Rolled and sheet penofol is attached to the concrete base only with special glue. The adhesive composition allows you to preserve and even strengthen the technical qualities of the heat-insulating material. For high-quality fastening of polyethylene foam, targeted adhesive preparations are used, the technological development of which is aimed at the rapid connection of concrete with penofol.

How to install reflective insulation on a concrete wall?

How or with what can you glue or attach reflective insulation to a concrete wall?

Thank you. Reflective insulation is a lightweight, flexible material with a thickness of 4 mm or more, consisting of a layer of foamed polyethylene or other polymer, onto which aluminum foil or metallized film is glued on one or both sides. Foil thermal insulation materials are environmentally friendly, easy to install and significantly reduce heat loss.

Manufacturers of reflective thermal insulation materials do not exclude the use of glue during installation, but draw the attention of consumers that they are most effective if an air gap of 2 to 10 mm is created between the wall and the thermal insulation. After all, air is also an additional thermal insulation layer.

The method of attaching reflective thermal insulation to a concrete wall is chosen depending on the type of material, capabilities, location and purpose of the room. In any case, the concrete wall must first be cleaned of dust and treated with an antiseptic, and if necessary, dried.

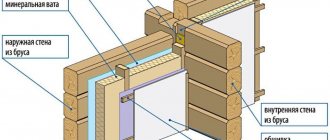

When insulating balconies or cold external walls with a heat insulator with a double-sided foil coating, it is necessary to fill the concrete with a lathing of slats 5-7 mm thick and attach the material to it with a construction stapler or glue. A second sheathing is mounted on top of the heat-insulating material for laying the finishing coating with an air gap.

When installing on reflective materials with a one-sided metallized coating, it is allowed to use rubber or acrylic-based adhesives such as 88-NP, Akrol Contact, Neoprene 2136 spray, etc. You can also use polyurethane foam, sealing sealant and double-sided reinforced construction tape . The adhesive composition is applied to the back side of the material pointwise in a checkerboard pattern or randomly, so that after gluing to the concrete the required air gap of about 2 mm remains.

Reflective insulation sheets are glued end to end and the seams must be taped with aluminum tape. As a result, an airtight coating is created on the wall, reminiscent of a thermos, onto which a lath of slats can be mounted to secure the finishing material.

Finally, if increasing the thickness of the walls is undesirable or impossible, self-adhesive foil thermal insulation material can be used for insulation. To install it, you only need to prepare the concrete surface and remove the protective film from the underside of the canvas, and after gluing, seal the joints with foil tape. But when fastened to the sheathing, the efficiency of self-adhesive metallized insulation is higher.

Mounting features

The first layer of double thermal insulation using these materials is penoplex; penofol is laid on it. Further finishing is allowed:

- MDF;

- Laminate;

- Chipboard and other suitable materials.

Penoplex boards are attached to the surface using fungi, and to secure the penofol layer, you can use the simplest option. Namely, purchase a heat insulator that has an adhesive base on one of its sides. If you choose a foil-coated thermal insulation material, the connection can be made using self-tapping screws or a construction stapler.

As an adhesive solution, it is permissible to use a mixture of glue with the addition of polyurethane or cement. In this case:

- fastenings are more durable;

- the structure increases the level of strength and resistance to mechanical damage;

- significantly extends the life of active use.

When using such solutions, the thermal insulation qualities also increase, since the mixture fills possible gaps, creating a kind of waterproofing between the slabs of thermal insulation material.

Another way of fastening penofol and penoplex without an intermediate layer of other materials is the use of bitumen-based glue. This is an affordable option that provides reliable connection of elements.

Video: Insulating a balcony with penoflex and penofol

Penofol adhesive - rules for selection and use

Greetings! In articles about insulation, the use of penofol is constantly recommended, but I had a question, how to glue penofol to concrete, for example, if I am using a non-self-adhesive option? Thank you.

Hello. We will try to answer your question.

Penofol is an energy-saving material with a layered structure. It combines the properties of foamed polyethylene and thin aluminum foil. The material is characterized by lightness and low thickness, and therefore is often used on various objects (including balconies) for insulation, ensuring tightness, thermal, noise, vapor and waterproofing. However, to ensure high-quality protection, it is not enough to lean penofol against the insulated surface - you will need special glue for penofol.

Features of adhesive installation of penofol

Adhesive for foil foam foam allows you to quickly complete work on insulating surfaces. In addition, the adhesive installation method is easy to implement and low-cost, since it does not require any special skills or specialized tools.

Usually, when choosing gluing as a method of installing insulating surfaces, you need to take into account the load-bearing capacity of the adhesive layer - but when using penofol, this fact will not be decisive, since the material is incredibly light.

