I have my own country house and am well versed in all the intricacies of its construction. I also have a car that uses antifreeze (the idea is similar).

He built the house himself and provided the main communications to it himself. I am an engineer by training and therefore they ask me about construction and consult on creating a heating system in houses. I decided to answer the main questions once and for all in this article so that they won’t be asked to me anymore. The article examines the basic postulates of creating a heating system in a house and provides answers with recommendations to readers.

Based on my personal experience, I tried to thoroughly understand the issue and wrote the text as succinctly as possible.

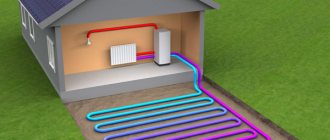

Considering the frosty weather and the peculiarities of Russian climatic realities, outside the window in winter the temperature may well drop to 20-30 degrees with a minus sign, or even drop to less than 40 degrees. What could this mean? This only means that if the heating in the house does not work at the proper level and warm the air in the room throughout the entire time, and there is water in the heating system, it will quickly freeze.

It would seem, is this bad and can it affect life? In fact, it can be very strong. The fact is that during freezing (when the organic medium changes from one state of aggregation to another), the volume of water increases by an order of magnitude and can thereby damage the entire heating system in the house.

Accordingly, if water suddenly freezes in the pipes and in the heating system as a whole, there is a sufficient probability that the pipes will burst and some internal parts of the heating of the house will fail: the same pipes and batteries may well break, and the boiler itself may also fail and other elements.

Antifreeze - as the main antifreeze mixture for a home heating system

- Household antifreeze (or as it is also called home antifreeze) is a special mixture in the form of a coolant that is used in various elements and systems, including heating elements in the house. In general, there are many types of antifreeze, which are based on various solutions based on chemicals: including mixtures based on alcohols, compositions based on organic and inorganic acids or salts, compositions based on the so-called propylene glycol and others.

- These compositions must (almost always) be supplemented with additives that are special in their structure, making the properties of the above solutions even better for the heating system.

- And another excellent characteristic is the reduced freezing point.

- But which antifreeze should you choose for heating your home? First, it’s worth understanding their composition.

About the pros and cons of glycol antifreeze

The main advantage of artificial coolants based on glycols is the preservation of the liquid phase at subzero temperatures. We list other positive aspects of using antifreeze in closed water heating systems:

- coolants do not contain calcium and magnesium salts, which form scale inside the heat exchangers;

- due to the penetrating ability of glycols, the effect of lubrication of moving parts occurs, ball valves and thermostatic valves do not sour, the fittings last longer;

- the boiling point of antifreeze 103-106 °C delays the moment of vaporization and airing in case of overheating of a solid fuel boiler;

- When the temperature drops below the freezing threshold, glycol solutions turn into a gel mass.

Note. The paragraph about scale implies that the “anti-freeze” is diluted with demineralized distilled water.

Let us explain the last 2 points. Ordinary water, often poured into the heating system of country houses, begins to boil at 96-98 ° C, actively releasing steam. If the circulation pump is on the TT boiler supply, the steam phase penetrates the chamber with the impeller, water pumping stops, and the boiler completely overheats. A higher boiling point of antifreeze will delay the moment of the accident.

Unlike water, glycol hardened in the cold does not expand and does not destroy pipe walls. In the event of freezing, the only unit that will suffer is the forced circulation pump. The crystallizing gel will jam the impeller and the motor will burn out.

Unfortunately, there are plenty of disadvantages to non-freezing substances:

- Ethylene glycol is poisonous and requires careful handling and disposal of the solution. Glycerin and polypropylene glycol are harmless.

- The heat capacity of the “anti-freeze” is 15% less. To deliver the required amount of heat to the batteries, the liquid flow will have to be increased.

- The viscosity of antifreeze creates additional hydraulic resistance. You will need a more powerful and expensive circulation pump.

- Good turnover is a double-edged sword. Glycols penetrate through the slightest leaks, from which plain water cannot flow.

- Coolants and additives decompose during operation, losing their frost-resistant properties and forming flakes of sediment. The maximum service life of 1 refill is 5 years, then the heating is flushed and replaced.

- When using antifreeze, many gas boiler manufacturers void the warranty of the purchased product.

