Stainless steel chimney is widely used in heating systems. This is a popular system for installing boilers and stoves at home and in bathhouses. Stainless steel ensures efficient operation of the heating and chimney systems. At the same time, it benefits from durable operation and simple installation.

Stainless steel chimneys are easy to install at any stage of the work thanks to the prefabricated system. Chimney elements include pipes, adapters, tees, adapters, clamps, flanges, bends and other elements.

Connecting and transition elements are available in different diameters and with different bending angles. A huge selection of components allows you to create a design of any complexity.

For the manufacture of chimneys, AISI 304 , 316 and 321 elements and pipes are in demand. Due to the high chromium content and the addition of nickel, these grades can withstand operation in aggressive environments when exposed to high temperatures.

Advantages of steel chimney pipes

Stainless steel stove pipes and chimneys are characterized by a number of advantages that are difficult to underestimate:

- long operational period, which is due to the unique properties of the manufacturing material;

- high strength;

- the ability to install systems of varying complexity;

- versatility;

- acceptable price.

A stainless steel chimney pipe is stronger than one made of brick, which is relatively unstable to temperature changes, which in turn leads to its destruction. A steel pipe is not afraid of corrosion processes; it is not affected in any way by high humidity or air dryness, increased heat and aggressive environments.

This pipe has a modular structure that allows you to quickly replace any structural part manually if necessary. The chimney is installed using special outlets. Using such elements, you can bypass engineering blocks or architectural structures.

Manual installation of a stainless steel chimney pipe can be carried out with a shift in any direction without moving the heating equipment.

The circular cross-section of the steel pipe makes the intensity of deposition of combustion products on its surface from the inside lower. These pipes do not require cleaning as often.

About air ducts in the boiler room

Particular attention should be paid to ventilation for a gas boiler in a private house. Usually a special room is allocated for the boiler room

Modern boilers require high-quality chimneys. To clean the room from combustion products, separate ventilation is installed from the hood and gas pipe.

To make it effective, a ventilation duct is installed in the boiler room in the form of two exhaust pipes that go outside and can be installed inside a brick duct. The first serves as a chimney and removes combustion products. The second channel is intended for cleaning and ventilation of the room. It is advisable to equip it with a fan that can rotate in both directions to enhance air exchange into the room. A special steel hood is used, coated with heat-resistant enamel and withstanding high temperatures.

Two pipes for boiler room ventilation

For a gas boiler in a private house, a coaxial chimney is also used, consisting of two pipes located one inside the other. Exhaust gas is discharged through the internal one. In addition, sections of pipes passing through the attic and other cold rooms must be insulated to prevent condensation from forming on the pipe. You can use special pipes insulated with insulation, or use fire-resistant mineral wool insulation.

A variety of stainless steel chimney pipes

When installing manually, the following types of components are used:

- Single layer pipe.

- Corrugated pipe.

- Sandwich pipe.

A stainless steel chimney pipe of one layer is characterized by a thickness of 0.6-2 mm, reasonable price, but limited scope of use.

Single-layer stainless steel pipes

This pipe can only be used inside insulated rooms.

A large temperature difference between the outside and the inside contributes to excessive energy consumption, and the large amount of condensate that appears affects the overall functionality and operating life of the heating system.

A corrugated stainless steel chimney pipe is used to make curved transitions. These products made from other materials rarely boast strength and temperature resistance. The corrugated steel structure easily withstands heat up to 900 °C and removes the combustion products of a fireplace, boiler, stove, etc. quite well.

Corrugated chimney pipe

Sandwich pipes are multifunctional. Their installation is carried out manually both from the inside and from the outside of the room.