Rules for preparing surfaces before gluing

Correctly selected penofol adhesive is not a guarantee of successful work. To ensure the integrity of the connection, the main thing is that the surfaces to be glued are prepared. All defects, chips, unevenness, cracks, as well as dust must be eliminated on them.

Important: Surfaces made of metal, concrete or wood can be additionally primed for better adhesion of the layers.

One of the most important conditions for a quality result is the evenness and cleanliness of the surface. Thus, concrete floors and walls are leveled, cracks are eliminated, and metal elements are treated with an anti-corrosion coating.

What can be used as adhesive for penofol?

Penofol adhesive can be special or universal. For these purposes, professionals also allow the use of liquid nails, double-sided tape, and a thin layer of polyurethane foam. The choice of the type of adhesive depends on both the purpose of the surface and its further design.

It is very important here that the characteristics of the adhesive composition correspond to the performance indicators of the insulation:

- ability to withstand operating temperatures in the range of +100…-60°C;

- permission for indoor use;

- biological non-toxicity;

- adhesion resistance.

If insulation is carried out outside, on the facade, then the adhesive composition must be resistant to water vapor and water. Non-toxicity requirements are also mandatory, since the balcony belongs to residential premises. Therefore, adhesive for foiled penofol must certainly have hygienic safety certificates.

How to properly glue penofol

To correctly glue penofol, you need to apply the selected adhesive composition to the side of the material that is not protected by foil. It is important to apply the glue in an even, thin layer so that all areas of the insulation are coated, without gaps.

When coating, special attention is given to the edges of the panel so that the penofol does not begin to peel off during operation. In order to fix the insulation, the material must be kept for 5-60 seconds so that the glue applied to it dries slightly. This will ensure better adhesion of the composition. Then the prepared canvas is pressed to the surface to be pasted, held and very carefully smoothed - until it is completely fixed.

Examples of manufacturers

Selecting an adhesive composition that allows you to connect the insulation to the concrete surface. big enough.

Weicon Easy-Mix PE-PP 45

It is a two-component structural adhesive. Used for high-quality joining of polyethylene and polypropylene. The glue base is methyl acrylate.

Moment

Moment adhesive sealant is suitable for foilgizol. It has two components - they need to be mixed before use.

Other

- Titanium is lightweight, easy to use, has good ability to bond to a concrete surface, one-component. Suitable for base - reinforced concrete.

- Tilit - used to connect the seams of insulation.

- Atlas Stopter K-20 kley - suitable for mineral bases.

- Ceresite (CT83) is suitable for any surface.

- T-Avangard-K - gives the surface additional waterproofing.

- Allfix is a universal adhesive suitable for any substrate.

Return to contents

For such purposes, the material that is optimally suited is penofol, which has a layered structure and consists of aluminum foil supplemented with polyethylene foam. It is characterized by its low thickness and low weight, as well as ease of installation.

This material is used for finishing building structures, units of specialized machines and entire mechanisms, individual parts of technical equipment on a production scale, pipelines, air conditioning systems, drying cabinets, as well as inclined surfaces with a complex profile.

In order to ensure maximum steam, thermal, hydro and noise protection, Penofol must be glued to a previously prepared surface (cleaned and well-dried).

Before you begin gluing Penofol and the working surface, it is recommended that you read the instructions for the selected adhesive. However, there is one rule that applies to working with any adhesives, namely, all surfaces to be fastened must be clean and solid.

How can you glue penofol?

To insulate the loggia, we bought penofol. How can you reliably glue penofol to a concrete wall so that it sticks?

Do you want to insulate yourself from the inside? You can use penofol of all three types “A”, “B”, “C”

It can be glued both to the frame itself and to the insulation. The glue used is ceresit, dragon or titanium.

But it is better to leave a gap (ventilation); such insulation improves air exchange and prevents condensation from accumulating.

The mounting method is as follows. Slats (lathing) are attached to the wall and penofol is attached to them using a stapler. I advise you not to leave penofol as a finishing layer, but to cover it with panels or drywall.

You can glue it with glue from the “liquid nails” series, for example “Moment-Montazh”,

There are “liquid nails” of this brand for wet rooms (baths, saunas), there are some for exterior, and for interior work.

Also take into account the surface material (metal, brick, concrete, etc.).

In general, the very idea of gluing penofol is not entirely correct.

If some air ducts are insulated with penofol,

If the wall is insulated, then penofol is attached with an air gap (up to 2 cm, this is enough), that is, at the beginning of the lathing, then penofol, fastening with staples (a stapler is needed), then counter-latten and finishing finishing material.

