What is a garden branch shredder and how does it work?

Such devices simplify the process of caring for the area. The resulting woody grass mass is perfect for mulching the ground and protecting it from weeds. It is a valuable additive to organic fertilizers and an excellent absorbent of excess soil moisture. And recycled branches are perfect for a smokehouse.

The operating principle of a simple chopper resembles the operation of a meat grinder:

- A chain or belt drive is a transmission link that drives the shaft due to the torque of the engine.

- Branches or other garden debris are fed into a receiving box.

- The introduced organic waste is crushed with special knives.

During the operation of the chipper, wood and grass debris crumbles into small pieces. Their size depends on the shredder model.

Not every unit is universal: some are capable of “grinding” even large branches, others are only suitable for grass.

Conventionally, shredders can be divided into three categories:

- for branches. A chipper like this is an excellent choice for processing wood waste. Some models crush even thin trunks. But chopping grass or vines can be difficult;

- for grass. The unit copes well with processing any herbaceous greenery, but is capable of grinding only small branches supplied in small batches;

- for branches and grass. It is usually equipped with a large number of knives (vertical and horizontal) that process all the supplied material.

When purchasing, you need to focus on what kind of garbage there is more on the site. If the garden and shrubs predominate, it is better to choose a grass chipper. Their knives are designed in such a way that they do not clog when chopping dry or fresh organic matter. If there is a garden on the territory, a shredder for branches is suitable

When choosing, you need to pay attention to the largest diameter of wood debris. If you have a vegetable garden, choose a universal model, since it will process both hard branches and grass

The main advantage of such devices is the simplification of site maintenance with significant time savings. There is also an environmental component - eliminating wood waste by burning harms the environment and can cause a major fire. The disadvantage is the cost of the device. You can level it out by constructing the unit yourself. Other advantages, as well as disadvantages, need to be considered when choosing a specific device model.

Main components of a garden shredder

To independently assemble a grass and branch chopper (shredder) at home, you must first understand the structure of the mechanism, as well as the principle of its operation. This will help you assemble the equipment correctly and, if necessary, make changes to its design.

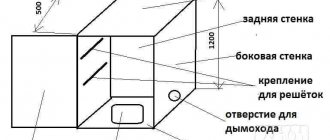

A homemade unit, designed for grinding mown grass and sawn branches up to several centimeters thick, has the following main structural components:

- engine;

- knives mounted on the working shaft;

- frame (usually metal);

- protective casing;

- a box designed to receive cut vegetation;

- starting system.

The equipment itself can be made stationary or mobile. To create the latter option, you will additionally need wheels, as well as a handle. To make the frame, use metal corners or ready-made frames from workbenches. Boxes for processed vegetation are made from plastic buckets, tin, and bags. The protective casing around the knives should be thick and durable enough so as not to quickly wear out from the impact of grinding vegetation.

When processing plant debris, crushed pieces may fly out of the opening through which it is fed. Therefore, the neck is covered with a lid or simply with a cloth, for example, a bag.

The operation of the chopper is that rotation from the motor shaft is transmitted directly to the knives or through a chain/belt drive. The vegetation chopped by the blades enters the box. In this case, the final product is immediately ready for use.

According to the principle of operation, some homemade shredders are comparable to a meat grinder (they draw in and then grind organic matter), while others are comparable to a coffee grinder.

Varieties of engines for assembling homemade products

Electric and gasoline engines removed from unused equipment are used as a drive for homemade products. Each of these two options has its own advantages and disadvantages. Models with an internal combustion engine are more convenient in that their operation does not require a nearby power supply. But in general, they are more expensive and have a more complex design than their counterparts equipped with an electric motor. Therefore, it is easier to make electrical equipment, and also more compact.

The maximum thickness of cut branches that a branch chipper can grind depends on the power of the electric motor installed on it and the characteristics of the knives.

- Models with a motor up to 1.5 kW are capable of grinding sticks up to 20 mm in diameter. They are designed for low intensity work.

- If an electric motor of 3 to 4 kW is installed, then such units can chop branches up to 40 mm thick.

- More powerful electric motors (over 4 kW) are used to make a shredder for wood with a diameter of 7-15 cm.

To create a homemade shredder, you can use electric motors from an angle grinder, washing machine, or trimmer. They must be adapted to work from a stationary network with a voltage of 220 V. In order to grind material as thick as possible at home, it is recommended to equip the shredder with an electric motor of 1500 rpm with a power of about 3.5 kW. This parameter for internal combustion engines corresponds to 5-6 horsepower.

