The ventilation duct is a mandatory structural element of the exhaust system, which is designed to remove gases, steam, unpleasant odors, and dust from the premises into the main ventilation duct. Available with various technical and decorative parameters. Its design is simple, so self-assembly is possible.

Roof ventilation box

What is a box?

Structurally, it is a ventilation duct of round, square or rectangular cross-section. Depending on the installation method, it can be built-in or mounted.

Additional elements include:

- adapters designed for sealed connection to the main ventilation duct;

- an elbow used to change the direction of laying, usually at an angle of 450 or 900;

- connecting elements that allow you to create channels of the required length;

- a check valve installed inside the structure to prevent reverse draft from the ventilation system;

- protective grille that prevents foreign objects from entering the ventilation system.

The hood box can be plastic, plasterboard, metal or wood.

Hanging structures are attached to walls or ceilings. For use in residential premises, they can be made with decorative finishing, and for industrial use - without it. Provide convenient access to the channel for its maintenance, inspection, and repair.

Built-in structures are designed for installation inside interior items to hide them and maintain a single design style for the room. The benefit of this solution is to reduce noise and vibration from the operation of the hood and other ventilation equipment. However, their maintenance is difficult.

The main characteristic of ventilation ducts is their throughput. It depends on the size, shape of the channel, evenness and smoothness of the inner surface, and the quality of the joining seams.

Dimensions

The dimensions of the exhaust duct must be such as to provide the necessary capacity for pumping out air masses. To reduce the resistance of the internal surface, round structures are used. Standard diameters for domestic purposes are 80 mm, 100 mm, 125 mm, 150 mm, and for industrial purposes - from 200 mm.

Rectangular boxes are manufactured in the following dimensions:

- 110x55 mm;

- 120x60 mm;

- 204x60 mm.

Adapters are available from round to rectangular boxes with the following dimensions:

- from diameter 100 mm to 110x55 mm;

- from a section of 100 mm to 120x60 mm;

- from diameter 125 mm to 204x60 mm.

The wall thickness of the exhaust pipe is from 1.5 to 4 mm. The lengths of one element range from 35 to 200 mm.

Types of hoods

There are the following types of hoods for boxes:

- A suspended dome with an air filter for air purification, mounted directly above the source of air pollution. It is easy to replace and maintain.

- Built-in, installed inside furniture, niches, ceilings. It may have non-standard sizes, so finding replacement analogs may be difficult.

- Flat, with optimal power. Capable of purifying the air without additional connections. Requires frequent filter replacement. Their service life is minimal compared to other types of hoods.

The shape of the hood is:

- corner;

- island;

- wall-mounted

Dome suspended hood

Materials for choosing boxes for the kitchen: advantages and disadvantages

The kitchen hood box can be made from the following materials:

- plastic;

- metal;

- drywall;

- wood or MDF panels.

Plastic construction

Plastic ventilation ducts have the following advantages:

- light weight and ease of processing compared to other materials, making installation easy even for beginners;

- high level of sound insulation;

- resistance to high humidity;

- built-in or external installation on walls even with minimal load-bearing capacity;

- ease of cleaning from all types of contaminants;

- service life up to 10 years without loss of aesthetic properties.

Disadvantages of plastic products:

- round and rectangular plastic structures are unstable to external mechanical influences, as a result of which dents and cracks form;

- fading under the influence of direct UV rays or loss of color saturation compared to the original;

- not suitable for ventilation of industrial premises where powerful equipment or an increased level of fire hazard is used.

Metal construction

Metal channels for ventilation are made of stainless, galvanized, powder-coated steel and aluminum. The service life is up to 50 years, they are characterized by high strength, the ability to withstand temperature changes and vibration.

However, it is worth considering the disadvantages of ventilation ducts for metal kitchen hoods:

- high complexity of installation;

- impossibility of fastening to walls with low load-bearing capacity;

- decrease in corrosion resistance when the protective coating is damaged;

- high level of noise and vibration;

- the cost is higher than that of channels made of other materials.

Metal channels for ventilation

Plasterboard construction

Installing a plasterboard box in the kitchen is beneficial for the following reasons:

- ease of construction;

- increased fire resistance and optimal moisture resistance;

- ease of processing.

The disadvantages are:

- fragility, which significantly complicates transportation and installation;

- low level of sound insulation;

- high requirements for sealing the gypsum layer inside the material, since when moisture enters it loses its properties;

- instability to mechanical stress.

