Over time, the heating system becomes dirty inside. Not only scale, but also dirt, debris, iron oxide and other deposits accumulate on the pipe walls. The thermal conductivity of the pipes decreases, and more energy is needed to warm the air in the room to a standard temperature. Corroding areas spread over a large area, which over time leads to damage to the integrity of the pipes and reduces their service life. Therefore, the internal surface of the circuit and other elements of the system requires periodic cleaning. For this, various chemical compositions are used. Here are the TOP 10 products that will help you cope with the task.

Signs of circuit contamination

The system must be flushed in the following cases:

- the temperature in the room dropped without reason while the boiler was on;

- pipes heat up slowly;

- with a hot pipeline, the radiators remain cold;

- the integrity of the pipes is compromised, fistulas appear and ruptures occur;

- The boiler is noisy.

In addition, the heating system must be flushed immediately after installation. During equipment installation, debris, oils, and other products may have gotten inside.

The heating system must be flushed immediately after installation.

When is system flushing required?

Signs indicating the need to remove dirt and plaque:

- The temperature on the surface of the devices decreases significantly.

- The interval between turning on the heating system and completely warming up the radiators to the required levels increases.

- The batteries warm up unevenly, you can feel it to the touch: warm bottom, cold top.

- When radiator heating is completely absent, only the pipes remain hot.

- The monthly heating bill is increasing.

TOP 10 products and liquids for flushing heating systems

| Photo | Name | Rating | Price | |||

| Ready solutions | ||||||

| #1 |

| HeatGUARDEX Cleaner 808R | ⭐ 100 / 1004 — votes | Find out the price | ||

| #2 |

| GEB G30 Desembuant | ⭐ 99 / 1005 — votes | Find out the price | ||

| Powders | ||||||

| #1 |

| SteelTEX ZINC | ⭐ 100 / 1001 – voice | Find out the price | ||

| #2 |

| G63 | ⭐ 99 / 100 | Find out the price | ||

| Concentrates | ||||||

| #1 |

| SYNTILOR Watesup All | ⭐ 100 / 1001 – voice | Find out the price | ||

| #2 |

| YNTILOR Watesup | ⭐ 99 / 1001 – voice | Find out the price | ||

| #3 |

| TELAKKA HEAT | ⭐ 98 / 1002 — votes | Find out the price | ||

| #4 |

| Heat Guardex Cleaner 824R | ⭐ 97 / 1002 — votes | Find out the price | ||

| #5 |

| ARGUS SUPER POWER | ⭐ 96 / 100 | Find out the price | ||

| #6 |

| DIXIS LUX | ⭐ 95 / 1001 - voice | Find out the price | ||

Which heating system flushing product would you choose or recommend?

Take the survey

Washing methods

There are two ways to clean the internal surface of batteries: mechanical and chemical.

Chemical cleaning methods include household cleaning products that have a chemical effect on contaminants. Such substances are:

- lemon acid;

- household chemicals containing caustic soda;

- means for cleaning car radiators.

All the substances described above clean well, for example, cast iron radiators, but with varying effectiveness.

The product for car radiators is considered the most effective, but it is not cheap. Acetic acid removes contaminants in the form of salt deposits. But if there is a fairly large layer of deposits in the batteries, then with such a product you will not be able to completely get rid of it.

Citric acid copes much better with complex stains.

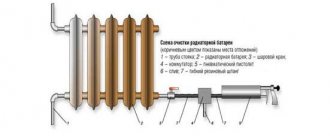

The mechanical method includes flushing the heating system by tapping the radiator body. This way the plaque will peel off from the surface.

Clean the batteries at the end of the heating season.

In order to perform the best possible cleaning of batteries, you should:

- First of all, unscrew all the plugs, insert the supplied hose into each hole one by one and rinse the radiator with water.

- After all three holes are plugged, you need to add dishwashing detergent to the water through the fourth. The remaining hole must be closed and the radiator itself must be moved. Caustic will dissolve organic pollutants and with the help of citric acid it will be possible to get rid of salt deposits.

- At the next stage, you need to unscrew the plugs, drain all the liquid and add water with dissolved citric acid. After which all holes are closed for several hours.

- When the specified time has passed, the water must be drained.