Motor from an old washing machine

Engine selection

For a country shredder, both gasoline engines and those powered by an electrical network are suitable. Each of them has its own characteristics. For processing large branches, a mobile gasoline engine is more suitable, since it can work throughout the entire area. But this cannot be done with an electrical device, since it needs a power source. But it is more compact than gasoline.

We recommend: How to create a wood chipper for heating with your own hands

In addition, devices equipped with an electric motor are lighter and more convenient to use, but they will not be able to process large elements of wood, since they have low power.

When choosing an engine for a wood chipper in Tyrsa, you need to consider:

- for processing branches no more than 2 cm thick, a power of up to 1.5 kW is enough (read how to make a branch shredder with your own hands here);

- for branches with a thickness of about 5 cm, it is best to take motors with a power of 4 kW;

- Large and thick branches with a diameter of 10-15 cm can be processed by an engine with a power of 6 kW or more.

But still, for gardening work, when you have to process branches of different thicknesses, it is better to purchase a universal engine, the power of which ranges from 4 kW for an electric one and from 5 horsepower for a gasoline equivalent.

What else can a chopper be made from?

When making a branch chopper with your own hands, any household appliances can be useful. When many home appliances reach the end of their useful life, they can be reused with some modification. The main necessary element is the engine; you just need to modify it and the mechanism acquires a second life in a new useful device.

Wind chopper from a walk-behind tractor

To give a second life to the design of a walk-behind tractor that has expired, it is necessary to prepare the following materials:

- walk-behind tractor directly

- knives

- shaft

- bearing set

- channel

- a set of keys

- grinder for cutting and cleaning work

- sheet metal

- drill and jar

- hammer and electric planer

During assembly, the following manipulations should be carried out:

- A frame is formed from a section of channel.

- A shaft from an old electric plane is installed on the bed.

- A knife and a pulley are attached to the shaft to transmit torque from the engine.

- The torque from the walk-behind tractor is transmitted to the pulley using a belt.

- A receptacle for branches is formed from sheet metal by welding.

- The entire assembly is installed on a prepared walk-behind tractor and carefully secured.

- We start the mechanism, feed the branches into the shredder, the chips fall down where you can place the container.

Saw blades

The knife discs themselves are cutting blades with many teeth, onto which special carbide inserts are soldered, thanks to which the tool acquires increased characteristics. The knives are directly installed on a pre-made shaft up to 80 mm long, on which threads are cut on both sides to secure the tool.

Washers are placed between the discs on the shaft to separate them, since the saw teeth have a slight deviation from the plane to increase cutting properties. Due to the divergence of the teeth, placing the disks close together becomes impossible, so a washer with a diameter of 20 mm becomes a necessary element in the design.

Frame design

The electric motor is installed on a frame made from corners with your own hands using welding; a frame is attached to it directly under the shaft with cutting discs. Holes for bearings are made in the necessary elements, the shaft is inserted into them and secured.

Start-up

The loading conveyor is made of galvanized steel. Pre-cut sheets are fastened with rivets into a pyramid truncated at the top and attached to a frame on which saw blades are mounted. Pulleys are attached to the shafts of the engine and cutting tools, then belts are put on them, with their help the movement from the electric motor will be transmitted to the saws.

We supply power to the drive, branches and debris are loaded into the receiver, a set of disks grinds the material into chips, which fall down.

Description of the wood and log shredder, scope of application

When working with wood, waste always appears. Crushers are units that transform large pieces of wood into a fine mixture. The use of machines can increase labor productivity and reduce worker injuries.

Reference! Automation of raw material processing by the forestry industry has reduced the amount of waste disposal by 50%.

The tree shredder is used in production and gardening. It comes in several types:

- rotary;

- hammer;

- disk and cone;

- screw and roller;

- ball mill.

Installations can be mobile or stationary. Large amounts of waste are processed using powerful crushers. Utility farms can cope quite well with mobile units with low power.

The equipment will help grind wood waste after trimming branches, leftover building materials, and old furniture. The crushed raw materials are used for mulching or fertilizing beds.

You can use environmentally friendly types of wood for soil. Furniture waste contains harmful components. They cannot be used to fertilize plants.

Manufacturing methods

In addition, the bark contains a lot of tree sap, which, even after loss of moisture, has not gone away, turning into a dry mixture of various substances.

You also need to carefully examine the cleaned wood to look for rot and other diseases, because they change the temperature and smell of smoke.

Chopping in shredders

There are numerous models of chippers that process wood to produce chips of various sizes. You will find more detailed information about devices of this type in the article Equipment for wood processing.

Due to the fact that the size and shape of the wood chips do not affect the smoking result in any way, you can obtain fuel for smoking using any type of device. Therefore, any shredder will do , including a homemade one, more detailed information about which you will find in the article Do-it-yourself wood chipper.

