If you live in a private house, then installing an indirect heating boiler together with a boiler will allow you to kill two birds with one stone - heat the house and provide constant access to hot water. We have selected for you the best models of water heaters that can be found on sale today - choose!

Briefly about the main characteristics

In conventional storage water heaters, the temperature of the liquid increases due to the operation of heating elements, while in boilers heating is carried out due to the circulation of the heated coolant in the system.

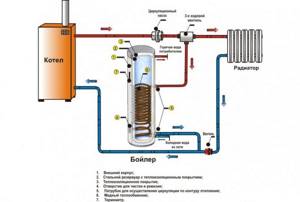

It looks something like this: water is heated in a single- or double-circuit boiler and supplied through pipes to a coil or other heat exchanger installed in the tank; at the same time, cold water enters the tank from the main line, which is subsequently heated due to heat exchange through the walls of the coil. Instead of a coil, a tank-in-tank design can be provided. In this case, the coolant is supplied to the outer tank, and the heated liquid is supplied to the inner tank. The presence of temperature and liquid volume sensors inside the container, as well as automatic relays ensure the smooth operation of the equipment. Some models are also equipped with additional electric heaters - even in case of force majeure with the boiler you can use hot water. Everything seems simple, but before purchasing you need to understand the main technical characteristics of such equipment. Reminder for upcoming purchases

| Selection criterion | Varieties | Note |

| Volume of the tank | from 50 to 400 l and more | The most popular models for domestic use use tanks with a volume of 80 to 200 liters. The volume is selected based on the consumption of hot water and the number of water points. |

| Power | from 2 to 60 kW and above | Together with the volume of the tank, the power determines the rate of heating of the liquid. The more powerful the equipment and the smaller the capacity, the faster the heating occurs. |

| Maximum water pressure | 6-10 bar (0.6-1 MPa) | The pressure that the boiler can withstand in operating mode. It is advisable to install pressure reducers to prevent damage from water hammer. |

| Mounting method | Wall | Equipment with a small tank volume (up to 100 liters) is often mounted on the wall. The larger the volume, the more difficult it is to do this, so capacious water heaters are manufactured in a floor-standing design. |

| Floor | ||

| Combined | ||

| Heat exchanger design | Coil | The coolant from the boiler is supplied through a metal coil installed in a tank with heated water. The most common type. |

| Coil within a coil | The heat exchange area is increased due to the use of two coils with different spiral diameters. | |

| Tank in tank | There are two steel tanks - one inside the other. The larger tank is supplied with coolant from the boiler, and the smaller tank is supplied with heated water. | |

| Heat exchanger material | Stainless steel, brass | The vast majority are made of stainless steel. However, this material may vary in quality. Therefore, you should not save money and buy products from an unknown brand. |

| Material and thickness of the thermal insulation layer | Foam rubber, mineral wool, polystyrene foam, polyurethane foam - thickness from 20 to 60 mm | The effectiveness of thermal insulation is determined by the value of thermal conductivity (the less, the better) and the thickness of the insulation layer (the more, the better). Today, a good solution is to use 50-60 mm of polyurethane foam insulation. |

| Maximum productivity in flow mode when heating at ΔT °C, l/min | where ΔT °C = 25, 45, 55, etc. | Determines the efficiency of the heater in flow mode. Depends on its power. |

| Heating time at ΔT °C, min. | where ΔT °C = 25, 45, 55, 60, etc. | Determines the heating rate of the entire volume of water in the tank. Depends on volume and power. |

| Options | heating element | Many models can be upgraded with tubular electric heaters, which are activated when the boiler is turned off. |

| Recycling | The tank may be provided with a circuit connection for water circulation using a pump. This is necessary to ensure that water is supplied to the consumer at a constant temperature. | |

| Solar collectors | Using solar energy to heat the coolant and then transfer the heat to heat the water. Collectors are installed on the roof. In the CIS, this option is relevant only in the warm season. | |

| Heat pump | Possibility of connecting a heat pump to minimize the cost of heating cold water. A very rare option. |

We omitted such a parameter as the diameter of the thread for connecting to pipes, because... If necessary, this issue can be resolved by installing adapters.