Glycol liquids are poorly compatible with electric boilers. Instructions for the use of various antifreezes categorically do not recommend filling systems operating in conjunction with electrolysis heaters with antifreeze. That is, for electrode boilers of the “Galan” type, a special coolant developed by the specified company is needed.

Under rare circumstances, antifreeze can release flammable gas that breaks through the automatic air vent. Example: the heat source is an electric boiler, the heaters are Chinese-made aluminum radiators. Heating glycol causes a complex chemical reaction and gas formation. The fact is demonstrated in the video:

Composition of antifreeze

Cooling mixtures usually include various types of additives that are necessary to impart to the mixture the properties necessary for the operation of the entire heating system. Eg:

- preventing breakdown or preventing the destruction of sealing elements in the home heating system;

- dissolution or removal of scale, as well as removal of sediments that can accumulate in boiler pipes over the years of using antifreeze;

- protection of steel from rust and the effects of corrosion itself.

Work order

At first glance, filling in the coolant is a simple task, but even with water there is a lot of hassle, and with antifreeze a number of nuances are added.

First of all, the question arises of how to correctly calculate the amount of concentrate in order to ultimately obtain a solution with the necessary parameters. And even so, they begin with preparing the heating for operation.

Preparation

Taking into account the requirements of the antifreeze manufacturer, heat exchangers, gaskets, valves, etc. are checked. Materials that are not compatible with the selected solution are replaced. If, for example, pipes or devices with a galvanized internal surface are found, they will have to be replaced when using ethylene glycol antifreeze.

The integrity of the connections is checked by pressing for leaks, washed with water or special compounds recommended by the boiler manufacturer to remove blockages and scale with deposits. Before final filling, the entire structure is completely washed with water.

Before proceeding with the preparation of the coolant solution, it is necessary to know the volume of the system. This is a key factor for coolant preparation. It is enough to fill the heating with water until the air completely escapes through the air vent or expansion tank. After prolonged operation of the circulation pump, air is bleed from the radiators and the highest point. Only after this the water is drained to obtain the exact volume.

How to dilute the concentrate

Knowing the exact volume of heating, proceed to preparing the solution in accordance with the instructions for the selected antifreeze. Use clean filtered or distilled water. There is no need to dilute solutions that are supplied ready-made with the required concentration.

The dilution container can be a plastic barrel or a metal one for food products. Water is poured into it and then a measured amount of antifreeze is added. There is no need to stir the solution, otherwise foam will form and the solution will receive additional oxygen saturation.

How to fill a heating system

Filling begins from the lowest point, this reduces the risk of air pockets or antifreeze foaming due to mixing.

To fill the coolant you will need:

- Vibration pump, such as baby;

- Flexible hose for connection to the drain valve and drain from the highest point of the system.

To fill, open the valve on the bypass of the circulation pump. A pump connected by a hose to the drain valve and the end of the hose from the top drain from the expansion tank are lowered into the barrel with the solution.

Most of the contents of the barrel are poured in until a clean solution begins to emerge from the expansion tank. After this, air is released from the radiators and boiler using a Mayevsky tap. Next, the solution is added until it is completely filled so that the coolant level in the open expansion tank reaches the minimum permissible level.

How to fill a closed system

Filling is also done from the bottom point, connecting the pump to the drain valve. Additionally, a pressure gauge is used to monitor the pressure. It should not exceed the permissible threshold set on the expansion tank.

Air is released using an air vent located at the highest point of the system and with the help of Mayevsky taps on each radiator. It is especially important not to forget about radiators when connecting them at the bottom.

The filling speed is approximately 4-5 liters per minute and depends on the operation of the air vent. As soon as clean liquid without air flows from the top point, filling with coolant continues until a pressure of 1-1.5 atmospheres is reached in accordance with the settings of the expansion tank and boiler and taking into account the expansion of the coolant, in order to obtain a maximum of 2 atmospheres at operating parameters.

The circulation pump turns on. During the first cycle, residual gases that were not previously detected will be released. If the pressure drop is noticeable on the pressure gauge, it means that the air is gradually moving, making room for another portion of the coolant. When the heating operates without the boiler on for 2-3 hours without any visible drop in pressure, it means that the coolant has been filled successfully.

Fill it up and enjoy?

However, not everything is as smooth as it seems at first glance, since in domestic realities, turning off light or heat in a house for a long period of time is essentially a completely standard procedure, and this can be done without even warning. Consequently, in cold weather, dangerous problems may well appear in country cottages.

