviceability of the DHW flow sensor. It is necessary to call line d.36 of the service menu, which displays the flow sensor readings. If, when the hot water tap is open, the flow readings in line d.36 are equal or close to zero, then we conclude that the flow sensor is not working.

The location of the water flow sensor is indicated by the green arrow in the figure above.

The water flow sensor is removed by pulling the fixing steel bracket to the left. After removing the bracket, you need to pull the sensor towards you and pull it out of the socket. Before removing the sensor, it is necessary to drain the water from the DHW circuit of the boiler, as described above.

To avoid failures in the operation of the flow sensor, it is recommended to supply water to the boiler through an additional tap water filter installed in front of the boiler.

Conclusions and useful video on the topic

On the presented video you will find brief instructions for installing a gas boiler equipped with an automatic Eurosit system.

A modern gas boiler is a rather complex design that provides many useful functions. The automation of most models greatly facilitates their operation, taking over control of the mechanisms and monitoring their operation.

This significantly increases the level of safety during the operation of the heating system, and also increases its efficiency by selecting the optimal mode.

Do you need to adjust the automation of your gas boiler? Do you want to tackle this problem yourself and want to clarify some points? Don’t be shy – ask your questions under this article, and our experts will try to help you.

Gas equipment is found everywhere in apartments and country houses. You independently regulate the equipment, setting a comfortable temperature in the room. This way you are not dependent on utility companies and can save fuel at your own discretion. But for operation to be truly economical, correct settings of the gas boiler are important.

Features of the autoblock device

As a rule, manufacturers use special control units, which include the devices listed above. Despite their external differences, they all act on the basis of the same principles. To get acquainted with the best models and manufacturers of automation, follow this link.

The most widely used products are the Italian brand EuroSIT. The most popular model is Eurosit 630, which is characterized by easy functionality, compatibility with designs from various manufacturers, reliability and durability.

Using Eurosit 630 as an example, we will consider in detail the design of the automatic block.

Detailed design of the automatic control unit Eurosit 630, which is equipped with a significant part of modern gas boilers produced by different manufacturers

The device is a casing containing all structural components (spring valve, pressure regulator module, shut-off valve), which makes its installation much easier.

A pipe is connected to the body through which gas is supplied, as well as cables from sensors and other devices.

In addition to the Eurosit 630 block, there are also other models on the market: SABC, “Vakula” SIT, Dungs, Honneywell, which include sets of valves, pressure stabilizers, filters, temperature regulators

There are some difficulties when installing and setting up this device, but once you get used to it, you can practically not worry about the operation of the gas boiler.

Regulating the temperature in rooms - setting guide

Setting up a gas boiler allows you to set the optimal temperature in the rooms. The only condition is the presence of a thermostat, the task of which is to regulate the burner power. The thermostat is connected to a temperature sensor located in the room. You first need to set the required temperature value that is comfortable for you. After this, you can enjoy the warmth by reading books or watching your favorite movies.

There are some limitations when using thermostats. For example, this device allows you to set the temperature in only one room. To eliminate this drawback, it is necessary to install a thermostatic valve in the supply pipe in front of each heating radiator. Due to the narrowing or expansion of the working substance located inside the valve, the cross-sectional area of the pipe changes. Such valves react to the slightest temperature measurement; even an increase in the number of people in the room can lead to a narrowing of the working fluid.

Failure of thermostats can cause simultaneous shutdown of all heating radiators. This will lead to the cessation of coolant circulation in the heating equipment circuit. It is necessary to pre-install a jumper tube or bypass to avoid such problems.

Operating principle of non-volatile automation

At the same time, individual boiler parts that perform the control function do not require the use of electricity. They are adjusted manually, as well as under the influence of geometric changes that occur in mechanisms under the influence of heat.

Despite the large assortment of models with electronic equipment, options with mechanical control are also very popular, which is explained by several reasons:

- Democratic price. Prices for such devices are significantly lower than for fully automatic analogues.

- Ease of use. The simplicity of the non-volatile automation device used in mechanical models allows even a person who is not related to technology to quickly understand the settings.

- Reliability. Mechanical devices do not depend on power surges or complete power outages, so they can function without a stabilizer, which is desirable when working with volatile equipment.

The disadvantages of such models include lower accuracy of adjustments, as well as the need to monitor the operation of the boiler.

How to manually configure

Each mechanical device is equipped with a temperature scale, the numbers of which indicate the maximum values (from min to max). The operating temperature is set by selecting the required mark on the gradation bar.

