The Immergaz gas boiler is a product of the Italian company of the same name, specializing in the production of wall-mounted double-circuit models. These are reliable devices with a stylish design, for which the manufacturer provides a five-year warranty.

IMMERGAS was founded in 1954. Its slogan: “Two hundred heating horses.” The company promotes the latest technologies, focusing on efficiency and reliability. The range of attachments includes more than 8 dozen modifications. Immergaz's products are not as widely represented on the Russian market as their competitors - Baxi and Ferroli. A limited number of models are supplied to Russia: only those that are adapted to local climatic conditions. That is why there are very few reviews about Immergas products online.

Advantages and disadvantages of Immergaz boilers

pros

- Compactness. A wall-mounted unit always takes up less space than a floor-standing unit. Does not require a separate room. It fits easily in a kitchen or room that meets the requirements for rooms in which gas equipment is installed.

- Multifunctionality. Italian devices are able to function autonomously, without requiring regular user intervention; they fully control their operation.

- High quality of assembly, components, materials.

- Minimal noise during operation.

- Availability of service in the regions.

- Positive feedback from experts.

Minuses

- Price. Equipment assembled in factories in Italy is quite expensive.

- High cost of spare parts. Many components and parts need to be ordered and await delivery.

- Inconvenient controls - pressing the buttons requires effort.

- Reaction to power surges. The need to purchase a voltage stabilizer.

- No chimney included; it must be purchased additionally.

What's special about them

Immergaz products are not cheap, but if you compare the positions in the price-quality formula, this is exactly the option that many people need. The manufacturer offers:

- Single-circuit and double-circuit versions.

- Single-circuit with built-in boiler 40/60 l.

- Classic and condensation.

- With open (atmospheric) and closed (turbocharged) firebox.

Condensing devices are frightened by high prices. Gas in the Russian Federation is cheap, and the main advantage of condensing versions is high efficiency. Fuel savings of 20–30% are of little attraction to our customers, so few are willing to overpay for a gas boiler. But in Europe, where gas is hundreds of percent more expensive, “condensers” are very popular.

Operating and configuration instructions

The boiler is configured at the manufacturer's factory. It includes setting the primary parameters of all main functions, setting the operating mode of important catches and parts.

At the first start, additional settings are made , adjusting the factory parameters in relation to the existing conditions and operating features.

Then, as a matter of routine, the user adjusts the temperature and switches the boiler to summer/winter mode.

This already applies to operational work that does not require calling a specialist and can be carried out by the boiler owner himself . It is recommended to check the manual so as not to make mistakes and get the expected result.

Download instructions

Download instructions for Immergas gas boilers.

What does Immergaz offer?

Boilers with one circuit Nike Mini X 3E and Eolo Mini X 3E only heat the house, they are not designed for heating hot water. The cost of single-circuit versions is slightly lower than double-circuit ones. The first ones cost between 30,000–35,000 rubles, with two circuits - 40,000–95,000 rubles. The price depends on the power of the equipment and its efficiency.

Options with two circuits are in great demand: users are attracted by the possibility of providing DHW. Moreover, all single-circuit modifications require the connection of a BKN (indirect heating boiler).

Eolo series - dual-circuit with a closed chamber:

- "Eolo mini". Two heat exchangers.

- "Eolo Star." One is bithermic.

Nike open fire series:

- Nike Mini 24 E. Two separate heat exchangers.

- Nike Star 24 3R. One copper bithermic.

The Star series has one bithermic heat exchanger, while the Nike series has two separate ones. One made of copper is used for heating, the second made of stainless steel is used for hot water supply (DHW).

Kinds

Immergas offers its customers a complete list of existing design and functionality options.

There are several types of gas boilers, which can be conditionally combined according to various characteristics.

By type of execution:

- Wall-mounted. They are installed on strong load-bearing walls, are compact, small in size and limited in power.

- Floor-standing. Installed directly on the floor or on a special stand. May have increased strength, power and size.

By feature set:

- Single-circuit. Designed only for heating the coolant (heating the house). However, most models can be connected to an external indirect heating boiler, which significantly expands the capabilities and allows you to increase the functionality of the equipment to the maximum.

- Dual-circuit. Capable of simultaneously heating the coolant for the heating system and preparing hot water for domestic needs.

By type of heat transfer:

- Convection . Heat transfer is carried out in a standard way - from the flame of a gas burner.

- Condensation . The coolant is preheated from the energy obtained by condensing water vapor from the exhaust smoke. Increasing the temperature allows you to reduce gas consumption and make the heating mode softer, which increases the service life of the heat exchanger and burner.

Important! Condensing boilers are much more expensive than conventional models (2-3 times), however, they are able to fully function only on low-temperature heating systems such as underfloor heating and with a difference in air temperatures outside and inside the room of no more than 20°, which is unrealistic in Russian conditions.

By type of combustion chamber:

- Atmospheric . Combustion air is taken directly from the room, and smoke is removed using natural draft.

- Turbocharged . The combustion chamber is sealed; air is supplied and flue gases are removed using a turbocharging fan.

There is also a division according to the type of heat exchanger:

- Separate (primary - copper, for heating the coolant, secondary - stainless steel plate, for preparing hot water).

- Bithermal (combined). Manufactured according to the “pipe in pipe” principle, it simultaneously heats the heating agent and hot water.

The choice of a specific model is determined by the wishes and preferences of the user.

Installation and operation

In order for Italian gas equipment to work properly and uninterruptedly, its installation must be carried out by specialists. They also carry out the setup and first launch. The device must be suitable for the heated area. Each device comes with instructions detailing the installation process. How to install a wall-mounted boiler:

- The device is attached to the wall.

- The device is grounded - it will protect it during thunderstorms, and connected to the electrical network.

- Install the expansion tank. If forced circulation of the coolant is provided, install a pump.

- Connected to the heating system.

- The system is tested for leaks; the instructions describe this process.

- Remove oxygen accumulated in the pipes.

- When the connection is complete, perform the first launch.