Calculation of water volume

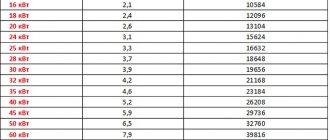

Only you can determine the exact required volume, because... calculations are tied to water consumption conditions. Our task is to provide information that will somehow help in making a choice or give you ideas when making a calculation. For example, we open SNiP 2.04.01-85 and see that the standards set 7.9-10.9 liters of hot water (HW) per hour per person. Following some simple calculations, we get the following table.

| Number of people, persons | Required volume of hot water, l. | Approximate volume of warm water, l. |

| 1 | 7,9-10,9 | 20 |

| 2 | 15,8-21,8 | 40 |

| 3 | 23,7-32,7 | 60 |

| 4 | 31,6-43,6 | 80 |

| 5 | 39,5-54,5 | 100 |

These calculations can only be taken into account under the condition of sequential use of water heated by the boiler and the simultaneous operation of one water supply point (only one tap is open). In practice, the given values need to be multiplied by 3-5. Why is this happening? Because the standards do not take into account the desire to warm up in the shower (+20 liters of hot water) and run a bath (+80 liters of hot water), wash a mountain of dishes (+20 liters of hot water), etc. and so on. Consider peak loads on the boiler - choose the volume that is most suitable for your needs.

We recommend using the following values:

- 50-60 liters is enough for 1 person;

- for 2-3 people you need to choose from models with 80-120 liters;

- for a family of 3-5 people, a boiler capacity of 120-200 liters is enough

To make it more convenient for you to choose the appropriate equipment model, we have identified four product groups depending on the volume of the storage tank: up to 100, 200, 300 and 400 liters. All technical specifications are taken from open sources, and prices are provided for comparison purposes only.

Important! Please note that some water heaters are only suitable for certain boiler models. In the description we will focus on this, but we recommend that you clarify all the nuances before purchasing.

Summary of schemes

Such water heater connection systems eliminate the simultaneous operation of heating the liquid and heating the house. This inconvenience will only occur once when the system starts. Since the coolant will be cold, the entire process will take about an hour, depending on the amount of coolant. With constant operation, much less time will be spent maintaining the temperature, so temperature changes will not be felt.

These circuits can also be used in more complex heating systems. Heating boilers are divided for them: one will work only for heating water, the other for heating.

Up to 100 liters

Baxi Combi 80 (80 l.) – from 52,500 rub.

A well-known Italian player specializing in heating and water heating equipment, Baxi has been maintaining a quality brand for decades.

The Baxi Combi 80 small-volume boiler model is designed to work in conjunction with boilers of the LUNA-3 Comfort series from the same manufacturer. The placement is on the floor, the water heater can be installed directly under the boiler, saving space. One of the advantages of this system is its compact size. Corrosion protection is provided by the use of stainless steel and magnesium anode. Polyurethane foam is used as thermal insulation. Connection of a heating element is not provided. Main characteristics

| Characteristics | Meaning |

| Volume, l | 80 |

| power, kWt | 31 |

| Maximum productivity in flow mode at ΔT=35°С, l/min | 12,6 |

| Accommodation | floor |

| A heating element | coil (1 piece) |

| Maximum water pressure, MPa | 0,8 |

| Possibility of connecting heating elements | — |

| Dimensions, mm | 450×550×915 |

| Weight, kg | 45 |

Gorenje GBK80ORRNB6 (72.6 l.) – from 24,000 rub.

When looking for a small model that can provide hot water for one or two people, pay attention to the Slovenian equipment Gorenje GBK80ORRNB6.

This is a classic compact boiler with two tubular heat exchangers, the performance of which is sufficient for two water points at once. The device is equipped with an electronic control unit and allows you to change the DHW temperature in the range of 15-75 °C. It has outlets for connecting to the boiler on the right side; two dry heating elements are installed as an additional heater. The model is equipped with several types of protection: against corrosion (magnesium anode), against freezing (effective thermal insulation), against overheating and heating without water. The manufacturer also provides a control function for legionellosis (a pulmonary disease whose pathogens actively multiply in hot water). One of the best combined solutions in terms of price/quality ratio. Main characteristics

| Characteristics | Meaning |

| Volume, l | 72,6 |

| power, kWt | 2 (heater) |

| Accommodation | wall-mounted |

| A heating element | coil (2 pcs.) |

| Maximum water pressure, MPa | 0,6 |

| Possibility of connecting heating elements | + |

| Dimensions, mm | 803×500×507 |

| Weight, kg | 51 |

* operating parameters in flow mode are not specified by the manufacturer. The power of the heat exchanger itself is not indicated - only for heating elements.

