In order to firmly join pipes, they usually resort to the welding method. Currently, the market offers a considerable range of devices for welding processes, used not only in large industrial enterprises, but also for domestic purposes. At the same time, owners of private houses or apartments have a wonderful opportunity to perform welding processes with their own hands.

Novice welders often ask questions about how to make a weld reliably and efficiently. In this case, you should know which welding electrodes should be used, how to prepare the surface of the elements being welded, and how to accurately test the seams for strength.

It is suggested that these questions be addressed below.

How to weld pipes

There are several methods for welding pipelines (steel). But the advent of inverters pushed back all methods, and now pipe welding in everyday life is carried out with this particular device. Firstly, it is the simplicity of the welding process, and secondly, accessibility and high safety. Moreover, the technology for welding pipes is not very complicated; the main thing is to carry out the preparation correctly and select the necessary consumables.

Preparing for work

Before proceeding directly to welding, preliminary preparation should be carried out. Its stages are the same regardless of which method is used.

First of all, you need to prepare a work site of sufficient size that will accommodate all the necessary equipment, the pipes and fittings themselves (if used). Before starting work and connecting the welding machine to the network, check the integrity of the electrical cables. It is also worth making sure that the clamp and electronic sensors are in good working order, the cutter knives are sharpened, and the liners prepared for work match the diameter of the pipes. Parts that are subject to friction during operation are lubricated, and the heater, trimmer and scraper are cleaned and degreased.

The pipes themselves are also processed: the surface at the supposed joints is cleaned. In this way, it is possible to get rid of various contaminants that would interfere with creating a reliable connection.

Welding pipes using electric welding with consumable and non-consumable electrodes

It is most effective to weld technological pipelines with an electrode manually or using an automatic machine. This can be a method of working with a consumable or non-consumable electrode (argon-arc welding). Pipe welding technology is implemented in three main stages:

- Preparatory, which is divided into two parts - preparation of the master and preparation of the material. The preparation of a welder should be taken very seriously, since his safety depends on it. Be sure to prepare special clothing and a protective eye mask to prevent burns from bright sparks. By preparing parts we mean thoroughly cleaning pipes for welding from corrosion, paint and contaminants. Before manual arc welding of pipelines, you need to thoroughly treat the joints and the area adjacent to them with a metal brush or sandpaper. If this is not done, there may be “gaps” in the seam itself, since the material will not “get caught” on the contaminated pipe.

- Welding process. When everything is ready, you can start. The most important thing in the arc method (whether it is done manually or with an inverter) is to hold the arc. First you need to ignite the electrode and initiate the arc. Then the seam is fully completed. Its type is selected directly by the master during the work process. The method of guiding the electrode and the technology of pipeline welding in general is influenced by many factors - the location of the pipes, the material they are made of, and the preferences of the welder.

- Checking the quality of work. When the seam is ready (do not forget to beat off the slag that forms above it in the form of a roller), you can start communication to control the quality of the connection.

Preliminary activities

Preparatory surface treatment of products and the correct selection of materials for the welding process are an integral part of the preliminary activities before connecting pipes.

Selection of welding electrodes

Electrodes are used as a working material for the production of manual arc welding. Such auxiliary products are manufactured in large quantities. It is for this reason that the question of the correct choice of the appropriate electrode is always relevant.

All manufactured electrodes of various types can be generally divided into the following two categories:

- Electrodes whose base melts.

- Electrodes whose base does not melt.

The material from which the electrode core (base) is made is a decisive factor in determining the category for a given electrode. Thus, electrodes that melt are made from special welding wire with different thicknesses and unequal chemical composition. The base of the electrodes, which do not melt, is made of a material such as tungsten, as well as electrical coal or graphite.

We recommend: How to remove severe blockages in sewer pipes at home: remedies

At the same time, electrodes are further divided into different types depending on the type of coating material.

Construction of pipelines.

When constructing pipelines, the pipes are butt welded. The assembly of pipes for welding is done using special devices called centralizers. The gap between the diameters of the welded pipes is allowed no more than 1 cm.

