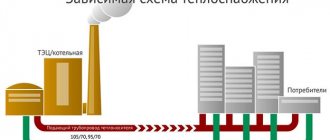

Dependent

This connection scheme, as a rule, provides for the presence of in-house heating points, often equipped with elevators. In the mixing unit of the heating station, superheated water from the main external network is mixed with the return water, thereby acquiring a sufficient temperature (about 100°C). Thus, the internal heating system of the house is completely dependent on external heat supply.

Advantages

The main feature of this scheme is that it provides for the supply of water to the heating and water supply systems directly from the heating main, and the price pays off quite quickly.

- subscriber input equipment is simple and inexpensive;

- heating systems can withstand large temperature changes;

- the diameter of the pipeline is smaller;

- the circuit reduces coolant consumption;

- low operating costs.

Flaws

Along with the advantages, such a connection also has some disadvantages:

- uneconomical;

- temperature control is significantly difficult during weather changes;

- overconsumption of energy resources.

Connection methods

Connection can be made in several ways:

- through direct connection;

- with elevator;

- with pump on jumper;

- with a pump on the return or supply lines;

- mixed method (pump and elevator).

Connection with elevator.

Types of heat supply systems

The term “ heat supply” refers to the provision of thermal energy to consumers. The term “heat supply system ” means a set of interconnected power plants that supply heat to a city, region, or enterprise.

The main elements of the heat supply system are the heat source (thermal power plant or boiler house), heating networks, and consumer installations.

The heat source is the determining element of the heat supply system: its power and location influence the type, linear dimensions, and equipment of the remaining elements of the heat supply system.

Depending on the location of the heat source, heat supply systems can be decentralized or centralized.

Centralized heat supply is divided into district heat supply from quarterly and district boiler houses and district heating from combined heat and power plants (CHP).

A feature of decentralized systems is that the heat source is located in close proximity to thermal energy receivers (consumers). In such systems, the length of heating networks is, as a rule, small, which allows transport of coolant with virtually no heat loss.

Decentralized heat supply systems are divided into individual and local. In individual heat supply systems, the heat source is designed to supply thermal energy to a separate room. In local systems, heat is supplied to a separate building from a heat source. An example of an individual system is an apartment heating and hot water supply system, where a wall-mounted gas boiler acts as a heat source. However, the installation of such systems requires additional capital investments during their construction. Thus, the placement of wall-mounted gas boilers in each room of the building requires the installation of additional exhaust and supply ducts, a fire-fighting water supply system, and the installation of booster pumps at the water supply inlet into the building for the uninterrupted operation of gas boilers.

Local systems, as opposed to individual ones, have become more widespread in domestic heat supply. Currently, there is a large range of domestic and imported low-power household boilers that can be used in local systems as heat sources.

For the application of both local and individual heating systems, a detailed feasibility study is required by comparison with centralized heating systems.

In centralized heat supply systems, the heat source and heat receivers (subscribers) are located, as a rule, at a considerable distance. The presence of large heat transport systems, the length of which can exceed 10 km, is a distinctive feature of centralized systems from local or individual ones. Significant disadvantages of large heat transport systems are significant heat losses, caused, as a rule, by the imperfection of existing designs of thermal insulation of heat pipelines, and the inertia of heat supply systems: when the temperature of the network water changes at the heat source, the transport delay at the most remote consumers can be several hours.

Based on the type of coolant, heating systems are divided into water and steam.

Water systems are used mainly for heating, ventilation and hot water supply, and in some cases for technological processes. Steam heat supply systems in our country are widespread mainly in industrial enterprises where high-temperature heat loads are required.

According to the method of supplying water to hot water supply (DHW), water heating systems are of two types: closed (closed) and open (open). In closed

systems, water circulating in the heating network is used only as a heating medium for heating tap water in surface heaters, which then enters the local hot water supply system; Water is not taken from the heating network.

In open

In heat supply systems, hot water is supplied to the water taps of the local hot water supply system directly from the heating network.

Depending on the number of pipelines used to supply heat to a given group of consumers, water systems are divided into one-, two-, three- and multi-pipe.