Protherm FS B100S (95 l.) – from 36,200 rub.

The Czech boiler Protherm FS B100S is structurally linked to boilers from the same manufacturer - Medved.

Compact, with a laconic but informative control panel, it easily fits into the kitchen interior as a built-in appliance. Enameled stainless steel, magnesium anode and antibacterial coating are all designed to protect against corrosion and microorganisms. The tubular heat exchanger provides a high heating rate of the entire volume of liquid: the water heats up by 50 degrees in 13 minutes. To keep warm, the product is protected by a polyurethane foam coat. Main characteristics

| Characteristics | Meaning |

| Volume, l | 95 |

| power, kWt | 26,1 |

| Maximum productivity in flow mode at ΔT=25°С, l/min | 18,3 |

| Accommodation | floor |

| A heating element | coil (1 piece) |

| Maximum water pressure, MPa | 0,6 |

| Possibility of connecting heating elements | — |

| Dimensions, mm | 880×550×520 |

| Weight, kg | 46 |

ACV COMFORT 100 (100 l.) – from 48,000 rub.

A Belgian manufacturer with almost a century-old history offers an interesting solution based on a “tank-in-tank” heat exchanger - model ACV COMFORT 100. The boiler consists of two stainless steel containers of different volumes, one of which is inserted into the other.

Particular attention should be paid to the inner container: its surface is corrugated, therefore, due to thermal expansion, a change in size takes place with the subsequent removal of the resulting deposit of hardness salts (scale). The equipment is installed on the floor by default, but with the help of additional fasteners it can be mounted on the wall. The thermal insulation layer is made of polyurethane foam 30 mm thick. The range of standard functions is small, but an optional control panel can be installed. It is also worth considering the lack of recirculation and connection of the heating element. Main characteristics

| Characteristics | Meaning |

| Volume, l | 100 |

| power, kWt | 23 |

| Maximum productivity in flow mode at ΔT=45°С, l/min | 8,45 |

| Accommodation | floor/wall (optional) |

| A heating element | tank in tank (1 piece) |

| Maximum water pressure, MPa | 0,86 |

| Possibility of connecting heating elements | — |

| Dimensions, mm | 525×845 |

| Weight, kg | 37 |

We recommend watching a visual video about the design and operating principle of this water heater.

Up to 200 liters

Baxi Premier plus 150 (150 l.) – from 50,600 rub.

You can ensure full operation of two hot water collection points using the Baxi Premier plus 150. The series of these heaters uses a “coil-in-coil” tubular heat exchanger.

Due to its low weight, the device can be hung on the wall or placed on the floor. Parts of the structure in contact with water are made of DUPLEX stainless steel, minimizing heat losses is achieved by using polyurethane foam. The model is equipped with a thermostat and can be used in conjunction with any type of boiler. Optionally, it is possible to connect a tubular electric heater. The manufacturer has provided for the connection of a recirculation circuit. According to reviews, this is one of the best solutions in terms of price and quality ratio for a family of four. Main characteristics

| Characteristics | Meaning |

| Volume, l | 150 |

| power, kWt | 30 |

| Maximum productivity in flow mode at ΔT=35°С, l/min | 12,25 |

| Accommodation | floor/wall |

| A heating element | coil in coil (1 piece) |

| Maximum water pressure, MPa | 0,7 |

| Possibility of connecting heating elements | + |

| Dimensions, mm | 522×1090 |

| Weight, kg | 31 |

BOSCH WSTB 160 (160 l.) – from 28,000 rub.

If a gas boiler is installed in your house, then you should think about purchasing a BOSCH WSTB 160 water heater. Although there is no possibility of connecting a heating element, there is a recirculation system.