Thus, by following all the above steps, you can clean the batteries well.

Powders

G63

The powder removes scale from the heating system. The finished solution is compatible with cast iron, metal, and aluminum surfaces. When saturated with scale, the solution turns brown. The product is used in a concentration of 25–100 g/l of water. Washing is carried out at a temperature of 30...40 °C.

Price: from 61$/2 kg.

Descaling powder - G63

pros

- with corrosion inhibitor;

- contains a scale saturation indicator;

- suitable for steel;

- The line includes an acidity neutralizer;

- contour processing in 45 minutes.

Minuses

- high price.

SteelTEX ZINC

The drug is compatible with most metals used in heating systems, enameled surfaces and zinc. Before pouring the finished solution into the system, mix it with water until a concentration of 7–15% is achieved; more powder is added during the washing process. The composition includes an indicator of residual acidity. It is recommended to use it with a neutralizer of the same line, which will enhance protection against metal oxidation.

Price: from 4557 rub./5 kg.

SteelTEX ZINC

pros

- the solution can be poured into the sewer;

- compatible with most metal surfaces;

- anti-corrosion protection.

Minuses

- No.

SteelTEX ZINC

Facilities and equipment

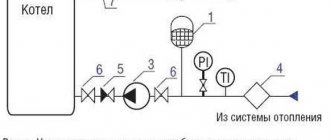

Scale and rust reduce thermal conductivity. To maintain temperature conditions, it is necessary to increase fuel consumption and budgetary funds. Equipment such as a compressor is used for washing.

Cleaning the system with special equipment

Attention! Within 10 years of operation, the pipeline without cleaning can become clogged by 50%. One millimeter of layering on the inner walls increases fuel consumption by 25%. If you do at least one cleaning, the heating efficiency increases and budget costs are reduced.

Selecting equipment for flushing heating

Electronically controlled devices are considered the best equipment.

When using them, there is not a simple supply of chemical solutions or streams of compressed air, but a complete analysis of the intensity and nature of vibrations in the circuit. The operator is only concerned with timely regulation of the frequency and power of the pulses.

The devices are equipped with special sensors that monitor pressure and fluid flow and protection in case of unexpected activation.

Washing technology

First, it is necessary to check and assess the condition of the system. Afterwards, the cleaning method and equipment mode are determined. There are 2 ways:

- Filling method. The pipeline is filled with pure liquid or with chemical impurities. After 30 minutes the compressor turns on and compressed air is supplied. The supply valve is closed and the drain valve opens. Dirt is thrown out through it. The procedure is repeated until the water becomes clear.

- Flow washing method. This is a continuous supply of liquid with compressed air into the heating system. The growths on the walls peel off and are instantly removed.

Not every compressor unit is designed for two cleaning methods and can only supply water or compressed air. Ask the seller about technical specifications.

Ready solutions

GEB G30 Desembuant

The product can be used not only in metal, but also in plastic pipelines. 1 liter of solution is designed for 100 liters of coolant.

Price: $14.

GEB G30 Desembuant

pros

- suitable for plastic pipes;

- compatible with underfloor heating systems;

- small expenditure of funds.

Minuses

- high price.

HeatGUARDEX Cleaner 808R

A product based on hydrochloric acid is designed to combat long-term deposits older than 3 years. The manufacturer promises that flushing with the drug will extend the life of the heating system by 10 years. 1 liter of the drug is designed for 100 liters of coolant.

Price: 3990 rub./l.

HeatGUARDEX Cleaner 808R

pros

- easy to use;

- effective in combating heavy pollution.

Minuses

- not identified.

Filter materials for water treatment systems HeatGUARDEX Cleaner 808R

Why is regular maintenance essential?

In addition to the occurrence of emergency situations, the accumulation of scale in a pipeline heating system also sharply reduces its efficiency. Thus, just a millimeter of scale on the inner surface of a heating radiator reduces its heat transfer by 15 percent. Accordingly, in order to achieve a normal temperature in the house, you will have to increase the power of the boiler, and therefore increase fuel costs. In order not to incur extra costs, you need to clean the system.