Features of boilers from the Immergaz company

Immergaz boilers are available for sale in many models. Among them there are single-circuit and double-circuit samples, devices of condensation or convection type, as well as floor- and wall-mounted devices. In total there are over 10 series, differing in characteristics, type of installation and principle of operation. Each series includes models of varying power and performance.

- According to the standard double-circuit scheme without a boiler;

- According to the scheme with a built-in boiler;

- According to the diagram with the connection of an external water heater.

Models with built-in storage boilers hold up to 120 liters of hot water. Some samples with a standard design use Aqua Celeris technology. It provides instant supply of hot water when the tap is opened.

Gas boilers from Immergaz are divided into single-circuit and double-circuit. They include built-in piping - there are circulation pumps, safety valves and expansion tanks on board. Some models are complemented by built-in hot water storage tanks. As for pumps, some boilers have a unique system for regulating the rotation speed through frequency modulation. This reduces gas consumption for the heating system.

In the gas boiler segment from the Immergaz company, condensing type models are presented. They can be floor or wall mounted. The devices have increased efficiency and reduce heating costs by up to 10-15%. All of them are divided into five lines - Victrix Tera, Victrix PRO, Victrix TT and Victrix Superior (wall-mounted), as well as Hercules Condensing (floor-mounted).

The wide range of Immergaz boilers includes models with different types of heat exchangers - traditional copper, stainless steel and cast iron (including separate and bithermic). Cast iron heat exchangers are presented in the ARES series. The power of boilers from this line is up to 60 kW. If we talk about the most powerful units, we will find them in the Victrix PRO series - their power varies from 35 to 120 kW.

Also found in Immergas gas boilers are:

- Weather-dependent automation – controls the climate in the house depending on the outside air temperature;

- Independent heating circuits - in high power models;

- Superior automation – makes it easier to control gas boilers;

- Heat exchangers of increased volume - they are resistant to clogging;

- Remote control systems.

Flue gases are removed forcibly through coaxial chimneys or naturally through traditional chimneys.

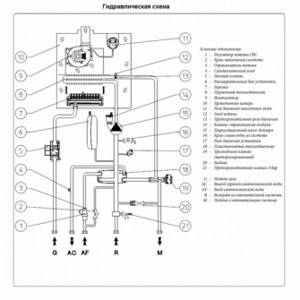

Device

Design Features:

- All modifications are equipped with Grundfos circulation pumps (Denmark) - they ensure the movement of the coolant, and a SIT gas valve (Italy).

- Supply pipes (gas and water) are copper.

- There is a 6 liter expansion tank.

- Equipped with a digital screen that displays the set settings - the user can monitor temperature, pressure, winter/summer mode. It also displays error codes to notify the user of malfunctions.

- All modifications have NTS temperature sensors, traction sensors and overheating protection.

- If desired, an external thermostat can be connected, a simple mechanical one or an “intelligent” one, which allows you to program the operating mode for a week in advance.

All models are equipped with:

- anti-blocking pump;

- anti-blocking three-way valve;

- frost protection.

The operating principle of Immergas boilers is quite simple, and their operation does not require special knowledge. The display shows all information about settings and errors.

Help in troubleshooting Immergaz boilers

___________________________________________________________________________

Question: We have a double-circuit gas boiler installed - Immergas EOLO STAR 24 3 E - it goes out and turns on periodically only during the heating season, maybe this can be fixed somehow? Answer: If this happens once a day, then this is a self-testing system. There's nothing wrong with that, it should be like this (in all boilers). If this happens more often, there may be a problem with the control board. Question: Wall-mounted boiler Immergaz Eolo Mini, has been working for 3 years, no problems. Suddenly the water stopped heating, but the heating works as usual. What is the reason and how to fix it? Answer: If cold water flows from a hot tap, then the flow sensor needs to be cleaned or replaced. And if it doesn’t come out of the tap, that’s very bad. Most likely you will have to change the heat exchanger. Question: The boiler has been operating for the second year, model Immergas EOLO star 24 3e. Last year (2012), service center specialists carried out maintenance, which consisted of cleaning it from dust using a vacuum cleaner. In this (2013) did not call. Problems started recently. There is a room programmer.

