The warm water floor system includes various technical solutions. The simplest option is to directly connect the heating pipes to the boiler using a manifold used as a regular connector. Such a circuit will work and release heat, but you will have to forget about any temperature adjustments. Therefore, normal operating systems include additional elements that perform management and control functions. One of them is a servo drive for underfloor heating, which is responsible for supplying liquid to the water pipe circuit.

Node Description

The servo drive for a warm water floor regulates the temperature of the supplied coolant. This occurs due to the fact that this unit controls the opening and closing of the manifold valves.

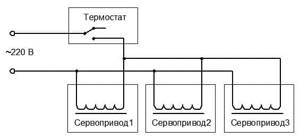

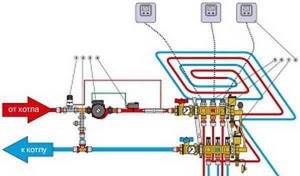

Installation diagram of servo drives for heated floors

The servo drive for a warm water floor consists of a spring mechanism and a small container with liquid. An electric current passes through the nichrome element. It is he who heats the liquid in the bellows, which, as a result of this effect, expands and acts on the rod.

It extends and presses on the thermal valve. This mechanism is called a thermal drive because it works by expanding the liquid inside under the influence of high temperature.

When voltage is applied, the valve closes only after 1-3 minutes. This time is necessary to warm up the liquid. If there is no voltage, the mechanism cools down, which takes a lot of time. As a result, the valve returns to its original position. This requires from 5 to 15 minutes.

Heating manifold servo drive

There is also a servo drive for a warm water floor collector without liquid inside. In such models, the movement of the rod occurs when the compensation element is heated. It is a plate or spring. During heating, the thermoelement expands and changes its position.

Rehau heated floors and servo drives

The manifold servo is also equipped with a retractable mechanism, which is located in the upper part of the housing. It is designed to determine the fit of the actuator in the thermal valve. A retractable mechanism indicates whether the device is turned on or not. The servo drive for a warm water floor is necessarily equipped with overheating protection. Its body houses a mechanism that allows you to automatically turn off the power.

Installation

In a system in which only underfloor heating circuits are present, the servo drive is installed on the manifold. A sensor from the zone that is heated by this circuit is connected to it.

In the simplest circuit, the servo drive turns on and off the supply of coolant to the circuit.

Collector with commutator and servos

Installing a servo drive on a three-way (or two-way) valve in a circuit without manifolds is simple, since you just need to correctly connect all the circuit elements:

- First, a thermostat with an air and floor temperature sensor is installed.

- Then two-way or three-way valves are installed.

- Servo drives are screwed onto the valves.

- The servo drive and thermostat are connected.

- Food is being served.

On the lid of many models there are LEDs that indicate the presence of power and the status of the valve. In simpler models, the condition of the device can be judged by the mark that appears as a result of the movement of the rod. The installation of this type of servo drive can be seen in the video.

Video of installing a servo drive on a heating system manifold:

The servo drive is used in heating systems of any complexity. It is indispensable in cases where manual configuration is simply impossible. With its help, you can automate the simplest underfloor heating system with one circuit or separate several loops and set them to different temperature conditions in a system with one heater.

Average rating of ratings is more than 0 Share link

Servo drive and its varieties

The servo drive regulates the flow of water into the system

. As mentioned above, the servo drive is an additional equipment that is installed on the distribution manifold for a warm water floor.

The device is used to regulate the flow of water entering the heating elements. This process is carried out by opening and closing control valves, which are located on the return comb of the manifold.

Mechanical servo drive

This device is the simplest version.

A mechanical servo drive is the simplest version of this device.

It has a simple design and reasonable cost.

The temperature is adjusted directly on the device itself by rotating a special wheel that decreases or increases the temperature.

There is no need to control the device itself; the main thing is to set the required value, and a servo drive of this type will control the temperature.

Mechanical devices are not combined with a temperature sensor.

Such a device is not coordinated with a temperature sensor and cannot automatically operate (turn on and off) when the temperature of the heated floor increases and decreases from a given setting.

The device requires constant monitoring of the temperature when leaving home and even before going to bed, but its service life is very long and the device does not require preventative settings or additional maintenance.