The model is adapted to the harsh conditions of use in the CIS, i.e. Suitable for hard water. To protect the steel from corrosion, the material is coated with a special glass-ceramic composition. There is a recirculation line, so you can always count on receiving water at a constant temperature. To minimize heat losses, a fur coat made of 50 mm polyurethane foam is provided, the lining is made of PVC, soft. The connection is frontal, it is possible to connect a temperature sensor. The entire volume is heated to ΔT=45°C in 37 minutes. Main characteristics

| Characteristics | Meaning |

| Volume, l | 160 |

| power, kWt | 20,8 |

| Accommodation | wall-mounted |

| A heating element | coil (1 piece) |

| Maximum water pressure, MPa | 1 |

| Possibility of connecting heating elements | — |

| Dimensions, mm | 550×1193 |

| Weight, kg | 42 |

Protherm FE 200 BM (184 l.) – from 41,650 rub.

Many manufacturers offer storage heaters that are suitable only for their boiler models.

If you have installed a Protherm boiler, then to satisfy the needs of a large family for hot water supply, you should consider installing Protherm FE 200 BM. This is an indirectly heated floor-standing boiler made of stainless steel, coated with enamel to protect against corrosion. The installed titanium anode serves the same purpose. To avoid the growth of bacteria on the walls of the container, they are coated with a layer of antibacterial substance. The productivity is high - with a delta of 25 degrees you can get more than 30 liters of water per minute. Without the possibility of connecting the recirculation line and heating element. Main characteristics

| Characteristics | Meaning |

| Volume, l | 184 |

| power, kWt | 43,2 |

| Maximum productivity in flow mode at ΔT=25°С, l/min | 32,6 |

| Accommodation | floor |

| A heating element | coil (1 piece) |

| Maximum water pressure, MPa | 0,6 |

| Possibility of connecting heating elements | — |

| Dimensions, mm | 590×1206 |

| Weight, kg | 97 |

Gorenje GV 200 (188.9 l.) – from 25,800 rubles.

Floor-mounted indirect water heater Combustion GV 200 – simplicity of design, reliability of design and laconic design.

The product is an enameled steel tank with a tubular heat exchanger inside. Installed on the floor under the boiler. An overpressure relief valve is used as protection against overheating. The device is protected from corrosion by enamel and a magnesium anode. It takes up to 24 minutes to heat the entire volume of water in the tank from 15 to 75 degrees. A 40 mm thick layer of thermal insulation is responsible for maintaining the temperature of the hot water supply. Main characteristics

| Characteristics | Meaning |

| Volume, l | 188,9 |

| power, kWt | 17,6 |

| Accommodation | floor, under the boiler |

| A heating element | coil (1 piece) |

| Maximum water pressure, MPa | 0,6 |

| Possibility of connecting heating elements | — |

| Dimensions, mm | 500×1510 |

| Weight, kg | 88 |

* the possibility of working in flow mode has not been announced by the manufacturer

Connecting a storage boiler to a gas boiler

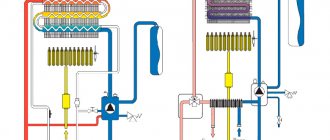

You can heat water in the unit in question using a gas or solid fuel boiler, solar water heater or heat pump. Moreover, its operation is possible in conjunction with two types of heating equipment: single- and double-circuit.

According to the standard wiring diagram for an indirect heating boiler, it is connected to the heating system, as well as to the hot and cold water supply branches. In this case, cold water comes from below, hot water is removed from the container located on top of the tank, but the recirculation point is located in the middle of the boiler. The direction of movement of the heated coolant is the opposite - from top to bottom. That is, from the gas boiler it enters the water heater pipe located at the top, and returns to the heating pipeline through the lower pipe of the unit.

The principle of operation and connection of an indirect heating boiler to the boiler

Thanks to this connection scheme for an indirect heating boiler, the efficiency of this device increases. After all, heat is first transferred to the heated layers of water.

Features of connecting an indirect heating boiler to a double-circuit boiler

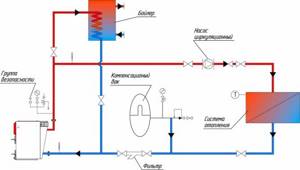

In order for the boiler to work successfully in tandem with a heating unit that has a hot water supply circuit, a three-way valve is used. It distributes the coolant flow between the additional water supply circuit and the main heating circuit.

A thermostat is installed in the indirect heating storage boiler. It is he who generates control signals for the three-way valve. When the temperature of the water in the tank drops below a certain level, the valve, upon command from the thermostat, will turn on and redirect the flow to the hot water supply branch from the heating pipeline. Signals from the thermostat will return the valve to its original state if the water temperature in the heater exceeds a preset point. The coolant flow is directed into the heating pipeline.

