Home » Central heating » Combined

Owners of private houses who do not have the opportunity to install gas equipment can try the heating option with a combined heating system. Such heating heats the room efficiently, and creates comfort and coziness in it.

Combined heating system

Features of the mixed heating system

Before purchasing a heating boiler for a summer cottage or a private home, you need to familiarize yourself with the power parameters of the device. When designing such work, the area of the room and heating needs are taken into account. Various combinations of heating systems are considered, having three principles:

- thermal energy can be obtained from different sources;

- it is generated, stored and transformed. Subsequently, it is used rationally;

- a combined heating system can be created at the beginning of construction of a facility or already completed living space.

Quite often you can find a mixed heating system in private houses. This is very convenient and allows you to switch between different types of fuel.

The process of switching between fuel types does not take much time. There are no special changes in the equipment settings. Even due to different fuel prices, this option is more acceptable.

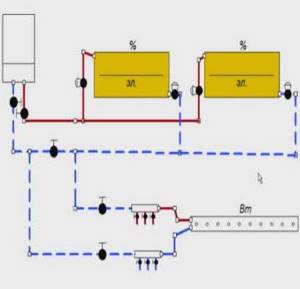

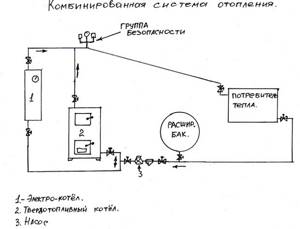

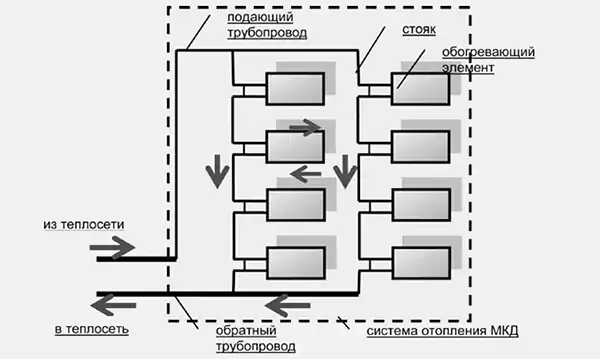

Combined heating system diagram

Gas + diesel heating

This combined heating system is a very common heating method. And this is due to the fact that the transition from one fuel to another is carried out only by such an action as replacing the burner. The burner is included with the device. When replacing, you do not need to perform complex setup operations, and the instructions will answer all questions. The simplicity of this operation is explained by the fact that the same combustion chamber is used for gas and diesel fuel.

If we evaluate it from a technical point of view, this is a very effective combination, although the cost of diesel fuel differs from the cost of gas.

Combination of gas and diesel boiler in the heating system

The service life of the device depends mainly on such a parameter as the quality of the heat exchanger. This element can be made of cast iron, steel, combined or separate. Many users of such a system say that if you have a gas main near your house, then it is better not just to install water heating, but to combine heating of the house with gas and diesel fuel. It is cheap not only when purchasing, but also in further work.

Design features

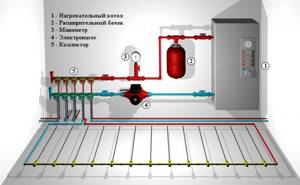

A heating boiler has several combustion chambers, usually two, for different types of fuel. One compartment, for example, is solid fuel, the second is liquid (diesel fuel or antifreeze). This combination makes it possible to connect an autonomous line and set individual temperatures in any part of the room. For example, one line supplies heat to radiators, the other to heated floors.

The latest models of combined heating in a private house have heating elements for heating with electricity. There are also types with gas burners or with compartments for diesel fuel. You just need to turn the switch to the desired position. To save money, it is recommended to use a heat accumulator. It is more expedient to use it in wood-burning boiler equipment. When using solid fuels, the power of the boiler equipment is not regulated, and the room becomes very hot. It is for these purposes that a heat accumulator is needed. It performs some functions:

We recommend: Features of combined heating of carriages

- conserves excess heat;

- in case of lack of temperature in the hot water supply or system, depreservation occurs.

Thanks to this, there is no need to constantly switch the boiler. It is enough to turn it on once.

Connecting several boilers or heat sources

The use of several boilers in one heating system is forced by the cold climate and unstable operation of electrical networks. It’s good, of course, to have an automated boiler, but until the electricity is turned off and the automation stops working. If it is -20°C or lower outside, even a few hours of inactivity can result in the system freezing. Therefore, a non-volatile solid fuel boiler is often placed in parallel with an electric automated boiler.

