For smoking meat and fish, installations are used, each of which has a chamber for food - a smoking cabinet. It is called that because of its external similarity: most of these designs are a rectangular container with a side door. At home, you can make a smoking cabinet with your own hands according to our drawings.

The smoking cabinet is even made of wood

Stainless steel cold smoking cabinet

The best material for a smokehouse is food-grade stainless steel sheet with a thickness of 1.2-2 mm. It is not subject to corrosion and is easy to clean.

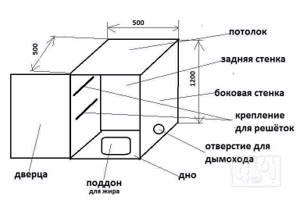

The design of a stainless steel smoking box is similar to a smoking cabinet from a refrigerator or a metal safe and is assembled from rectangular pieces of the required size:

- two pieces 500x500 mm for the bottom and ceiling;

- two pieces 1200x500 mm for the sides of the camera;

- two pieces 500x1200 mm for the back wall and door.

The smoking cabinet is assembled with your own hands using electric welding. For a better fit of the door and installation of grilles, stainless steel corners are welded to the walls. A hole is drilled in the bottom of the box to attach a smoke generator.

The drawing shows the dimensions of such a structure.

Cold smoking cabinet

What tools and materials will be needed

To make a homemade smokehouse from a refrigerator with your own hands, you need to prepare the following tools:

- a drill and drills of a suitable size - you will need to make places for screws; a drill will also be convenient for marking the contours along which to make cuts in the future;

- scissors cutting metal - sometimes you have to process the parts of the smokehouse to give them the desired size;

- an angle grinder with a metal disc – you will need it to adjust the pipe to the required dimensions;

- self-tapping screws - with their help the elements will be attached to the body of the refrigerator;

- screwdriver - will be needed to tighten the screws tightly.

You will also need to prepare materials. The main one is an old refrigerator. It can be of any model - the smokehouse will be the same from a two-chamber refrigerator and a single-chamber one. The only thing that needs to be taken into account is that there should be no rot or rust on the body. As for the remaining materials, you will need:

- bricks - will be used to equip the combustion chamber (in this case, fire-resistant brick is better, but you can take a regular one, but it will last much less);

- a metal device that will serve as a lid for the firebox - without it, smoke production and the smoldering process itself would be impossible;

- pipe and corners - a chimney will be created from them (the optimal pipe diameter is from 10 to 15 cm);

- door hook – you will need it to be able to close the refrigerator doors tightly;

- lattices and hooks for hanging - they will be needed to place food in the smokehouse;

- exhaust fan - it will create a stream of cold smoke;

- a tray or other container where the fat will drain (this is not necessary, but it will greatly simplify the care of the smokehouse);

- paint - needed only if there is a desire to paint the unit and give it a more fresh and attractive look.

Making a smokehouse from a refrigerator yourself is not difficult, since almost all the components can be found in everyday life.

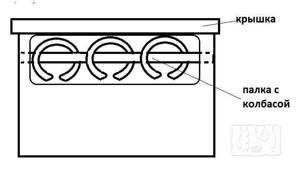

Sausage smoking cabinet

Homemade sausage is smoked in a suspended state, in rings. These rings are put on a wooden stick. Every hour during hot smoking and every 5-6 hours during cold smoking, these rings must be turned over. Therefore, it is more convenient to smoke sausage in a cabinet with a removable top lid.

Important! Sticks for hanging sausages should be made of hardwood and well dried.

Cabinet for smoking sausages

Tips for use

When you have a smokehouse, you can begin the cooking process. However, there are some tips to consider. In order for smoked meats to have high taste, you need to put in a lot of effort.

You can regulate the smoke not only with damp burlap, but also with fresh branches of trees or bushes. Currants or cherries, which have an incredible aroma, are suitable for this. Tree species such as pine or lilac, as well as birch, cannot be used. After all, they contain essential oils, sweet juice and tar, which can saturate the products, making them unfit for consumption.

