Among the variety of heating boilers presented on the Russian market, solid fuel units of domestic production are always popular and have good reviews. Many of them are not inferior in quality to imported analogues, although they have a more affordable price.

The Sibenergotherm plant is one of the manufacturers of heating equipment, represented by a wide range. A high level of production automation ensures precise execution of technological operations and control over compliance with quality standards.

Boiler models

Solid fuel boilers from the Prometheus model range have different operating principles and a power range from 12 to 800 kW. They can be used for heating private houses and industrial facilities. These include the following models:

- Solid fuel boilers with varying power from 12 to 60 kW, designed for 8-12 hours of combustion, have a spacious loading chamber. They are made of heat-resistant steel 4 mm thick. Efficiency from 78 to 84%. Coal of various grades (except anthracite) is used as the main fuel; firewood is used as an additional fuel. It is possible to install heating elements for additional heating of the coolant. The main technical characteristics are presented in the table.

- Automatic long-burning boilers on brown coal Prometheus Automatic with a power from 40 to 800 kW cope with heating rooms from 150 to 8000 m2. Efficiency is up to 85%. Thanks to the large fuel bunker, the heat generator can operate on one load for up to 7 days. Thanks to automation, the temperature set by the owner is maintained at the specified level.

- Universal pellet boilers Prometheus Combi with a power of 25 kW can operate on any type of fuel. In addition to the furnace for burning solid fuel, they can install a burner (gas, diesel or pellet) or heating elements. The heated area can be up to 250 m2. When using pellets as the main fuel, efficiency up to 90% and a high level of automation are achieved.

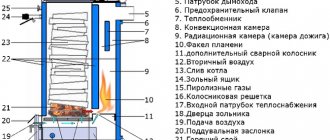

- Gas generator boilers Prometheus Eco with a power of 30 kW operate on wood. They have two chambers, in one of which fuel is burned, releasing pyrolysis gases, and in the second, these gases burn with a large release of heat. The boiler operation can be adjusted automatically. The combustion chamber is made of refractory concrete. Efficiency is up to 93%.

Scope of use

Since Prometheus solid fuel boilers are equipped with automation and do not require constant human presence, they have found application in various spheres of people's lives. With their help, heating of municipal housing and communal facilities was organized. The equipment is used in programs such as reconstruction and modernization of old coal boiler houses and heat supply facilities. The customers in this area are regional enterprises.

Prometheus boilers heat production sites, warehouses, garage complexes, etc. Modular solid fuel boiler houses based on Prometheus equipment are used for heating industrial greenhouse complexes and livestock farms. Such rooms are characterized by high heat loss, so powerful heating devices are needed to heat them.

Automated Prometheus boilers operate on the cheapest energy source - coal, they have high efficiency indicators and are able to operate in a completely autonomous mode for a long time (up to 5 days). To service such a boiler room, one operator is enough.

Prometheus heating equipment is also used for heating private houses and cottages. For private boiler houses, the manufacturer offers devices with a capacity of 40-80 kW. Autonomous boilers allow owners to forget about adding coal for several days, because... have a built-in spacious fuel storage bin. They are easy to use and repair. The operation of a separate boiler room will rid the house of dirt and unpleasant odors. Using solid fuel will save time and money, because... its cost is significantly lower. This type of heating does not require approvals, unlike connecting central heating or gas equipment.

Choosing a boiler for your home

To decide which model of solid fuel unit is best suited for your home, first of all, you need to choose the type of fuel. It can be hard or brown coal, firewood, pellets. Sometimes it is advisable to use another energy source, such as electricity, as an emergency or additional source.

The use of pellets or brown coal allows for a high level of automation of the boiler operation and reduces the frequency of approaches to it for loading to once every 5-7 days. For use in regions where there is no possibility of connecting to the power grid or where there are frequent power outages, you should choose non-volatile models.

The power of the Prometheus boiler is chosen based on the area of the house and its heat loss. If you make calculations according to all the rules, you need to take into account the heat loss of all surfaces based on their resistance to heat transfer. This indicator can be found in construction reference books.

In this case, it is necessary to take into account the minimum winter temperatures. The boiler power should replenish the heat loss of the house, but should not significantly exceed it. For an approximate calculation, you can use the ratio of 1 kW per 10 m2 of area with a ceiling height of no more than 3 m.

Advice! For economical fuel consumption, it is necessary to ensure high-quality thermal insulation of all surfaces bordering the external space. The main heat losses occur through windows and roofing. The walls and foundation also need to be insulated.

Coal automatic solid fuel boilers Prometheus

The Prometheus automatic solid fuel boiler, according to reviews, may well replace a gas heater. There is minimal hassle with it, and all thanks to its design and control unit. Let us immediately note that the unit depends on electricity. Its design consists of three main elements:

- fuel bunker;

- combustion chamber with heat exchanger and smoke removal system;

- ash pit.

The heater runs on coal only. Coal can be used even of low quality; in this regard, the unit is unpretentious. The size of the fuel tank depends on the power. It is calculated in such a way that a full load will last you for a week. Human participation in the boiler operation process is required only during the first start-up. Subsequently, you only need to add coal to the bunker. Even if the unit does not work for some time, the smoldering process in the firebox still does not stop and as soon as fuel is added, the work will resume again.