Decorative wood box

Wooden decorative boxes for kitchen hoods can easily be combined with interior items and naturally fit into the overall design concept.

Decorative wooden boxes have the following advantages:

- natural material that provides an optimal microclimate and regulation of air humidity levels;

- ease of processing and installation;

- good sound insulation;

- high strength.

Disadvantages of wooden structures:

- low moisture resistance, leading to the appearance of mold, mildew, and rot;

- with minor mechanical impacts, defects (scratches, dents, cracks) may form on the surface;

- increased absorption of moisture, as a result of which the weight of the structure increases and, if it is poorly fastened, it can break off;

- unwanted contact with materials that do not absorb moisture, as condensation will begin to appear at the joints, leading to loss of wood properties.

Pros and cons, scope

Plastic air ducts are perceived negatively by many, as they are not sure that plastic does not emit harmful substances during operation.

Poor quality plastic may be unsafe, but even household appliances contain so many plastic parts that this consideration seems irrelevant. For example, in a kitchen hood with filters, most of the components are made of plastic. And here are the most difficult operating conditions - high temperature, large amounts of fat, evaporation of chemically active substances. Even open laying of plastic pipes does not spoil the appearance

In general, experts recommend installing plastic on exhaust ventilation ducts. There are no restrictions here. But for the inflow, you need heat-resistant ones made of special plastic. Especially if the inflow is heated or recuperated.

Where can I use it?

Another reason why plastic ducts are not recommended is fire service concerns. There have been cases where permission to use gas equipment was not signed if the ventilation was made of plastic. But it was a frame house, and there the requirements are different. If in doubt, it is best to check with your local fire inspector. In general, there are recommendations in regulatory documents.

Extract from SNiP 41-01-2003

According to SNiP 41-01-2003, paragraph 7.11, plastic air ducts can be used in low-rise residential, public, administrative and industrial buildings of category D. They cannot be laid in basements, undergrounds, attics and technical floors, in rooms with regulated fire safety conditions.

Advantages and disadvantages

Plastic air ducts have both supporters and opponents. Their main disadvantages:

- Flammability. Everything is clear here. Only metal air ducts do not spread fire. Although not all plastics burn and spread combustion, such materials with “reduced” flammability are expensive. Therefore, plastic air ducts are allowed only in one-story houses.

- The accumulation of a static charge, which leads to the accumulation of dust (it can flare up again). In fact, much more dust accumulates in corrugated areas. To reduce its amount, it is necessary to install a plastic air duct after completing “dusty” construction work and install filters that catch most of the dust. In addition, plastic ventilation pipes are treated with a special compound. It forms a film on the surface that prevents the accumulation of static charge.

- With low quality workmanship, thin walls or a large cross-section, gaps may form at the joints due to changes in geometry. This can be fixed, but there is such a drawback.

These are the disadvantages of using plastic ducts. There are more than enough advantages:

- Easy installation. The presence of fittings and shaped elements allows you to create a system of any configuration. Plastic is easy to cut and weighs little.

- Due to the perfectly smooth walls, the air encounters less resistance.

- Easier to ensure tightness. For reliability, the joints can be coated with sealant.

- Modern plastic air ducts are joined using end-to-end joints without overlaps, which reduces resistance to air movement.

- Low noise level. With a capacity of up to 100 cubic meters per minute, air movement is almost silent.

- Not subject to corrosion.

Overall, plastic ductwork is not a perfect solution, but the ease of installation and good performance outweigh the disadvantages. In general, experts recommend installing plastic on exhaust ventilation ducts. There are no restrictions here. But for the inflow, you need heat-resistant ones made of special plastic. Especially if the inflow is heated or recuperated.

Also, when selecting, you should proceed from the operating conditions. For example, it makes sense to use a plastic air duct for an exhaust ventilation duct from wet rooms, since galvanized ones are susceptible to corrosion, and stainless ones are very expensive.

How to choose?

The choice of hood box depends on the following criteria:

- operating features - temperature, humidity, dustiness of the room, mechanical influences;

- maximum permissible load on supporting structures;

- ventilation equipment capacity;

- requirements for vibration and noise insulation.

When choosing an air duct, you must follow the following recommendations:

- the number of joints should be minimal;

- you should reduce the number of structural elements when creating a wiring plan and at the same time maintain the system parameters;

- To reduce the number of blockages, flow resistance, noise and vibrations, channel turns should be kept to a minimum.