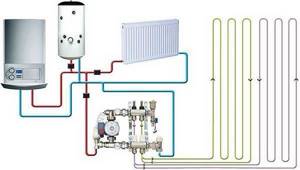

There are many schemes for connecting two boilers into one heating system, but the easiest way to implement this idea is using a heat accumulator. In this case, it is possible to operate one boiler or both at once, which can be a solution during abnormal cold weather. Another good thing about this scheme is that you can connect both underfloor heating and heating. You can also easily add one of the alternative heat sources. Solar radiators have become the most popular recently. They are connected to the free inputs of the heat accumulator.

Types of combined heating systems

A combined heating system for a private home can include various coolants, thanks to which the devices can be divided into the following types:

- gas plus diesel boiler equipment. This design can be made of cast iron or steel, or combines both materials. Owners of private houses with a gas pipeline nearby use combined boilers - diesel fuel plus gas. This boiler model is very economical;

- gas plus solid fuel equipment. This system combines gas mixed with solid fuel. Such equipment can be multi-fuel, since it is possible to use firewood and coal. This combined equipment is not entirely effective. The device does not have automatic switching. Even because the design is quite complex, such a device is in demand due to its low and favorable price;

- solid fuel plus electrical equipment. Combined heating of a private house with wood and electricity to heat the room, this combination can very often be seen in country houses. The power connection is to electricity - 220 or 380 Volts, with a power of 5-8 kW. While the owners are in the mansion, general heating is carried out with wood or coal; after leaving and burning the fuel, the temperature in the boiler drops and a relay is activated, turning on the electrical equipment. Thus, during the absence of the owners, the system itself maintains the desired temperature in the room. This device is not cheap, but the result is worth it. But you can be absolutely confident in the reliability of the device;

- gas plus solid fuel and electrical equipment. Perhaps, this type of combined heating boilers for a private home can rightfully be called the best. Because it already runs on three types of fuel, this means that the efficiency of the heating system increases. This design can be installed in any area, but must be equipped with a gas pipeline. If for any reason there are interruptions in gas and electricity, owners will always be able to use any type of solid fuel;

- pyrolysis plus electrodes. This device is suitable for heating a country house. By combining a pyrolysis and electrode boiler, it becomes possible to maintain the desired room temperature, even in the absence of the owners. The system consists of two multi-fuel devices and is very popular.

Solid fuel and electric heating

Option 1: convection and underfloor heating

Device

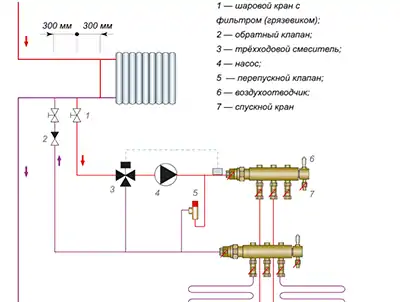

In one heating circuit, radiators and heated floors operate simultaneously or alternately. This scheme of work can be implemented in two ways:

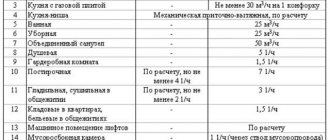

| Scheme | Description |

| The warm floor is powered from the radiator return . In this case, the return temperature at the outlet of the high-temperature circuit should not be higher than 40 degrees, and the boiler should be able to operate at a return temperature of about 30 °C. Of modern boilers, only gas condensing boilers are capable of this. The obvious disadvantage of such a scheme is the impossibility of independent operation of the circuits: if you turn off the radiators, the coolant temperature will be too high for a heated floor, and without an in-floor circuit, the return temperature at its inlet will rise to values unacceptable for the boiler. |

| The heated floor is connected independently of the radiators through a three-way mixer. Depending on the temperature at the outlet of the in-floor circuit, the mixing valve opens or closes, increasing or decreasing the amount of hot coolant from the supply in the recirculation circuit. Recirculation of the coolant in the low-temperature circuit is ensured by its own circulation pump. The circuit works with any boiler; the radiator and heated floor circuits can be turned on and off independently of each other. |

What materials should you prefer when installing such a system yourself?

Pipes:

- For radiator heating - inexpensive polypropylene with aluminum reinforcement. The temperature in the autonomous circuit does not rise above 80 °C, and the pressure does not exceed 2.5 kgf/cm2, which is exceeded with a margin by the operational parameters acceptable for polypropylene pipes. Reinforcement reduces the elongation of pipelines when heated: for unreinforced polypropylene it is 6.5 mm/linear meter when heated by 50 degrees, for reinforced with aluminum foil - 1.5 mm;

When heated, rigidly fixed unreinforced polypropylene pipes will wave due to elongation.

