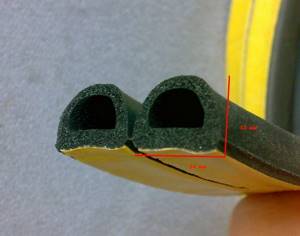

The main materials from which insulation is made are rubber, PVC, foam rubber and polyethylene foam. An adhesive composition, protected with special paper, is applied to one side of the insulating tape. When applying insulation, the paper is removed.

Insulation materials are supplied in the form of cut strips, combined into reels, or in the form of formatted rolls.

Rubber

They are distinguished by the lowest price among analogues. They retain heat effectively and are attached using glue or a stapler. One of the disadvantages is poor resistance to moisture: when water gets on the rubber, the material quickly peels off.

If you buy rubber insulation, then the softest one. Rigid models do not adhere well to the window and allow heat to pass through.

Polyvinyl chloride

Reliable and environmentally friendly insulation, which has good frost resistance and resistance to deformation.

When choosing, it is important to pay attention to the rigidity of the product: overly hard models will not adhere well to the surface. The service life is 2-3 years.

Foam rubber

Safe to use and reliable insulation. In addition to thermal insulation, they provide good protection from extraneous sounds. Foam insulation is supplied in the form of strips. The advantages of such seals include low cost and provision of air flow for the room.

However, in terms of thermal insulation, foam rubber is significantly inferior to PVC and polyethylene foam, plus it peels off from the surface quite quickly.

Figure: the shelf life of foam rubber is 1-2 years.

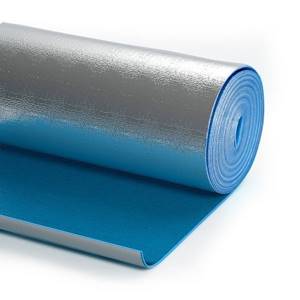

Polyethylene foam

They are bundles made of foamed polyethylene. They retain heat perfectly, provide sound insulation and even protect against moisture on the balcony. The most expensive insulation materials among those presented. Service life – 3-5 years.

Benefits and Features

The advantages and technical characteristics of self-adhesive insulation include:

- Frost resistance . Depending on the material from which the insulation is made, its thermal conductivity coefficient varies. However, for all of them it is at a high level: after application, the tape will maximally limit the contact of the room with the environment and prevent the appearance of drafts and cold bridges.

- Versatility . The insulation is suitable for cracks up to 7 mm wide.

- Reliability . The material is not afraid of temperature changes, moisture, and chemical influences.

- High-quality sound insulation . Most types of insulation can not only protect the room from frost, but also from extraneous sounds.

- Environmental friendliness . The materials do not come into contact with the environment or react with chemicals. Insulation materials are absolutely safe for human health.

- Convenience . Once applied, the insulation will not interfere with closing and opening windows. And the installation process itself will not require the help of specialists: the owner of the house will be able to insulate the window on his own.

- Low cost . Compared to other methods, self-adhesive insulation has an optimal combination of price and quality.

- Variety of colors . Among them are white, black, dark brown, which allows you to choose the material to match the windows, ensuring a harmonious appearance of the finished structure.

- Fire safety . The materials from which insulation is made are low-flammable and difficult to ignite.

The video shows self-adhesive foam insulation for windows:

One of the disadvantages of insulation is its fragility - the material is enough for one or two seasons. And also that the tape is not suitable for insulating plastic windows or loggias with double-glazed windows.

But this information will help you understand how a mortise seal is used for wooden doors and how installation occurs.

But this article will help you understand how to use foam insulation for windows and how to do it correctly.

But what self-adhesive insulation for metal doors is and how it is used correctly can be understood by watching the video in this article.

Application area

The product is used for interior and exterior decoration. Among the important features are water resistance, fire resistance, lightness and strength. In addition, the material is environmentally friendly, hypoallergenic and does not emit harmful substances.

Due to its technical characteristics and quality, the material is in demand in construction.

Applicable in the following areas:

- floor insulation;

- sealing windows and doors;

- wall protection;

- thermal insulation of pipes;

During installation, self-adhesive wall insulation is laid with the foil side up.