The layer of branches laid on top of the smokehouse should be approximately 30 centimeters. This is enough for three days. By the condition of the top leaves, you can determine the readiness of the product.

When starting to prepare firewood for smoking, you need to know that trees such as pear or cherry are best suited for this. However, they must be cleared of bark before use. If smoking occurs in the forest, then aspen or linden can be used as firewood. To give smoked meats a tart taste, you can use walnut or oak. In order to smoke fish that smell like silt, you need to use willow or broom.

Coniferous trees should not be used, otherwise they may spoil all products. Also, if the trees are infected with any fungi, they should not be taken either.

Also, do not forget about preparing the products. Before you start smoking, you need to marinate the meat well. Any method known in cooking is suitable for this. Marinating must be done one day before the smoking process. You can also simply rub the meat with salt and spices. The finished product will be better preserved in the refrigerator.

Cooking fish requires much less time. It just needs to be well gutted and cleaned. Then soak in salted water to eliminate the unpleasant fishy smell. Then soak it in a salty solution, and after an hour it will be ready for smoking. Almost any fish is suitable for smoking, both small and large. As a rule, the choice depends on the size of the smokehouse itself and the presence of the necessary functions in it.

Chicken meat is a little softer than pork, so marinating it for four hours will be enough. Salt and sugar are used for the marinade. Many people add wine and spices. This adds flavor to the bird. But you can get by with a classic set of chicken spices.

To marinate lard, a solution of salt, garlic and various spices is used. Marinating lasts two weeks. This is one of the longest processes. However, do not forget to periodically turn the pieces so that they are equally aromatic and appetizing on all sides. They need to be washed well before smoking.

It is also worth knowing at what temperatures and for how long a particular product is cooked. When using hot smoking, products are smoked differently. For meat and lard, the temperature varies from 100 to 150 degrees, and the smoking time is two or three hours of cooking. The fish is cooked for approximately one hour at a temperature of 70 degrees, which then rises to 100 degrees. The chicken is smoked at 110 degrees for about two hours.

If cold smoking is used, the smoking temperature reaches 30 degrees Celsius. It is because of this that the cooking process takes a lot of time. But the result will please anyone. After all, such products not only turn out to be very tasty, but are also stored for a long time. For example, chicken legs are smoked for up to four days, and then kept for another three weeks, hanging in a dry room. But they are stored for several months.

To smoke ham, 2-3 days will be enough, but lard is smoked for 7-10 days, until it turns golden brown.

Building a smokehouse for cold smoking is not difficult and will not take much time. You just have to make the right calculation and choose a place for the smokehouse. And then you can please yourself and your family with delicious smoked meats, without being afraid of being poisoned by a low-quality purchased product.

To learn how to build a smokehouse for cold smoking yourself, see the following video.

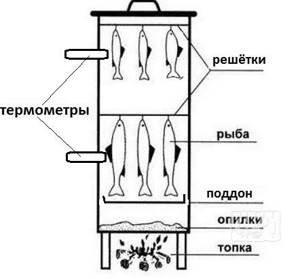

Fish smoking cabinet

A smokehouse for smoking fish is no different from other similar devices, except for one feature. Fish is a delicate product; when overheated, it dries out, loses fat and becomes boiled rather than smoked.

Therefore, when smoking it, it is necessary to control the temperature in the chamber, preferably on each tier of grates, and, if necessary, reduce the heat or the processing time.

Scheme of a cabinet for smoking fish

Firewood and wood chips: how to choose the right one

The key to the taste of smoked meats is properly selected firewood . It is known that smoke from different types of wood has completely different flavors. The easiest way is to use purchased wood chips in this case, choosing the one suitable for each type of product:

- alder - universal, suitable for meat, lard, fish and vegetables;

- oak - mainly for smoking game and red meat;

- willow, birch - game with a specific taste, for example, elk or bear, as well as swamp fish;

- cherry, apple tree - cheeses, vegetables, nuts and berries.

The humidity of firewood and wood chips should be within 15%, otherwise too much steam will be generated and the smoked meats will become soggy, after which they will not be stored well.