Electronic servo drive for manifold

The electronic device receives information from a temperature sensor.

The electronic version of the heated water floor servo drive is also a fairly simple device that is capable of automatically adjusting the supply of coolant to the heating circuit of the system.

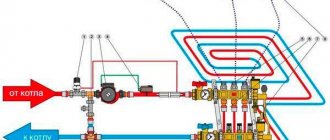

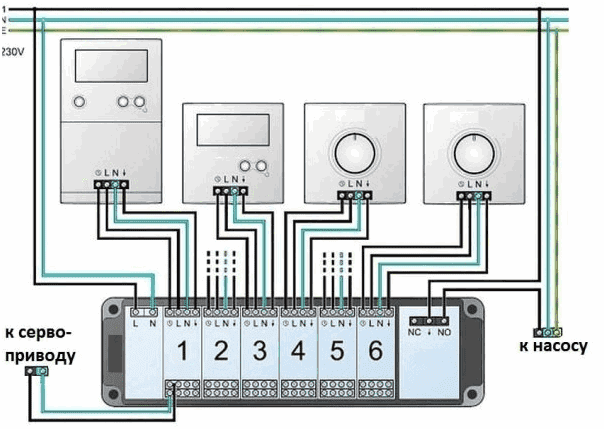

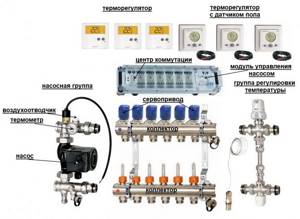

Servo-drive commutator circuit

The device is in constant electronic coordination with the thermostat, which is the brain center. The thermostat or thermostat is coordinated with a temperature sensor, which is installed near the heating elements in the heated floor screed.

Accordingly, the temperature limits at which the servo drive will open and close the adjustable valve to supply hot water to the heating circuits are set on the thermostat. One of the options for connecting a thermostat to servos can be seen in the table diagram.

An electronic type device is capable of completely independently producing and controlling the supply of coolant to the heating system, but in order to purchase it, each owner will have to shell out a considerable amount of money.

It should be remembered that when choosing an electronic servo drive, it is necessary to take into account the characteristics of the room itself, or rather the power supply area. You should also pay attention to how often power outages occur.

If they happen often, then you should additionally install a UPS (individual power supply) or opt for a mechanical device for regulating the coolant supply. For more information about servos, watch this video:

Existing types of servos today

Among the regulators that exist today and have become widespread in everyday life, the following servos are found. All devices can be divided into several types. Each type has a different operating principle and functionality. There are two types of device design:

- closed;

- open.

By the names you can judge the principle of operation. Enclosed servos typically remain open when no power is supplied. The incoming signal activates the mechanical part, blocking the access of water to the system. For open-type devices, the operating principle is reverse. In the normal state, the servo drive is closed; only when a signal is received, the mechanical part is activated, opening the flow of water into the pipeline. You can judge which type is best suited for domestic use by assessing the capabilities of your own heating system and the climatic conditions outside the window. Normally open servos are most often used in our country.

Note: if the device fails, the coolant in the pipeline continues to circulate, leaving the floor warm for a certain time. This feature is especially relevant for country houses located in a cold climate zone.

*

According to the method of power supply, servomotors are divided into devices powered by a constant flow voltage of 24V and devices connected to a regular AC power supply of 220V. Servo drives with 24V power supply are equipped with inverters.

Often consumers use another, rather rare type of device. We are talking about devices that are set to their normal position depending on the technological requirements of the heating system. Such servos are called universal and can change functionality from a normally open state to a normally closed state, and vice versa.

All three types of servomotors can be connected to the collector. The only condition is the correct setting, balancing and operating conditions of the heating system.

More about the design

By design, servo drives can be divided into 2 groups of devices – electromechanical and electrothermal. In the first, mechanical gearing is used to set some part in motion. In electrothermal devices, instead, the property of a liquid (gas, solid substance) to change its quantity when heated is used, and they are used in heating systems.

When choosing a specific model, you need to know the designations used; you will see options such as:

- normally open/closed;

- voltage 230 or 24 V.