The boiler heats up to 80 degrees. turns off, the pump pumps water, and when the temperature drops to 40 degrees. turns on again. Three batteries connected. But the farthest one is cold. I blocked the two near ones, and the far one started working. This didn't happen before. Who can tell me what's wrong? Answer: the filter under the boiler or in the boiler is dirty (heating water), or the heat exchanger is clogged - i.e. small flow of heating water, hence overheating. Question: I just can’t clear code 05, the boiler eolo star 24 3 e does not turn on, what should I do? Answer: Error 05: Malfunction of NTC heating sensor. Appears when the boiler is in any mode, including “stand-by” mode. The reason for the appearance is a break or short circuit in the NTC sensor circuit of the heating circuit. When error “05” appears: the gas valve closes, the pump runs out, the fan runs out. Restart - automatically after troubleshooting. Try replacing the sensor. Question: An Immergas Eolo Star gas boiler has been installed and connected, it has been operating for one year. Periodically, a single “biting” crack is heard from the boiler. I don’t understand where it comes from and for what reason. Secondly, the heating circuit heats up strangely. I set the boiler to 50 degrees, the boiler starts heating, the temperature reaches 50 in 30 seconds, the heating turns off, then in 10 seconds the temperature becomes 40 degrees and after three minutes the heating of the heating circuit turns on again. In fact, when set to 50, it heats at 40. Could the coolant circulation in the boiler itself be disrupted? Answer: The circulation is disrupted, the boiler is boiling. Either the boiler or the system. Question: wall-mounted double-circuit boiler Immergas Eolo Star 24 3e. Operates for 1 year (since October 2012). The heating system (pipes, radiators) is new. After starting the heating this fall, I started getting error E27. I don’t catch a specific pattern - sometimes several times a day, but there seem to be days without this error. It seems that when it’s colder outside and, accordingly, it works more intensely, it produces an error less often. I checked the valves for releasing air on the radiators and connecting the heated floors - I did not find any airiness. What else can you do on your own? By the way, if you turn on hot water from the tap, it starts to heat the water, sometimes you hear some gurgling/knocking, and stops giving error E27. Answer: Error code 27 means insufficient circulation in the heating circuit, but this error usually appears after opening the hot water tap in the bathroom (the distance from the boiler through the pipes is about 10-12 m). At the same time, opening a hot tap in the kitchen (next to the boiler) does not cause such problems. I noticed a few more times that sometimes hot water does not run in the bathroom, and in order for it to flow, you need to turn off the water and open it again. Question: I have an Immergas EOLO MINI 24 gas boiler connected, it’s three years old, there are always some problems, this time the problem is this: the heating works fine, but when you turn on the hot water, there is simply no hot water, cold water flows, and the boiler starts to gain temperature , and there is a sound as if it is about to take off. Help me correct the defect? Answer: The DHW flow sensor is faulty (most likely the float is jammed due to dirt. You can wash it or replace it if it doesn’t help. Question: We have a wall-mounted boiler Immergas MINI Nike 24 3 E installed, it worked for two winters without any problems, only small popping noises are heard when igniting. But suddenly, when you turn on the hot water, it goes crazy and begins to sharply increase the temperature. All three torches on the display are on. The numbers go over one hundred, you can hear crackling and overheating, error E27 appears. And if you don’t turn on the water again, it will blink for a long time. How to fix this? Answer: because of this you have very poor draft and claps, if overheating occurs after turning off the hot water, then you need to clean the flow switch, if during use it knocks, it looks like the boiler is clogged with scale, in any case, first sort out the smoke removal and air intake, this is primary ( By the way, because of this, there may well be a problem with hot water, especially if the heat exchanger honeycombs are clogged with soot.) Question: I installed and connected the Immergas EOLO Star 23kw boiler periodically, it starts to crackle and the temperature jumps on the display, error 27 appeared a couple of times, I’ll restart it, and starts working again. What could this be, and how to deal with it? Answer: It looks like the heat exchanger is clogged. The heating circuit is practically not cleaned. Check the inlet filter, the heating system may be of poor quality. Question: tell me what the problem could be, the boiler stopped heating more than 32 degrees, Immergas mini boiler 28 kw, new 2-3 months after installation. Answer: Small flame. Low gas pressure at the inlet, the grid on the gas valve is clogged. Lack of modulation of the gas valve (you need to look at the currents on the coils). If the currents are greater. 200mA, which means the control is coming from the board. Watch the pressure at the valve outlet. Question: Gas boiler Imergas NIKE Star 23kW. It has been working for eight years. Because of the breakdowns, I haven’t looked into it at all for 6 years. In the seventh year, the valve for filling the system was replaced (it began to leak), and this year it constantly gives error 01 “Lockout due to lack of ignition.” According to the instructions, press “reset”. I do. It behaves unpredictably - it may start working, or it may continue to flash 01 again. 20 times per day. What to do? Answer: First of all, it was necessary to provide timely service. You need to call a smart service technician. In your case, 1. there may be no ionization current at the central electrode (the current is very small and cannot be measured with every device). 2 board is faulty. 3 The gas valve is not working correctly. Question: Error 28 is flashing in the boiler. We checked the entire system and there are no leaks anywhere. But it still turns off. When I restart it again, it seems to work, but not for long. And again error 28 Answer: Error 28 - leak in the DHW system. Your hot water faucet is leaking somewhere. The system sees that the boiler is working for heating, and the temperature in the hot water supply is also increasing, although it should be constant. Fix the leak. Question: I have an Immergas EOLO Star 24 kw boiler connected after installation. 3 years. The problem is that yesterday morning the power was turned off, the boiler stopped working and I turned it off from the network. Half an hour later the lights were turned on, I turned on the boiler, and it started flashing and gave error E10 (insufficient pressure in the system). I typed the system and it seemed to start working, then after a few hours the error E10 returned. I again dialed the system to almost 2. The next morning, the same thing. I checked every pipe and peeled everything, I thought there was a leak somewhere, but no, everything was fine. Tell me what to do? Answer: The pressure in the boiler can drop only in two cases: a problem in the expander (original or additional - not so important) - most often, or a breakdown in the heat exchanger - one case in a million, provided that the heating system is indeed 100% sealed. Question: The apartment has an Immergaz EOLO STAR gas wall-mounted boiler. Tell me, what does error code 03 mean? First it turned off, 11 was on, and then 03? Answer: error 03 - the fan is faulty. 11 - “no exhaust” - no pressure of combustion products. I solved the problem this way: first, I removed the casing and opened the chamber, there is an engine that draws air from the combustion chamber, 15*15cm in size in the shape of a snail, I unscrewed it with 3 screws, cleaned the blades from the stubborn dust on the blades with a hard brush, the main thing is not to upset the balancing ( some blades have paper clips).

I lubricated the bearings and put them in place. I turn it on - same problem. Moreover, I began to clean it, because 1 day before error 11 was issued, I began to experience excess noise from this engine. After cleaning it disappeared. I looked in the instructions and it points to a “combustion product pressure switch”; this relay is located on my upper right. A capillary tube is connected to it. The principle of the relay is the following: through a tube that fits in the fan chamber, when this fan is turned on, a small air pressure is supplied, which closes the relay. The closed relay sends a signal to the control unit, and the burner lights up (well, at the same time, a number of other conditions are probably met, but for me this was not important).

Basically, the problem is that the fan motor was running, but the burner was not igniting. I pulled out this transparent capillary tube from the fan chamber and blew into it (i.e. into the sensor) and the result was that the relay closed and the burner lit up. As a result, I realized that either the sensor was reconfigured to higher air pressure, or there was dirt in the capillary tubes, or in the fitting attached to the fan chamber. I pulled out the fitting (from which I pulled out the drip tube on the fan chamber), cleaned it and sawed the inner tube, which is located in the fan chamber, at an angle for better air passage. I put everything in place and connected it. And the Cauldron started working as before. But a few hours later I saw the same picture again - error 11. Then I turned off the “combustion products pressure switch” (by the way, after that I got error 03, so it’s likely a bad contact, and this sensor is located in a place where it’s very warm, I I would say heat).