The costs of making a smokehouse are insignificant; you can use scrap materials and leftovers. A self-made smokehouse and a properly selected smoking mode will allow you to prepare delicacies that are unique in taste and will surprise your family and guests.

Source

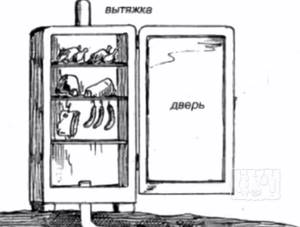

Smoking cabinet from the refrigerator

The easiest way to make a home smoker is from the refrigerator. Its design depends on what type of device the resulting device will be used for - hot or cold smoking.

Advice! It is best to use Soviet-made refrigerators with wire grilles

Cold smoked smokehouse

For a cold smoked smokehouse, smoke is produced using a smoke generator. With this type of processing, the temperature does not exceed 50°C, so all plastic parts can be left:

- Remove the shelves. It would be better if they were made of wire, like in old Soviet-made refrigerators.

- In a single-chamber device, remove the freezer and wires. In a two-chamber cooler, it takes up little space, so you can leave it.

- Seal the resulting holes. Wooden or plastic plugs are suitable for this.

- Cut a hole on the side or back at a height of 10 cm above the bottom for the incoming chimney. Place the refrigerator body on the stand so that the smoke channel slopes upward at a slight angle. Another hole for escaping smoke is made in the ceiling of the smoking cabinet.

- Place a tray at the bottom to collect fat. A disposable baking dish is suitable for this, or simply line the bottom with aluminum foil.

- Install gratings at the required height in the grooves of the housing. If desired, a hole is drilled in the housing and a thermometer is installed.

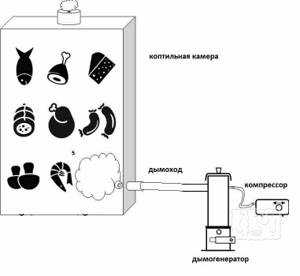

Diagram of a cold smoked smokehouse from a refrigerator

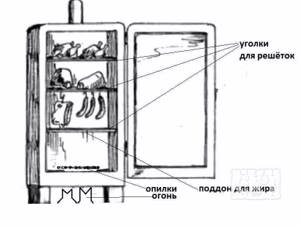

Hot smoked smokehouse

Converting a refrigerator into a hot smoker is more difficult. This process takes place at temperatures from 50 to 120°C, so the device is subject to modification:

- it is necessary to remove all non-metallic parts - plastic sheathing, thermal insulation and sealing rubber in the door;

- seal the resulting holes in the body with wooden plugs, and replace the elastic band with a felt strip;

- Screw metal corners for grates and a tray for collecting fat to the walls at the desired height, as well as at a distance of 10 cm from the bottom;

- Place the smoking cabinet on a brick stand.

The smoking process is carried out in the same way as in other hot smoking devices:

- sawdust is poured onto the bottom;

- a tray is placed on the lower pair of corners, and food is placed on the upper racks;

- A small fire is lit under the bottom.

The fire heats the sawdust, it smokes and smokes meat and fish.

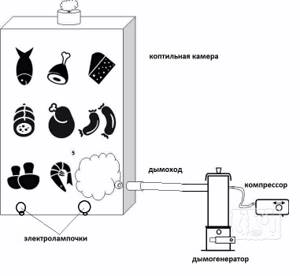

Diagram of a hot smoked smokehouse from a refrigerator

How to make a smokehouse with your own hands. Step-by-step instruction

In order to build a smokehouse yourself, it is not necessary to have professional builder skills and have expensive equipment in stock. For quite primitive designs, ordinary tools and materials are suitable, which can be bought in a store for little money or even found in the country.

Depending on your capabilities and desires, you can build the following smokehouses:

Camping smokehouse.

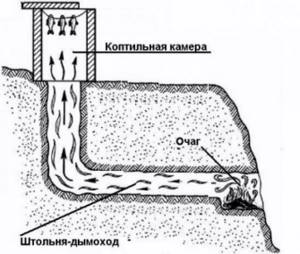

Your own smokehouse, located on a slope near the dacha, is very convenient and practical to use, because it is suitable for cold smoking of a wide variety of products. The main material for its production is wood.