- For the heated floor contour - cross-linked or thermally modified polyethylene. Pipes are supplied in coils up to 200 meters long; this allows you to move all connections outside the screed.

Laying water heated floor pipes in a screed. For underfloor heating, a pipe made of thermally modified polyethylene PE-RT is used.

Radiators : aluminum sectional. The instruction is due to the fact that they combine high heat output (up to 210 watts per section) with low cost (from 240 rubles/section).

An aluminum radiator will provide an optimal balance of price and heat transfer.

Advantages

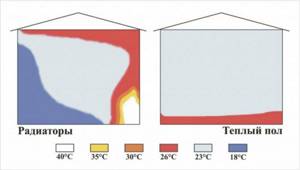

The disadvantage of radiator heating is the irrational distribution of temperatures in the heated volume. The air near the ceiling is several degrees warmer than above the floor. But the space under the ceiling is uninhabited, and heating it only increases heat loss through the ceiling and the top of the walls.

Warm floors are more economical: they heat the room from below; As you approach the ceiling, the temperature drops. A decrease in the average temperature in the heated volume leads to a decrease in total heat loss.

Air temperature in a heated room with convection and underfloor heating.

The disadvantage of a heated floor is that its temperature is limited to +35-+40°C. With a fixed heat exchange area and limited temperature, heat transfer is also limited, and with large heat losses it may be insufficient.

Radiators will help make up for the heat deficit. In an autonomous circuit, they can heat up to 75-80 degrees and, due to the greater temperature difference with the air, give off much more heat than a warm floor with the same surface area.

How to properly heat a private home

With a large selection of heating devices, you can’t help but try to heat the room yourself; for this you need to know some rules and be able to use the equipment. Nowadays, country life has become a priority. There is a 24-hour hot water supply. It became possible to heat the room at will. You can heat it hot, or, on the contrary, you can make it cooler. It all depends on the wishes of the owners.

We recommend: Features of combined heating of carriages

In order to equip a combined heating system, it is necessary to draw up a project. It must be approved by the relevant organizations. If mixed heating includes gas equipment, you will have to suffer even more with other documents and their certification.

Heating a private house

The mixed type of heating the premises of a private house is a real breakthrough in the field of heat provision. Modern boiler equipment uses different fuels - it all depends on individual needs. Each type of fuel has its own disadvantages, but if you combine them correctly, you will be able to choose the most effective type of heating for a private home.

YouTube responded with an error: The request cannot be completed because you have exceeded your quota.

- Related Posts

- How to choose a collector for a combined heating system?

- Features of combined heating of carriages

How to combine heating devices?

We are accustomed to the fact that in city apartments central heating radiators are widely used as a heating device. It is they who, with a centralized heat supply, provide coziness and a comfortable temperature in our homes.

Radiators and heated floors

Recently, heated floors have been added to radiators, which operate either on water or electricity. Indeed, in this case, the level of comfort increases significantly due to the fact that heating occurs under our feet, and then the heat rises to the top.

It is worth remembering that the presence of a heated floor does not force us to completely abandon radiators. The combination of these two types of heating devices is the same combined version of the heating system of a private house, when the necessary harmony and comfort is achieved. The following proportion is considered optimal: 70% of the heat in the house comes from underfloor heating, and only 30% from central heating radiators. To make this happen, you need to heat the coolant for the floor to 60°C, and the one that goes to the radiators to 75°C.

If the combination of underfloor heating and heating radiators is based on the use of electrical energy, then the batteries will be electric, and the floor will be heated using a special cable

This combined system usually uses:

- Electricity. To do this, a special heating cable is placed underground, and electric batteries are used in the rooms.

- Coolants. Pipes are laid under the floors, and ordinary radiators are installed in the rooms.

When a coolant is used as heating energy, a wide variety of pipes can be used. The materials used for them are copper, metal-plastic, polyethylene, and so on. It is important to correctly calculate the need for pipes, make a reasonable laying scheme and, when making calculations, do not forget about the pump power, the thickness of the pipes and the force of hydraulic resistance. Similar calculations are used to determine the need for radiators for a specific room.

Using water as a coolant, we will use pipes for heated floors. And we will have the most ordinary heating radiators - with hot water inside

To reduce the costs associated with the operation of combined systems, you can install the same radiators only where there is a real need for them: in storerooms and in some other technical premises they are not needed. But with the onset of real frosts, it is better not to skimp on your own health, but to warm up the premises at full capacity. And here is what the collector looks like for this combination:

You can learn more about installing such a home heating system from our material with instructions:.