Double-walled sandwich chimneys

Find out more about stainless steel sandwich pipes

STEPS OF THE SURVEY

When inspecting pipes, the following scope of work is performed, according to RD 03-610-03 “Guidelines for the inspection of chimney and ventilation industrial pipes”:

- analysis of existing design, executive and operational documentation;

- external inspection of all structural elements of the pipe;

- thermal imaging inspection of reinforced concrete and brick pipes (if necessary);

- internal inspection of the gas outlet shaft or lining;

- inspection of the annulus of pipes of the “pipe-in-pipe” type;

- determination of the strength and condition of materials using non-destructive testing methods, sampling and laboratory testing (if necessary);

- determination of roll (curvature) and settlement of the pipe in the absence of appropriate measurements;

- study of changes in the characteristics of foundation soils and hydrogeological conditions in the presence of unacceptable pipe tilt;

- measurements of temperature, humidity, aerodynamic conditions and operational parameters of the gas environment in case of non-compliance with the design operating conditions and lack of data on the actual conditions (if necessary);

- calculations of the bearing capacity of the shaft and structures, taking into account identified defects and damage of hazard category “A”;

- establishing the causes of damage;

- drawing up a conclusion.

Stainless steel grades

A stainless steel pipe for a chimney can be of different grades, which in turn affects the operational parameters of the product.

| steel grade | Characteristics |

| 304 | Similar to grade 316 stainless steel, but has fewer alloying additives. It is characterized by excellent weldability, corrosion resistance and high strength at fairly low temperatures. |

| 310S | It is resistant to heat up to 1000 °C. |

| 316 | Enriched with inclusions of molybdenum and nickel. This increases the resistance of stainless steel to chemical attack and temperature differences. Excellent for organizing a chimney exhaust for fireplaces and boiler rooms, the heating units in which operate on diesel fuel, wood or gas. |

| 316i, 321 | Multifunctional. They are characterized by high plasticity, heat resistance up to 850 °C and acid resistance. Experts recommend using pipes of these steel grades for wood-burning stoves. |

| 409 | Suitable for devices that run on solid fuel (fireplace, stove). |

| 430 | Used for parts that are least susceptible to aggressive influences. External casings are often made from it, since the humid surrounding atmosphere does not affect it. |

The diameters of steel chimneys vary from 80 mm to 300 m.

| Diameter | N | Weight 0.5 | Weight 0.8 |

| 80 | 195 | 0,27 | — |

| 100 | 195 | 0,32 | 0,61 |

| 110 | 195 | 0,36 | 0,68 |

| 115 | 195 | 0,37 | 0,7 |

| 120 | 195 | 0,39 | 0,74 |

| 130 | 195 | 0,42 | 0,8 |

| 135 | 195 | 0,43 | 0,82 |

| 140 | 195 | 0,45 | 0,86 |

| 150 | 195 | 0,48 | 0, 91 |

| 160 | 195 | 0,51 | 0,97 |

| 180 | 195 | 0,58 | 1,1 |

| 200 | 195 | 0,64 | 1,22 |

| 220 | 195 | 0,71 | 1,35 |

| 250 | 195 | 0,8 | 152 |

| 280 | 195 | 0,9 | 1,71 |

| 300 | 195 | 0,96 | 1,82 |

Popular ones are:

- stainless steel 150 mm;

- stainless steel 80 mm.

Chimney pipes made of stainless steel 150 are usually used in fireplaces with sufficient power to heat a house outside the city or a bathhouse with a large steam room.

Do-it-yourself installation of furnace equipment

The sandwich chimney design initially has a high degree of fire safety, so it is not difficult to install. And by adhering to some rules, you can install it yourself. The main recommendations are:

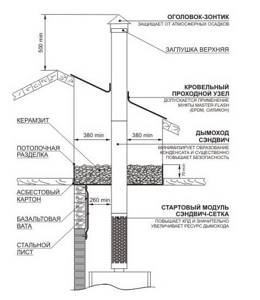

- When a pipe passes through the most fire-hazardous area, an additional layer of thermal insulation is required;

- It is prohibited to install a sandwich pipe above the furnace device.