The instructions for building a camp smokehouse are as follows:

● dig a shaft for a chimney, the width of which is 0.3 meters, length - 6 meters; ● lay a pipe, the diameter of which is 0.2 meters, into the resulting ditch and run it from the location of the fire to the entrance to the smokehouse; ● make the firebox out of brick or weld it out of metal. Its shape should be in the form of a cube with sides of 4 meters; ● connect the firebox to the pipe; ● install a valve on the firebox on the other side to create draft; ● knock down a sealed smoking chamber from the boards; ● install gratings, a valve, or a panel for collecting products inside the chamber.

Stationary smokehouse.

In order to equip such a unit on a summer cottage, you will have to spend not only time and effort, but also money. However, the result will be worth all the effort, because the design will not only look aesthetically pleasing, but also work efficiently.

To install it, follow the step-by-step instructions:

● pour a foundation 0.4 meters deep with reinforced wire, metal rods and pieces of reinforcement; ● in advance, make a channel for the chimney in the foundation hole at a distance of 1.5 meters from the smoking chamber; ● lay the pipe along the trench to the firebox; ● build a sealed firebox out of brick or use a metal box; ● connect the firebox to the pipe; ● after the foundation hardens, begin bricklaying the walls; ● make metal rods during the laying process; ● equip the building with a lid.

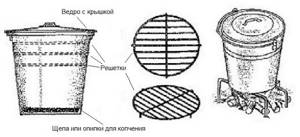

The simplest hot smoked smokehouse.

A similar design can be purchased at any specialized store, but in order to save money, you can build it yourself:

● choose a suitable location for the smokehouse on a hill; ● equip the area with a metal sheet on which the fire will burn; ● lay the brick base on both sides of the sheet; ● install a metal box on top of the brick posts. You can use a saucepan or bucket; ● equip the box with shelves on which food will be smoked; ● install a tray that will be needed for sawdust; ● equip the box with a lid through which the process of placing products will take place; ● install the valve.

Smokehouse on the grill.

When you suddenly want smoked meats on vacation, but you don’t have a special unit at hand, and don’t see it in the near future, you can build a smokehouse from a barbecue. The construction of such a cunning and simple structure will take at least an hour, or even less, and ready-made and delicious-smelling food will appear on the table in the near future.

To make a smokehouse on the grill, follow the step-by-step instructions:

● find a piece of pipe or a small metal barrel; ● place the find on the grill; ● equip the pipe with a grill; ● add sawdust; ● seal the pipe tightly; ● light a fire.

A simple smokehouse made from a barrel.

A very simple smokehouse can be made from a metal barrel and an electric heater. To do this, follow the instructions:

● make a hole in the bottom of the barrel;

● install the heater on the bottom by pulling the cord through the hole;

● place a container with sawdust on the stove and cover it with a cap;

● hang food on rods or place it on a wire rack;

● cover the barrel with a lid.

Smokehouse in the attic.

Another interesting option for a smokehouse is a smokehouse built in the attic. It is connected to the chimney from a home fireplace or stove. This way you can not only heat your home, but also cook delicious smoked meats. The photo shows a diagram of such a smokehouse.

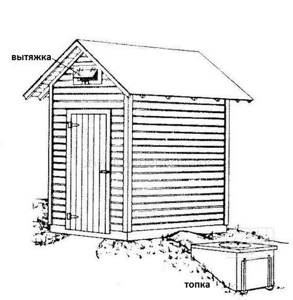

Wooden cold smoked smokehouse cabinet

A stationary smoking cabinet can be made of wood. It is better to use deciduous wood, otherwise before starting operation you will have to dry smoke it several times, without products, so that the walls are saturated with smoke. For home use, a chamber measuring 0.5 x 0.5 x 1 meter and a smoke generator with a capacity of 3 liters is sufficient for 100 kg of products. The smoking process continues for a day. If there are no boards, then you can build a similar stationary smokehouse from brick

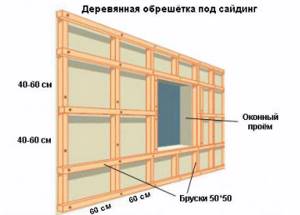

Structurally, such a wooden smokehouse is similar to a box with a door or a country “house of an unknown architect.” It is assembled on a frame made of 40x40 mm bars. Guides for the gratings are made from the same bars. The frame is covered with boards or plywood.