When welding, a weld reinforcement is formed, which is called burr. From the outside it can interfere with insulation, and from the inside it can interfere with the passage of the pipeline. Therefore, after welding, excess is removed using a special device - a deburring device.

To speed up the laying of pipelines, they usually use not individual pipes, but sections at once, that is, parts of the pipeline welded in workshop conditions. The main method of joining pipes in industrial conditions is automatic submerged arc welding or flash butt welding. This ensures the tightness and strength of the welds.

Methods of welding metal pipes

There are several ways to obtain a high-quality welded pipe connection. Much depends on where exactly the pipes will be used. If this is a pipeline and complete tightness of the connection is required, then one method is applicable; for installing greenhouse supports, for example, a completely different one.

There are several ways to cook pipes:

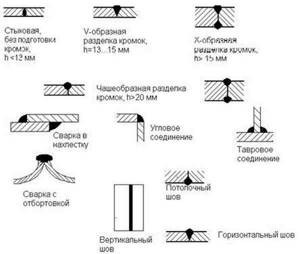

- Butt welding - this method of welding pipes is most common among welders. When performing it, the pipes are located in front of each other with little or no gap. In this case, it is very important to carefully adjust the pipes so that their edges are absolutely even.

- Overlapping - the method is applicable for welding pipes of different diameters, when one pipe is put on another. This is the simplest method of welding metal pipes to each other, which is distinguished by its simplicity and speed of implementation.

- T-joint - this pipe connection is necessary when it is necessary to maintain an angle of 90 degrees between the pipes.

- Corner - the connection is used in cases where the angle between the pipes is less than 90 degrees.

For beginners who have just started welding pipes, there are a few simple tips that will help you weld metal pipes efficiently and without errors.

Current control

When butt welding, it is very important to accurately calculate the current supply parameters, as well as the speed of the process. Current control is essential.

Its increase or decrease is carried out in strict accordance with the assigned tasks for welding beams, pipes, fittings, and so on, any metal products. By increasing the current, the master speeds up the butt welding. With reverse polarity and a decrease in current, the metal is melted more reliably, and the penetration depth increases. This is very important when performing restoration work on damaged metal products.

Types of connections

If welding of process pipelines takes place, then the steel sections are usually butt-joined. Threaded connections are most often unreliable. In addition, this technology is quite complex. The use of threaded (coupling) connections, as well as flanges, is advisable only in cases where the project involves repeated separation of joints.

Diagram of types of welded joints.

During the welding process of steel pipes, various joining methods are used. This is about:

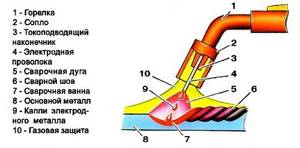

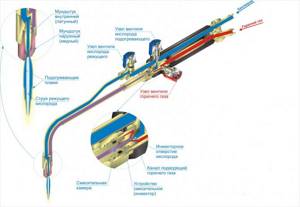

- gas (acetylene) welding;

- electric arc welding in air;

- welding in shielding gases;

- semi-automatic welding;

- fully automatic processes.

For domestic conditions, where it is necessary to install water supply branches, connect heating systems of varying thicknesses of varying degrees of complexity, and manufacture other structures from chrome-plated pipes, the use of the first two types of welding is recommended.

Types of coating

When selecting the required electrode for welding work, you need to pay attention to their coating - each coating has its own special purpose.