When working with shredders, you must follow safety precautions , which are set out in the instructions for the devices.

Slicing and chopping

If only thick branches and trunks are available for making wood chips, then they are first cut into layers 2–5 cm thick, then chopped into wood chips of the required size.

For cutting, use a hand or gasoline saw . Sometimes the same method is used for branches of medium thickness, in which case they are cut using a circular saw or jigsaw .

When working with a circular saw, a branch or branches are placed on a table (workbench) and pressed firmly, then cut into pieces of the required length. If the circular saw is made in the form of a machine, then it is turned on and the branches are brought in from the side, cutting to the required size.

The trimmings are shaped like barrels or thick nickels, so they are first split in half, then each half is divided into the required number of pieces.

It is advisable to split along the grain , as the wood will split more easily, but you can split parallel to the first line along which the barrel was divided in two.

This approach will allow you to make neat chips of approximately the same size . However, apart from its aesthetic appearance, such fuel has no advantages.

Chopping with an ax

If a chopper or other equipment is not available, and also when you have to make chips from thin branches , the diameter of which is 1–2 cm , you can use an ax .

To prepare fuel using this method, you will need a thick log (block) and a sharp ax. A dull ax will not chop, but will crush the wood, which is why normal wood chips will not work.

The easiest way to chop is to rotate the ax relative to the branch by 10–15 degrees . The result of such cutting will be oval chips of varying thickness.

You can also place the ax at an angle of 90 degrees , but tilted to the side at least 30 degrees. This type of cutting is suitable if you need to obtain chips 1–2 cm thick.

Homemade electric shredder

You can make your own chopper if you have the necessary elements. The most practical is considered to be a branch crusher consisting of two shafts. For manufacturing, a drawing is created according to which the assembly is carried out.

Initially, the necessary material and tools are selected:

- electric motor with rated power up to 4 kW

- a pair of steel plates up to 10 mm thick

- two gears made of high-strength steel

- a couple of pulleys

- shafts, hardened and machined

- bearings for reliable shaft mounting

- direct cutting steel blades

- metal case

- steel pipe of the required diameter

- set of wrenches

- welding machine

- powerful drill or hammer drill

From a square blank we grind shafts on both sides. In the center we drill holes for 4 knives, threads are cut into them. The rounded edges are inserted into bearings. The drum is made from 4 studs and two steel plates in which holes are cut for the bearings.

Bearings and pulleys are firmly secured to the shaft, and gears are installed on the opposite side. We install the housing with the cutting mechanism and the engine on the pre-prepared frame. The transmission of torque from the drive will be carried out using belts through pulleys on the motor shafts and knives.

The receiver body is made of sheet metal, cut in the shape of 4 trapezoids. Using a welding machine, they are fastened together in the form of a truncated pyramid. The box is connected to the cutting mechanism body using a bolted connection.

Garden shredder from washing machine

To assemble a branch chopper with your own hands, you need to carry out the following manipulations:

- The activator is removed from an old type washing machine.

- A pre-made knife is installed directly on the motor shaft.

- The size of the working tool is made slightly smaller than the diameter of the drum.

- A hole is cut in the lower part of the body from which the wood chips will spill out.

- The housing is attached to the hole.

Homemade grinder grinder

Making a branch chopper with your own hands from a grinder is divided into several stages:

- We take a 20 liter bottle, cut off the bottom part, and enlarge the hole in the top. This will be the receiver.

- We pass the axis of the device from the side.

- We install the cutting element on top of the shaft and securely fasten the entire structure.

Trimmer crusher

For a branch chopper made with your own hands from a garden trimmer, you need to prepare the following necessary elements:

- container made of plastic or metal with a volume of up to 50 l

- several metal pipes with a diameter of up to 20 mm

- steel network with an area of about 1 sq.m. with a small mesh

- scrap of wooden board or plywood

- you need to purchase metal clamps for fastenings

- wooden blocks and screws for fastening them

- directly the trimmer itself of any design

As an auxiliary tool, it is recommended to prepare:

- screwdriver

- anvil

- drill

- jigsaw

- plumber's hammer

In order to make a chopper, you must follow the step-by-step instructions:

- Initially, prepare the container of the veterinary chopper. To do this, holes in the form of trapezoids are drilled and cut out at the bottom. The edges are processed.

- The mesh is secured to the bottom using bars. This creates a membrane.

- The container is placed at a low height using a pipe structure.

- The trimmer motor is mounted on the board.

- The rod of the device is shortened slightly and also installed on a base with a drive.