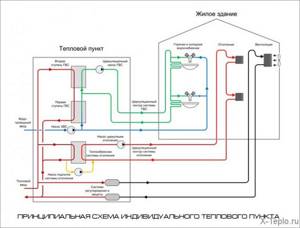

An important element of centralized heat supply systems are heating points

– thermal units designed to distribute coolant by type of heat consumption.

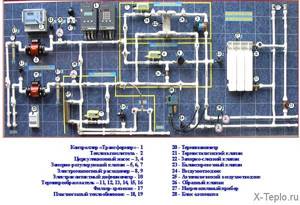

Equipment, fittings, monitoring, control and automation devices are placed at the heating point, through which the following are carried out: converting the type of coolant or changing its parameters; control of coolant parameters; accounting of thermal energy, coolant and condensate costs; regulation of coolant flow and its distribution among heat consumption systems; protection of local systems from emergency increases in coolant parameters; filling and replenishing heat consumption systems; collection, cooling, return of condensate and quality control; thermal energy accumulation; water treatment for hot water supply systems.

A heating substation serving two or more buildings is called a central heating substation

.

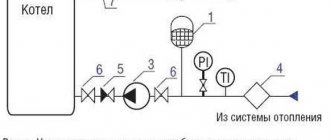

Independent

An independent heat supply system allows you to save consumed resources by 10-40%.

Operating principle

The consumer heating system is connected using an additional heat exchanger. Thus, heating is carried out by two hydraulically isolated circuits. The external heating circuit heats the water of the closed internal heating network. In this case, mixing of water, as in the dependent version, does not occur.

However, such a connection requires considerable costs for both maintenance and repair work.

Water circulation

The movement of the coolant is carried out in the heating mechanism thanks to circulation pumps, due to which there is a regular supply of water through the heating devices. An independent connection circuit may have an expansion vessel containing a supply of water in case of leaks.

This connection method allows you to maintain the circulation of water with a certain amount of heat in case of heating main failures. Those. During an emergency, the temperature in heated rooms will not decrease.

Components of an independent system.

Scope of application

Widely used to connect multi-storey buildings or structures to the heating system, which require an increased level of reliability of the heating mechanism.

For facilities that have premises where access to outside service personnel is undesirable. Provided that the pressure in return heating systems or heating networks is higher than the permissible level - more than 0.6 MPa.

Advantages

- possibility of temperature adjustment;

- high energy saving effect;

- possibility of using any coolants.

Negative points

- high price;

- difficulty of maintenance and repair.

Energy dependence of the heating system

Energy dependence refers to the ability of heating to operate in the absence of power supply. Energy independence may be needed in cases where there is a danger of frequent and prolonged power outages. You can, of course, install emergency power supply in your home: an electric generator or batteries with an inverter. The automation will start emergency power supply immediately after the loss of power in the network. But equipment costs money and not everyone is ready to spend the money. How to ensure energy independence of heating?

Firstly, to provide energy-independent heat generation. Finding a solid fuel boiler that does not require an electrical connection is not a problem. But the vast majority of pellet, liquid fuel and especially gas boilers are equipped with automation, which does not work without power supply. However, you can find models with simpler controls. But you need to understand that you should not expect special efficiency and high comfort from a non-volatile gas boiler.

Gas non-volatile heating boilers are equipped with simple controls. Piezoelectric ignition, the specified level of coolant temperature is maintained

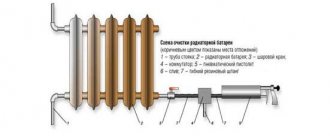

Secondly, to ensure effective circulation of the coolant. The movement of liquid through pipes and heating devices can be carried out naturally (gravitational) or forced (circulation). Let's briefly explain these concepts:

Gravity (non-energy independent) heating

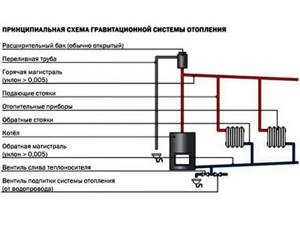

The movement of liquid in a gravitational system occurs due to differences in the densities of the heated and already cooled liquid. The hot coolant leaving the boiler has a lower density and volumetric weight than the coolant that has already passed through the pipes and batteries and cooled down. Accordingly, heated water constantly rises, while cooled water sinks down. As long as there is a sufficient temperature difference, the coolant circulates. For normal operation of the gravitational system, a number of strict conditions must be met:

- The heating boiler must be installed at the lowest part of the system. Preferably in a pit if heating appliances are located on the same floor.