Everything is clear with voltage - 230 V means powering the device from the mains, and 24 V means using batteries. But open/closed are directly related to the operating mode and scope of application of the device.

- the normally closed type, when the circuit is closed, releases water through a section of the pipe, just this type is used in space heating;

- normally open - on the contrary, when the circuit is closed, it blocks the movement of the substance through the pipe; such devices are used mostly in air conditioners and refrigeration equipment.

Device and principle of operation

The main element of this device can be called a sealed chamber with a corrugated wall. This chamber may contain a gas, liquid, or solid substance - when heated, it will change the dimensions of the bellows (sealed chamber) and regulate the flow of the substance through the pipe.

During operation, a thermostat located anywhere in the room signals to the servo drive that the temperature exceeds the optimal one. The circuit closes and current begins to flow through it.

Along with this, the bellows heats up and elongates. When extended, the bellows begins to put pressure on the valve stem, reducing the passage opening in the pipe.

The design is spring-loaded, so that after the chain opens again and the bellows cools, the spring will return the pusher to its original position, and the passage hole will increase in size.

Installation Features

When installing the servo drive independently, the instructions will look like this:

- First, a thermostat is installed in the room - it will record changes in air temperature;

- after this, a two- or three-way valve is installed (the highlights of each type of valve are discussed below);

- A servo drive is installed specifically on the valve and connected to the thermostat. The device is receiving power.

Note! In 4-wire servos, 1 contact is provided for possible connection of other devices.

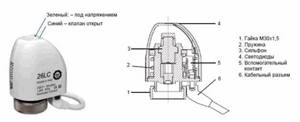

If all the connection work has been completed correctly, the LED on the servo drive head should light up; based on its color, it is possible to draw conclusions about the position:

- light blue color indicates that the device is now de-energized, in other words, it will be in the open state;

- The green indicator informs that voltage is supplied to the device, in other words, the servo drive is closed.

Application of two- and three-way valves

The servo drive can be used with two-, three- and four-way valves. In heating systems, the first 2 types of valves are much more often used.

Two-way valves with a servo drive are, in most cases, installed in front of radiators. Such a device has only an inlet and an outlet, and changing the passage hole allows you to regulate the flow of coolant through the valve. Installation of the control device is done by hand.

Three-way ones provide significantly more chances. Installing a servo drive allows you not only to regulate the coolant flow through it, but also, if necessary, to isolate the heating circuits from each other.

Note! Separation of heating circuits is simply necessary when using simple radiator and low-temperature heating (warm floors).

During temperature control, the servo drive on the 3-way valve can, for example, organize the addition of water from the return line into the supply pipe. This gives a 100% guarantee that excessively warm coolant will not enter the heating device.

Design and principle of operation of servomotors

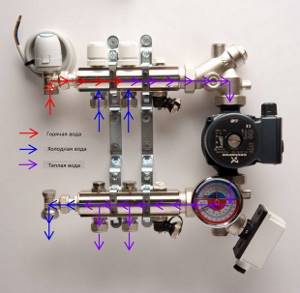

Those. the same part as in the three-way valve. A small, sealed cylinder with an elastic body is filled with a substance that is sensitive to temperature. Depending on whether the temperature increases or decreases, the volume of the substance changes accordingly. The figure - diagram clearly demonstrates the structure of the servomotor, where the bellows occupies the main place. The bellows is in close contact with the electric heating element. Receiving a signal from the thermostat, the heating element is switched on from the mains and starts working. Inside the bellows, the substance is heated and increases in volume. Thus, the cylinder, which has increased in size, begins to put pressure on the rod, changing its position and blocking the path of coolant flow. Evaluating the operation of the servo drive, we can conclude that the device is not equipped with any motors, it does not have any gears or transmission links. The usual working connection is “thermal energy and electricity”. Hence the common name for the devices, thermoelectric regulators.

In order for the valve to become open again, the entire process is repeated only in the opposite direction. Lack of power causes the heating element to stop working. Consequently, the substance inside the cylinder cools, decreasing in volume. The pressure on the rod decreases, it rises, acting on the valve, and, consequently, hot water access to the system opens.