- A cutting tool is placed at the end of the rod.

- Before carrying out actual work, tests must be carried out. You can use different attachments to chop branches of different thicknesses.

Twin shaft shredder

The work on creating a twin-shaft shredder consists of the following phases - assembling the frame and receiving compartment, creating a chopping drum with knives, installing the drum and engine.

Necessary materials:

- engine;

- plate 10 mm – 2 pcs;

- gear – 2 pcs;

- pulley - 1 piece;

- shaft for knives – 2 pcs;

- bearings with fasteners – 5 pcs;

- knives;

- profile pipe;

- sheet metal (thickness 2 mm).

The first step is to make the frame. To do this, cut 4 parts from the profile pipe: 2 – 40 cm, 2 – 80 cm. Using a welding machine, fix the short parts between the long ones at right angles to form a frame. The distance between the two inner cross members must be such that the chopping drum can fit between them.

So that the chopper can be moved later, wheels must be attached to it. To do this, fix 2 racks on the frame, which will then hold the axle and wheels.

Mechanism assembly:

- When the frame is ready, you can assemble the grinding drum. To make a shaft, take a square blank for 4 knives or a round one for 3.

- For a square piece, grind the ends, making them round, so that they fit into the bearings. If you are using a round piece, sharpen the center section by making 3 flat cuts to accommodate the knives.

- The knives themselves can easily be made from Kamaz springs. Cut the required piece of spring, align it if necessary, heating it in a forge and hitting it with a hammer several times. Re-harden the part and let it cool.

- Make holes in the knives for the bolts.

- Sharpen the knives on the machine, choosing a cutting edge angle of 35-45°.

- Place the blades on the shaft and mark the attachment points. Drill holes at the marked points and make threads in them.

- To make a chopping drum, take two plates - these will be the walls. Use a welding machine to cut holes for the bearings and sand the edges. If it is not possible to do this step yourself, you can contact a locksmith workshop or enterprise.

- Install the bearings inside.

- Attach the covers to the metal walls with bolts.

- Insert the shafts into the bearings and secure them.

- Connect the walls with threaded metal studs and secure them with nuts.

- All that remains is to make a receiving compartment through which the wood will get inside. To do this, take sheet metal and make 4 identical blanks in the form of a parallelepiped.

- Find the narrowest side of each piece, step back 5 cm from it and fold the edge.

- Bend the remaining three blanks in the opposite direction.

- Assemble the box and make sure that the pieces fit snugly together.

- Connect the edges by welding or self-tightening rivets.

- At the base, on the bent sides, drill places for fastenings.

- Install the entire assembled structure onto the frame and secure it with bolts.

- Install the engine and tension the drive element (chain or belt).

- Lastly, install and secure the receiving compartment.

- Cover all internal parts with a protective cover to prevent wood chips and debris from getting into the rotating mechanisms.

Assembling the wood chipper in the video below will help you more fully imagine how the whole process goes:

SUBSCRIBE to OUR YouTube channel Ekonet.ru, which allows you to watch online, download free videos from YouTube about human health and rejuvenation. Love for others and for yourself, as a feeling of high vibrations, is an important factor in healing - econet.ru.

Please LIKE and share with your FRIENDS!

https://www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

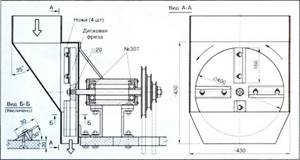

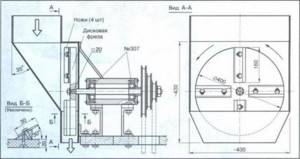

How to make a disc crusher?

If you like this type of chopper, then you need to understand that its assembly will require good welding skills. In addition, you need to prepare the following materials:

- steel sheet with a thickness of 10 to 16 mm;

- the same, 5 mm thick - on the casing and loading hopper;

- high-carbon steel for knives, a car spring is suitable;

- round or profile pipes to weld the frame;

- steel shaft with a diameter of 20 mm;

- 2 rolling bearings No. 307 or others;

- fasteners (bolts and nuts)

- pulleys, belt.

On various Internet resources you can find all sorts of drawings of a wood chipper; we bring to your attention one of the popular options:

A regular circle with a diameter of 400 mm is cut out of thick metal, and a hole for the shaft is made in its center. The pulleys and shaft must be turned on a lathe, and threads must be cut at the ends of the shaft to attach the flywheel and pulley. Knives can be made at home, following the drawing; in extreme cases, entrust this task to a milling machine operator. Next, a protective casing with a hopper must be welded from a steel sheet, and cages for bearings with holes must be made from it.