After starting the unit, the thermostat is responsible for its operation. The operating element of this device is a rod, which, contracting when cooled, opens the gas supply valve, and then increases in size due to the increase in temperature and shuts off the flow of blue fuel. Using a similar process, you can also reduce or increase the heat level.

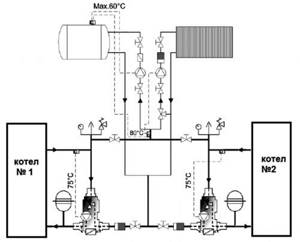

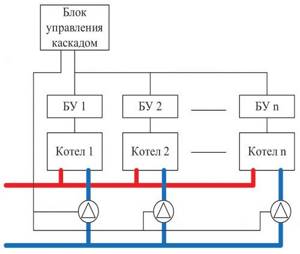

Solid fuel boilers in cascade

D»Ã Ã²Ã¾Ã·Ã¼Ã¾Ã¶Ã½Ã¾ÃÂÃÂø øÃÂÿþûÃÂ÷þòðà ýøàýõÃÂúþûÃÂúøàúþÃÂûþò ò þôà þÃÂþÿøÃÂõûÃÂýþù ÃÂøÃÂÃÂõüõ, à¸, ÃÂõü ÃÂà°Ã¼ÃÂü, þñõÃÂÿõÃÂõýøàÃÂõÿûþü þñ 400 ü2, úðÃÂúðôýþõ ÿþôúûÃÂÃÂà µÃ½Ã ¸Ãµ (ÃÂøÃÂ. 4). âðúøü þñÃÂð÷þü, þñÃÂðàÃÂÃµÃ¿Ã»Ã¾à ²Ã°Ã Ã½Ã°Ã³ÃÂÃÂ÷úð ÿõÃÂõÃÂðÃÂÿÃÂõôõÔ › »Ã¾Ã², ò ÃÂþþÃÂòõÃÂÃÂÃÂòøø àøàüþÃÂý þÃÂÃÂÃÂÃÂ.

àøÃÂ. 4. ²ÃµÃÂôþÃÂþÿûøòýÃÂàúþÃÂûþò

› Note:

The A ¾Ã½ÃÂÃÂ, ò ÃÂÃÂðòýõýøø àÿÃÂøüõýõÃà½Ã¸ÃµÃ¼ úþÃÂûþò ñþà»ÃÂÃÂþù üþÃÂýþÃÂÃÂø;ÿÃÂþòþôøÃÂàþà VALUE ÃÂþøûðúÃÂøúø, ò ÃÂþ öõ òÃÂÃµÃ¼Ã Ã¾à ±ÃµÃÂÿõÃÂà¸Ã²Ã°Ã ÃÂðñþÃÂàþÃÂþÿøÃÂõûÃÂýþù ÃÂø ÃÂÃÂõüàñûðóþôðÃÂàþÃÂÃÂðûÃÂýÃÂü ÿà þôúûÃÂÃÂõýýÃÂü úþÃÂûðü;ààThe ´Ã½Ã¾Ã³Ã¾ óÃÂðÃÂøúð ÃÂðñþÃÂàúþÃÂûþà- »ÃÂöñÃÂ.

ÃÂûàÃÂõðûø÷ðÃÂøø ÿÃÂþõúÃÂð úðÃÂà úðôýþóþ ÿþôúûÃÂÃÂõýøàþÃÂþÿà¸ÃÂõûÃÂýÃÂàúþÃÂûþò ÿÃÂà¸Ã¼ÃµÃ½ÃÂõÃÂÃÂàÃÂõýÃÂÃÂðûÃÂýÃÂù ÿÃÂûÃÂàÃÂÿðòûõýøÃÂ, úþÃÂþÃÂÃÂù þÿÃÂõôõ ûÃÂõàÿþÃÂûõôþòðÃÂõûÃÂýþÃÂÃÂàøû ø þôýþòÃÂõüõýýÃÂàÃÂðñþÃÂàÃÂõÿûþóõýõÃÂðÃÂþÃÂþò (ÃÂà Section 5).

àøÃÂ. 5) ÃÂûþò ò úðÃÂúðôýþü ÃÂõöøüõ (ÃÂã â ñûþúø ÃÂÿÃÂðòà»ÃµÃ½Ã¸Ã Ã¾ÃÂôõûÃÂýÃÂàúþÃÂûþò)

Main page: 13,465