The accumulated scale on the internal surfaces of the system has a much lower thermal conductivity than conventional metal used to make pipes. Scale is essentially a heat insulator - its thermal conductivity is 40 times less than that of metal. Even a thin layer of scale reduces the efficiency of the heating system to minimum values. Moreover, scale actively interacts with the metal of the pipes, which leads to increased corrosion and even the formation of fistulas.

Before and after washing

In order to improve the quality of operation of the heating system, it is not necessary to wait for emergency situations. Such work must be carried out regularly, usually at least once a year.

Comparison of consumption and cost of different heating system cleaning products

| Type | Name | How to breed | Cost per 1 liter (kg), rub. |

| Concentrates | DIXIS LUX | 1 liter per 10 liters of water | 153 |

| ARGUS SUPER POWER | 1 liter per 10–15 liters of water | 300 | |

| Heat Guardex Cleaner 824R | 1 liter per 30 liters of water | 6400 | |

| TELAKKA HEAT | 1 liter for 5–10 liters of water | 450 | |

| SYNTILOR Watesup | 1 liter for 5–15 liters of water | 480 | |

| SYNTILOR Watesup All | 1 liter for 5–15 liters of water | 320 | |

| Powders | Descaling powder - G63 | 25–100 g/l | 2250 |

| SteelTEX ZINC | 1 to 15 | 911 | |

| Ready solutions | GEB G30 Desembuant | 1 to 100 | 975 |

| HeatGUARDEX Cleaner 808R | 1 to 100 | 3990 |

How to choose a liquid for flushing the circuit?

It is necessary to select a means for flushing the circuit taking into account the material from which the pipes and radiators are made. This information is indicated in the instructions for the drug.

The type of coolant also matters - water or antifreeze (propylene glycol, ethylene glycol, glycerin). Thus, systems operating on “anti-freeze” systems are characterized by the deposition of sludge and glycol residues formed during the decomposition of the coolant. Other active ingredients are used to dissolve them.

Ideally, before flushing the circuit, regardless of the type of coolant, it is recommended to analyze the composition of the coolant and, depending on the substances contained in the circulating medium, select a product. But it is clear that at home no one will burden themselves with unnecessary complications. Therefore, masters use the product they trust the most.

Means and liquids for flushing heating systems

Dosage forms

Reagents for flushing the heating system are divided into three types according to the dosage form:

- powders;

- concentrates;

- ready-to-use formulations.

Powder and concentrated forms are diluted with water before use. The third type is immediately poured into the system.

Active substance

Circuit cleaning products are usually based on acids - citric, phosphoric, hydrochloric, acetic, citric. Alkali-based detergents are also produced. The second ones clean more delicately. But they are usually used only in certain areas - for example, to clean the membrane.

Flushing the boiler circuit with a special liquid

Attention! Acidic products must be used with extreme caution on old metal pipes. If pockets of corrosion have formed on the inside, then under the influence of acidic agents, a leak may occur in these places after cleaning.

Other components

In addition to acids and alkalis, the composition includes surfactants - surfactants that wash away the dirt accumulated inside the circuit and prevent it from re-settling on the pipe walls. The rinses also include components that prevent metal corrosion.

Some manufacturers add color indicators to indicate the chemical activity of the product. If the color changes at the very beginning of the wash, this means that the concentration is too low and needs to be increased.

Attention! Spent products are often prohibited from being discharged into the sewer system. First it must be neutralized with a special solution.

But some manufacturers add additives to their products that make the cleaner biodegradable. This point should always be clarified in the instructions or with the seller.

Video - What is better for the heating system: water or anti-freeze

Cleaning batteries yourself

Radiators that have been operating in a heating system for many years invariably become dirty. This fact must be accepted and acted upon using preventive methods. After all, the cleaner the equipment, the more powerful it is, and accordingly, the house will be warmer and more comfortable. The self-cleaning procedure is not complicated and is performed in several stages.

Preparing and dismantling the radiator

To properly clean the “insides” of the radiator, it is disconnected from the communications and removed from the brackets. It is best to take the equipment outside, otherwise the process may become somewhat more complicated, and the smells will not be pleasant.

With central heating, you need to make sure that there is no water in the system. If the heating is autonomous, you will need to drain the coolant.

The threaded clamps on the battery are unscrewed, for which you will need an adjustable wrench. It is better to place something under the joints of the pipes with the radiator, since liquid may remain inside.