Definition of self-adhesive insulation

Materials with heat insulating properties are also used in the construction and renovation of buildings as hydro- and sound-proofing coatings. The main working layer, which provides heat retention, is polyethylene foam, which can be protected on one or both sides with a thin layer of aluminum foil. If a layer of foil is applied on one side of the thermal insulation, then the adhesive layer is applied on the back side of the material, and if the thermal insulation has two layers of foil, then the adhesive is applied to one of the aluminum layers. Before gluing begins, the adhesive layer is protected with paper or polymers that prevent damage or temporary adhesion of the adhesive layer during storage or transportation of the insulation. » alt=»»>

Joining the insulation

The demand for such materials is ensured not only by their small thickness, but also by the fact that self-adhesive insulation can be fixed to the surface without any tools or devices: just peel off the protective layer of paper. In addition, self-adhesive materials are often used not only as the main insulating layer, but as an addition to traditional thermal insulators - mineral wool, polystyrene foam, etc.

Penofol brand insulation

Advantages of self-adhesive insulation:

- The minimum thermal conductivity coefficient with the same minimum thickness of all known thermal insulators;

- High coefficient of reflection of light and thermal energy by the foil protective layer;

- Due to the foil coating of the surface, the material does not allow moisture to pass through and has a 100% vapor barrier coefficient;

- Any self-adhesive insulation is very simple and quick to install - you just need to glue it to a clean protected surface;

- Many options for making foil heat insulators (rolls, tapes, strips, patches) allow you to choose the right brand for any type of work and for any surface;

- Taking into account all the listed characteristics, we can talk about the cheapness of the material: self-adhesive materials with a foil surface are quite competitive with traditional insulation materials, but are many times superior to them in their qualities and parameters.

This is interesting: Only foil self-adhesive insulation reflects thermal energy outward in the warm season, and the feast of negative temperatures retains thermal energy in the house. For comparison: traditional insulation materials have this effect only in 3% of the volume of foil self-adhesives. If self-adhesive materials are used for external insulation, it is first recommended to stick a perforated film material onto the surface to avoid the sheathing or frame getting wet when steam is generated from the moisture contained in the air.

Installation of thermal insulation

Facade thermal insulation: varieties

In Moscow, mats and thermal insulation boards for facades made from the following materials are in demand:

- glass wool;

- basalt wool.

Both options are light in weight, which means they do not create additional load on the building’s load-bearing structures, are not flammable, and demonstrate good sound insulation performance. They are not susceptible to mold, and insects do not grow in them. They are characterized by high vapor permeability - they do not retain moist air, allowing it to “pass” through the insulation (and then through the waterproofing layer). The thermal insulation properties of basalt and glass wool are approximately the same. These are durable materials - with proper use, the service life of basalt and glass wool thermal insulation is identical. During operation, they do not emit harmful substances, which means they are safe from an environmental point of view. Thermal insulation boards and mats are easy to install: installation will not take much time and money.

However, there are slight differences between these materials. Basalt has a higher melting point and is resistant to aggressive substances (alkalies, acids). Glass wool is less dense, has elasticity (since the material consists of long fibers) and is lightweight - it is about 2 times lighter than basalt, which is important for the facade.

You can choose and buy thermal insulation for facades in our online store - we offer both types of insulation. We cooperate with, whose products are of high quality and affordable prices.

Insulation Penofol is a new generation material for insulating rooms and pipes of various diameters. Insulation materials are made from foamed polyethylene with a foil coating. The areas of application of Penofol insulation are wide. They can be used to insulate walls both outside and inside the room. Thanks to high vapor and thermal insulation, the house maintains a favorable climate for living (cool in summer and warm in winter).

Penofol insulation materials are divided into several classes:

Attention! This price is for wholesale. Check the price in the price list.

Insulation PENOFOL 2000, Type A

Material based on blue closed-cell polyethylene foam, backed on one side with polished aluminum foil. Recommended for insulating large diameter pipes in heating systems, water supply systems and tanks. Used for internal insulation of walls, roofs, loggias.

The product is certified according to GOST R 56729-2015

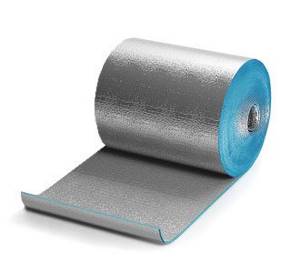

Insulation PENOFOL 2000, Type B

Material based on blue closed-cell polyethylene foam, backed on both sides with polished aluminum foil. An additional layer of foil allows the material to be used in structures with two air layers (reflect heat flow in both directions). Recommended for internal insulation of walls, roofs, loggias.

The product is certified according to GOST R 56729-2015

Insulation PENOFOL 2000, Type C

Self-adhesive material based on blue closed-cell polyethylene foam, backed on one side with polished aluminum foil. Recommended for insulation of ventilation and air conditioning systems, climatic chambers, refrigeration units, insulation of process equipment.