When connecting an indirect heating boiler, you must make sure that all communications are possible and also purchase the necessary pressure sensors

During the warm season, the unit works differently: the flow is not redirected, but the combustion modes of the gas boiler are controlled. When the temperature of the water in the boiler decreases, the thermostat transmits a corresponding signal to the three-way valve. Based on this “command,” the last device “ignites” the main burner of the heating unit. When the water temperature exceeds a certain value, the gas supply to the burner is stopped.

Important! When setting the maximum water temperature in the tank (also known as the temperature for automatic operation of the thermostat), the user should take into account that its value should be less than the value of this parameter set for the boiler automation.

The above scheme works most effectively when using gas boilers equipped with automation and a circulation pump. In this case, the heating unit itself can control the valve based on the signal received from the water heater thermostat. You should be aware that when operating a water heating system with a three-way valve, the priority of the heater circuit is higher than the heating circuit.

Connection diagram for an indirect heating boiler to a single-circuit boiler

To ensure effective joint operation of an indirect heating boiler with a single-circuit gas boiler, a circuit with two circulation pumps is used. A connection of this type can actually replace the above-described three-way valve circuit. Separation of coolant flows using pumps through different pipelines is the key feature of this type of connection. The distribution of circuit priorities is the same as in the previous case. However, higher priority of the water supply circuit over the heating circuit is ensured only through special settings of the pump activation algorithm.

Connection diagram for an indirect heating boiler to a single-circuit boiler

The alternating activation of the pumps is also controlled by signals from a thermostat installed in the tank. A check valve must be installed in front of each device. Creating such a piping for an indirect heating boiler prevents mixing of coolant flows.

This scheme works like this: turning on the DHW pump is accompanied by turning off the heating pump. That is, the heating system will begin to cool down. However, a noticeable decrease in the indoor temperature will not be observed for the reason that heating the water in an indirect heating boiler with a gas boiler will last a short period of time. The inhabitants of the house will feel this only during the initial start-up.

Sometimes, to create a large area of a building at a comfortable temperature, owners use several heating units. Then an additional pump is installed in the storage water heater piping.

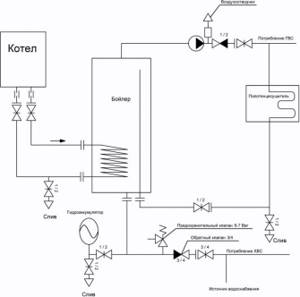

Features of piping an indirect heating boiler with recirculation

If hot water is not drawn for a long period of time, it will begin to cool. It may take several minutes for the hot flow to reach the end consumer. Reducing the time for draining cooled water is ensured by using a piping scheme for an indirect heating boiler with recirculation. This is realized by organizing the forced movement of a heated flow through pipelines closed in a ring.

Connection diagram for a boiler with a recirculation system

Helpful advice! When choosing a piping scheme for heating and hot water circuits (with or without the possibility of recirculation), it is necessary to take into account the features of the heating system, as well as make accurate calculations of the equipment power and the level of demand for hot water.

The recirculation technical solution ensures almost instantaneous delivery of hot water to any connected plumbing fixture. It provides that another circuit, equipped with its own circulation pump, is installed in the indirect heating boiler piping, and additional structural components are installed:

- safety valve (designed to protect the water heating device from high pressure);

- automatic air vent (prevents the pump from airing);

- expansion tank (performs the function of compensating pressure in the DHW circuit when the taps are closed);

- check valve (prevents reverse water flow in the pipeline).

Related article:

Water boilers: review of the best offers on the modern market

Review of the best models and manufacturers. Types and rules for choosing a suitable water heater. Draining water from the boiler.

Up to 300 liters

ACV COMFORT 240 (240 l.) – from 65,000 rub.

Another representative of indirect water heaters, which use a “tank-in-tank” heat exchanger.