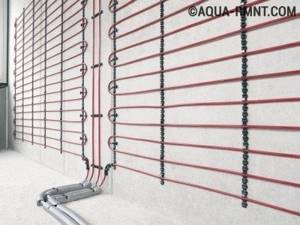

Warm walls

Another possible combination in the heating system: you can use wall heating together with or instead of a heated floor. Just as in the case of floors, tubes are laid into the wall structure through which the coolant will circulate. When heating the walls, the heat will spread evenly, although there will be no highly heated surfaces in the room.

When making warm walls in your home, you should remember that you need to be extremely careful when hammering nails into them to decorate them with pictures or sconces.

Heat propagation occurs mainly through infrared radiation. Such flows are very favorably perceived by our body. If heated water is used as a coolant, then the pipes are connected in separate branches using a radial circuit.

By the way, walls can be used not only for heating, but also for cooling the room. If in winter we need warmth, then in hot summer none of us will refuse the coolness that will remain in the room if cold water is passed through the pipes. Such cooling will be very useful.

Connection diagrams

There are several ways to put into operation a room heating system of this type.

In each of the schemes, it is necessary to ensure that there are no particles in the pipes, otherwise this will lead to clogging of the underfloor heating structural elements.

Via separate input

With this method, the circulation pump is not allowed to run dry. To do this, install a relay that regulates pressure or flow.

It is also permissible to use an overhead thermostat, which allows you to block the operation of the pump when it crosses the lower temperature threshold.

The most effective option is to install a regulator that adjusts the room heating temperature in accordance with the outside temperature of the room.

Through vertical wiring

The main purpose of such a scheme is the process of restoring the existing radiator system.

By fixing underfloor heating pipes directly to the riser, you can double the amount of heat received. This is explained by the fact that at the same temperature in the supply and return pipes, at the moment of the difference in the heated floor pipes, it will be higher than in the radiator.

If there are 4 risers in a residential building, the coolant from two is in transit, and from the remaining ones, warm water from the central heating system is used.

Photo 1. Connection diagram of a water heated floor to a heating system via vertical wiring.

The sequence of actions according to this scheme:

- installation of new heat exchangers in place of previously used radiators;

- parallel fixation of the secondary circuit from the heated floor.

Important! When carrying out the process, it is necessary to use PVC pipes of the same length

Single pipe system

This scheme does not provide for regulation of coolant flow and lowering its temperature.

The heated water floor is connected to the central heating system using a riser. This can be done by replacing the radiator with a heated floor circuit.

The difference in thermal loads between the central heating system and underfloor heating should not be more than 5–10 degrees.

In this case, the room temperature can be controlled using a circulation pump and a thermostat.

If there is no coolant in the riser, the pump operation automatically stops.

To maintain a comfortable temperature in winter, you can use a peak electric boiler in the used circuit. This element will be able to perform this function with the help of a thermostat, provided it is connected to the central heating on one side, and to the heated floor on the other.

Features of water heated floors in the bathroom

An example diagram for connecting a water heated floor.

To install water floors in the bathroom, a pipe of the required diameter is placed under the covering or on the subfloor. The pipe, as already mentioned, can be in the form of a snake or a spiral. Hot water will be supplied to the pipe from the boiler of the gas heating system or central heating system. It should be noted that it is more convenient to use a snake-shaped pipe lining, because in this case, supply and return are carried out in parallel. As a result, the cooling of one sector will always be compensated by the heating of the other.

By choosing such a warm floor for your bathroom, you will ensure the safety and environmental friendliness of your heating system. In addition, you will have the opportunity to save money when using the device.

It must be remembered that the installation and installation of water heated floor systems is quite labor-intensive and complex work, so you will have to pay quite a lot for it. In addition, you should not neglect the quality of water, which can also significantly affect the degree of heating in the system pipes.

Liquid fuel boilers

As a rule, such designs run on diesel fuel. Typically, such boilers are chosen if it is not possible to connect to the gas mains. It is also wise to use the boiler if there are problems with power supply in the area. The advantages of liquid fuel boilers include:

High efficiency. Easy control - as a rule, all models have an automatic control system. In order to use natural gas, it is enough to install the appropriate burner.

But there are also disadvantages that outweigh the advantages:

The cost of the boiler itself is very high - gas ones are cheaper. Burners are also expensive. Diesel fuel today has a high cost. The unit makes a lot of noise during operation. It is necessary to ensure the constant availability of diesel fuel in the container. Moreover, the tank must be mounted in a specially designated place. When burning fuel, the boiler becomes very dirty and has to be cleaned frequently. Sometimes fuel has to be cleaned of impurities - sand, water, resins. If there is sulfur in diesel fuel, then the destruction of the metal elements of the boiler will occur much faster.