The product is certified according to GOST R 56729-2015

Penofol insulation has a number of advantages:

- made from environmentally friendly materials;

- easy to install;

- no protective clothing required during installation;

- prevents drafts in the house;

- penofol acts as reflective insulation;

- performs the function of sound insulation;

- provides comfort.

How to choose glue

There is a fairly wide range of different adhesives for sale for working with polyethylene foam. And it is advisable to make the choice using the following criteria.

- The temperature range must match this characteristic of the insulation.

- Adhesive properties must be extremely high.

- If you plan to use glue for interior decoration, it must be certified and non-toxic.

- If adhesive is selected for exterior finishing, it must be resistant to a variety of weather conditions and temperature changes.

- If you intend to finish the sauna and bathhouse, then the glue will need to be mixed with water-repellent agents.

Water-based adhesive is absolutely not suitable for working with isolon, because it does not allow the adhesive to penetrate into all the pores of the insulation. Consequently, the level of adhesion will be insufficient.

Advantages of our company

Tepofol is an insulation based on polyethylene foam, with different types of coatings:

As well as auxiliary materials for installation without heat loss:

The market for insulating materials is now quite wide. Tepofol is especially popular. Our insulation Tepofol is a complete analogue of Penofol. Tepofol is a common and inexpensive material that is widely used in almost any area of construction:

- Thermal insulation;

- Soundproofing;

- Waterproofing;

- Vapor barrier;

- Cold insulation;

Types of insulation

Self-adhesive thermal insulation is sold in the form of rolled tape or boards in white, brown or black. The 1 cm thick material is very durable and perfectly seals a variety of cracks up to 7 mm in size. The minimum price per square meter is 49 rubles.

The most popular is foil thermal insulation, which is made on the basis of foamed polyethylene. The material is foil foam and is equally in demand in everyday life and industry (food, oil and gas industries).

Foil insulation

Advice! There is no point in using simply foamed polyethylene, without foil, since there will be no insulation effect, which is confirmed by numerous reviews.

Tape insulation is most often used on old-style wooden windows. The material is attached to frames, replacing traditional paper tapes with soap. On faulty plastic windows, tape insulation is also sometimes used to close the cracks.

To ensure maximum sealing, foam and rubber thermal insulation is used, which is laid, as a rule, along the perimeter of one of the adjacent parts. The main property of such a material is the ability to compress as quickly as possible without harm to surfaces and then restore its shape.

Rubber self-adhesive insulation

The following raw materials are used for the production of self-adhesive insulation:

- rubber;

- penoplex (foamed polyethylene);

- PVC;

- foam rubber

Insulation foam NPE MK PET with adhesive layer

NPE MK PET foam film has the same characteristics as Penofol S. The insulation is reflective insulation, consisting of two parts: a duplicated metallized film and an adhesive layer.

In addition to thermal insulation, NPE MK PET foam acts as a vapor barrier and sound-absorbing product, is resistant to negative environmental influences and is easily attached to the surface.

The scope of application is wide. Can be used both for installing heated floors and for insulating baths.

Door insulation

When it comes to doors, there are a large number of seals on the market that would be suitable for this purpose. Now there are many different options that differ in thickness, height, width, purpose and material. They are used for both wooden and metal structures. It should be noted that seals of different materials should be used for interior and entrance doors. That is why this self-adhesive type device must be purchased carefully, carefully selecting what is really useful. If the door goes directly onto the street, then it is best to prefer options with a rubber base. Silicone and foam models will be an excellent option for interior structures.

Self-adhesive insulation for doors with foil is considered the best option, as it minimizes the percentage of heat loss. It is mounted on the inside of the door. First, you should completely clean the door from dust, degrease its surface, and only then glue the seal.

An important detail is that the foil layer should face where the heat source is, and not vice versa. If you glue the seal incorrectly, then there is no need to talk about preserving heat in the room. All the heat will constantly go into the wall. It will not be possible to accidentally mix up the sides, since foil is glued to the seal. Before purchasing, you need to pay attention to the shelf life of the material, its shape and condition. Preference should be given to the softest options, since hard ones will interfere when working with the structure.

Material characteristics

The basis is polyethylene foam with different structures and densities. A layer of foil and a self-adhesive coating are applied to the polyethylene base using heat welding. This multilayer structure provides the combined effect of penofol:

- foamed polyethylene, due to its large number of pores, creates a barrier to the movement of heated air;

- aluminum foil retains heat due to its reflective properties;

- The adhesive layer is similar in properties to adhesive tape and allows you to install the material without additional devices and compounds.

Penofol is able to retain up to 80% of the heat in a room, prevents the building from overheating in the summer and neutralizes the consequences of sudden severe frosts in the winter.

