Home / Gas boilers

Back

Published: 05/04/2020

Reading time: 5 min

0

863

The modern market for climate control equipment provides a large selection of options for organizing autonomous heat supply using simple and inexpensive devices.

A single-circuit gas boiler is a stationary heating device that has one heat exchanger. It is a basic element of the heat supply system, which is directly responsible for the generation of heat energy and effectively heats the coolant in the intra-house heating system.

- 1 Design of single-circuit gas boilers 1.1 Operating principle

Installation of single-circuit gas boilers

The fundamental design of gas units is the same and quite conservative, since their main elements remain unchanged for several decades:

- A furnace or combustion chamber in which, during combustion, the chemical transformation of gas into thermal energy occurs.

- The burner device, usually rectangular in shape, performs the function of creating a gas-air mixture and igniting it, and also contributes to the uniform distribution of the flame throughout the combustion chamber.

- Heat exchanger - serves to carry out the process of heat transfer from combustion products to the coolant.

- The smoke exhaust system is responsible for removing gas combustion products into the atmosphere.

Despite the fact that structurally single-circuit gas heating boilers are designed for heating, the latest modifications provide special pipes for connecting an external indirect hot water boiler.

Principle of operation

The operation of a single-circuit boiler occurs when gas is supplied to the burner device, where the igniter automatically ignites the gas-air mixture.

During the combustion of gas, hot smoke combustion products are formed, which wash the heating surfaces of the heating heat exchanger. Heat due to convection and heat transfer is transferred to the coolant, which enters the boiler from the return cold heating circuit.

The heated network water enters the supply pipeline and is supplied by a circulation pump or through natural circulation to heating devices installed in the room.

Thanks to convection, the heat from the hot water in the radiators is transferred to the internal air. The cooled coolant is returned through the return line to the boiler for the next heating cycle.

The igniter operates continuously and heats the thermocouple of the boiler safety and regulation system, which controls the operation of the gas valve. Cold flue gases, after they have reached their maximum temperature in the boiler heat exchanger, enter through the gas outlet channels into the chimney and are then released into the atmosphere.

The movement of flue gases occurs naturally: in open type fireboxes - due to the temperature difference between hot and cold flows, or forcedly in closed fireboxes, thanks to the creation of an aerodynamic pressure in the combustion chamber by an air fan.

Requirements for the location of such a boiler

The boiler room must meet all fire safety standards and have good ventilation. Also, the chimney must be straight - vertical, without deviation to the sides. You should not build an extension from flammable materials, but if this is still necessary for the aesthetics of the building, then take care of covering the walls. Special materials can increase the flammability threshold of even ordinary wood.

There should also be enough space in the extension for free maintenance of the boiler. And in a zone 1 by 2 by 1 meter from it there should not be any flammable objects. The specialist you hire for installation must tell you more about safety precautions.

The gas boiler needs to be cleaned from time to time. How this is done is described in this article.

The difference between single-circuit and double-circuit boilers

Both of these variations of boilers operating on gas fuel are practically indistinguishable in appearance; they are equally easy to control thermal processes, efficient and durable. Their design differs in their internal structure, which is determined by the types of services produced.

Single-circuit units operate only for heating, so they have one water heater. Double-circuit gas devices generate thermal energy for heating and water heating.

The designs of heaters can be different from two separate devices to paired in one housing, called bithermic. Naturally, single-circuit boilers, when DHW preparation is not required, benefit both in price and in ease of installation, operation and repair.

And if previously they were inferior to double-circuit boilers in terms of functionality, since they could not heat hot water, then modern single-circuit gas boilers do not have this drawback. They have the ability to connect an independent heating circuit in the form of an external boiler.

This scheme is energy efficient, since it reloads the boiler during transitional climatic periods “autumn-spring”, allowing it to operate with high efficiency.

When choosing a boiler for heating a private home, the user buys based on the maximum negative outdoor air temperatures, which actually occur no more than 20% of the entire heating season.

The rest of the time the boiler is not loaded, which sharply reduces its efficiency and increases the cost of thermal energy. Recharging the boiler eliminates these problems.