In essence, a homemade wood chipper is a cutting mechanism mounted on a frame of any design. The drive motor can be placed in a convenient location depending on the length of the belt. Do not forget to make the engine mount sliding so that the belt can be tensioned. The mechanism shaft is also installed on the frame, and a pulley and flywheel are attached to it. The knives should be bolted to the flywheel so that their angle of inclination is 30°. To do this, you need to prepare special steel linings.

Disc crusher for roundwood chips

Disc crushers have proven themselves well when crushing stationary round timber of large diameters and when crushing small lump waste and branches mobile. When crushing stationary round timber of large diameters, this type of equipment competes with drum crushers and has the following advantages over them:

- A disk chip crusher occupies a much smaller area than a similar drum crusher. But at the same time the height of the crusher is greater. This advantage is advantageous to use in workshops with a small area.

- The quality of wood chips is higher than that obtained from drum crushers. This makes it possible to obtain higher quality chips from such chips in the future.

- Disc crushers do not have a separate mechanism for feeding raw materials to the cutting part, since specially positioned knives and feeding raw materials at an angle allow the wood to be pulled in without additional devices. We would also consider this criterion a plus, since there is no need to maintain an additional unit.

Specially made blades allow you to throw wood chips at a distance of 3 - 10 meters.

The advantage of small disc crushers is their low price and long service life. For example, here you can buy a disc crusher quite inexpensively.

Branch crusher made from improvised means

Some craftsmen use ready-made devices as a basis, for which it is only necessary to make additional elements or parts. Instead of powerful stationary motors, you can use an electric drill or grinder. Let's look at the most common crusher manufacturing options:

From the washing machine

An activator-type “washer” is an excellent “semi-finished product” for making a homemade shredder. You will need to dismantle the activator and install a knife on the motor shaft, the size of which is slightly smaller than the diameter of the inside of the tank. The principle of operation of the knife is similar to that used in a coffee grinder - a horizontally mounted plate with sharpened edges. A hole is made in the lower side of the tank to which the outlet casing is attached. While the shredder is operating, wood chips will enter the shredder. The design is quite simple and reliable, tested many times in practice.

The washing machine motor has a low power, rarely exceeding 500 watts, so with the help of such equipment it is possible to chop only straw or grass

From the Bulgarian

To make a shredder from a grinder, you will need a metal container, in the central part of the bottom of which a hole is made for installing a knife. The axis of the grinder is passed through this hole, and a knife is installed on it. The tool itself is fixed in a stationary state so that the knife rotates freely without touching the walls of the container. The rotation speed of the tool is quite high, so it is recommended to set it to a minimum so as not to end up with a “puree” of green mass.

To make a shredder, it is recommended to use an angle grinder with a power of 3 kW or more

From a drill

In order to use a drill as a grinder, you will need a stand (usually it is recommended to use a regular stool with a 12 mm hole in the central part of the seat). A bucket with a similar hole in the bottom is installed on top; to keep it stationary, it is attached to the stool with self-tapping screws. The knife, the size of which is slightly smaller than the diameter of the bottom of the bucket, is mounted on an axle inserted into a bushing with a bearing. The sleeve is attached to the bottom of the stool. A drill with a self-locking chuck is attached to the axle and started. The device is suitable for processing green mass in small volumes.

A homemade shredder for branches or grass stems allows you to speed up the process of chopping material before putting it into a compost pit or oven, mulching the soil, and when carrying out other work. The costs of creating a shredder are much lower than the costs of purchasing a finished product, and many design options from scrap materials and elements allow you to choose the best option for a given estate. Considering the occasional nature of using such a crusher, making the installation yourself is a profitable and simple undertaking, and the efficiency of the shredder depends only on the thoroughness of the work.

Useful tips

To make a unit with which you can easily chop wood, it is not enough to purchase the necessary parts and find a good drawing. You will need to have at least minimal experience in the locksmith profession. You also need to know a few subtleties about making a crusher; only in this case will the homemade device work properly and efficiently.

When assembling the device, you need to consider some points:

- Even before starting work, it is worth familiarizing yourself with the drawing to understand exactly how the assembly takes place. In this case, the master will protect himself from minor mistakes that often occur during work.

- For better operation of the device and for its greater productivity, it is recommended to install as many saws as possible, the maximum is 25 pieces.

- The best performance is provided by saws whose thickness is 0.1 m.

- If you plan to process not only wood, but also material with a harder structure, then it is better to install motor blocks on the unit; they have more power than electric motors.

- It is most convenient to use saws with light-alloy attachments, then the gardener will not have to sharpen them himself.