Note: the substance placed inside the cylinder is toluene, which has high thermodynamic characteristics. The electric heating element is a nichrome thread.

Having become familiar with the principle of operation of the device, it is important to remember that the mechanical action of the valve requires a certain time. Despite the fact that when a signal is received from the thermostat, the heating element begins to heat the substance inside the cylinder. The time required for changes in the physical state of the liquid is 2-3 minutes, so the valve is not activated immediately.

For reference: when choosing a servo drive model, pay attention to the parameters of the heating element and the heating time of the liquid specified in the device passport.

*

Unlike heating, cooling of a liquid occurs more slowly. To the reverse process, i.e. Closing the valve will no longer take 2-3 minutes, but 10-15 minutes. If overheated, each servomotor should automatically turn off. For this purpose, the design provides an emergency shutdown mechanism.

For example: the servos used in the operation of the collector group are not all equipped with cylinders and cylinders with a substance. There are models in which this role is played by thermocouples, resembling a spring or plate, which heat up under the influence of the same heating element. Expanding, these parts again act on the rod, ultimately bringing the valve into working condition. You can determine what position the valve is in by changing the appearance of the servomotor. The retractable element signals the operation of the device. If this does not happen, it means that your device is not connected correctly or the heating system is not working properly.

For reference: a servomotor that is hot to the touch means that in this case the device is closed and turned off. If the device is cool to the touch, therefore, the valve is open, the coolant circulates normally through the water circuits of the heated floor.

Review of popular models

Servo drives for water heated floors are produced by different manufacturers. Each model has its own characteristics.

VALTEC

VALTEC is a manufacturer of devices for water and heating supply for the home. A group of Russian and Italian specialists is working together to create products. VALTEC produces the following drives to regulate the operation of a floor-type heating system:

- TE3042.A. Belongs to the group of normally open. Designed to control valves of climate systems using commands that will be set by a thermostat, controller or manual switch. Device power – 2 W, conductor cross-section – 0.75 sq. mm. The connecting size is M30x1.5;

- TE3061.0. This is a normally closed electrothermal device. Designed for three-way valves. The operation of the device is possible due to the thermal expansion of the liquid - toluene. Drive power – 2 W, conductor cross-section – 0.22 sq. mm;

- TE3041A.0. The device works thanks to the presence of liquid in the body, which expands under the influence of temperature. Belongs to the group of normally open. Connection to the valve occurs through an adapter, which is included in the kit. Unit power – 1.8 W, conductor cross-section – 0.75 sq. mm.

Watts

Watts is the world's leading manufacturer of heating equipment of various formats. It is distinguished by high quality, affordable price and efficiency. Servo drives from Watts are models with an electromagnetic motor. Popular series:

- 22C. It is installed on the return pipeline valve and regulates the flow of coolant into the underfloor heating system. Power is 2.5 W. Depending on the model, the 22C series includes normally open and closed devices. Protection class – IP44;

- 22СХ. They belong to electrothermal devices to ensure the efficient operation of water heated floors. There are normally closed and open models. The level of power consumption in normal operation is 1.8 W. The operating temperature of the liquid in the system is +110°C;

- 26LC. Electrothermal drives for the collector. There is an LED indicator on the case that indicates its operating mode. If the green light comes on, voltage is supplied to the drive, blue light means the device is open.

REHAU

Drives for adjusting the operation of water heated floors from a German manufacturer. They combine innovative developments and proven quality over the years. The most popular models from REHAU:

- UNI for 230, 24 V. The device is mounted on the valves of the manifold group using a special adapter. Applies to normally closed devices. Control over the operation of the drive is carried out through an indicator. Connecting cables with a cross section of 2x0.5 sq. mm;

- Drive 230, 24 V. When de-energized, the valve is in the closed state. To control the functioning of the device, a light indicator is placed on the case.