The characteristics of the material will depend on the type and thickness of the insulation. Average technical indicators of the material:

- reflection coefficient - 97%;

- heat transfer resistance - 1.2-1.23 m2xC/W (for material 4-5 mm thick);

- thermal conductivity - from 0.037 to 0.051 W/mK;

- resistance to ultra-low and ultra-high temperatures - from minus 60 °C to plus 100 °C;

- vapor permeability - 0.001 mch/mkhch Pa;

- water absorption by volume - from 0.35 to 0.7% (depending on type);

- specific gravity of material with a thickness of 4 mm - 44+/ - 10 kg/m3;

- dynamic modulus of elasticity under a load of 2 Kpa - 0.26-0.39 MPa;

- heat absorption coefficient - 0.45-0.51 W/(m²°C) for a design period of 24 hours.

Qualitative characteristics of penofol:

- no odor or harmful fumes;

- light weight, soft consistency;

- does not contain or create dust particles;

- impermeable to liquids, steam and solar radiation;

- absorbs mechanical vibration, sound waves;

- low flammability, high fire safety.

In terms of basic characteristics, insulation is similar to polystyrene foam, but surpasses it in mobility, ductility and dimensions.

The most popular adhesives on the market

As such, there is no universal option for all types of surfaces. However, among the most popular there are three: Signacool-300, Crones-colfix Eticol-909, K40K2. They are most widely used when applying labels to glass surfaces: alcoholic and non-alcoholic drinks, canned food, medications, and so on. They are characterized by a high level of viscosity and increased setting speed. At the same time, they are quite resistant to high and low temperatures and high humidity.

In addition to easy application and high strength, such adhesive compositions are very practical for reusable containers. In order to remove the label, it is enough to treat it with a slightly alkaline aqueous solution. A 1-3% solution of caustic soda is well suited for these purposes. An excellent option for saving on the production of new packaging. However, at the same time, it can cause a deterioration in environmental performance at the enterprise and the appearance of a large amount of unusable water. Among other disadvantages of such adhesive compositions, one can highlight strict requirements for their storage and operation.

The most universal are adhesive compositions based on synthetic adhesives. And their main advantage is that there is no need to use weakly alkaline solutions to remove the label. On the other hand, this means that the label is not held as firmly as is sometimes necessary. Even without this there are some difficulties. Removing the label is in most cases not a problem at all. However, removing glue residue is a much more difficult task. It is necessary to use a large amount of water and special equipment for surface treatment. Otherwise, marks will remain, and the new label will stick much worse on such a surface.

Types of adhesives for labels

As you can see, there is no ideal option for all cases. Therefore, we will consider several types of glue, which are no less widely used in the production of labels:

- Permanent glue . Refers mostly to the species discussed above. High adhesive properties and strength are an advantage for the buyer and, in some way, a disadvantage for the manufacturer. It is physically impossible to remove such a label without damaging the product itself or leaving marks. Accordingly, this implies some difficulties for product manufacturers in the issue of container processing.

- Semi-permanent adhesive . The peculiarity of this composition is that the sticker can be easily removed within 24 hours after gluing. With longer contact with the surface, it becomes permanent and the label becomes more difficult to remove. This allows you to quickly eliminate defects when gluing packages in production.

- Removable adhesive. Compared to others, it has rather low adhesive properties. You can easily remove such a label, and there are practically no traces of glue left on the surface. All residue can be easily removed with a sponge and warm water. Currently, there are also ultra-removable adhesives, which have extremely low adhesive properties;

- Acrylic adhesives . A distinctive feature is very high adhesion, resistance to aging, ultraviolet radiation and other factors.

- Rubber-based adhesives. They have even higher adhesive properties than acrylic ones. But in a number of stability characteristics they are slightly inferior. At the same time, we should not forget that this is mostly a natural product, which is more environmentally friendly and safer for human health.

Useful tips

Recommendations from experts on the selection of heat-insulating materials will help you choose the most suitable option, which will have excellent quality and properties:

- Foam rubber and silicone thermal insulation options are ideal for interior doors.

- For a door facing directly onto the street, rubber-based insulation is suitable.

- When purchasing self-adhesive insulation, pay attention to its expiration date, condition and shape.

- Be sure to carefully follow the instructions during installation.

- It is better to seal narrow cracks with rubber-based thermal insulation (rubber insulation), wide and uneven cracks with silicone, as it has better ductility.

Self-adhesive insulation is ideal for building facades and indoors, easy to install and environmentally friendly. The structure of the material makes it possible to protect surfaces from condensation, high humidity and steam.