Here are the basic rules that should not be ignored when making a wood chipper. The presented scheme will help create a practical, high-quality device that, with proper and careful operation, will serve the summer resident for a long time, and will also save him from numerous branches, boards and other wood debris.

Due to high prices for building materials, owners of private houses and those simply wanting to build a household structure are thinking about reducing the cost of work. In this case, a wood chipper will be an excellent assistant. With its help, material is produced for building blocks, from which a building is subsequently created. At the time of completion of construction, you should not hide the unit until the next need to construct the premises; the equipment will be useful for processing waste collected after spring or autumn garden cleaning.

In order not to spend money on purchasing new equipment, you can make a wood chip cutter yourself. To manufacture the unit, you need to carefully study the design of the device, create drawings, assemble the necessary parts and a set of tools.

Main components of a garden shredder

To assemble a grass and branch chopper (shredder) yourself at home, you need to first understand the structure of the mechanism, parts (see here), as well as the principle of its operation. This will help you assemble the equipment correctly and, if necessary, make changes to its design.

A homemade unit, designed for grinding mown grass and sawn branches up to several centimeters thick, has the following main structural components:

• engine;

• knives installed on the working shaft;

• frame (usually metal);

• protective casing;

• a box designed to receive cut vegetation;

• starting system.

The equipment itself can be made stationary or mobile. To create the latter option, you will additionally need wheels, as well as a handle. To make the frame, use metal corners or ready-made frames from workbenches. Boxes for processed vegetation are made from plastic buckets, tin, and bags. The protective casing around the knives should be thick and durable enough so as not to quickly wear out from the impact of grinding vegetation.

When processing plant debris, crushed pieces may fly out of the opening through which it is fed. Therefore, the neck is covered with a lid or simply with a cloth, for example, a bag.

The operation of the chopper is that rotation from the motor shaft is transmitted directly to the knives or through a chain/belt drive. The vegetation chopped by the blades enters the box. In this case, the final product is immediately ready for use.

According to the principle of operation, some homemade shredders are comparable to a meat grinder (they draw in and then grind organic matter), while others are comparable to a coffee grinder.

Varieties of engines for assembling homemade products

Electric and gasoline engines removed from unused equipment are used as a drive for homemade products. Each of these two options has its own advantages and disadvantages. Models with an internal combustion engine are more convenient in that their operation does not require a nearby power supply. But in general, they are more expensive and have a more complex design than their counterparts equipped with an electric motor. Therefore, it is easier to make electrical equipment, and also more compact.

The maximum thickness of cut branches that a branch chipper can grind depends on the power of the electric motor installed on it and the characteristics of the knives.

• Models with a motor up to 1.5 kW are capable of grinding sticks up to 20 mm in diameter. They are designed for low intensity work.

• If an electric motor of 3 to 4 kW is installed, then such units can chop branches up to 40 mm thick.

• More powerful electric motors (over 4 kW) are used to make a shredder for wood with a diameter of 7-15 cm.

The drive of the last category is equipped with equipment if it is necessary to constantly perform large volumes of work associated with the processing of waste of various thicknesses.

To create a homemade shredder, you can use electric motors from an angle grinder, washing machine, or trimmer. They must be adapted to work from a stationary network with a voltage of 220 V. In order to grind material as thick as possible at home, it is recommended to equip the shredder with an electric motor of 1500 rpm with a power of about 3.5 kW. This parameter for internal combustion engines corresponds to 5-6 horsepower.

Motor from an old washing machine

Shredder design for branches and grass

The purpose of the unit is to quickly and safely grind plant debris. The main function is performed by the cutting block. The knives are driven by the engine directly or via a belt drive. The units are installed on a stable frame. The moving elements are covered with a casing. Two compartments are made for feeding branches and unloading chips.

Metal frame

A homemade shredder with a powerful electric or gasoline engine needs a stable, durable frame with space to install the engine and a rectangular support for the cutting unit.

To make the shredder frame use:

- profile pipe 25;

- corner at 30;

- channel.

Fasteners:

- ears for the engine,

- nuts,

- hairpins.

Engine

Full autonomy, work anywhere in the garden, independence from the outlet - the advantages of a gasoline engine. A homemade shredder for processing branches, tomato tops, and grass is equipped with a motor from a motor-cultivator or walk-behind tractor with a capacity of 6 liters. With. It is moved from one unit to another.

You need a gearbox that provides 90° rotation if the gasoline engine has a horizontal shaft and the chopper has a vertical shaft.

Electricity costs are lower than gasoline, so if there is a network on the site, an electric motor is installed on the unit. To chop branches 2-3 cm thick, a 3-phase electric motor of 2200-3500 W is sufficient. When making a low-power grass cutter, they take engines from household devices. They are removed from washing machines and vacuum cleaners.