Wall and floor models

The boiler is a heating system device with one heat exchanger, which is designed to heat the coolant. It is immediately worth noting that single-circuit boilers are not used for hot water supply.

If we highlight the main advantages of these devices, we get the following:

- affordability in comparison with other boilers, for example, double-circuit boilers;

- a wide range of brands, manufacturers and functionality, which allows you to choose the most suitable one for yourself;

- presence of automatic adjustment;

- economical gas consumption;

- the ability to connect several boilers into a single heating system (cascade);

- reliability of the design.

Returning to the question of choosing a single-circuit boiler for a private home, we can separately mention that there are several types of such equipment:

- Wall-mounted boiler . One of the most popular and functional boilers, mainly for small, private buildings. The optimal area is up to three hundred square meters. It has a relatively light weight (about 50 kg) and takes up very little space. If you compare it with the floor-standing version, its power and performance will be less. Maximum power - 35 kW.

- Floor standing boilers . Such heating means already have more impressive characteristics. A floor-standing boiler can be safely purchased for rooms over 300 square meters in area. Power up to 120 kW.

It is always worth choosing from these two options, based on your preferences and the characteristics of the room. Sometimes, even for large houses, it is more advisable to connect two wall-mounted boilers, and sometimes - one floor-standing boiler.

Types of single-circuit boilers

The climate control market is oversaturated with various modifications of single-circuit boilers; in order to understand them, they are grouped by indicators:

- By type of installation: wall-mounted and floor-mounted boilers.

- According to the power supply option: volatile and non-volatile.

- According to the heat transfer method used: convection - traditional units, condensing units, operating with low flue gas temperatures, parapets on the body of which are equipped with special openings for the circulation of hot air in the room.

- By type of combustion chamber: atmospheric or open and turbocharged with a closed combustion chamber.

- According to the material of the heating heat exchanger: cast iron, copper or steel.

Wall-mounted units are mainly equipped with heat exchangers made of thin-sheet and lightweight structures: enameled steel, stainless steel and copper. Reliable floor-standing devices are equipped with more expensive, but durable cast-iron devices.

Floor standing boiler

Classification of single-circuit gas devices

- At the installation location. Powerful boilers that are capable of heating huge areas (from a thousand square meters or more) are called floor-standing units. They, however, require a special room with a built-in chimney, a separate exit and ventilation. But if the chimney is led to the roof of the house through the ceiling, it is necessary that its height be at least half a meter. Such boilers use heat exchange from materials such as cast iron, which allows them to extend their service life.

- According to the substance of the heat exchanger. To make a heat exchanger, most people use copper, steel and cast iron. True, heat exchangers made of steel are more susceptible to rusting, and if the wall thickness is small, the service life is very short, which is up to 20 years. A cast iron heat exchanger has a slightly longer service life (about 50 years). Some of its parts can be replaced, and the cast iron itself is rust-resistant.

Floor standing gas boiler

How to calculate the required power

The thermal power of the boiler unit is selected so that it can cover all the heat losses of the heating object. Low power will not be able to provide the heating load at subzero cold air temperatures, while operation with constant overload will quickly damage the main elements of the device.

You should also not buy a boiler with a large supply. It will wear out due to the “clocking” process, since it will often automatically “turn off/on”.

Both modes, in addition to premature decommissioning of equipment, lead to excessive fuel consumption for heating, low efficiency and high cost of thermal energy.

Performing an accurate thermal calculation of building losses is a labor-intensive engineering task that can only be handled by highly qualified thermal power engineers.

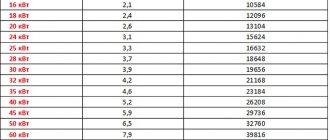

In practice, a simpler calculation of power is used, which has proven itself well for the average residential property located in the climatic zone of central Russia with walls built of at least 2 bricks and a ceiling height of up to 2.7 m.

The minimum power size is calculated based on the ratio: for 10 m2 of total area, 1 kW of power is taken with a margin of 15-20% for DHW needs.