It is best to make the walls of the box from clapboard or floorboard. These lumber have grooves with which the boards are connected to each other. This connection is tight enough to prevent smoke from escaping.

If there is no lining, then it is permissible to make a smoking box with your own hands from boards. In this case, when assembling the cracks, it is necessary to seal them with tow or other sealant.

A good result is obtained by sheathing the walls with plywood. There are no cracks in the walls of this material, but under the influence of moisture the plywood warps and delaminates. Therefore, after each use, the plywood cold smoking box must be dried and the outside painted with waterproof paint.

Such a smoking cabinet can be built from logs. The resulting structure will look like a wooden hut. A sealant is laid between the logs.

On a note! In a log structure, the door is still made of planks.

The door in the box for cold smoking is made with your own hands, assembled from several longitudinal boards and two transverse ones. A plywood door is simply a piece of plywood of the required size.

The door is attached to two hinges and has a rubber or felt seal along the contour.

The roof is made of a single or double slope. Single-pitch is simpler. To make it, just bevel the top of the side walls and make the back wall smaller than the door. A chimney is installed in the roof.

The smoke generator is placed on the ground; if necessary, a chimney is laid in a recess or instead of it in the ground, at the other end of which there is a firebox, and the smoking cabinet is made without a bottom.

Wooden smokehouse cabinet

The advantages of your own smokehouse.

Building a smokehouse with your own hands is a completely feasible task for every man who knows how to hold ordinary tools in his hands, wants to acquire a similar unit and loves smoked meats. It’s worth making a smokehouse yourself for several reasons:

● price - specialized stores offer a wide selection of smokehouses, which can be either a primitive device or equipped with additional functions and capabilities. However, the cost of such devices is always high and not everyone can afford it. A DIY smokehouse requires virtually no financial costs. Available materials and means can be used;

● time – it will take very little time to make a smokehouse. Depending on the type of construction, the unit can be built in either a day or an hour;

● ease of use - primitive smokehouses are quite functional and easy to use and maintain. They will allow you to prepare delicious and aromatic meat, fish, cheese and other food products without much effort;

● service life - devices built according to instructions and using recommended materials will serve their owner for several years;

● ease of installation - the design of the smokehouse is elementary, therefore it is easy to install. It easily adapts to existing materials and capabilities.

During the construction of a smokehouse, in fact, as with any other construction work, it is necessary to follow safety rules. So, you should get work gloves, make sure the tools are in good working order and the materials at hand are reliable. You should also not neglect basic safety precautions when operating the unit.

We also recommend reading our article How to make a smokehouse yourself - 100 best photo ideas.

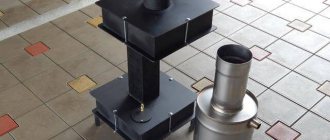

Smoking cabinet with smoke generator

In cold smoking devices, smoke is not produced in the chamber, but separately, in a smoke generator. It is placed below the smoking cabinet and the smoke, passing through the chimney, is cooled.

Advice! To improve the quality of smoke, the chimney is equipped with a condensate collector, filter, refrigerator and other accessories.

Diagram of a smoking cabinet with a smoke generator

Manufacturing process

Before you start making a smokehouse at home, you need to make drawings of the future structure.

Only after this can you, using the developed scheme, build a smokehouse for cold smoking yourself. First you need to decide on the dimensions of the structure, and then choose a place for it. Having chosen a brick smokehouse, you need to make a design for this design. This will help you save time and choose the right installation location. The area should be four meters long, and it is better if the area is sloped so that the chimney runs at the desired angle. Having made the necessary calculations, you can dig a trench.