There is also another difficulty. Some manufacturers of heating systems strongly advise against using antifreeze in a home heating system that involves various technical devices and devices.

A completely logical question arises: what is the reason for this?

Reason number 1

Since plain water and antifreeze have completely different physical properties, when creating a heating system for a cottage, it is worth remembering whether you will use one liquid or another. The main designs are carried out, naturally, for water. If you plan to use different types of antifreeze in the heating system, you need to change many basic options in the operation of the heating system:

- increase the pressure rating of the circulation pump by 50 percent;

- increase the volume of the expansion tank by 50 percent and increase the strength/speed of radiator fans by 40 percent.

Problem number 2

Antifreezes created on the basis of ethylene glycol have something special - they “don’t like” when the heating system heats up excessively. For example, if in any place of the heating mechanism the temperature level rises to the highest, then there will be decomposition of chemical additives, resulting in the appearance of solid particles and other substances.

It is important to consider: the decomposition of additives can provoke a decrease in the protective properties of antifreeze, which is quite capable of causing heating or even leakage at the joint points of the pipes.

Propylene glycol products

In appearance, propylene glycol cannot be distinguished from ethylene glycol; many of their physical properties are the same. But propylene glycol has fluidity and if a leak is not noticed in time, it can leak out completely.

Propylene glycol-based antifreezes are green in color due to the presence of a food additive in it, which suggests that it is not toxic. Moreover, this additive is widely used in the production of various cosmetics and food industries. And if a leak suddenly occurs, it will not cause any terrible harm.

The temperature at which it freezes (or rather, changes consistency) is higher than ethylene glycol antifreeze and is about minus 50 degrees. Propylene glycol antifreeze does not damage the internal surface of systems, but, on the contrary, has the opposite effect. Which carries such positive qualities as less resistance and less energy loss.

This type of antifreeze is more expensive and is used when environmental friendliness is important. The high cost is due to the fact that high-quality imported materials are used in production.

How to choose the right antifreeze for your heating system?

Now they have started selling on the market, although they are the most expensive, antifreeze made on the basis of environmentally friendly ethylene. This chemical composition is practically safe for use in a heating system and is harmless to people; this antifreeze can also be used in multi-level heating systems of a private home.

Their thermal and technical properties can be compared with many mixtures based on ethylene glycol antifreeze. It is also important to note that many pipe and boiler equipment manufacturing companies have freely approved the installation/use of this product.

Why you should not use water as a coolant

There are several known factors limiting its use as a universal coolant. One of the main ones is that this substance passes from a liquid to a solid state at 0 °C. If this happens, the volume of water will increase by 10%, which will certainly cause damage to the networks. Therefore, to solve some problems, a coolant with more flexible properties should be used.

Effective operation can be ensured by using antifreeze. And this concept includes not only liquids such as ethyl alcohol, automobile antifreeze and transformer oil. Special-purpose antifreeze is better suited for heating systems. The main requirement for the coolant in this case is safety in terms of combustibility and flammability. There are also restrictions regarding standards for premises where people live. In addition, antifreeze should not be chemically active when in contact with metals.

Differences between antifreeze and antifreeze for home heating

- They differ in temperature and boiling rate.

- Anti-corrosion characteristics, as well as lubricating characteristics.

- These mixtures are produced in several shades: green, yellow and, more often, red.

- We have practically figured out the differences between antifreeze and antifreeze for a home heating system and understood the basics.

- Since all boilers and houses have different cooling systems and, in general, they are made of different materials - some brands use copper in the system, while others more often use aluminum and some of its types.

Every home owner should know

- According to the accepted international standard, the cooling mixture, regardless of its type - it may be a new generation of antifreeze, should not contain any physical impurities in the form of metals and, in general, nothing dangerous to humans. Try to buy such mixtures, especially since they have recently begun to be released on the market in large quantities.

- The mixture for pipes of a home heating system should be transparent.

- Different types of antifreeze may have the same shade, but this does not mean that these antifreezes can be mixed.

- When choosing antifreeze for your home heating system, pay attention to the tendency to form sediment or foam, as this increases the likelihood of heating system failure. Over time, this sediment will clog the pipes in the system and stop the pumping equipment.

- But still, after strong heating of this product, soot or even a suspension of small particles harmful to the engine may appear.