LUXOR

The Italian company LUXOR specializes in the production of water shut-off valves and systems for regulating the temperature of the heating system for the home. The installed collector group will include an SM 1347 drive. It is designed to regulate the temperature of the supplied coolant for a warm water floor. Main technical characteristics of the device:

- power supply – 24 V;

- The operation of the device is provided by a stepper motor. Its control is electronic;

- there is an LED indication on the case that indicates the operating mode;

- installation takes place in a straight position - vertical or horizontal;

- maximum temperature in the system – +100°C;

- cable 1.5 m long;

- device storage temperature – from 0 to +50°С;

- The body is made of synthetic materials. Its color is gray;

- Warranty available - 2 years.

Regardless of the model chosen, installation of the servo drive and its operation must be carried out in accordance with the manufacturer’s recommendations. These can be found in the instructions for the device. After installing the drive and all system elements, they begin to use them after full testing.

Servo valve: how to choose

Servo drives are used in the operation of heating and plumbing systems. They are installed on the collector when installing heated floors, or on radiators in the room. Thanks to servo drives, control of the heating system becomes automatic.

Types of servos:

- Open. In idle mode they remain open and close when power is supplied.

- Closed. In the inactive state they are in the closed position; they open when power is applied. If there is no electricity, the coolant does not enter the system.

For heating systems only enclosed actuators are used. They have a threaded union nut and can be installed on standard radiator valves.

Today, there are many manufacturers that produce servos and other elements for heating and water supply systems. It is difficult to say which manufacturers are better, since each model has both advantages and disadvantages.

Among the leading manufacturers of servo drives are VALTEC and Watts.

REHAU produces servo drives for installing heated floors, LUXOR, in turn, concentrated on the production of elements for installation in autonomous heating systems.

Installation and operation of servos must be carried out strictly according to the instructions from the manufacturer - the operation of the entire heating system of the house depends on correct installation.

Connection features

Improper installation of the device can lead to ineffective operation of the system, and even its breakdown. Therefore, connecting the servo drive should be done very responsibly and carefully.

The location of the device is the manifold valves. There is no exact diagram for connecting the device to the system. It all depends on which thermostat the master chose. If it will control only one circuit, then the servo can be connected to it directly. If the thermostat is responsible for several circuits, then the wires need to be inserted into specially designed terminals. More details in the video:

The most common types of servos have only two wires, one of which receives zero, and the second - phase. However, if there is no one phase wire, then the device will be focused on performing only one function. That is, the device will either close the valve or open it.

In any case, the servo drive is a very necessary device that is installed in the manifold specifically to regulate the temperature of the coolant. Without it, a water heated floor may not work efficiently. We are waiting for your comments!

Servo drive for underfloor heating manifold

The stable functioning of any warm water floor scheme depends on many external and internal conditions. One of them is the correct installation and further use of all components that are subject to a predetermined load.

An important place in the system is occupied by a servo drive, installed on the collector and regulating coolant flows. By periodically closing and opening the valves, it maintains the set temperature at the desired level.

When choosing a servo drive design, you need to determine in advance which mode will last the longest. If regular circulation of the coolant is required, it is recommended to use a normally open type of device. This option is best suited for areas with cold climates. Even as a result of the failure of such equipment, the coolant will still flow into the pipes and give off heat as long as the water is heated. Normally closed appliances are best suited to warm climates where cutting off the heat supply is not critical.

Among the many modifications, there are servos with smooth settings. They are additionally equipped with electronic regulators that provide the required voltage value. Such equipment has proven itself well when dosed supply of coolant is required. In other cases, its use may not be appropriate.

Servo drive installation location, thermostatic valve installed on the manifold.

Important! When the heating system operates underfloor heating from a solid fuel boiler, a switch function such as turning off the pump can stop the heating device itself. Installing a bypass and bypass valve will allow you to avoid stopping the pump and running the heater idle.

conclusions

It should be noted that thanks to the advent of modern devices and devices, managing and adjusting heated floors has become a commonplace and simple process. The design of many devices used to operate heating circuits is not particularly complex. The operating principle of many components and assemblies is also clear. This can be said with confidence about servos. The devices are mostly reliable, practical and easy to use. Thanks to servomotors, it has become possible to fully automate the control system for heated floors, making the conditions for using heating equipment simple and understandable.