The joints are sealed with foil tape,

There is no need to glue penofol at all, it is attached differently, without an air gap it is of no use.

To insulate the loggia, we bought penofol.

For the loggia you need penofol type “B”, this is penofol with double-sided foil, one layer of foil (don’t forget that penofol is reflective thermal insulation) will not release heat from the room, the other will not allow the sun’s rays to overheat the room in the summer (this is important for the loggia ).

Penofol type “B” does not stick; it is attached with a gap to the brackets (see above).

In your case, the adhesive method will not work, you’ll just ruin the material and won’t insulate the loggia. Attach penofol according to the technology described above (lathing, gaps, and all that).

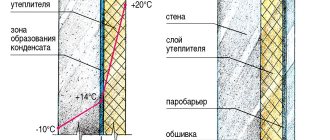

By choosing the adhesive method for strengthening penofol on insulated surfaces, you will do the right thing, since it is technologically simple, does not require professional tools and skills, and is the least expensive in terms of money/time. One thing is important: take into account the load-bearing capacity of the glue in order to reliably attach it, having determined the maximum weight of the coating. But since foil penofol (and its analogues too) is a very light material, the main requirement for glue is its adhesion. This is the name given to the glue’s ability to penetrate small pores/irregularities in the material, providing adhesion to it. Any material based on an organic polymer (including penofol) has low adhesion if it is not porous. Therefore, it is clear: water-based adhesives are absolutely useless for gluing penofol. The composition must contain an organic solvent; it “dissolves” the surface a little, thereby increasing adhesion.

And since absolutely universal solvents have not been invented, you need to look for a special glue for penofol. Adhesives called “universal” most often glue everything, but poorly. Or they are incredibly expensive.

How to insulate a room from the inside yourself?

Before you begin, you need to insulate the electrical wires and stock up on the necessary materials. In addition to penofol, the contractor will need assembly glue or a stapler, as well as wooden sheathing and hardware.

- The first task facing the performer of this work is the construction of a wooden frame to which the penofol will be attached. The air layer separating the insulation from the wall should not be less than 20 millimeters.

- Then, armed with glue or a stapler, you need to fix the insulation on the wooden frame, not forgetting that foil is an excellent conductor of electric current. All electrical wiring must be insulated in advance.

- Now it's time to install the second wooden frame. Finishing materials will be applied to it. The maximum thickness of the structure is 20 millimeters.

How to glue polyethylene foam: choosing glue

There are a large number of insulation options on the market. Foamed polyethylene is the most commonly chosen material because it has impressive vapor, heat and sound insulation properties. The choice in today's market is truly great. The proposed options may have a self-adhesive surface, may be foil-coated on one side or both. There are such types of foamed polyethylene on sale as isolon, polyfom, penofol. The insulation can be attached to different materials. And depending on all its characteristics, glue is selected.

Mounting features

Izolon (penofol) is covered with aluminum foil, which allows for the best possible retention of heat. Its adhesion to the surface of the insulation can be chemical or physical, that is, cross-linked. Izolon may have additional characteristics such as thickness or color. If you are looking for win-win insulation for your home, then this option will be the best choice. It is also perfect for insulating elements of air conditioning systems, pipelines, and production mechanisms. Foamed polyethylene is used for both external and internal work. The material has quite significant advantages.

Among them are:

- small thickness;

- ease of installation;

- environmental cleanliness.

Installation of insulation is possible without the use of special tools. Working with foamed polyethylene does not require additional protection of the respiratory tract and skin. The material is so light that the load-bearing capacity of the glue will not be critical.

How to choose glue

There is a fairly wide range of different adhesives for sale for working with polyethylene foam. And it is advisable to make the choice using the following criteria.

- The temperature range must match this characteristic of the insulation.

- Adhesive properties must be extremely high.

- If you plan to use glue for interior decoration, it must be certified and non-toxic.

- If adhesive is selected for exterior finishing, it must be resistant to a variety of weather conditions and temperature changes.

- If you intend to finish the sauna and bathhouse, then the glue will need to be mixed with water-repellent agents.

Types of material

Let's look at what types of insulation are called:

- With foamed polyethylene, it looks like a roll of self-adhesive material, similar to film with foil. Scope of application in various equipment, lining of pipes, shafts, roofs, since it has a high temperature range from -160 to +160 degrees, it is fire resistant.

- Mineral wool with foil coating can have the form of a plate or cylinder. It also has a high degree of fire resistance.