Knives

The thickness of the branches processed by the shredder depends on the design of the cutting unit. In home-made designs, several options are implemented:

- to grind branches with a diameter of 7-8 cm, several cutters are installed on the shaft;

- hammer-type cutting block for grinding thin rods;

- the universal cutting mechanism is made of 15-30 circular saws mounted on a shaft;

- knives from factory garden equipment - brush cutters, lawn mowers;

- chop grass - trimmer line;

- stump crusher from a plane;

- two shafts with 3-4 steel knives for cutting branches of bushes and trees.

Homemade knives are made from springs.

Protective cover

To prevent chips from flying around, you need a protective cover. It is made from sheet steel with a thickness of at least 1.5 mm. Tin is not suitable for this purpose. During active use of the shredder, it quickly becomes deformed from strong impacts of wood chips.

Container for receiving sawdust

Old shopping bags, boxes, buckets, and bins are used to collect small garbage. For powerful units, the bunker is welded from steel sheets and riveted from galvanized steel.

Electrical wires and start/stop button

To turn on and off a homemade unit, use a push-button station designed for the appropriate current. Its purpose:

- turning off and turning on electrical equipment;

- changing the direction of rotation (reverse).

To connect the engine to a three-phase network, you need a five-core flexible copper cable in double insulation; for a single-phase household network, a three-core cable is sufficient.

Frame making

For any type of shredder it is necessary to make a base. All other structural elements will be attached to the frame. It can be welded from corners or pipes (preferably square ones).

Recommendations for making the base:

- The height of the bed should be adjusted to your height.

- The width should be sufficient for the stable position of the entire structure (it is recommended to make it at least 50 cm).

- A cross member should be welded in pairs between the posts. This will give the base additional rigidity.

- To give the unit mobility, you can attach wheels and a handle. This will allow you to quickly and easily move the device around the entire site.

The engine is installed in the frame frame - this way it will not stick out. This is especially true for shredders that are made by hand.

Manufacturing Guide

It should be noted right away that even the simplest design will not work if the summer resident does not have metalworking skills. You will have to work not only with your hands, but also with your head - the drawing is taken as a basis, you need to be able to read it.

When the scheme is selected, they prepare the necessary materials and parts. Before assembling the country shredder, all work is divided into stages.

Selection of engine and calculation of belt drive

For the selected type of shredder, the number of motor revolutions does not matter - the required rotation speed will be provided by the drive itself. Therefore, you should not take an engine that is too powerful.

The wood chipper will work fine at 1500 rpm. The best option for a summer resident is 2.5-3.5 kW. For mini-tractors and walk-behind tractors, you should choose an engine with a power of 5-6 hp.

Important! The main criterion that people pay attention to is the diameters of the pulleys. At the same time, the speed of rotation of the knives does not play a special role in productivity. What matters here is the force applied (i.e.

torque)

What matters here is the force applied (i.e. torque)

Example of a wood chipper with two shafts

Sample calculation

Presumably the farm has a 2800 rpm engine. They decided to connect a wood chipper to it. But the optimal solution is the number of revolutions is half that (1400). The parameter can be reduced if the diameters of the shafts differ from each other by 2 times. In other words, the driving pulley should have a size of 100 mm, and the driven pulley should have a size of 200.

Note! The distance between the pulleys is not particularly important. Although a belt that is too long is less tensioned, which reduces transmission efficiency

Preparation of materials

To make an electric garden branch shredder with your own hands, it is not necessary to purchase new materials. For this, improvised means are quite suitable.

A good owner will always have several types of rolled metal in his barn necessary for making a frame:

- profile pipes 40x40 mm or round pipes 32-48 mm;

- corners of 35 mm, welded in a box, and single-shelf angles with parameters of 50-63 mm;

- channel No. 6.5-10.

To make a shredder, you will have to buy from 20 to 25 circular saws, which will provide a working part with a width of 80 mm. The disc kit will require supplied washers with a diameter of 20 mm.

Example of a circular saw blade shredder

For the chipper you also take:

- shaft with bearings;

- sheet metal 5 mm for the casing and 1-2 mm for the hopper;

- steel circle (its parameters are selected based on engine power);

- bolts with nuts M12-16 (necessary for fastenings).

Having prepared everything you need, you can begin assembling the unit.

Frame making

Having prepared in advance a drawing of the future device, first they make a frame to which the units will be attached.

To prevent chopping branches from being tiring, when welding corners (or pipes), you need to adhere to the following recommendations:

- the height of the frame is adjusted to the height of the worker;

- for the stability of the structure, its width must be at least 0.5 m;

- cross members welded to the racks will ensure the rigidity of the frame;

- For mobility of the unit, it is recommended to place the frame on wheels and attach a handle.