By choosing a simpler option, you can get by with installing conventional control valves. Automatic regulators, temperature sensors and servos are a category of devices that work for your comfort and safety. Installing additional devices, such as a switch and a bypass valve, will make your heating system as efficient and safe as possible.

Selection rules

The main thing you should pay attention to when choosing a servomotor is its type and how compatible the device is with the thermostat. The best option is a universal device that copes well with the operation of a closed and open servo drive.

The advantage of a universal device is that, if necessary, a specialist can replace a closed servo drive for a heated floor with an open one and vice versa. And there will be no difficulties during installation.

The quality of the device is also an important point. Experts advise not to buy a servo drive at sales points that do not have special certificates. All devices must be accompanied by certain documents that guarantee quality. It is better to choose popular manufacturers that have won the trust of users.

Installation

The servo drive is installed on the finished collector assembly according to the following scheme:

- The device can be installed in any position, regardless of whether it is normally closed, open or universal. But before the first switching on, the drive must be in the open state.

- Check the compatibility of the valve and servomotor using a template. It can be found on the device box.

- A threaded adapter (included) is installed on the valve. Correct installation is confirmed by snapping the latch.

To install the drive, you do not need to use any additional tools. Also, there is no need to use any sealing materials in the threaded connection. The electrical connection of the drive must be carried out according to the diagram provided by the manufacturer. You can find it in the operating instructions. To dismantle the servo drive, you need to press on its housing from the side and pull it up. This will cause the device to disconnect from the adapter.

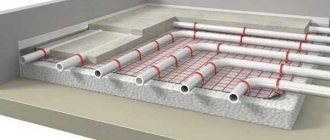

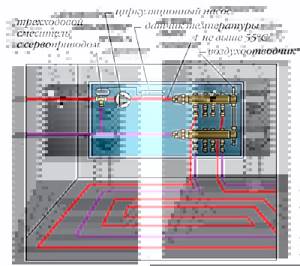

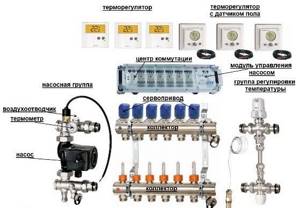

Equipment diagram for heated floors

Tips for connecting

The entire system may not work efficiently if the device is not installed correctly. Therefore, you should connect the servomotor carefully, being aware of all the responsibility.

The device is installed on the manifold valves. There is no more precise diagram for connecting it to the system. Much depends on the chosen thermostat. If it is possible to control the thermostat with only one circuit, the servo drive for heated floors can be connected directly to it. When the thermostat has the function of working with several circuits, the wires should be routed into certain terminals.

The most common types of servomotors have only two wires. One receives zero, the second receives phase. But when one phase wire is missing, the device will perform only one specific function (it will either close the valve or open it).

It must be said that after the advent of new devices and devices, managing heated floors has become even easier.

Basic and additional functions

Distributing coolant along the circuits is the main task of a heated floor collector, but it can perform a lot of additional functions. For example, most often there are two shut-off valves in the manifold: on the supply and on the “return”. Through them, the system is filled with coolant, tested (pressured) and drained. The manifolds are also equipped with bleed valves through which air leaves the system. These are shared devices.

The underfloor heating manifold distributes the hot coolant from the supply comb, and collects the cooled coolant on the return comb.

Manifold options

There is also an additional feature on the collectors. devices that are installed on each circuit or loop of a heated floor. Flow meters are the most commonly used. They are installed on the supply comb and serve to equalize the hydraulic resistance of underfloor heating loops of different lengths. All instructions recommend making floor heating circuits of the same length. In practice this is often unrealistic. But if circuits of different lengths are connected directly to the distribution, then most of the flow will go through the shortest one, because it has the smallest hydraulic resistance. To prevent this from happening, flow meters are installed. With their help, they regulate the flows in each loop of the heated floor, narrowing/expanding the gap for the passage of coolant.

This is what flow meters look like. When the system starts, they are filled with air, then coolant may appear in them. This is normal, it does not interfere with work

On the return manifold, at the outlet of each circuit, there are shut-off valves. With their help you can turn off one or more heating circuits. And thus regulate the temperature of the floor and/or air in the room. You can also do this with a flow meter, reducing the flow of coolant if it becomes too hot, increasing if it is frozen.