Actually, I tore off some yellow plug on this relay, saw two screws, tried to twist them and realized that one of them is responsible for adjusting the air flow at which the relay is activated. adjusted to the lowest flow. I plugged everything back into the boiler and started it up until it worked. Question: The IMMERGAS NIKE STAR boiler has already worked for 10 years. It was different, but this was the first time I encountered such a failure - when the heating (hot water) is turned on, the boiler goes into lockout (the yellow and red LEDs flash alternately “Not enough water in the heating system”), while on the pressure gauge 1.2, raised to three bar, the picture does not change.

When using DHW, the boiler immediately goes into lockout, but when using heating, the pump runs for 1-2 seconds, the relay is triggered (I haven’t determined which one yet), the spark plug does not work and the boiler goes into lockout. Manipulating the RESET position does not give the desired result. Next, after pouring water through the hot water supply system for 10-15 minutes, the boiler started up. Answer: Check the heating system pressure sensor. Maybe it's covered in dirt. Question: An Imergaz Nike star 24 kw gas boiler was installed; the water pressure sensor failed; operation was restored using a jumper. Is it possible to operate this way or is it better to install a new sensor? Answer: It is recommended to install a new sensor. Question: Boiler Immergas Nike Star 24. Problem: when operating in geyser mode, after closing the hot water tap, the flame does not go out, it heats the water further, accordingly it overheats, turns off and error 27 is triggered. The impression is that it does not work to shut off the water. The master said that it is possible that the taps are passing cold and hot water between each other and the sensor does not work.

I completely disconnected it from the hot water system and placed a tap directly behind the boiler (for the purity of the experiment). After turning off the hot water, the story repeats itself - the gas does not shut off, the boiler overheats and error 27. Answer: Check the functionality of the water flow sensor. The reed switch may not be working. Question: We made a connection and connected the Immergaz Nike star 23 kw boiler. Error 01 began to appear. The boiler lights up, but immediately goes out. then after 30 seconds it lights up again and burns normally. This doesn't always happen. Answer: Most likely, the electrode (flame control). You can clean it, but it's better to replace it. If it doesn't help, then the board is faulty. Question: Immergas Eolo Mitos 24 turbocharged double-circuit boiler. If possible, explain why it is better with a room sensor? For me it works in winter, it works for about 2-3 minutes, then turns off for 5 minutes. The pump continues to run.

Then it turns on again. After all, for uniform movement, it is better to apply little effort, but more often, than rarely, but for a long time. Or does this logic not apply here? After all, it will be guided by a sensor in one room, while in others the temperature may be different? I am at home all the time, so I can regulate the temperature of the coolant and cover the radiators and heated floors. Answer: Room thermostat, set the radiators in the rooms - where it’s cold to open, where it’s hot to close, set the boiler to +70C and you’ll save another 20 percent on gas, and the boiler will last much longer. Why? In short: the efficiency of the boiler is maximum at maximum temperatures, you can look at the technical data sheet. In this mode, it cycles less frequently, purges the combustion chamber less frequently, and turns on less often, which extends its service life and you will spend less electricity on pumps. Question: The Imergaz Eolo Star 24 3 E boiler has been in operation for 5 years. At the end of summer, the hot water pressure dropped, I called a specialist to clean the heat exchanger (the hot water circuit was practically clogged with scale). Two months later the picture repeated itself, the hot water supply circuit was flushed again. After rinsing, 2 weeks passed and the hot water pressure began to drop again; when the tap was closed, the temperature jumped to 80-85 degrees (set to 36). Will the question be helped by replacing the heat exchanger or is the problem in the electronic unit? Answer: Replacing the heat exchanger most likely.

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

- Malfunctions of the AOGV-23 ZhMZ boiler

- Parameters and design of gas boilers AOGV and AKGV

- Boiler automation Baxi Luna-3 Comfort

- Installation and installation of the Baxi Slim boiler

- Adjustments and maintenance of the Beretta Chao boiler

- Determination of error codes and malfunctions of Rinnai boilers

- Errors and malfunctions of the Termet gas boiler

- The meaning of error codes and malfunctions of Vailant boilers

- Determination of malfunctions and errors of Visman boilers

- Questions about servicing Navien boilers

- Questions about malfunctions of Kiturami diesel boilers

- Junkers boilers - Experts answer user questions

- Experts answer questions about Electrolux boilers

___________________________________________________________________________

___________________________________________________________________________

- Answers from Nova boiler repair experts

- Questions about Hermann boiler service

- Answers from Daewoo boiler service technicians

- Questions about servicing Ferroli boilers

- Questions from users regarding the repair of electric boilers Evan

- What causes an AKGV gas boiler to light up and immediately go out?

- What is wrong with the Alpha Color boiler if it shows error code E01

- Why does the AOGV boiler light up and go out quickly?

- How to eliminate error E01 on the Baltgaz boiler

- What is the problem if Dani’s boiler lights up but immediately goes out?

- Why does a Danko boiler light up but quickly go out?

- The Demrad boiler has stopped holding pressure, what is the problem?

- Why did the Gaslux boiler start to get hot and make noise?

- What is the reason if the Keber gas boiler lights up but quickly goes out?

- How to eliminate error code 01 on the Kiturami boiler

- What causes a Conord boiler to light up but immediately go out?

- What is the reason if the Lemax boiler lights up and goes out quickly

- Why does a Mimax boiler light up but suddenly go out?

- Why does the Hearth boiler light up but immediately go out?

- Why does a Ross gas boiler light up but go out quickly?

- What is the problem if the Siberia boiler lights up and goes out suddenly?

- Why does the boiler Signal light up and suddenly go out?