You can set the required temperature. It is maintained by adjusting the operation of the smoke exhauster. Everything happens automatically. You can choose a boiler with a power from 40 to 1000 kW. It is also possible to assemble several heaters in cascades to create modular boiler rooms. With a rated power of 40 kW, the unit at a minimum level can produce 5 kW if the situation requires it. It can work in heating systems where the pressure does not exceed 2.5 atmospheres, while heating the coolant up to 115 degrees. Efficiency largely depends on the quality of coal, on average it is 75-90%.

Installation and operation

The floor on which the solid fuel boiler will be installed must be strong enough and suitable for its weight. If necessary, an additional foundation larger than the boiler is installed. The floor covering under the boiler must be fireproof and level.

The distance from surrounding surfaces should not be less than 70 cm from the rear and side surfaces, not less than 125 cm from the front surface:

- The delivery kit includes a combustion regulator that needs to be installed in place.

- The connection of the boiler to the chimney must be carried out in accordance with the rules of construction supervision. The height of the pipe must correspond to its power.

- Electric heaters are installed taking into account all requirements. The boiler must be grounded.

Advice! Installation of electrical equipment must be carried out by a qualified representative of a licensed organization.

- The heating supply and return lines are connected to the boiler. The pipes must be laid without tension.

- To avoid exceeding the maximum pressure, an automatic air and safety valve is installed.

- Before starting operation, the boiler with piping must be checked for leaks.

Starting and using the boiler

Antifreeze can be used as a coolant, especially if there is a possibility of freezing. The heating solid fuel boiler is filled to the required pressure when cold. At the same time, air is released. Paper and wood are used to light the boiler.

When the fire burns well, the main fuel is loaded. After this, the flame level is adjusted using air supply. To clear the grate from ash, it is moved using a lever. The ash drawer must be cleaned regularly. It is advisable to invite a specialist once a year to inspect the boiler and check its operation.

Among the model range of Prometheus boilers, you can choose a solid fuel unit for heating any home with an autonomous heating system. The quality of the equipment meets the highest requirements, as evidenced by consumer reviews. To choose the appropriate model, you need to decide on the type of fuel and boiler power.

Prometheus boiler with fluidized bed

This Prometheus heating boiler does not have a grate. Instead, a special tray is installed, which contains nozzles. The fuel there is burned in a fluidized bed, hence the name of the line. This method of work allows you to use coal and firewood of low quality, with a high moisture content, and at the same time the combustion process will remain stable.

This unit has a built-in smoke exhauster, which creates forced draft, and a fan for supplying air to the nozzles of the pan. A fluidized bed is only possible if there is sufficient air pressure, which creates a turbulence effect.

Boiler characteristics:

- flue gas temperature is not higher than 220 degrees;

- the required minimum return temperature is 70 degrees;

- Efficiency 86%;

- heating pressure no more than 3 atmospheres;

- can work on coal, wood and peat;

- maximum water temperature 95 degrees.

The tubular heat exchanger, made of steel, stands in a horizontal position. It holds 600 liters of water. It can drive through itself a maximum of 14 liters of coolant per hour. The unit is quite large. The length is 2.15 m, width 1.2 m, and height 1.65 m.

How to choose

Choosing the right boiler from the brand’s assortment is not at all difficult; the main thing is to first understand why it is needed. For a summer residence, it is best to choose safe boilers that do not require regular supervision. For example, this could be a pyrolysis model “Eco Comfort” or an automatic boiler with a power of 40 kW.

When selecting the right model, you should study the technical characteristics and features of a particular boiler. It wouldn’t hurt to find out reviews from those who have already purchased a similar or the same model. Boiler models with low power of 12 and 20 kW are perfect for heating small rooms.

If you are not sure that you can independently choose the right model for your home, cottage or any other property, it is best to use the services of specialists.

All current models of Prometheus boilers can be viewed on the official website of the brand or at the relevant retail outlets that have the right to licensed sales of this type of product. Installation of any complexity is best trusted exclusively to professionals.

Types of modern gas boilers and their comparative characteristics with old models

Manufacturers produce about 1000 models of boilers, which differ in physical and technical characteristics, materials of manufacture, functions and design. Photos of their design options, from shapes and colors to installation methods, serve as further confirmation of the diversity of these devices.

Gas heating boilers are divided into:

- imported and Russian-made;

- single- and double-circuit;

- manual or automatic adjustment;

- with natural or forced circulation;

- wall and floor type installation.

The design of the boilers allows heating rooms of any size, maintaining the heating temperature of the boiler at the same level (if the heating boiler is of a combined type with additional heating elements). You don’t have to monitor the burning of the flame - this is done automatically.

At the same time, old-style boilers could not, even at the peak of their popularity, at the time of release from the conveyor belt, boast such a variety. They were produced only in a floor-standing version and did not allow precise regulation of the heating temperature of the coolant: it was necessary to manually reduce or increase the burning power of the flame and ensure that the gas supply did not stop.

Today, controlling heating appliances has become more economical and comfortable, but the models of previous years provided a reliable basis for the production of modern boilers.

Technical characteristics of universal boilers "Combi"

Long-burning boilers "Prometheus", reviews of which are often very positive, are also presented in universal models. The power in this case varies from 25 to 45 kW, and the area of the room can vary from 250 to 450 m2, respectively. The fuel used is coal and firewood, as well as pellets. Pellet consumption per hour varies from 7.2 to 11.6 kg, which depends on the power. The firebox capacity ranges from 80 to 95 liters, and the efficiency of pellets reaches 90%.