Important! The motor should not extend beyond the frame dimensions. Therefore, it should be immediately placed on target

Shredder drawing

The crusher manufacturing process includes three stages. At the first stage, it is necessary to make a drawing, then the material and tools should be prepared, and at the last stage the apparatus itself is assembled.

To manufacture the unit, you can use the following scheme.

It is not necessary to come up with your own design; you can use a simple circuit, and already in the process of work, upgrade the device by adding something of your own.

Necessary materials

When creating a drawing, you should pay special attention to the location of the cutting elements, as well as the cutting angle. Before work you need to prepare materials:

- saws with a thickness of 0.6-0.1 m in the amount of 20 pieces - this will ensure normal operation of the device;

- engine - each master chooses this part at his own discretion and taking into account the size of the material being processed;

- studs with which the cutters will be attached;

- welding machine;

- various washers, nuts;

- metal corrugated pipe from which the chopper body will be made;

- hopper and casing made of galvanized metal.

If all materials are prepared, the drawing is made, then you can begin assembly. All saws are installed on a prepared axle. Their size range must match the cutters. Then you need to secure the discs with prepared nuts and washers. This fastening has its own characteristics: it is done between the saws using thin washers, then the discs will not touch each other. The number of saws should be 1 unit more than washers.

After securing the axle, you need to start installing the pulley. For good rotation of this part you will need bearings with a diameter of 2 cm.

Frame assembly

After assembling the main mechanism, it is necessary to make the frame. To do this, you will have to purchase special professional pipes. Using a welding machine, weld the pipes together and strengthen the structure with metal profiles; they must be mounted inside the frame. This design will strengthen the hopper and the block that will chop the wood.

Preparation of materials

To make a shredder you will need quite a lot of metal. To save on materials, you can try to find some of them in the household. To assemble the frame you need:

- Single corner with equal edges. Width starts from 50 mm.

- A square pipe or two corners that are welded in a “box”. The edge size is 35 mm.

- Square pipe with 40 mm edges.

- Channel number from 6.5 to 10.

- Pipes with a diameter from 32 to 48 mm.

In order to secure the electric motor, you need to take a sheet of metal 10 mm thick. The dimensions must correspond to the designed distance between the mounting holes with a margin of 3-5 cm. To tension the belt, you can use two types of devices:

- The holes in the metal sheet are not round, but oblong. This is necessary in order to be able to move the frame and fix it with bolts.

- The plate is placed on a hinge (on one side). In this case, the belt tension occurs under the weight of the engine. On the other side, the plate is fixed.

To assemble the simplest shredder for crushing branches, you will have to buy 20-30 circular saws with hardened teeth and the same number of attachment washers (usually a diameter of 20 mm is used). With this number of saws, the working part will be about 8 cm. In the future, it can be expanded or reduced.

The teeth of a circular saw are slightly thicker than the base, so individual saw blades cannot be mounted end-to-end. You need to install washers between them.

The shaft is turned on a machine from a solid steel billet, but before that you need to select two bearings to the size of which the part will be made. It is necessary to make bearing housings or purchase them at a specialized store.

If the design of the shredder includes chopping knives, then the base can be a jointer shaft, but it will be necessary to change the diameters of the axles on which the bearings are pressed. It is better to make the working part up to 10 cm in size. Knives are usually machined from old car springs.

Cutting elements

Another main part in a homemade unit is knives. When choosing this part, it is necessary to take into account that a simple disk can only process thin twigs. Devices equipped with a combined design can handle even thick branches, while processing them into very fine chips. Therefore, if you plan to use wood chips as fuel, then it is better to equip the shredder with just such cutting elements.

The following blades are commonly used in garden shredders:

- A circular knife can only cope with small wood material, the thickness of which is no more than 2 cm. It processes thin stems and grass perfectly.

- Milling devices - such cutting elements crush wood up to 10 cm in diameter. But it should be borne in mind that the material that needs to be processed must be dry. The fact is that fresh bark and wet wood chips clog the cutter and the device simply stops working.

- Milling turbine cutting knives - these devices are the most common and easy to use. Their main advantage is versatility. With this cutting unit you can process wood of any thickness, regardless of the degree of humidity.

We recommend: Do-it-yourself vermicompost production at home

But we must immediately add that it is very difficult to make such knives yourself, so it is better to purchase them in specialized stores. If you wish, you can make homemade knives. Mostly designs made of knives and special disks are used, as well as a two-shaft system with knives mounted on it.