First you need to lay the foundation. Then, in the place where the smokehouse will be located, you need to remove the soil. The pit should be up to 60 centimeters deep. Then formwork is installed in it, which should be 25 centimeters above the edges. Reinforcement is made, and a regular bucket is placed in the center of the hole so that after pouring the concrete, a depression is created.

Red brick is used for the walls. The size of the smokehouse depends entirely on the wishes of the owner. In the middle you can make a small window with access to the north side so that direct sunlight does not harm the products.

The roof of a brick smokehouse is light and easy to install. To do this, you need to build a rafter system. Either OSB boards or moisture-resistant plywood are laid on them. And only then are the tiles laid on a flat base.

To build a firebox, you can use refractory bricks or a ready-made metal stove. You will need a fireproof pipe to remove smoke from the firebox to the smoking chamber. Its diameter must be very large so that the smoke flows slowly and, as it cools, leaves particles of soot on its walls. Grates are placed over the hole where the smoke comes out and the products that need to be smoked are hung.

To build a wooden smokehouse, first of all you need to dig a trench two bayonets deep. It should house the pipe, the combustion chamber and the smokehouse itself. The smoke, entering the pit, lingers there and is cleaned, and then rises into the smokehouse.

The firebox door must be made of cast iron and close securely. Its base is made of brick, and the walls extend slightly above the ground. Then a wooden structure is placed on it. The trench where the chimney is located is covered with earth and then compacted well. This is necessary so that the pipe and smoke cool down.

The base for the camera is made from blocks of wood. Then even boards are nailed to it, which should fit very tightly to each other. This is done to prevent smoke from escaping through the cracks. Then a hole is made in the roof into which the pipe is led.

Any smokehouse, even a quick one, must consist of a smoke generator, a smoke channel and a container used for smoking products. If you want smoked meats while on a hike or at a camp site, you can make a smokehouse using rods and plastic film.

This design is not at all complicated, but it needs to be done correctly. The frame is built from poles, a film is thrown on top, and the products for smoking can be placed on skewers. The coals from a burnt-out fire will serve as an excellent source of heat. Fresh branches with foliage are suitable for smoke. You can build a fireplace by digging a hole in the ground or using an ordinary bucket. The advantage of such a smokehouse is the speed of construction and the absence of purchased materials. The disadvantage is that it is necessary to constantly monitor the outbreak.

This type of smokehouse is perfect for those who go to the countryside for a while and do not want to build a full-fledged smokehouse on their site.

You can also pay attention to such a structure as a barrel smokehouse. Wood or other material is perfect for its base.

You can't just use plastic. The bottom of the barrel is removed to allow smoke to pass freely. In its lower part you need to make a compartment where the firewood will be stored. Here you will need hinges on which the door will be placed. This way the compartment can be closed.

Several holes are made in the bottom of such a barrel, which will serve as a ash pit, as well as a place for removing ash from the firebox. At the height of one third of the barrel, you need to weld an iron sheet, which will serve as the bottom for the smoking chamber. For it to last longer, the sheet thickness should be about 4 millimeters.

Heated cold smoking cabinet

The cold smoking process takes place at a temperature of 20-50°C. But if it’s cold outside, then the smoke coming into the smoking cabinet has a lower temperature. To heat the smoking chamber, an electric stove or several incandescent lamps are installed inside it at the bottom.

Advice! For a more stable temperature, the lamps are turned on via a thermostat, for example, from an incubator.

Scheme of a heated smoking cabinet

Basic smoking methods

Cold smoking, at a temperature of 30 to 50 degrees, gives the most delicate and refined taste. Pork smoked in this way can be stored in a dry basement for more than a year, while in the refrigerator it will soften within a month. However, cold smoking takes quite a long time - from three hours (if we are talking about small fish on the grill) to three days (for example, for a massive pork thigh). Moreover, the product must be properly prepared (more on this a little later), which takes another 1-5 days. However, a do-it-yourself cold smokehouse is the easiest to implement, although it requires a plot of land measuring 3.5 x 2 meters.