For example, for a household with an area of 150 m2, the required boiler power will be:

150*0.1*1.20= 18 kW

Types of single-circuit heating systems

Single-circuit heating systems are classified according to a number of characteristics and parameters. The main types of such systems are

Due to the high coefficient of thermal expansion of water, as noted above, it is necessary to compensate for the excess pressure and volume of the coolant in order to avoid pipe bursting. This process is carried out by installing an expansion tank. Inside it there is a polymer membrane that allows you to completely fill the tank.

When using such devices, we obtain a closed type system , which is fully automated. In this case, the fuel for the boiler can be either gas, pellets, fuel oil, and so on. This system is characterized by increased safety due to the possibility of emergency shutdown.

A little earlier, mostly open single-circuit heating systems . A special pipe was installed here to remove excess pressure.

Systems are also divided, as already discussed, into schemes with natural and forced circulation.

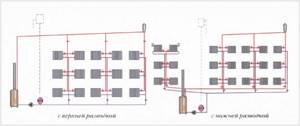

Types of wiring of a single-circuit heating system (upper and lower)

With vertical wiring diagram

A single-circuit vertical system does not allow each heating radiator to be turned off individually. However, the advantages include the fact that much less materials and pipes will be required for this wiring. Vertical wiring allows you to distribute heat as evenly as possible throughout the room, but the area of the room will be very limited. This scheme is advisable to use for multi-story buildings (three and above).

The vertical type of wiring allows you to exclude the use of a circulation pump from the circuit. This solution can also be applied to private houses. It should be borne in mind that this system cannot be scaled, and it will not be possible to regulate the heat in each room.

Vertical wiring can be top and bottom. Each variety has certain characteristics. With the upper type of vertical wiring, the supply will be carried out from the attic, on which a special container will be located. From it, the coolant will flow into risers that supply heat to the radiators.

Piping diagram for a single-circuit gas boiler

The most common piping schemes for such modifications of boiler units are: with natural and with forced movement of water in the heating circuit.

They are applicable for both floor-mounted single-circuit and wall-mounted modifications. Currently, a single-circuit unit with an external heat exchanger is often used.

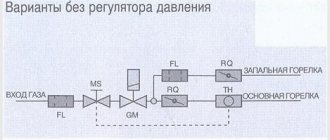

Piping diagram without boiler

There are 3 pipes in the device, to which they connect:

- gas main;

- heating circuit supply pipe;

- heating circuit return pipe.

The circuit of a single-circuit device using natural circulation of heated water can be non-volatile.

The safety group includes the expansion tank, relief valve and air vents. A drain line is installed in front of the heat exchanger so that the coolant can be drained during repair work.

In order to guarantee the natural movement of the heating medium, an expansion tank is installed in the upper zone of the heating circuit.

Heating pipeline lines are laid with a slope so that hot water can rise to the tank and then go down to the boiler. The height difference between the installed radiators and heat exchangers will determine the working hydraulic pressure.

Heating a private house

The organization of heating a private house using a 1-circuit gas boiler has become widespread due to fuel savings and reliability of the heating circuit.

When choosing a location for installing equipment, you need to consider:

- the level of illumination in the room - this will make it possible to easily service the device;

- the presence and effectiveness of supply and exhaust ventilation - according to the standards, it must provide at least 3 air exchanges within 1 hour;

- there must be a window in the window;

- the front door must open to the street - this is a requirement of the fire inspection to ensure the safety of the premises.

The piping of the wall-mounted boiler is carried out in accordance with the documentation for the equipment. It involves the use of reliable nodes and communication elements. The heating device is connected to the gas and coolant supply pipelines and the ventilation system. When choosing a tying method, the following are taken into account:

- number of circuits and presence of “warm floor”;

- type of coolant circulation - forced or natural;

- boiler type - with open or closed working chamber;

- temperature control method;

- presence of a boiler.