Kitchen hood box

Rules for choosing the duct cross-section

The cross-section of the air ducts is selected depending on the exhaust power, maximum air throughput, regulatory requirements for installation and operation. Usually the size is taken equal to the area of the hood inlet pipe or slightly larger. If ventilation is rarely used, the cross-section relative to the pipe may be reduced.

The cross-sectional area Sc (cm2) is calculated using the formula:

S_c=L×k/V,

where L is air flow in m3/hour;

V is the speed of air movement in the ventilation system m/sec;

k is the coefficient of dimensional coordination; in these units of measurement it is equal to 2.778.

The actual cross-section S (cm2) of a circular shape can be determined as follows:

S=(π·D^2)/400,

where D is the pipe diameter in cm2.

For rectangular air ducts, the actual cross-section is determined by the following formula:

S=(A B)/100,

where A is the channel width in mm, and B is the length, mm.

Manufacturers and models of ready-made solutions: ratings and prices

The rating of exhaust systems is as follows:

- in the budget class worth up to 10 thousand rubles: Siarko, Faber, Korting, Kuppersberg;

- in the middle class up to 50 thousand rubles: Miele, Siemens, Smeg, Teka;

- in the elite class from 50 thousand rubles: Electrolux, Falmec, Bauknecht.

TOP 5 manufacturers of hoods: Hansa, Gorenje, Samsung, Elikor, Bosh.

Installation of a rigid rectangular duct

To connect ventilation pipes to each other and to fittings, various connecting devices are used. The flange method is considered the most popular in this matter. Here, metal corners and tire rails are used as flanges for grooves of various profiles. They are sealed in the form of a square.

In practice, there are several ways:

- An object of the required cross-section is first manufactured and then secured by welding.

- A common option is to connect the parts of the channel using anti-corrosion rivets. They look like special clamps. On the metal structure, in the groove of the bus bar, stiffening angles with technological holes for connection with bolts are installed. Connections between metal structures are sealed with a rubber seal of six to eight millimeters. You can use silicone sealant. If there is warm air in the ventilation system, then asbestos cardboard is used in its design.

Not everywhere, thanks to bolts, studs and nuts, sufficient tightness of the system is achieved.

If the pressure in the structural ventilation device is not more than 1000 Pa, but the dimensions of the sides of the structure are large, clamps in the form of a bracket are used:

- bracket more than 900 mm with twenty mm flanges;

- bracket more than 1100mm at thirty millimeters.

At a pressure of more than 1000 Pa in the system, the need to use staples is as follows:

- for 20 mm joints, from 700 mm is used;

- for 30 mm joints it is used for widths greater than 900 mm.

On straight sections of the structure, fewer clamps are required at joints than on curved and conical surfaces. After any installation, be sure to check it.

Making a box with your own hands

You can create a high-quality ventilation system yourself. It is not necessary to purchase ready-made solutions, since you can make a plasterboard box for a pipe in the kitchen yourself. A minimum of tools and time for design and installation will be required.

Connecting the hood yourself is carried out in accordance with the instructions supplied by the manufacturer. The sealing of the pipe requires special attention.

Step-by-step instructions for making a box:

- A sketch is created based on the measurements taken.

- Materials are being purchased.

- The walls are marked for fastening the frame.

- The frame is mounted.

- A mesh and check valve are installed inside the frame.

- The hood is installed.

- The frame is covered with plasterboard.

- The joints are sealed with sealant.

- Exterior finishing is in progress.

- Build quality is tested.

Making a box with your own hands

Construction result

As we have already noticed, repairing ventilation is not an easy task and it will take a couple of days to complete a high-quality repair, especially if it’s not in the same room. Having the electrical tools needed for repairs will make the task much easier. To visually understand what each repair step looks like, it’s a good idea to watch the corresponding videos on the Internet.

WATCH THE VIDEO

In terms of attracting specialists to repair, do not expect to cope with the repair cheaply: although companies offer to solve this problem quickly and without monumental investments, the final amount is rather large. Therefore, it is better to do this work yourself, because there is nothing super complex here that an ordinary person cannot do.

Related Posts

- How to close the pipes in the toilet

- What should be the diameter and length of the exhaust duct?

- How to calculate the cross-section and diameter of an air duct?

- How to attach air ducts to the wall yourself

- Correct installation of a hood in the kitchen with your own hands

- The best plastic boxes for electrical wiring: how to choose the size and type of box for wiring installation

- Carbon filter for hood: device, principle of operation and replacement technology

- Pipe box

- Plastic ventilation pipes for hoods: types, their characteristics, application

- How to assemble a ceiling box from plasterboard?