As for hot smoking, it is performed at a temperature of 70 to 120 degrees. Some recommend raising the temperature to 350 (!) degrees, but it is not known where such recommendations even come from. Hot smoking does not require much time - everything takes no more than four hours. Also, no pre-preparation of food is required.

There is also semi-hot smoking, in which the temperature ranges from 60 to 70 degrees. For this, the simplest smokehouses designed for cold smoking are used. An ordinary person can hardly distinguish a cold-smoked product from a semi-hot one by smell or appearance, but its taste is the same as that of a hot-smoked one.

For the semi-hot method without preparation, you can use exclusively fresh products - fresh meat, for example, or freshly caught fish.

Below we will discuss several popular options for making a smokehouse. Let's start with the simplest thing - a cold smoking device.

So, now you know how to make a smokehouse with your own hands, you have several instructions with the corresponding drawings. All that remains is to prepare everything you need and get to work! That's all, good luck and warm winters!

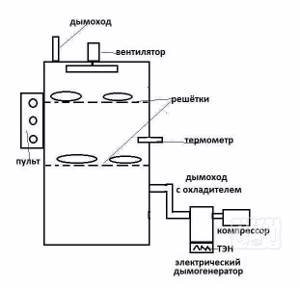

Electric cold smoking cabinet

Several companies produce electric smokers for homes and small businesses. In these devices, sawdust is heated in a smoke generator by electric heaters, there are built-in fans that blow smoke over smoked meats, thermostats and other devices. How to use the smokehouse is indicated in the manufacturer's instructions.

These cold smoking cabinets do not require an open fire for heating, but do need to be connected to a ~220 V network. The smoking process occurs at lower temperatures and longer than in hot smoking devices.

You can make such a household device yourself from a metal box and install it on the balcony.

All controls in an electric smokehouse are installed in the control panel, which is mounted on the wall of the smokehouse.

Components of an electric smoking cabinet

Types of smokehouses

A do-it-yourself smokehouse can be of different types and have its own design features, which directly depend on the needs of the user and his construction capabilities. The most popular are 3 types of smokehouses:

● shaft (vertical); ● tunnel (horizontal); ● chamber.

The mine smokehouse is the easiest to install and does not require a specific installation location. Its structure resembles a canonical hut, with food hanging at the top. However, this type of smokehouse has a number of significant disadvantages, among which some of the most significant are the inaccessibility of smoking by fumigation, as well as limited possibilities for adjusting smoke production.

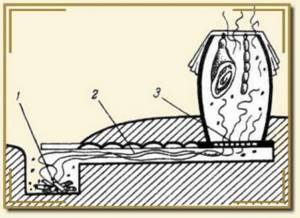

A tunnel smokehouse requires a fairly large amount of work, most of which is on the ground. It is also necessary to find a suitable site for its installation - it must be on a slope. The smoke generator in such a horizontal device is located in a special semi-closed chamber. Thanks to this, the smoking process can be carried out in any weather conditions. Depending on the length of the channel, both hot and cold smoking can be performed.

The chamber smokehouse is quite primitive in its design, but it is large in size: the height is 1.5 meters and the diameter is 1 meter. During construction, it is important to ensure the required angle of inclination, which varies from 10 to 30 degrees.

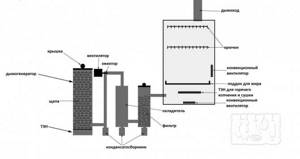

Universal smoking cabinet

Before choosing a smoker, you need to determine the necessary features. But there are “wide-profile” devices

They can process products in different modes, so it is equipped with an external smoke generator with a cooler, a built-in heating element at the bottom and an exhaust regulator at the top.

Different elements operate in different modes:

- Cold smoking. Smoke generator with cooler and exhaust fan.

- Hot smoking. Internal heating element on which a container with sawdust is installed.

- Drying. During normal drying, only the exhaust fan works, and during accelerated drying, a heating element is added to them.