Cleaning the Batteries

First you need to decide what method will be used to clean the radiator - chemical or mechanical. Regarding the first, household cleaners are usually used.

Contaminants are removed using:

- household cleaners containing caustic soda;

- citric acid;

- acetic acid.

Cast iron radiators can be easily cleaned with these products, but the effectiveness may vary. Acetic acid, for example, easily copes with salt deposits, but it cannot cope with significant deposits. Citric acid, being more chemically aggressive, is more effective against salt. As for caustic soda, it is found in many dishwashing detergents. The product is rather weak for removing salt deposits, but it will cope with other contaminants.

To achieve high-quality cleaning of a cast iron battery, it is recommended to alternate chemical and mechanical methods.

The procedure consists of the following steps:

- The plugs are unscrewed, a hose is inserted into them one by one and water is supplied. This simple manipulation will allow you to clean the inside of the pipes well, which will be noticeable by the leaked liquid.

- Next, three holes are plugged, and through the remaining radiator the radiator is filled with water, to which you must first add dishwashing detergent. As far as strength allows, the battery needs to be moved. Caustic salt will remove organic dirt, thereby clearing the way for a more serious remedy - citric acid.

- The plugs are unscrewed, the liquid is drained, and water diluted with citric acid is poured inside again. Then you need to close all the plugs and leave the equipment for a couple of hours. If possible, it is recommended to heat water with acid, which activates chemical processes.

- After two hours, the water is drained. Next, you need to tap the battery case with something wooden or a hammer with a rubber head. This is done so that softened salt deposits are removed from the internal surfaces of the equipment. Now water is added to the radiator again to wash away the residue.

- The battery is cleaned of dust and dirt from the outside and connected to the pipeline.

The DIY cleaning process is not that complicated and does not require special knowledge. The only difficulty you will have to face is the heavy weight of the equipment. Therefore, it is good if there is an assistant nearby.

Flushing technology

To flush with chemicals you will need:

- the remedy itself;

- a container into which the liquid will be drained;

- pump;

- hoses.

Important! When working with substances, you need to wear personal protective equipment. If a chemical reagent gets on the skin or mucous membranes, you need to rinse the area with plenty of running water and see a doctor.

Washing with solutions is carried out in the following order:

- Water is drained from the heating system.

- Mix the powder or concentrate in the proportions specified by the manufacturer.

- Pour in the cleaning solution. 1 liter of the drug usually corresponds to 1 liter of the volume of the heating system element. That is, a pipeline volume of 100 liters will require the same amount of liquid.

- Connect the pump and pump the chemical through the circuit for several hours.

- Drain the detergent.

- Refill the system with water.

When using ready-made solutions, drain the coolant from the system in a volume corresponding to the amount of cleaning agent and replace it with a cleaner. In this case, washing may take longer - up to 5 days. After this, the contents of the circuit are removed, the system is washed, and then water or “anti-freeze” is poured into the pipes.

Attention! It is recommended to carry out flushing every 2–3 years.

Timely flushing will extend the life of the heating system. In addition, you will not have to overuse energy resources to ensure a comfortable microclimate in your home.

Video - Do-it-yourself flushing of a heating battery using a vibration pump

Bucha: washing equipment

The installation for cleaning the Bucha heating system is a compact and portable compressor with a pulse pneumatic generator. All layers can be easily removed without the use of chemicals.

Bucha-K

It is enough to flush the system once to carry out high-quality cleaning of heating equipment. The device is compact, designed to remove deposits and prevent clogging.

The Bucha-K compressor is used for flushing Russian-assembled heating appliances, which is better than all foreign analogues in terms of price and quality.

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...

Voting for the best means for flushing heating systems

Which heating system flushing product would you choose or recommend?

HeatGUARDEX Cleaner 808R

23.53% ( 4 )

GEB G30 Desembuant

29.41% ( 5 )

SteelTEX ZINC

5.88% ( 1 )

G63

0.00% ( 0 )

SYNTILOR Watesup All

5.88% ( 1 )

YNTILOR Watesup

5.88% ( 1 )

TELAKKA HEAT

11.76% ( 2 )

Heat Guardex Cleaner 824R

11.76% ( 2 )

ARGUS SUPER POWER

0.00% ( 0 )