- All horizontal pipes must have a slope in the direction of flow of the coolant.

- The diameter of the pipes must be large enough to reduce hydraulic resistance. For an individual residential building this is approximately 35-50 mm.

The advantages of gravity heating include simplicity of design and energy independence. “Gravity” has a lot of disadvantages:

- Difficult to adjust, low efficiency.

- The natural pressure of the liquid is low, so the rate of passage of the coolant in the pipes is low, which is why the heating is very “thoughtful”, reluctant to warm up and does not quickly respond to changes in the operating mode of the boiler.

- The longer the pipelines, the weaker the circulation and the worse the heating of remote radiators. Horizontal branches over 30 m in length will not work properly at all.

- A low fluid flow rate corresponds to low heat transfer; the dimensions of heating devices have to be increased.

- It is impossible to install heated floors in a non-volatile gravity system; the choice of heating devices is limited to standard radiators.

- Thick distribution pipes that are difficult to hide do not look aesthetically pleasing.

Gravity heating is relatively simple in design, but it is necessary to strictly observe the necessary slopes along the flow of the coolant

Circulation (energy-dependent) heating

In a circulation system, the movement of the coolant is controlled by a circulation pump. The pump creates sufficient pressure to eliminate all the limitations associated with overcoming hydraulic resistance characteristic of gravity heating. The circulation system is completely devoid of the disadvantages of gravity. It uses small-diameter pipes without taking into account slopes, which makes them easy to hide in grooves or screeds. There are no restrictions on the height of the boiler; the expansion tank can be placed in the boiler room. In addition to wall-mounted radiators, heated floors, floor convectors are available; you can additionally heat air for supply and exhaust ventilation and water in the pool. The forced movement of the coolant makes it possible, with proper design and configuration, to constantly maintain the set temperature in all rooms. The heating heats up quickly and is sensitive to changes in the heating mode.

The circulation system is more economical, comfortable and aesthetically pleasing than the gravity system. Its only significant drawback is its energy dependence. In our opinion, the numerous advantages of the “circulation” system clearly outweigh its only disadvantage, and when choosing a heating system for a modern comfortable home, preference should be given to it. And you can insure against power outages by installing a generator or battery.

Example of circulation heating, pipe slopes are not particularly important

The gravity system also has the right to life in a country house or in a country house, which does not have high demands on interior aesthetics, comfort and heating efficiency. More logical is the combination of natural circulation with a solid fuel boiler. A rational solution is to install a circulation pump in parallel on the supply pipe of the gravity system. This will allow the heating to be operated in two modes: if electricity is available, it will work as circulation, more economically and comfortably. No electricity - operates in gravity mode. Less efficient, but it works.

A circulation pump is built into the gravity circuit, where all requirements for slopes and pipe diameters are met, so that the coolant can circulate both by gravity and by force

Basic heat supply schemes

Today in Russia there are two heat supply system schemes that differ in composition and design.

- The first option involves supplying heated water for heating and hot water needs through one transport network. Water is drawn from the supply main, which creates a situation where different volumes of water flow through two branches of the pipeline.

- According to the second scheme, heated water is supplied only for heating needs. To create hot water supply, tap water heating points with coolant are used.

The advantages of the first scheme are low cost of design (no heat exchangers required) and low cost of operation. The disadvantage is high water losses and deterioration in its quality.

The advantages of the second are stable temperature and water quality, ease of control. The disadvantage is the increase in the cost of hot water for subscribers due to the use and maintenance of additional equipment (boilers).

Important: developing a city heat supply scheme is the most important process for providing the population, industrial and cultural facilities with heat and hot water with minimal impact on the environment.