Advice! For better performance, it is advisable to equip all electrical appliances with a power regulator and insulate the housing.

Components of a universal smoking cabinet

Frame production and vapor barrier

The lathing is needed to fix the siding and create a ventilation gap that prevents condensation. For its construction, a wooden beam or metal profile is used.

A vapor barrier is first stretched onto the base; this is especially true for wooden and frame (panel) houses. The material is laid as follows:

The canvas is fixed to the surface in increments of 30–40 cm

A little sagging is allowed. Adjacent strips are laid overlapping and taped with adhesive tape. All connections and fasteners are sealed. Particular attention is paid to the corners: they are covered in solid pieces, without joints at the convergence of the walls.. Laying vapor barrier

The vapor barrier film must be laid with the rough side facing the surface of the facade, otherwise the desired effect will not be obtained.

Wooden frame

The design goes like this:

- The base is marked in increments of 50–60 cm (40–50 cm for base panels). The lines should be perpendicular to the siding being installed.

- Timber with a cross section of 50**50 is treated with protective and fire-resistant compounds. Holes for fasteners are drilled on its surface.

- The rail is aligned according to the markings, and the fixation points are transferred to the wall. Holes are drilled and dowels are driven in (not necessary for wooden bases).

- All fastening areas are prepared. The beam is placed at a given place according to the level. Substrates are used to ensure accurate and reliable alignment.

- Self-tapping screws are screwed in.

It is necessary to obtain a rigid structure with a single plane between the racks.

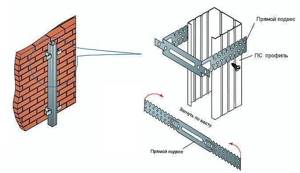

Metal sheathing

Installation is carried out using U-shaped profiles and hangers. The technology is as follows:

- Marking in progress.

- The locations of the hangers are marked on the line in increments of 40–50 cm.

- The holes are drilled and the rack fasteners are installed. To do this, dowels are driven in and screws are screwed in.

- The hanger is bent in the shape of a P.

- The racks are leveled and screwed.

To increase rigidity after insulating the house, you can install jumpers.

Selection of raw materials for smoking

The best choice when determining raw materials for smoking would be logs and shavings:

- fruit trees: apple trees, pears, cherries;

- hard deciduous trees: oak, beech, alder.

A homemade smokehouse from a refrigerator with your own hands is a reliable and affordable method of providing a large family with smoking products. A little effort, desire and creativity will give new life to an old refrigerator and diversify the dishes on the holiday table. Please be patient to get the best results!

Varieties

The most common are 2 options for smokehouses with their own design features:

- Vertical (shaft). The easiest to manufacture, taking up little space. The smokehouse looks like a kind of cone; products are located on its top. The disadvantages include inconvenient adjustment of the smoke volume.

- Horizontal (tunnel) . More difficult to produce, requiring a suitable site, preferably on a slope.

Pros and cons of wood

Among the main advantages of wooden smokehouses are the ease of assembly with your own hands and the ability to give the structure any shape. The camera body can be decorated with carved decor or tinted with special impregnations.

Wooden buildings are lightweight and mobile. If necessary, they can be moved; even one person can cope with such a task.

pros:

- environmental friendliness of the wooden blanks used;

- quick replacement of damaged structural fragments;

- the ability to assemble a structure without the use of welding tools;

- low cost and availability of building materials and components.

Minuses

- Wood is susceptible to fire, but this can be avoided with proper operation of the smokehouse. To reduce the negative impact of atmospheric manifestations and sudden temperature changes, the external structure should be treated with special varnishes and impregnations.

Stationary and mobile smokehouses

Today you can buy a cold smoked smokehouse in two versions – stationary and mobile. A stationary smokehouse is usually delivered on a turnkey basis. Most often these are houses like these with a smoke cooling system. They are installed on a pedestal on a personal plot or the territory of a country house.

Stationary cold smoking smokehouse Stationary cold smoking systems can be made to order in different versions, for example, they can be monolithic brick buildings.

Custom brick smokehouse