- What can cause a Termet boiler to make noise and get hot?

- Why does the Termotechnik gas boiler light up but suddenly go out?

- How can you eliminate error E01 on a Thermon boiler?

- For this reason, the Electrolux double-circuit boiler began to hum and heat up

- For what reasons does a Ferroli gas boiler display an error code A01?

- For what reason does the Immergaz boiler not operate on hot water supply?

- Why does the Navien gas boiler constantly turn off when heating and then turn on immediately?

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

- Heating boiler piping

- STS boilers

- KVT boilers for solid fuel

- Pellet boiler Peresvet

- Steel floor standing boiler Raton

- Solid fuel boiler Thermology

- Errors and malfunctions of the Termet gas boiler

- Termona boiler repair

- Boiler repair Nova

- Hermann boiler service

- Comparison of gas boilers Lemax Premium-20 and Danko-20s

___________________________________________________________________________

- Daewoo boiler maintenance

- Demrad boiler malfunctions

- Mora boiler malfunctions

- Westen boiler repair

- Malfunctions of Immergaz boilers

- Types of solid fuel boilers

- Models and design of combination boilers

- Liquid fuel and double-circuit boilers

- Cast iron boilers on coal

- Boilers with modeling burners

- Imported boilers for heating systems

How to choose an Immergas boiler

When choosing a wall-mounted double-circuit boiler, the buyer needs to decide on the following points:

- Power - it is selected based on the heated area. Typically there are 1000 watts for every 10 m².

- Type of combustion chamber - open or closed. For apartments, turbocharged versions with a closed firebox are more suitable.

- Number of circuits. Take it only for heating, you need one circuit; If you want DHW - two circuits.

- The method of exhaust gas removal is forced or natural. For apartment owners, forced draft is more suitable; you just need to buy a coaxial pipe. Residents of private houses can install models with natural draft, but they must install a chimney.

- Heat exchanger design. The most practical option is two separate heat exchangers. This option allows you to heat water faster and save gas. A secondary plate-type heat exchanger ensures uniform heating of water and avoids overheating.

Series and models related to them

The Immergas boiler range includes several series.

Wall boilers:

- Nike . The series consists of several Mythos, Star and Mini lines. Double-circuit models with a power of 24 and 28 kW. The Star line is equipped with a bithermal heat exchanger, which automatically increases the requirements for water quality. The remaining lines have a standard separate type of heat exchanger. Burner type - atmospheric, with natural draft of the stove type.

- Eolo . There are Mini (separate heat exchanger) and Star (bithermal heat exchanger) lines. The combustion chamber is a turbocharged type, dual-circuit design allows for heating and hot water supply.

- Avio/Zeus . A series of gas boilers with an integrated water boiler of 60 liters. They are distinguished by their increased dimensions and ensure an uninterrupted supply of hot water in any quantity.

- Maior . Boilers with increased power 24-32 kW. Double-circuit models with a turbocharged burner.

- Victrix Pro . Professional series of gas boilers with a maximum power of 120 kW. Capable of being connected in a cascade with a total power of 600 kW.

Floor standing boiler series:

- Hercules . Double-circuit boiler with a power of 32 kW with an integrated tank of 120 l.

- Ares . Single-circuit boilers with a capacity of 22-60 kW.

Let's consider the most popular model of Immergas gas boilers - Eolo with a power of 24 kW. This group includes the Eolo Mythos and Eolo Star units. The difference between them is the type of heat exchanger.

Models in the Mythos line have a separate heat exchanger, which increases reliability and somewhat reduces the requirements for water quality.

The Star line is equipped with a bithermal heat exchanger, which is sensitive to hard water due to the rapid appearance of lime deposits.

However, this line does not have a three-way valve, which increases the reliability of the unit and reduces the risk of failure of this unit.

Otherwise, the boilers are the same, which is confirmed by sales statistics.

Model overview

STAR Series

Their important advantage is their compactness. Small-sized option. Double-circuit scheme. For heating houses up to 240 m² and heating domestic water. Advantages:

- economical;

- high efficiency;

- digital control;

- bithermal heat exchangers;

- simple controls.

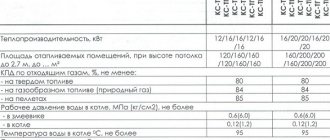

For example, the technical characteristics of the turbocharged wall-mounted boiler Eolo STAR 24 kW:

- Estimated cost: 76,000 rubles.

- Efficiency - 94.9%.

- Heating capacity - 24 kW.

- Bithermic heat exchanger made of copper.

- Heats 240 m².

- Maximum pressure - 3 bar.

- DHW capacity - 7.9/11 l/min (at 25/35°C).

- Weight - 34 kg.

There are also low-power versions in this series, such as Eolo Star 14 3 R:

- Heating capacity - 12,500 W.

- Efficiency - 90%.

- Closed chamber.

- Mounted type.

- There is automatic ignition.

- Built-in boiler.

- Expansion tank 4.2 l.

- Productivity - 11.1 l/min.

- Gas consumption - 1.47 m³/h.

- Weighs 29 kg.

- Dimensions (HxWxD) - 756x440x240 mm.

MINI series

Low-power and small-sized modifications designed for heating apartments and houses up to 280 m². They are economical and easy to operate. They have a built-in harness. Smooth power adjustment is provided.

These models attract owners of small homes. The depth of the devices is 250–310 mm. Occupy a minimum of space. Mini wall heaters are available with open and closed fireboxes. They feature a stylish design. Equipped with a digital control system, it makes control comfortable and operation economical. Mini EOLO 28 3 E is a turbocharged dual-circuit attachment.

Technical specifications:

- Heating capacity - 28,000 W.

- Cost - 44,000 rubles.

- Efficiency - 93.4%.

- Two heat exchangers - primary copper, secondary steel.

- Equipped with a circulation pump.

- Area - 280 m².

- DHW capacity - 13.3/9.5 l/min (at 25/35 °C).

- There is a “Summer” mode.

- Dimensions (HxWxD) - 725x450x310 mm.