The ACV COMFORT 240 model is capable of providing hot water to up to three water points. The product is protected from corrosion due to the use of stainless steel and a special approach to the formation of the walls of the internal tank. Here it is corrugated, which has a positive effect on its work even with very hard water. At the same time, the equipment is characterized by the same features as products of the same series: a minimum of functions, a 30 mm thermal insulation layer, the inability to connect a tubular electric heater and a recirculation circuit. Main characteristics

| Characteristics | Meaning |

| Volume, l | 240 |

| power, kWt | 53 |

| Maximum productivity in flow mode at ΔT=45°С, l/min | 21,8 |

| Accommodation | floor/wall (optional) |

| A heating element | tank in tank (1 piece) |

| Maximum water pressure, MPa | 0,86 |

| Possibility of connecting heating elements | — |

| Dimensions, mm | 525×1720 |

| Weight, kg | 65 |

Protherm FS B300S (295 l.) – from 63,000 rub.

This hydraulic accumulator is designed for use with Proterm Grizzly or Bison boilers.

Protherm FS B300S is a capacious tank with a tubular heat exchanger. The tank has two flanges: for installing a heating element and for servicing the boiler. Enameled surfaces that come into contact with water, as well as the presence of a titanium anode, protect the equipment from corrosion. It should be noted that there is an antibacterial coating. A layer of polyurethane insulation is responsible for reducing heat loss. The device is characterized by high productivity in flow mode; it is possible to connect a recirculation line. The capabilities of this heater will be appreciated by owners of large private houses with more than three bathrooms. Main characteristics

| Characteristics | Meaning |

| Volume, l | 295 |

| power, kWt | 46 |

| Maximum productivity in flow mode at ΔT=25°С, l/min | 46,2 |

| Accommodation | floor |

| A heating element | coil (1 piece) |

| Maximum water pressure, MPa | 1 |

| Possibility of connecting heating elements | + |

| Dimensions, mm | 500×1775 |

| Weight, kg | 125 |

Baxi Premier plus 300 (300 l.) – from 70,000 rub.

Often the main criterion for choosing a boiler is not only its volume, but also the heating rate.

In this case, it is important to consider models with a “coil-in-coil” heat exchanger. Baxi Premier plus 300 is what you need! Firstly, it is compatible with any boilers. Secondly, high-quality stainless steel is used for its production, which is perfectly protected from corrosion. Thirdly, with a fairly compact size and low weight, the equipment has universal placement and is equipped with an accurate thermostat. The model allows you to supplement the system with a recirculation circuit. Connecting a 2.7 kW heating element is optional. Main characteristics

| Characteristics | Meaning |

| Volume, l | 300 |

| power, kWt | 30 |

| Maximum productivity in flow mode at ΔT=35°С, l/min | 12,25 |

| Accommodation | floor/wall |

| A heating element | coil in coil |

| Maximum water pressure, MPa | 0,7 |

| Possibility of connecting heating elements | + |

| Dimensions, mm | 552×2040 |

| Weight, kg | 60 |

How to make a stratified heating boiler from an electric boiler

Continued: go to page 2:

Read page: Page 1, Page 2

More articles on this topic

- Clinker cladding of the facade of a house with bricks

- Films and membranes for water vapor barrier and wind protection at home

- Installation of internal sewerage in a private house

- Gas detector - detector of domestic and carbon monoxide leaks in the house

- Calculation of a reinforced concrete beam for a prefabricated monolithic floor

- How to remove the smell of hydrogen sulfide from water in a well, boiler, well

- Setting up gas boiler power adjustment

- Renovation and redevelopment will change your life for the better!

Up to 400 liters

Drazice OKC 400 NTRR/1 MPa (380 l.) – from 68,000 rub.

The Czech boiler Drazice OKC 400 NTRR/1 MPa is equipped with two tubular heat exchangers, one of which is designed to be connected to the solar collector, and the second to the boiler.

This allows you to save a lot on heating water on sunny days, especially in summer. If necessary, for example, a malfunction of the boiler equipment, two auxiliary electric heating elements can be installed. The enameled tank, as well as the presence of a magnesium anode, provide long-term protection of the tank from corrosion. 50 mm of solid polyurethane foam is used as a heat-insulating layer. There is a recirculation pipe. Main characteristics

| Characteristics | Meaning |

| Volume, l | 380 |

| power, kWt | 57 |

| Accommodation | floor |

| A heating element | coil (2 pcs.) |

| Maximum water pressure, MPa | 1 |

| Possibility of connecting heating elements | + |

| Dimensions, mm | 700×1631 |

| Weight, kg | 138 |

The manufacturer does not provide information on the rate of water heating in flow mode. This is explained by the presence of two independent heat exchangers with different operating temperatures.