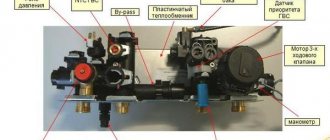

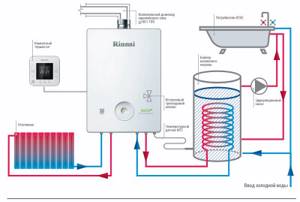

To provide consumers with hot water, models of 1-circuit boilers can be connected to external boilers using a 3-way valve. In this case, when the water cools, the temperature sensor is triggered. The liquid begins to flow into the indirect heating boiler. The water goes through the cycle until the desired temperature is reached. When the 3-way valve is activated again, the liquid is directed to the heating. This scheme makes it possible to organize hot water supply using a 1-circuit boiler.

Do I need a boiler?

The market for single-circuit boilers, in the fight for competition with double-circuit boilers, assumes the constructive possibility of installing an external indirect heating boiler.

The need for its use will depend on the user’s decision and the actual conditions for receiving central DHW services. If an electric boiler is already installed in the house, then naturally there is no need for such a connection.

Wiring diagram for a single-circuit gas boiler with a water heater

An indirect heating boiler in single-circuit boilers is an innovative development of modern heating engineers. It has a large water capacity that acts as a storage tank and internal heat exchanger. It is connected to the boiler flow and return parallel to the heating circuit.

The advantage of this scheme is great, since it allows the unit to be loaded during a decline in the heating load at positive outside temperatures. The scheme is well automated, providing the most efficient mode of operation of the boiler room’s thermal equipment.

Advantages and disadvantages of equipment

Both types of gas boilers are easy to operate, efficient and durable. They also have an attractive appearance.

The design of each type of gas boiler is designed to meet the needs of different categories of users, which clearly demonstrates their advantages and disadvantages. They also provide an opportunity to understand the differences between a single-circuit gas boiler and its double-circuit counterpart, helping the potential buyer make the right choice.

Pros and cons of single-circuit units

Such products are capable of providing stable heating of rooms of any size, number of floors, and distance from the heat exchanger.

And, in addition, single-circuit boilers:

- more reliable than their double-circuit counterparts, the design of which is more complex, which leads to a slightly larger number of breakdowns;

- easier to maintain , which is also caused by design features;

- cheaper.

An important advantage is that single-circuit units can become a base for connecting other equipment . This will expand their functionality and increase the comfort of living.

You should always remember that if you need to provide hot water supply in the premises, you will have to buy a storage boiler together with a single-circuit boiler. And this will lead to considerable additional costs. And a set of the listed equipment will take up a lot of space, which can be critical for small apartments

Connecting storage boilers will provide the premises with hot water supply. Moreover, the water will be supplied hot at any time, which is not always possible to achieve from dual-circuit analogues

This type of equipment, in the absence of the need for hot water supply, has no pronounced shortcomings. But otherwise, the lack of universality immediately affects. Which leads to the need to purchase an additional electric heating device.

As a result, its joint operation with a single-circuit boiler leads to:

- high costs for purchase, installation, maintenance;

- limited volume of water for domestic needs - boilers are most often purchased for joint use with single-circuit units, so the question may arise about the rational consumption of water, the volume of which depends on the capacity of the storage tank;

- greater load on the wiring.

The last drawback is relevant in cases where the house or apartment has old wiring or powerful electrical equipment is used in parallel. So, it may be necessary to modernize the electrical wiring and select a cable with a larger cross-section.

You should also be aware that a set of a single-circuit boiler and boiler takes up significantly more space than one double-circuit boiler. And with limited space this can be a significant disadvantage.

Advantages and disadvantages of double-circuit boilers

Units that belong to the specified type have some restrictions, but are still capable of providing hot water to two systems at once (heating, hot water supply). They also take up less space than their boiler counterparts. As a result, double-circuit boilers are more convenient to use.

Both types of gas boilers are easy to operate, efficient and durable. They also have an attractive appearance.

In addition, the competitive struggle of manufacturers has led to the fact that the difference in the cost of both types of units is gradually leveled out.

Therefore, today you can find a double-circuit boiler whose price is slightly higher than that of a single-circuit product. Which in some cases can also be considered an advantage.