- Weight - 34 kg.

Mythos

The Mitos line is classic 2-circuit heaters. There are three models in the series - 24, 28 and 32 kW. Compact devices with a laconic design. Quiet operation. Provide convenient use of hot water even at low pressure. Stable operation at 3.5 mbar. Characteristics of Eolo Mythos 24 4 R:

- Weight - 29 kg.

- Closed camera type.

- Two circuits.

- Heating capacity - 24,000 W.

- Heats up to 240 m².

- Water heating rate - 11 l/min.

- Fuel consumption - 2.77 m³/h.

- There is a screen.

- Expansion capacity - 6 l.

- Two separate heat exchangers.

MAIOR

This line includes only turbocharged versions (except for MAIOR Nike 28 kW). The chimneyless option is more convenient for placement in an apartment and simplifies installation and operation. The controls are simple, there are buttons on the panel. The temperature is regulated by mechanical regulators. Innovative composite materials that were developed in the company's scientific laboratories are used in production. An important characteristic of these ultra-strong materials is maximum resistance to thermal influences.

The MAIOR line is equipped with a rapid water heating system. There is a two-liter tank in which there is always stored hot water. As soon as the hot water supply is turned on, hot water from this tank provides an instant supply of heated water, the user does not have to wait for a hot stream to flow from the tap.

All versions of the line have electronic ignition. There is a reliable and multi-stage safety system that prevents breakdowns and emergency situations. There is a self-diagnosis system - the user is informed through a display that displays error codes.

Wall-mounted double-circuit version. MAIOR Eolo 32 kW:

- Cost - 93,000 rubles.

- Thermal power - 32,000 W.

- Efficiency - 93%.

- Can heat 320 m².

- Weight - 45 kg.

- Dimensions - 800x440x350 mm.

- DHW capacity - 15.2/10.9 l (25/35 °C).

Popular models

Boilers from the Italian brand Immergaz are divided into several lines. This division greatly simplifies the selection of equipment. We will look at the most popular models from these lines and study their technical characteristics.

Boiler Immergas Mini Nike X 24 3

Before us is a gas convection boiler with a capacity of 23.8 kW. Its characteristic features are its compact design and low weight of only 25.5 kg. The unit was equipped with electronic flame modulation, self-diagnostics, numerous protection systems, as well as built-in piping. The volume of the expansion tank is 4 liters. It is possible to connect a remote control system. The model is single-circuit, but the manufacturer allows the connection of a storage boiler. The maximum temperature in the heating circuit is +85 degrees. The cost of the device is about 42 thousand rubles.

Boiler Immergas Major Eolo 28 4

The Immergaz company makes beautiful gas boilers.

And this model is further confirmation of this. It is made according to a double-circuit scheme with a convection operating principle. Thermal power is 28 kW, connected load is up to 29.7 kW. The combustion chamber is closed and requires a coaxial chimney. The device is designed for wall installation. Gas fuel for its operation can also be liquefied - this will require reconfiguring the equipment. The Immergas Major Eolo 28 4 gas boiler has a surprisingly high efficiency - up to 94.3%. This is a rather rare indicator. If the unit were condensing, there would be no questions. But it is convection, so the figure is surprising. It is a pity that it is not achievable over the entire power range from 11.2 to 28 kW. To reduce gas costs, weather-sensitive control is provided. The cost in Russian stores is about 60 thousand rubles.

Boiler Immergas Hercules Condensing 32 kW

What we have before us is a fairly powerful condensing-type gas boiler.

Its power is 32 kW with a maximum thermal load of up to 33 kW. It is built according to a closed combustion chamber design and demonstrates an efficiency of up to 107.3%. In practice, of course, it is less than a hundred - the passport figure is a marketing ploy. But there will still be savings on gas of 10-15%. True, for this you will have to invest in the purchase of this unit - it costs about 260 thousand rubles. The gas boiler is made in a floor-standing form factor. And so that it takes up as little space as possible, the manufacturer made it tall . The result is a thin and elegant heating unit. Its height is 160 cm, on the floor it occupies an area of 60x60 cm. The weight of the device is 112 kg. Such strange dimensions are explained by the presence of a built-in tank with a volume of 120 liters. It stores hot water heated to a predetermined temperature. The capacity of the DHW circuit is 16 l/min. The heart of a gas boiler from Immergas is a stainless steel heat exchanger.

Boiler Immergaz Victrix Pro 55 1

The presented model is characterized by high power - 50 kW.

The maximum heated area is up to 500 square meters. m. Subtract the reserve from this and get somewhere around 400-430 “squares”. The device is made according to a condensing circuit that saves gas. Its gas burner is located in a closed combustion chamber, inside of which there is a copper heat exchanger. The Immergaz company claims an efficiency indicator of 107.4%, but in reality it is less than 100%. The gas burner of this wall-mounted unit can heat the coolant to a temperature of +85 degrees. The pressure in the circuit should not exceed 4.4 atmospheres. This boiler, developed by Immergaz, is designed for heating residential, commercial and administrative buildings. The possibility of heating small multi-apartment buildings is also provided. To increase power, several boilers are combined into one using a cascade scheme. To prepare hot water, external indirectly heated water heaters are used. The unit is designed for hard work and is equipped with a convenient control panel. Even a child can cope with it. The cost of the boiler is about 140 thousand rubles.

Boiler Immergaz Ares 22 R

The presented boiler is distinguished by its structural simplicity. It is atmospheric, its combustion chamber is open. The heating medium is heated in a durable cast iron heat exchanger. Thermal power of the unit is 25 kW. The efficiency indicator at maximum load is 88%. To prepare hot water, it is possible to connect an external boiler. Electrical power consumption is only 16 W. The cost of the boiler is about 65 thousand rubles.