The most common thermal insulation layer is basalt fiber, as it has good resistance to various chemicals and high temperatures. According to SNiP requirements, the dimensions of basalt insulation should be no more than 25-60 mm. Do-it-yourself installation of the structure can be carried out according to two principles:

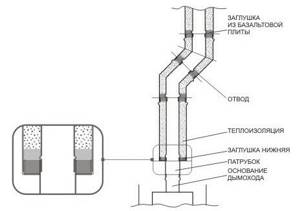

- By the smoke;

- By condensate.

Sandwich chimney installation

Chimneys are collected according to smoke in order to prevent carbon monoxide from entering the house by securing tees. The condensate is collected so that the condensate resulting from the temperature difference can flow down the pipe. With this installation, tees are not required. It will be correct if the inside of the pipe is installed for condensate, and the outside for smoke. Whatever method is chosen, the most important thing is that high-quality sealing of the joints is necessary. The chimney is connected in the following ways:

- Flanged;

- Bayonet;

- Bridge of cold.

You need to correctly install the structure with your own hands from the stove to the roof, connecting all parts step by step with clamps. To work you will need the following tools:

- Roulette;

- Level;

- Jigsaw;

- Bulgarian.

Sandwich installation using bends

The first part of the structure is installed from stainless steel without a layer of insulation, since the insulation will burn due to exposure to high temperatures. In order for the structure to be reliable, it is better to use a special high-temperature sealant to connect the joints. With a high degree of tightness, the thrust is much higher.

Some difficulty when installing stove heating with your own hands can be a passage through the ceilings. To do this, it is necessary to cut an opening and lay another layer of thermal insulation in the places where the ceiling comes into contact with special pipes. Next, the pipe is passed through the opening.

Types of steel parts for chimneys

On the specialized market you can see a variety of stainless steel elements produced for chimneys.

| View | Characteristic |

| Straight pipes with a length from 330 to 1000 mm | All are characterized by a special bell joint, which does not require any additional elements. |

| Elbow (bend) 45º | Used when it is necessary to change the direction of the chimney pipe on vertical or inclined sections. |

| Bends 90º | Typically used to transition from a short horizontal section near a heating device to the main part of the chimney. |

| Tees at an angle of 45º or 87º | It is installed at the installation site of the condensation collector or, in the case of installing two devices, when they are connected to a single chimney system (separate approval of the regulatory authorities is required). |

| Inspection chimney elements | Necessary for constant monitoring and cleaning of the system. |

| Condensation collector | Mounted in the lower part of the main vertical section, it is necessary for regular cleaning of the chimney from accumulated moisture. |

| Spark arrestor, cap, waterproofing skirt | These are the elements of the upper part of the chimney. |

You can also buy special parts for passing through a wall, ceiling between floors or roof. If these elements are not implemented by the supplier, they will need to be done manually.

Arrangement rules

Carbon monoxide is almost impossible to detect; it has no taste or smell, and is invisible visually. Moreover, it is heavier than air, so it settles and remains in the room. In this regard, it is necessary to follow the basic rules when installing the heat generator and chimney:

- When installing a stove or fireplace with a large mass, prepare a foundation for it in advance: a small platform that will not budge if the base of the building sag.

- Wall and ceiling ceilings, if they are made of flammable materials, should be located at a considerable distance from the flame source (about 40 cm). When passing through wall and ceiling ceilings: 500 mm - to combustible, 380 mm - to non-combustible.

- Maintain a minimum number of bends in the smoke duct. At the same time, do not allow right angles in the system; it is better to split such a bend into two sections or use elements with a smaller and larger angle.

There are standards put forward during installation work depending on the type of fuel used. These are SNiP 41-01-2003, NPB 252-98 and VDPO. Ignoring them can cause many violations that affect the quality of the heat generator. Incorrect selection of the device can lead to overheating of the floors, insufficient draft leads to soot settling, and a leaky assembly leads to smoke in the room.