The types of electrode coatings are as follows:

- Electrodes coated with class C cellulose - used for making vertical and circumferential seams on pipes with large diameters;

- Electrodes with rutile acid coating class RA. During welding, a slag of a special design is formed on the seam, which is easily removed at the end of the process;

- Rutile-coated electrodes of class R and RR attract attention by simple re-ignition, high level of slag impact, and make it possible to make seams with an attractive sellable surface. Such products are used for installing clamps, making seams in corners, welding the outer parts of seams in order to create an aesthetic appearance of the seams;

- Electrodes coated with rutile-cellulose type RC class. They are offered for making seams in various directions, as well as for making complex seams - vertical seams running from top to bottom;

- Electrodes with a coating of the basic type, class B, make it possible to produce seams with the necessary viscosity characteristics to eliminate the likelihood of cracks. Such products are proposed to be used for connecting pipes with thick walls. In the case of using welded pipelines in winter conditions, it is also recommended to use such electrodes that have an increased viscosity of the weld.

Pipe surface treatment before welding

First, before carrying out the welding process, it is necessary to process the edges of the pipes - the surfaces that will take part in welding the products.

It is also necessary to ensure that the pipes comply with the requirements specified in the piping system design. It is necessary not to miss such important points as compliance of dimensional characteristics, availability of documentation - quality certificate, absence of defects - deformation in the form of ellipse, absence of variation in pipe thicknesses. The chemical composition of metal products, as well as their mechanical properties, must meet the requirements of state standards.

We recommend: How to cut threads on a pipe with your own hands: video instructions

In order to treat the edges of pipes before welding, it is necessary to remove dirt deposits, oily areas, oxidation zones - rusty areas. For correct joining of products, it is necessary to check the rectangular location of the cross-sectional plane of the pipe relative to its axis, the angle of opening of the edge, as well as the level of bluntness.

To form a high-quality seam, it is recommended to open the edges at an angle of 60–70 degrees, and the size of the blunting is 2–2.5 mm.

In case of irregular cut shape of the edges of tubular products, it is necessary to clean them using special devices such as grinders, chamfers and trimmers. To finish pipes with a considerable diameter before welding, a milling tool is used or special thermal processing methods such as gas-acid and air-plasma trimming are used.

Pipeline electric welding technology

To reliably connect two pipes, you need to dock them correctly. Then form the weld using the selected method.

Correct pipe joining

This stage of welding work is performed as follows:

- Pipeline elements are secured in a vice or other device, installing them end-to-end or overlapping. The junction is grabbed with an electrode in several places. When forming 2 points, they are placed on different sides of the circle.

- If a single “tack” is provided, begin welding the joint from the opposite area.

Step-by-step instruction

Having installed the elements exactly, they begin the welding process. It is carried out like this:

- Adjust the operating parameters of the device in accordance with the selected pipe welding method.

- Excites an electric arc. To do this, touch the electrode to a metal surface.

- A welded joint is formed. To understand how to properly weld heating pipes, you need to understand the types of seams. The option is selected after welding begins. The directions of movement depend on the configuration of the pipeline, the material of its manufacture, and the professional skills of the welder. The connection must begin and end at the same point.

After completing work with the seam, the slag, which has the appearance of an influx, is removed. After this, a test run of the communication line is carried out, assessing the quality of welding.

What electrodes are best for welding pipes?

For welding steel pipelines, it is better to choose only the highest quality and time-tested consumables. In this case we are talking about electrodes, on the quality of which too much depends.

The best models of electrodes for welding pipes are rightfully considered:

- UONI electrodes make it possible to obtain a high-quality welding seam, although they require a stable arc in operation and a low welding speed. Nevertheless, UONI electrodes are attractive to both professionals and beginners, primarily for their welding quality.

- Electrodes ANO-21 and 24 - you need to work with these electrodes on alternating current. These models of welding electrodes are very popular when used in everyday life; they allow you to weld various types of structures, have a low cost, and are also capable of providing a high-quality weld.

- MP-3 electrodes are rightfully considered one of the best electrodes for welding steel pipes.

- Electrodes LB-52U - from a Japanese company, have also proven themselves well for welding metal pipes. They are able to provide arc stability, a strong and aesthetic welding connection.

Be that as it may, the success of welding metal pipes depends not only on the quality of consumables.

Much, of course, depends on the skills and experience of the welder. And since novice electric welders do not have it, questions arise, such as: how to weld pipes, and what methods of welding exist.