If we talk about the disadvantages of double-circuit boilers, the most important is the inability to instantly provide hot water of the same temperature to all water consumption points in a house or apartment.

So, in their heat exchangers the amount of water that is needed right now is heated. That is, no stock is created. As a result, the water temperature may differ from what you expect or may change as you use it. This happens when the pressure or pressure changes, for example, after opening/closing the second tap.

When using a double-circuit boiler, the water temperature often differs at two different water intake points - hot water can be delivered to the desired point with a significant delay. Which is inconvenient and leads to additional costs

As for installation, installation of double-circuit boilers is a more complex procedure, especially at the design stage. Since you will have to follow numerous manufacturer’s recommendations

The most popular manufacturers

Modern household heat power engineering is represented by boilers from both domestic and Western companies. The latter are higher in price and functionality, but domestic ones are ahead of them in low prices and long service life.

No less important factors that give advantages to domestic boiler manufacturers are the accessible market for spare parts, the availability of repair work and the ability to reliably operate in Russian utility networks: electricity, gas and water supply.

Particularly popular companies, according to users, are:

- Viessmann is a German company that produces wall-mounted and gas floor-standing boilers.

- Protherm is a Slovak company that produces a wide range of gas boilers, each series is named after a representative of the animal world.

- Buderus, a subsidiary of the well-known Bosch concern, produces modern wall and floor modifications.

- Vaillant is another popular German brand of high-efficiency boilers.

- Lemax is a Russian company that produces a non-volatile gas floor-standing single-circuit boiler.

- Navien - Korean units with affordable prices and high energy-efficient operating parameters.

Installation features

Installation of wall-mounted boilers is carried out in a certain sequence. Installation is carried out on a solid, ideally load-bearing (outer) wall. This is an important point, since models with a closed burner use a coaxial chimney (pipe-in-pipe design) that is vented outside.

As a rule, the delivery set includes a special template according to which the wall is marked. Mark the attachment points and the center of the hole for the chimney.

The hole is made with a diamond crown using special guides that feed the cutting tool onto the wall. While drilling, it is recommended to water the crown, otherwise there will be a huge amount of dust and it will become impossible to work.

After making the hole, the chimney is led into it. It is a double pipe. Air is supplied through the outer one, and smoke is exhausted through the inner one. All gaps are sealed with insulating material and the installation of the boiler itself begins.

The unit is fixed with special fasteners included in the delivery set. Connect the gas supply pipe, water make-up pipe, forward and return lines of the heating circuit. All connections must be made carefully and carefully so as not to mix up any pipelines.

The last step will be to connect the boiler to the power supply, fill it with water, supply gas and test switch it on. All detected deficiencies are immediately eliminated.

Rating of the TOP 5 best models of single-circuit boilers

The annual rating of boilers is compiled by large trading companies based on the results of sales of units. Based on the results of 2021, gas boilers became the most popular models on many trading platforms:

- Bosch Condens 5000 W is a German innovative condensing unit with an LCD panel and online control for large heating objects of 1000 m2. It is possible to connect the unit to the “warm floor” system and turn on an external indirect hot water boiler. Heating is carried out using the flow method in a plate heat exchanger, with automatic adjustment of thermal conditions and protection against overheating. The built-in electric circulation pump operates in energy-saving mode. The boiler has 100% automatic protection and regulation. Flame control is carried out using an ionization electrode. The pre-mix burner is made of stainless steel. Price — 305910 rub.

- The Vaillant turboTEC plus VU 282/5-5 gas boiler with a thermal load of 36 kW has a forced exhaust of gases to the atmosphere and a closed combustion chamber. Productivity is regulated by a modulating burner device; operation in combination with an external water heater tank is allowed. A backlit LCD display with push-button control is used to monitor status, set modes and diagnose technical condition. The boiler is designed for a heated room area of 280 m2 and has an efficiency of 91%. Price: 108874 rub.

- Single-circuit floor-standing gas boilers Baxi ECO Compact 1.14 Fi from an Italian manufacturer operate at low parameters in the gas main and have an electronic flame modulation system. Heating area - 140 m2 with a power of 14 kW. It has built-in weather-compensating automation and digital temperature display. Price: 38890 rub.