Bosch SK 400-3 ZB (388 l.) – from 59,500 rub.

Bosch's assortment does not include many indirect water heaters of the capacity we are interested in, but among them there is a special model - Bosch SK 400-3 ZB.

This is an enameled tank with a stainless steel coil. Corrosion protection is provided by a magnesium anode, which has already become a natural phenomenon in such equipment. The device is quite simple: a built-in thermometer and a flange for easy maintenance. In this case, it is possible to connect a hot water recirculation line, as well as synchronize with the boiler if the latter has a connector for an NTC sensor (temperature sensor). Those. You can fine-tune the operation of water heating equipment. Separately, it is necessary to say about thermal insulation. Here it is not polyurethane foam, but made of rigid foam, which, with equal thickness, gives a lower heat-shielding effect. Main characteristics

| Characteristics | Meaning |

| Volume, l | 388 |

| power, kWt | 60 |

| Maximum productivity in flow mode at ΔT=25°С, l/min | 24,2 |

| Accommodation | floor |

| A heating element | coil (1 piece) |

| Maximum water pressure, MPa | 1 |

| Possibility of connecting heating elements | — |

| Dimensions, mm | 710×1681 |

| Weight, kg | 150 |

BAXI UBVT 400 SC (395 l.) – from 58,100 rub.

If the majority of boilers are designed to work in tandem with a boiler, then the BAXI UBVT 400 SC model is an exception to the rule.

It is adapted for connection to a solar collector, so its purchase will be advisable in two cases: in places with year-round sunny weather or for seasonal use. Additionally, it is possible to install electric heaters for heating. The container itself is made of steel coated with titanium enamel - the result is a corrosion-resistant and durable coating. The latter is also facilitated by the presence of a magnesium anode. The kit includes a thermometer for temperature control, and there are sockets for connecting sensors. The design provides a flange for monitoring the condition of the coil, as well as a built-in pipe for recirculation. Main characteristics

| Characteristics | Meaning |

| Volume, l | 395 |

| power, kWt | 54 |

| Maximum productivity in flow mode at ΔT=35°С, l/min | 22,9 |

| Accommodation | floor |

| A heating element | coil (1 piece) |

| Maximum water pressure, MPa | 1 |

| Possibility of connecting heating elements | + |

| Dimensions, mm | 710×1671.5 |

| Weight, kg | 135 |

Hajdu STA 400 C (400 l.) – from 64,100 rub.

The Hajdu STA 400 C model from the well-known Hungarian manufacturer is interesting in that, with one heat exchanger, fine-tuning of the equipment is possible.

So, in the cold season, such an indirect heating boiler can be configured to work in tandem with a boiler, and in the summer it can be connected to a solar collector. In the latter case, if necessary, an additional heating element is connected. The tank and heat exchanger are protected from corrosion by a layer of hot enamel and an installed magnesium anode. To minimize heat loss, the outside of the container is covered with a layer of polyurethane foam, protected by a plastic casing. A pipe is provided for connecting the DHW recirculation system. Main characteristics

| Characteristics | Meaning |

| Volume, l | 400 |

| power, kWt | 69 |

| Maximum productivity in flow mode at ΔT=35°С, l/min | 28,3 |

| Accommodation | floor |

| A heating element | coil (1 piece) |

| Maximum water pressure, MPa | 1 |

| Possibility of connecting heating elements | + (2 pcs.) |

| Dimensions, mm | 670×1832 |

| Weight, kg | 145 |

The following video shows this boiler in cross-section.

Heat exchangers

Installation of suspended ceilings without heating

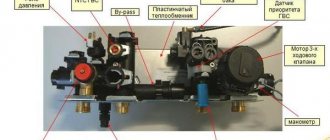

A double-circuit gas boiler has two heat exchangers (Fig. 4):

- Primary;

- Secondary.

The operating principle of this design is that the first heat exchanger is heated in the combustion chamber, and the secondary heat exchanger in an additional chamber. Heating of the coolant in the additional chamber occurs due to the influence of flue gases that exit into the chimney system. The secondary chamber is located above the primary one.

Rice. 4 Primary and secondary heat exchangers

The heat exchanger in a gas floor heating appliance can be:

- Steel;

- Cast iron.