Automatic temperature control device

Of course, you can regulate the heat transfer by hand, but you can leave this matter to automation. Then, instead of manual flow valves, servomotors are installed on the return manifold, and a regular or programmable thermostat (thermostat) is placed in the room.

They can control the air temperature in the room, or they can control the temperature of the heated floor. The temperature of the heated floor is controlled by a remote sensor, which is connected to the thermostat. The sensor must be installed before pouring the screed.

Thermostat and servo drive for water heating. One of many options

To install a sensor that controls the floor temperature, a groove is punched in the wall from the thermostat downwards. A corrugated hose is placed in it, which should extend to the floor and end at a distance of at least 50 cm from the wall. Moreover, the end of the corrugated hose should be located between the pipes, and not closer to one of them - this way its readings will be more accurate. When laying the corrugation, try to make as few turns as possible, and all of them are smooth.

The end of the corrugation that ends up in the screed must be sealed so that the solution does not get into it when pouring the screed. You can wrap it well with electrical tape or make a foam plug. This whole procedure is necessary so that the floor temperature sensor can be removed and changed if necessary.

This is what a connection diagram with a two-way valve, control from a thermostat and servos may look like

Let's put the sensor in place. To do this, from the end of the corrugated hose that is located near the thermostat, simply lower the sensor (it is attached to a long wire) until it stops. If the wire is too soft and the sensor will not pass the turn, try using thick garden fishing line as a broach. This usually helps.

When using sensors, a constant temperature will be maintained automatically. The control mechanism in this case is simple. You set the desired temperature on the thermostat. When the actual air temperature deviates from the set one by 1°C, a command is sent to the corresponding servomotor to turn on/off the coolant supply.

Connection and interaction with the thermostat

When controlling the thermostat, the error is applied to the armature of the electric motor. As it increases, the output voltage supplied to the armature of the electric motor also increases. While there is an error, the amplifier increases the voltage and feeds the armature accordingly.

The working principles of AC servo motors are based on the design with two different types of AC servo motors, they are synchronous and asynchronous (induction). The AC synchronous servomotor consists of a stator and a rotor and a thermostat. The stator consists of a cylindrical frame and a core. The armature coil is wound around the stator core and is connected to the supply wire through which current is supplied to the electric motor. The servo drive of the underfloor heating manifold is reliable and efficient equipment.

When the stator field increases in voltage, the rotor follows the rotating magnetic field at the same speed or synchronizes with the excited stator field, this is where the synchronous type is derived. If it is necessary to change the position of the rotor relative to the stator, a thermostat is installed, which provides feedback to the servomotor controller. The thermostat for the heated floor servo drive allows for a simple process of adjusting temperature values, which is very convenient.

Circulation pump control

In order to ensure a certain speed of the coolant in the floor line, a circulation pump is installed on the output circuit. It is designed to pump cooled liquid into the heat exchanger located in the boiler.

For each branch of the main it is recommended to install its own circulation pump with its own thermostat. This is necessary in order to be able to control the temperature individually in a specific room.

If the underfloor heating is equipped with only one pump and one control unit, the heating will be maintained at the same level in all rooms. The system will turn off not only in a room where the temperature is higher than normal, but also in a room with a lower temperature. Automation for underfloor heating, which controls the operation of the pump, is represented by the following elements:

- temperature sensor; the equipment is installed on a chilled water circuit; it transmits data to the thermostat;

- thermostat; the equipment is designed to analyze the temperature that was set for a certain room and the data transmitted from the sensor; when the indicators decrease, the thermostat turns off or turns on the circulator;

- hysteresis; the device ensures harmonious operation of the system; a reserve temperature range is set; it can be from +/-1 to +/-10 degrees; if the thermostat was set to 30 0C, the hysteresis is +5 0C, then the pump will turn off at a temperature of 25 0C; it will turn on when the coolant is heated to 35 0C;

- uninterruptible power supply unit UPS or generator; the equipment will ensure constant operation of the pump and automatic control, regardless of the power supply.

We recommend: How to repair underfloor heating?