- Gas boilers Lemax Premium-20 are a domestic, inexpensive unit with a power of 20 kW, capable of efficiently heating a room of up to 200 m2. The boiler has a mechanical control and an efficiency of 90%. The advantages include reliable and stable operation, simple operation and low price: 29,900 rubles.

- The Hephaestus KSG-16 boiler is suitable for open heat supply systems. The unit is equipped with an Italian automatic “630 EUROSIT” and a stainless steel “BRAY” slot burner that does not require air flow regulation. The burner device has a quiet start and operates silently at any power. It can heat an area of 180 m2 with a thermal power of 18 kW with an efficiency of 90.8%. A long warranty period of three years indicates the high quality of the unit. Price: 17999 rub.

In addition to the basic elements listed above, most modifications are equipped with an expansion tank to reduce the effects of thermal expansion of the coolant, which can disrupt the integrity of the heating network due to increased pressure.

In dependent heat supply schemes, the set is equipped with a circulation pump, and closed fireboxes are equipped with a fan.

What it is?

Wall-mounted models are mounted in a hinged manner on solid walls. Since the load on the supporting structures should not exceed a certain limit, wall-mounted models are not too large. Their power is limited to 40-50 kW, and the most popular are models from 15 to 16 kW, designed to heat rooms from 150 to 260 m2.

Such units have an attractive appearance, which allows them to be installed in kitchens or hallways. Installation is allowed only on sufficiently strong walls - a plasterboard partition cannot be a load-bearing surface. Separate premises are not required for them, but installing gas equipment in living rooms is prohibited by the rules. If the model is equipped with an open type burner, then installation is allowed only in rooms with a closing door (for example, in the kitchen).

Classification of single-circuit wall heaters

Single-circuit wall-mounted gas devices are classified according to many design features that determine the performance characteristics and cost of heating devices.

By heat exchanger type

This is an important element of the boiler, designed to transfer heat from the gas burner to liquid. The average price, operating efficiency and service life of a wall-mounted single-circuit heater are significantly influenced by the material from which the heat exchanger is made. It is also important how high quality a particular metal is.

Three types of basic materials are used for the manufacture of heat exchangers:

- Cast iron. Does not burn out or corrode. The disadvantages of cast iron products are their heavy weight and high fragility. Therefore, they are mainly used in floor-standing models of gas heaters.

- Copper. The best material for heat exchangers of wall heaters, lightweight, non-corrosive. Such devices have the greatest efficiency in heat transfer. But boilers with copper heat exchangers are the most expensive.

- Steel. This material is much lighter than cast iron, but heavier than copper. Steel heat exchangers resist mechanical stress well, but are susceptible to rapid burnout and corrosion when condensation appears on them. The use of stainless steel devices prevents oxidation processes, increases the service life of the boiler, but also increases its cost.

By type of control

For safety reasons, all gas heating boilers are equipped with instruments and automatic control and monitoring devices.

Based on functionality and design features, the following types of automation are distinguished:

- mechanical or electrically independent devices;

- electronic or volatile devices.

Mechanical automation is the easiest to operate. In this case, equipment adjustment is carried out using manual adjustment of mechanical rotary toggle switches. The main element of the system is a thermostat, which maintains the temperature of the coolant within the specified parameters and protects the boiler from overheating.

Non-volatile control has sensitive draft and flame sensors. If the gas pressure suddenly decreases or the draft in the chimney drops, the boiler turns off. Using a safety valve, the system determines the amount of coolant in the heating circuit.

Volatile automation is an interconnected complex of electromechanical devices and electronic elements that functions only when there is voltage in the network.

Allows you to solve the following functions of the heating process:

- Gas supply control.

- Automatic start of the heating system.

- Adjustment of burner power (through the use of a thermostat).

- Shutdown of equipment both in the case of a given technological mode and in the event of an emergency.

- Displaying data on the operation of the boiler on the display.

Gas heating equipment has a wide range of models with both mechanical and electronic control, which allows the consumer to choose the model that is acceptable to them.