The secondary (upper) heat exchanger can be made of copper or aluminum. As a rule, both heat exchangers are made from the same material. But there are also models in which the primary heat exchanger is made of more durable materials (steel or cast iron), and the secondary heat exchanger is made of copper, aluminum or stainless steel. This can be explained by the fact that the lower heatsink is exposed to high temperatures, while the upper heatsink is affected by temperatures much lower.

The double-circuit cast iron floor-standing gas boiler is distinguished by its high strength, which means it lasts a long time

But it should be said that a cast-iron heating device must be transported with great care, as there is a risk of damaging the integrity of the cast-iron part or body. This is explained by the fact that a cast iron boiler is resistant to high temperatures, but on the contrary is sensitive to mechanical damage

And as a result of careless transportation, chips and cracks may form on a cast iron device.

Cast iron heat exchangers can last up to 50 years, while steel heat exchangers are predicted to last much less, up to 20 years. The service life depends on the conditions in which the unit operates. If problems are identified with the heat exchanger, the steel part can be repaired, which cannot be said about the cast iron part. A cast iron heat exchanger cannot be repaired; it will have to be completely replaced.

Rice. 5 Cast iron heat exchanger from an industrial unit

The steel heat exchanger also has its positive qualities, for example, resistance to corrosion processes, and also has high heat transfer. In this regard, a cast iron heat exchanger is inferior to a steel one.

Editor's Choice

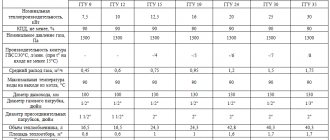

For ease of comparison, let’s enter the main characteristics into the table and decide on the most successful models.

To make it clearer, we choose a boiler for 1-2 people, 2-4 people, 4-6 people. (marked in the table below in bold from top to bottom, respectively). Because Not all manufacturers adhere to uniform standards when preparing technical documentation; for example, not all indicate the value of productivity in flow mode, then we introduce the characteristic N. It shows the ratio of a unit of power per 1 liter. water. Those. we simply took and divided the capacities indicated by the manufacturer by the usable volume of storage devices. The larger this value, the faster the heating occurs. Rating of indirect heating boilers

| Model name | Useful volume, l | power, kWt | N, kW/l | Accommodation | Heat exchanger | heating element | Rec-tion | price, rub. |

| Baxi Combi 80 | 80 | 31 | 0,3875 | floor | coil | — | — | 52500 |

| Gorenje GBK80ORRNB6 | 72,6 | 2 | 0,027548 | wall-mounted | coil | + | — | 24000 |

| Protherm FS B100S | 95 | 26,1 | 0,274737 | floor | coil | — | — | 36200 |

| ACV COMFORT 100 | 100 | 23 | 0,23 | floor/wall | tank in tank | — | — | 48000 |

| Baxi Premier plus 150 | 150 | 30 | 0,2 | floor/wall | coil in coil | + | + | 50600 |

| BOSCH WSTB 160 | 160 | 20,8 | 0,13 | wall-mounted | coil | — | + | 28000 |

| Protherm FE 200 BM | 184 | 43,2 | 0,234783 | floor | coil | — | — | 41650 |

| Gorenje GV 200 | 188,9 | 17,6 | 0,093171 | floor | coil | — | — | 25800 |

| ACV COMFORT 240 | 240 | 53 | 0,220833 | floor/wall | tank in tank | — | — | 65000 |

| Gorenje KGV 300-2/BG | 280 | 69,6 | 0,248571 | floor | coil | + | + | 83700 |

| Protherm FS B300S | 295 | 46 | 0,155932 | floor | coil | + | + | 63000 |

| Baxi Premier plus 300 | 300 | 30 | 0,1 | floor/wall | coil in coil | + | + | 70000 |

| Drazice OKC 400 NTRR/1 MPa | 380 | 57 | 0,15 | floor | coil | + | + | 68000 |

| Bosch SK 400-3 ZB | 388 | 60 | 0,154639 | floor | coil | — | + | 59500 |

| BAXI UBVT 400 SC | 395 | 54 | 0,136709 | floor | coil | + | + | 58100 |

| Hajdu STA 400 C | 400 | 69 | 0,1725 | floor | coil | + | + | 64100 |