Instead of a temperature sensor, a pressure switch is installed on the circulator. The device determines the intensity of coolant supply into the main line. Water circulates in the system at a pressure of 4-6 bar. When the indicator increases, the relay turns off the pump. Water enters the system at low pressure, which reduces the heating intensity. When the pressure in the line decreases, the relay turns on the circulator.

Adjusting the heated floor temperature

The simplest adjustment option is with manual taps. A slightly more comfortable option is automatic thermostats with sensors and servos, but only with the additional installation of a restart valve and switching unit. In addition, there are other ways to regulate the heating of floor water systems:

- change in coolant flow;

- change in coolant temperature.

The second method is used especially often and involves the installation of a three-way valve, which is entrusted with the function of controlling the mixing unit. The relay output of the temperature sensor is connected to the solenoid of the electric shut-off device: at the slightest excess of the temperature of the value set in advance, the valve opens, causing the cooled water to mix with the incoming liquid, reducing the heat capacity.

Types and types of sensors

Remote electric floor temperature control sensor

All sensors and regulators can be divided into two types:

- The mechanical device has an operating principle based on the property of changing volume depending on temperature readings.

- Electronic, installed remote sensor in the form of a thermistor. It is supplemented by a separate control unit containing an electronic circuit, operating order and indication elements.

Devices are also divided by type:

- a device operating in economy mode, which allows you to reduce the level of floor heating in the room when there are no people;

- sensors with a timer, which have a program for turning on/off the heating system;

- intelligent sensors with a built-in operating algorithm and control of other factors: humidity conditions, temperature fluctuations outside the room, presence/absence of people in the room, etc.;

- limiters are thermal devices that turn off the heating of the coolant when a predetermined temperature is reached.

Advice! In simple heating systems, the presence of highly intelligent sensors is less justified than connecting a conventional electronic regulator. Numerous functions of the devices will not be in demand, for example, in warm water floors.

Example of a mechanical sensor with a temperature element

Thermostats for water heated floors differ in the type of monitored environment:

- floor temperature control;

- control of the degree of air heating.

As a rule, sensors for determining air temperature are located in the thermostat housing. This provides additional convenience, since no unnecessary installation problems are foreseen; on the other hand, the installation of the thermostat must meet a number of conditions:

- absence of nearby sources of heat/cold;

- There is no threat of direct sunlight or draft blowing.

Important! The installation location of the device is selected taking into account the accuracy of the temperature display, so it is best to place the equipment at a height of at least 1-1.5 m from the floor.

The water floor system can be supplemented with a remote temperature sensor. Representing a small-format device attached to the end of a long cable, the measuring device is mounted in the floor with a distance of 0.5 meters from the wall. The placement is shown at a distance equidistant from the nearest coolant pipes. The second end of the structure is connected to a temperature sensor and attached to the terminals according to the diagram.

Where are the most expensive new buildings in the Moscow region?

Advice! This type of device must be installed during pipe laying before pouring the concrete mixture. It happens that such devices fail, so it would be useful to provide for the possibility of replacement by laying a corrugated hose.

Servo drive device

The servo drive for water heated floors is an important part of the underfloor heating system. Its main part is a bellows - a movable flask filled with a special liquid (methylobesole or toluene). The substance, under the influence of an electric current coming from the thermostat, heats up and increases the bellows. The flask begins to press on the valve stem of the return console outlet.

Constant rotation servo drive

Servo drives usually have a limited rotation angle of 180 degrees, and are called “180° servo drives.”

But there are servos with unlimited axis rotation angle. These are constant rotation servos or “360° servos”.

The constant rotation servo can be controlled using the Servo or Servo2 libraries. The difference is that the Servo.write(angle) function sets not the angle, but the rotation speed of the drive:

| Arduino function | Servo 180° | Servo 360° |

| Servo.write(0) | Far left position | Full travel in one direction |

| Servo.write(90) | Middle position | Servo stop |

| Servo.write(180) | Far right position | Full stroke in reverse direction |

To illustrate how to work with constant rotation servos, we have assembled two mobile bots - on Arduino Uno and Iskra JS. For assembly instructions and examples of sketches, see the article “Assembling an IR bot.”