Sale of insulation Penofol 2000 - characteristics, properties, price

Self-adhesive foil penofol is a polyethylene insulation with a foil self-adhesive coating. Of all the Penofol variants, Penofol 2000 is the most famous and popular.

This insulation is obtained by foaming ordinary polyethylene until a special cellular mass is formed, creating an effective air-bubble structure with excellent thermal insulation characteristics.

A unique feature of the foil self-adhesive insulation Penofol 2000 is not only its low price, but also its excellent heat-shielding characteristics with a relatively small thickness of the polyethylene layer.

Buyers consider Penofol’s great advantage, or rather convenience, to be the presence of an adhesive layer with the properties of adhesive tape, which allows for quick and accurate installation of insulation.

Our company is the official representative of ZAO Zavod Lit, which produces self-adhesive foil penofol, and therefore you can buy it at a favorable factory selling price.

Unlike basalt insulation or basalt slabs, which have a decent thickness and are used in the same way as foamed polyethylene foam for insulating walls, floors and roofs, the thickness of Penofol is measured literally in millimeters - from 3 to 5 mm (ultra-thin insulation) and from 8 to 10 mm (thin insulation).

Such a small layer size makes it possible to use this insulation where saving working space is required. For example, Penofol 2000 is used for insulation of loggias and balconies, heat and sound insulation of cars, reflective insulation behind heating radiators, as well as when using a large number of heating appliances or refrigeration units.

Penofol type A

Penofol type B

Penofol type C

CJSC LIT produces Penofol insulation of three different types:

- Penofol type A - foamed polyethylene, foil-coated on one side;

- Penofol type B - foamed polyethylene, foil-coated on both sides;

- Penofol type C is polyethylene foam, foil-coated on one side and having a self-adhesive layer on the other;

The aluminum coating of Penofol has a high heat-reflecting ability, and the polyethylene itself has extremely low thermal conductivity, due to which it is able to very effectively remove heat from the contact surface.

The most popular insulation on the domestic market is self-adhesive Penofol Type C, because on one of the sides it has a sticky layer consisting of a highly adhesive adhesive composition resembling scotch tape in its properties.

Foamed polyethylene is, in fact, small air bubbles enclosed in a cellular polymer shell. Therefore, thanks to this waterproofing structure, Penofol has another very important characteristic - effective moisture and vapor barrier.

This expands its use not only as a reliable thermal insulation material, but also as a highly effective waterproofing agent that prevents the penetration of water vapor and moisture through walls and partitions in residential and industrial premises.

Insulation with Penofol does not require special technical knowledge, because Installation of this insulation is very simple. It is only necessary to take into account the scope of its use and the characteristics of the tasks being solved.

The main advantages of foil penofol (self-adhesive)

Distinctive characteristics of Penofol and Penofol 2000 insulation

Due to the fact that foamed polyethylene has a very low thermal conductivity coefficient - 0.037-0.052 W/m °C, and the foil layer is capable of reflecting up to 97% of the heat flux, Penofol (2000) is a highly effective heat-insulating material that can efficiently remove incoming thermal energy from the contact surface or limit its heat exchange with the environment as much as possible.

The air-bubble structure of foamed polyethylene does not allow moisture to pass through at all, thus acting as a kind of barrier to the spread of water vapor or the penetration of precipitation.

This distinguishes Penofol from other waterproofing materials and allows for reliable and effective waterproofing of building structures and structures.

Studies have shown that Penofol is a good noise insulator, especially in the low frequency range from 120 to 3600 Hz, and is capable of attenuating low-frequency noise with high efficiency (up to 50%): hum, stomping, sounds of operating equipment.

This feature of Penofol, together with the small thickness of the polyethylene layer, makes it an indispensable material for soundproofing the engine and car interior.

The polymer molecular chains of polyethylene are similar to long intertwined threads. If, in addition to foaming, Penofol undergoes additional processing, called chemical or physical “cross-linking” of its molecules (this creates additional transverse intermolecular bonds), then this further strengthens its structure and gives it increased strength and flexibility.

In addition, the foil layer, which is bonded to polyethylene, is not a smooth, but a ribbed surface, which allows it to be bent without fear of breaking through on complex surfaces.

The small thickness of Penofol is another of its strong advantages. It is not possible everywhere to provide high-quality thermal insulation with dense and thick thermal insulation materials.

Penofol is chemically inert. It does not react with the contact surface or the external environment. It is environmentally friendly and absolutely harmless to humans and animals. Does not cause allergies and is not subject to rotting.

— very carefully monitors the environmental condition of its products and has all the necessary environmental and sanitary safety certificates.