Reviews

EOLO Star 23kw: Rodion G., Suzdal

I installed it two years ago. Before purchasing, I learned as much information as possible about this manufacturer, or rather, about its products. My apartment is 75 square meters. Heats well, gas consumption is moderate. Heating of water is immediate, even at low pressure. The hot water temperature can be adjusted to the nearest degree. Simple control, you just need to configure it correctly, and then the automation takes care of everything. Protected from power surges. Almost silent. On the downside, the radiator temperature settings failed.

EOLO Mini 24kW: Ilya T., Urzhum

Easy installation. Wall. The front cover can be easily removed to clean the burners. It does not heat up during operation, there is a digital interface. I like the self-diagnosis system; all problems are easily deciphered using error codes. There is only one drawback - it is expensive.

Immergaz boilers have earned the right to be the best among Italian competitors and one of the best on the European market. This is reliable gas equipment, equipped with the latest technology and adapted to Russian conditions. The company supplies the domestic market with the most popular models among ordinary consumers - wall-mounted heaters with a hot water supply circuit, designed for heating residential buildings and apartments.

Classification

Gas boilers for heating private houses Immergas are divided into double-circuit and single-circuit. The design of such models includes a built-in piping with safety valves, circulation pumps and expansion tanks. Some gas boilers are equipped with built-in tanks for storing heated water. Some Immergaz gas double-circuit boilers are equipped with a unique system that regulates the pump rotation speed through frequency modulation, which reduces gas consumption for the heating system.

Condensing models of Immergaz boilers are divided into two types - floor-mounted and wall-mounted. The devices are characterized by a high level of efficiency and a 10-15% reduction in heating costs. All boilers are included in five model lines.

A wide range of gas boilers for heating a private home from the Immergas brand is presented in models equipped with different heat exchangers - classic copper, cast iron and stainless steel. The ARES series is equipped with cast iron heat exchangers.

Immergaz gas boilers are also equipped with:

- Automation that regulates the microclimate in the room depending on the ambient temperature.

- Independent heating circuits.

- Superior automatic system, facilitating boiler control.

- Heat exchangers of increased volume, resistant to clogging.

- Remote control systems.

Flue gases are removed naturally through classic chimneys or forced through coaxial chimneys.

In the review of Immergaz gas boilers, it is worth noting that the company’s products are fully adapted to Russian operating conditions and remain operational when the pressure of water and gas changes.

TRADITIONAL AND CONDENSING BOILERS IMMERGAS

You can see different lines of models, each with individual advantages.

Traditional boilers operate on the basis of energy obtained from combustion products, which they cool, lowering the temperature of 200 degrees to 146; below this point, cooling does not occur, since the chimney draft will decrease, a chemically aggressive substance is formed, causing corrosion of the boiler elements. Condensing devices initiate an energy recovery process where water is condensed into steam; traditional boilers release the energy to the outside.

Condensing boilers operate on the basis of condensing steam, which accumulates and allows water to be heated. When the boiler is running, combustion products must be cooled to a strictly defined temperature, which is called the dew point, 55 degrees. When the combustion products are cooled, the water in the boiler heating system is returned from the general section. The central heating system must contain colder water compared to traditional devices.

These boilers are significantly economical; condensing boilers allow the user to save 11 percent of energy, are environmentally friendly, and can be used in a small room. The function allows you to adjust the noise power level so that the operation of the boiler does not cause discomfort.

The design of traditional and condensing boilers is floor-mounted, wall-mounted, externally the systems differ little, the only point is the plastic condensate drain pipe. All types of boilers must have a main working element - a heat exchanger; condensing boilers, due to the peculiarities of the operating process, have two heat exchangers or one of a two-stage type.

Boilers with a separate closed combustion chamber are suitable for rooms where there is no chimney, for example, for city apartments and offices. Devices with an open chamber can be connected to the chimney pipe.

Features of these gas boilers

After you have purchased or built your home, the first question that interests you is which gas boiler to choose for your home? The Immergas gas boiler is an excellent option for this purpose, as it follows an excellent formula - price / quality, and also comes with clear instructions for use. That is, the price is acceptable for most residents of the Russian Federation and the quality of these products is very high.

So, what features are inherent in these wall-mounted gas units:

- Thanks to their compact size and weight, they can be installed even in a small kitchen. For the Immergas gas unit, there will be no need to allocate a separate installation room.

- Boilers of this brand come in both single-circuit and double-circuit. If you just need to heat the room, then the first option will do. If, in addition to heating the room, you also need to heat water for family use, then it is better to choose a double-circuit gas boiler.

- Many wall-mounted models of units have a liquid crystal screen on which you can see the codes of all problems, if any, but one thing is for sure that you will not have to do repairs for a long time. The codes can be deciphered by looking at the instructions for these gas boilers.

- These units have operating mode indicators.

- Each boiler has a copper heat exchanger with natural circulation or forced circulation. If you often leave home, then it is best to install with forced circulation, since such a heating system works completely autonomously.

- Some models are equipped with a room thermostat. You can also connect a remote control to the devices - then it will become even easier to care for wall-mounted units.

Immergas wall-mounted units do not have to be connected to a chimney; you can simply connect a coaxial pipe, which discharges all combustion products through a hole in the wall. This is very convenient for those who live in apartments and want to make autonomous heating for themselves. The instructions for Immergas wall-mounted units tell you how to properly install the boiler, as well as how to properly care for it if you decide to do it yourself.

Installation diagram

The installation of any equipment consists of several stages, and connecting the Immergaz boiler is no exception. The list of actions is as follows:

- 1. First, installation and high-quality fastening of the brackets is carried out.

- 2. Next, all necessary communications are provided for the supply and removal of combustion products from living rooms.

- 3. Then the Immergas wall-mounted boiler is hung on pre-prepared mounts. They must be clearly leveled.

- 4. First, water communications are connected and tested along with the circulation pump. It is necessary to pump out the air from the system.

- 5. If the previous stage was successful, the automation is turned on, grounding is carried out and a test run of the boiler is carried out with full functionality.

- 6. You need to make at least one run in each mode to make sure everything is working properly.

- 7. At the end, you need to test the tightness of the joints, make sure that all the bolts are tightened as much as possible, and that the parts are in place.