- Decorative overlay for a heating pipe: what is better to choose to make it look beautiful?

- Corrugated air ducts for ventilation: corrugated hoses and corrugated pipes

- Dimensions and types of plastic air ducts for ventilation

- Soundproofing ventilation: device features and installation methods

- Features of the box for the LED strip and its installation yourself

- Calculation of the area of air ducts and fittings, aerodynamic and other indicators

- How to install a hood in the kitchen with your own hands

- Choosing a corner hood for the kitchen

- How to clean the ventilation in an apartment yourself

- Ventilation in a suspended ceiling

- Ventilation grille with non-return valve

- Features and installation of galvanized air ducts for ventilation

- How to glue fiberglass correctly?

- How to choose a hood over a gas stove: what criteria to consider when choosing a suitable model

- Fum tape technical characteristics, how and how much to wind on the thread

Read with this

- How to close the pipes in the toilet

- What should be the diameter and length of the exhaust duct?

- How to calculate the cross-section and diameter of an air duct?

- How to attach air ducts to the wall yourself

- Correct installation of a hood in the kitchen with your own hands

- The best plastic boxes for electrical wiring: how to choose the size and type of box for wiring installation

- Carbon filter for hood: device, principle of operation and replacement technology

- Pipe box

- Plastic ventilation pipes for hoods: types, their characteristics, application

- How to assemble a ceiling box from plasterboard?

Hood box: operating rules and use of accessories

Rules for using hood boxes:

- periodic replacement of filters;

- control of check valves operation;

- keeping the external surface clean;

- identifying blockages and removing them.

When using a plasterboard box in the kitchen, you need to ensure the integrity of its outer protective layer, avoid using it in high humidity, and do not use abrasive tools when cleaning.

If the appearance of the structure deteriorates, you need to use special decorative accessories. It is important to select them in accordance with the material of the ventilation duct.

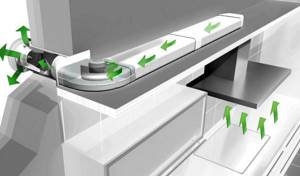

Principles of operation of forced ventilation systems

Ventilation of kitchens has become a prerequisite for the normal functioning of the premises. In general, a kitchen exhaust system has the following elements:

- engine;

- fan;

- filters;

- pipes.

Diagram of the forced ventilation system in the kitchen

The engine powers the fan, which supplies contaminated air flows to the filters, where fat and burning particles are retained, then the flows enter the box - the pipe system for ventilation. There are two types of operation of exhaust systems:

- circulation;

- in-line.

The circulation system involves taking contaminated air with the help of a fan, passing it through several filters, where smoke and grease first settle, and then the air flow itself is filtered, and returning the purified air back into the room. This is an expensive system, it is difficult to operate, since there is a frequent need to wash and replace filters.

They resort to using such an air purification system most often in cases where the connection to a common ventilation duct is complicated (relevant for apartments) or the external ventilation outlet is on the facade of a private building. Systems with in-line cleaning are very popular, when dirty air, after passing through a filter, is discharged outside. These systems have several advantages:

Forced ventilation systems are divided into two types - circulation and flow

- more effective air purification;

- easy care;

- affordable price.

But such a system requires the presence of a ventilation duct. Consequently, the installation becomes somewhat more complicated, where the placement of the common ventilation duct will be of great importance. In addition to solving technical problems, there is a need for the right design choice: a kitchen with a ventilation duct should be cozy and aesthetically pleasing.

Causes of blockage and procedure for restoring the ventilation duct

Canal blockage can occur for the following reasons:

- increased dustiness or humidity in the room;

- incorrectly selected channel section;

- lack of fresh air flow, resulting in stagnation;

- discrepancy between throughput and calculated values for a given system;

- improper assembly of joints, as a result of which the smoothness of the inner surface of the channels is disrupted;

- insertion of an additional channel without carrying out calculations that violated the efficiency of the system.

To restore the ventilation duct, you must perform the following steps:

- make sure the ventilation equipment is in working condition;

- check the condition of the shaft for blockages and remove them;

- replace filters, clean meshes;

- start the system and search for leaky areas;

- If there is irreparable damage to the channel, replace the entire section or repair it locally.

When installing a box over a kitchen unit, it is recommended to use materials with high moisture resistance and excellent aesthetic properties. Many choose materials similar in external finishing to the headset.