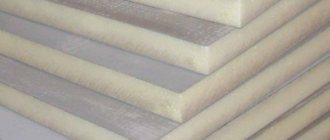

- Expanded polystyrene, coated with foil on both sides. It also has a wide temperature range, the diameter can be 5mm, 10mm, 15mm.

- Basalt, just like the materials described above, is made on the basis of foil material, however, thanks to its unique technology, it can withstand temperature fluctuations from -200 +600 degrees, and is resistant to aggressive chemical environments.

How to put insulation on pipes

As a rule, such material has the form of a pipe “cocoon” made of mineral wool (withstands high temperatures) or polystyrene foam (moisture resistant). And how to insulate them, the question disappears in itself, since they have the appearance of a “cocoon”, which is put on top and fixed. There are main ones for chimneys of various diameters and temperature conditions.

However, if you decide to purchase sheet insulation, you may be faced with the question of how to glue it to metal? Aluminum tape will come to your aid, which is wound onto the insulation over the pipe. And, as in the options described above, you need to wear it with the shiny side facing you.

Is it possible to insulate the walls from the outside?

To insulate the walls from the outside, perforated foil insulation is used. This is a material that, among other things, has soundproofing qualities, can protect your home from moisture and wind, and also does not prevent moisture from leaving the room. This option is ideal for those who do not have the opportunity to perform such work indoors. However, such activities can only be carried out in the warm season and in dry weather.

To do this you will have to do the following:

- If you had any covering on the wall, you need to get rid of it. Then treat the surface with an antiseptic solution. It is better to do this in hot weather so that everything dries well; treat the lower part of the building especially carefully. Within two days the surface will dry completely.

- Next, build a frame from timber, secure it with self-tapping screws. Lay Penafol, then leave an air tunnel, glue the joints, then install the outer frame.

In conclusion, we suggest watching a video about the installation of Penofol thermal insulation:

Secret. How to glue foil insulation to a wall.

Kind. Somehow I encountered a problem with gluing foil insulation to the wall. There is a lot of information on this matter on the Internet. But I didn’t try what kind of glue I used, and in the end it didn’t work out. Everything was falling off. And the secret is simple. The insulation is covered with a thin polyethylene film, to which the glue does not stick (to a smooth surface, there is nothing for it to catch on). The manufacturer did not take this into account, or did not want to. It is enough to make the glue application areas rough, that is, sand them with sandpaper. You can use any glue, as well as polyurethane foam. And you won’t need a stapler, nails, dowels, or military-strategic toxic liquids - as mentioned in many construction forums. Good luck everyone, keep at it.

Minor observation. But many do not see the little things. Hence the big problems.

It is enough to make the glue application areas rough, that is, sand them with sandpaper.

And most importantly, why waste money on this and other materials and glue something that will not bring any effect.

jekasus wrote: And most importantly, why waste money on this and other materials and glue something that will not bring any effect.

I’ll support it. Apparently TS just has free material and needs to kill time.

jekasus wrote: And most importantly, why waste money on this and other materials and glue something that will not bring any effect.

Yes, I agree with you. But this effect does not consist in preserving heat; there is enough of it; water heating comes from the house. If you look more closely at the last photo - this is an extension to the future greenhouse on the north side, of course there will not be enough light for the plants. Reflective paint is not available. So the foil serves to reflect it. Even with artificial lighting, when entering a room at night it is impossible to look; the eyes are hurt by the bright, dazzling, iridescent light. (Checked, a few electric lamps are enough) This is a plus for energy saving. In general, the issue was not considered regarding the construction of greenhouses and where and why to glue foil insulation. The meaning is how to glue it!

ykamerton wrote: Yes, I agree with you. But this effect does not consist in preserving heat; there is enough of it; water heating comes from the house. If you look more closely at the last photo, this is an extension to the future greenhouse on the north side

Any other thoughts? Can you offer a photo?

ykamerton wrote: You can use any glue, as well as polyurethane foam.

More precisely, any contact adhesive. The polyethylene film does not spoil the matter much, because the foam material itself is also polyethylene. The most convenient way is foaming glue for PPS. Unlike polyurethane foam, it has almost no post-expansion. I successfully glued parquet boards to door slopes using it.

ykamerton wrote: the future greenhouse is on the north side, of course there will not be enough light for the plants. So the foil serves to reflect it.

plants in the north will wither and foil will not help. photosynthesis requires sunlight from the south, not your foil tricks. You can mock people by building rooms with windows facing north. But this trick doesn’t work with plants.

Apply polyurethane foam with a gun and press it with a large area panel for half an hour. For better adhesion, I made notches with a regular hacksaw. In slang, the process is called “combing”; it has been described many times on the forum.