Instructions for use

If your system previously ran on water, switching to antifreeze will not be easy. Theoretically, radiators with a boiler can be emptied and filled with cold-resistant coolant, but in practice the following will happen:

- due to lower heat capacity, the output of batteries and the efficiency of heating rooms will decrease;

- due to viscosity, the load on the pump will increase, coolant flow will drop, and less heat will reach the radiators;

- antifreeze expands more than water, so the capacity of the old tank will not be enough, the pressure in the network will rise;

- To improve the situation, you will have to increase the temperature on the boiler, which will lead to excessive fuel consumption and increased pressure.

Addition. After filling the liquid, the old connections sealed with flax and paint are guaranteed to flow.

. In order for heating to function normally using a chemical coolant, you need to calculate in advance or remake the existing system according to the new requirements:

- Select the capacity of the expansion tank at the rate of 15% of the total volume of liquid (water was 10%);

- The pump performance is assumed to be 10% more, and the generated pressure is assumed to be 50% more. Let us explain with an example: if previously there was a unit with a working pressure of 0.4 Bar (4 meters of water column), then use a 0.6 Bar pump for antifreeze.

- In order to operate the boiler in optimal mode and not raise the temperature of the coolant, it is advisable to add 1-3 (depending on power) sections to each battery.

- Pack all joints with dry flax or use high-quality pastes - sealants such as LOCTITE, ABRO or Hermesil.

- When purchasing shut-off and control valves, consult with the seller about the resistance of rubber seals to glycol mixtures.

- Pressure test the system again by filling the pipes and heating equipment with water.

- When starting the boiler unit at negative temperatures, set the minimum power. Cold antifreeze needs to be warmed up slowly.

Advice. The total amount of coolant is easy to calculate - the cross-sectional area of the pipe is multiplied by its length, the capacity of the boiler and radiators is indicated in the product data sheets. Find out how to properly place and connect the expansion tank in our separate publication.

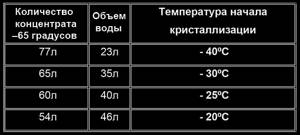

concentrated coolant must be diluted with water, ideally with distillate. Do not rely on an excessive reserve of frost resistance - the more water you add, the better the heating will work. Recommendations for preparing coolant:

- For heating elements, electric and gas double-circuit heat generators, prepare the mixture at minus 20 degrees. A more concentrated solution may foam upon contact with the heater, and carbon deposits will form on the surface of the heating element.

- In other cases, mix the components at freezing point according to the table below. Proportions are indicated per 100 liters of coolant.

- If there is no distillate, first conduct an experiment - dilute the concentrate in a jar with plain water. If you see a precipitate of white flakes - a product of the decomposition of inhibitors and additives, this water should not be used.

- A similar check is done before mixing antifreeze from two different manufacturers. It is unacceptable to dilute ethylene glycol with propylene composition.

- Prepare the coolant immediately before pouring.

To find out the amount of ingredients for a volume of 150 liters, multiply the given figures by a factor of 1.5. The maximum service life of any non-freezing substance in pipes and heating radiators is 5 years. At the end of the specified period, the liquid is drained, the system is flushed twice and filled with fresh antifreeze.

Benefits of antifreeze

In order to sum up the article, I will try to outline the advantages of using antifreeze in the home

- antifreeze itself has a special chemical formula and a weak threshold for its crystallization during use, which is why ruptures in pipes are almost completely eliminated when used;

- the need for insulation of the boiler or pipes automatically disappears;

- the chemical composition of antifreeze does not provoke corrosion of the inside of the pipes;

- there is no need to remove liquid from the pipes after the end of the heating season;

- Antifreezes, compared to plain water, are practically not subject to evaporation, so filling the product is carried out much less often.

Coolant requirements

The coolant is the liquid circulating in the heating system. In most cases it is water. There are no ideal coolants - each of them is effective only under certain conditions. Along with water, antifreeze, antifreeze or a mixture of components are used.

The working fluid must meet a number of the following requirements:

- effective heat retention;

- low viscosity, as this affects the speed of movement through the pipes;

- safety for human and animal health;

- availability;

- reasonable cost;

- Possibility of long-term use without replacement.

Of course, water meets these requirements better than any other coolant. However, if the air temperature in the room drops below zero, freezing of the heating system will be guaranteed.

Antifreeze is the most obvious alternative to water because it crystallizes at very low temperatures.