The procedure is completely standard and should not cause any difficulties. But if you have any questions, you can always refer to the instructions for Immergaz boilers, which are included in the delivery kit. All the listed stages will be described and illustrated there in detail.

The drafters will draw the client’s attention to important points that should not be overlooked.

HIGH QUALITY AND ADVANTAGES OF IMMERGAS BOILERS

The high quality of Immergas is undoubted, the boiler parts are made in Italy, the most important parts are manufactured in Italian factories, the rest - by the company's European branches.

Immergas boilers have a number of advantages that make using the equipment comfortable.

- The automatic system of devices works based on the temperature of the open space, increasing or decreasing the level of heat supply; the operation of the system allows you to create a comfortable environment and consume the minimum possible amount of energy.

- The boilers have an automatic self-diagnosis system, which starts up, checks the operation of parts, reporting malfunctions, errors, and displaying information on the screen.

- There is an automatic anti-freeze system; the boiler can be safely left in an unheated room without fear that the system will become unusable, freeze, or pipes will burst.

High-quality Immergas boilers will make life more comfortable, bring warmth, reliable Italian quality will serve uninterruptedly, providing a pleasant indoor microclimate.

gas35.ru

Features of operation

The most famous gas boiler is Immergaz 24, because its power is enough to cover more than 90% of consumer needs. The model is purchased for private houses, apartments in high-rise buildings, office and warehouse premises. In any case, it shows its best side both in terms of service and in terms of efficiency.

Good automation and reliable components make it easy to customize the boiler to suit your needs and operate it for many years without problems. In case of any malfunctions, the service center specialists are ready to provide any services to return the device to normal operating condition.

If there is no hot water supply and poor heating, do not be upset. The Immergaz double-circuit gas boiler will help solve the problem. It will work for two specified purposes, both of which will be executed in parallel without compromising each other. This is possible thanks to the special design of water heaters that have the ability to function in multitasking mode. Such a boiler will consume more fuel, which is not surprising, given that it works in two directions at once. But from an economic point of view, its use is completely feasible.

Gas boilers from Immergas

The Immergas company was founded in Italy more than 50 years ago. During its activity, the company has developed many models of gas boilers, characterized by compactness, performance and high efficiency.

The most successful modern designs were taken as a basis, to which our own amendments were made, some parts were strengthened, and the strength and performance of the most critical components were increased.

As a result, a number of model lines have been obtained that are capable of functioning in difficult conditions and performing assigned tasks with unstable power supplies, gas and water supplies.

Features of the gas boiler Immergas EOLO Star 24 3 E

Gas boiler Immergas EOLO Star 24 3 E

This year the Immergas STAR line of boilers has been updated. Immergas Star boilers belong to economy class boilers with a bithermic heat exchanger and are well known in our market for many years. Over the years, they have proven themselves to be excellent thanks to their reliability, durability and unpretentiousness in operation. The Immergas Eolo Star 24 3 E boiler is capable of heating and providing hot water up to 220 m2 of living space. For apartments, offices, shops and country houses, the Star 24 3 E boiler is a worthy solution, because the ratio of power, performance, dimensions, and most importantly, the price of the model is optimal. The minimum dimensions and weight of the boiler will save living space in your home and will also simplify the installation of the boiler. The modern design of the boiler will be harmoniously perceived in any interior. The Nike Star 24 3 E boiler with an efficiency of 93.4% is in widespread demand due to the possibility of installation in apartment and multi-storey buildings where chimney ducts were not installed during design and construction. Hot water productivity is 11.1 liters per minute at t = 30 ºС. The boilers are fully adapted to operating conditions in domestic conditions. Advantages:

- Reliability and durability - “Made in Italy” (Boiler production takes place in Italy (Bresello)) - No. 1 in Italy (According to the “Italian WHB market”, Immergas has occupied a leading position in the heating equipment market in Italy since 1998.)

- The smallest (boiler depth 24 cm; thanks to its very compact size and silent operation, the Star boiler can easily be used in apartment heating).

- Control panel with digital display and easy to use interface.

- Autotest system with digital parameter display

(Display is green during normal operation; red or orange in case of malfunction).

The electronic circuit of the boiler is controlled by a built-in microprocessor

(The boiler is equipped with automatic equipment that controls the boiler. The boiler is also equipped with frost protection and a diagnostic system).

- Electronic ignition and burner modulation.

- Automatic bypass system.

- Frost protection function "Antifreeze"

(activates the pump and burner when the temperature of the heating system water inside the boiler drops below 4°C).

- Anti-scale and circulation pump blocking functions.

- New design of chimneys (to prevent freezing during the cold season).

- Convenient for service and maintenance (all important components are easily accessible and can be replaced, which saves time for service personnel and money for consumers).

- Possibility of connecting a remote control, room temperature controllers.

- Protection class IPX5D

How to install an Immergas boiler

If you want the wall-mounted gas unit to work uninterruptedly and at full capacity, then you will have to invite a highly qualified specialist in this field for installation. Firstly, it will have all the components to hold the system together, and you won’t have to think about it, and secondly, professional work is always different from amateur work.

Rice. 2 Double-circuit wall-mounted unit Immergas

How to install Immergas gas boilers:

- First you need to decide which equipment is suitable for your home, buy it, and only then think about installation.

- Next, you should find instructions that will tell you everything in detail about installing the gas unit.

- The boiler must be attached to a selected location in the kitchen or another room. If this is a wall-mounted unit, then it needs to be attached to the wall.

- Then the wall-mounted device should be connected to electricity, having first made a grounding in order to avoid the boiler burning out during a thunderstorm.

- Next, you need to install an expansion tank and a circulation pump if you connect heating with forced circulation.

- The next stage is connecting the Immergas gas dual-circuit unit to the heating system.

- Then you should test the system for leaks (the instructions indicate how to do this).

- Then you need to remove excess air. How to do this correctly is also described in the instructions.

- Well, the last step is to launch the Immergas dual-circuit gas unit.