How to make a vapor barrier from polyethylene film

A vapor barrier made of polyethylene film creates a vapor barrier, as a result, the warm air of the room does not escape to the street.

Such materials serve to protect the insulation from water vapor that forms inside the room. This is how moisture condensation is regulated in the area of the building envelope. The harm of moisture accumulation in rooms is that as a result, spores of fungi, mold and other bacteria multiply.

By using polyethylene film as a vapor barrier, this will be able to resist the penetration of water vapor. The material is made primarily of multilayer polyethylene.

Why do you need a vapor barrier in a roofing pie ↑

First of all, a vapor barrier is necessary to protect the insulation from moisture absorption. The thing is that mineral wool and other materials used for insulation tend to absorb water contained in the air. As a result, the thermal insulation properties sharply decrease, mold and mildew appear, and the destruction of the material begins. In addition, due to temperature differences, condensation often forms on the inner surface of the roof, which affects both the insulation and building structures. The living conditions in such a house are deteriorating sharply.

So, the main task of vapor barrier is to protect heat-insulating and other building materials from steam penetration and condensation.

Why do you need a vapor barrier?

During the insulation process, the temperature affects the inner layer of the polyethylene film. There is still a small amount of water vapor in any room. Sometimes they form water droplets, this happens in certain cases:

- When excess moisture is fixed indoors.

- When the indoor temperature drops. If it decreases significantly, then the steam can no longer retain moisture.

Insulation with films may be necessary if the temperature inside the room is the same as outside. After installing a vapor barrier, steam will no longer turn into water. When the air temperature in the room begins to rise, the steam will disappear on its own.

Myth No. 2: “Any tape will do for gluing overlaps and junctions of vapor barriers.”

If unsuitable connecting tapes were chosen to seal the overlaps and junctions of the vapor barrier, then after some time the vapor barrier layer may look like this...

It is therefore important that connecting tapes are used in accordance with their intended purpose. For example, some of them are intended only for sealing vapor barrier overlaps, others for sealing overlaps and making connections to smooth surfaces, and to make a hermetic connection of vapor barrier with rough or porous surfaces, a third type of tape is required, etc.

It is advisable to use connecting tapes of the same brand as the vapor barrier itself. This is due to the fact that when creating such tapes, the manufacturer takes into account the characteristics of the materials being fastened to ensure not only the tightness of this connection, but also its maximum service life.

To obtain a truly high-quality and reliable connection, in addition to all of the above, you should also comply with the basic requirements for the installation of connecting tapes:

- The surfaces to be glued must be dry and clean;

- Do not install tapes at temperatures lower than recommended.

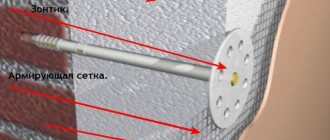

Installation of vapor barrier

All further actions are thought through in advance, namely:

- The most suitable type of insulating material is selected.

- Installation work is underway.

- The film used is installed according to certain rules, this allows it not to disturb the structure of the building and other elements.

Most often, a vapor barrier is installed using polyethylene film. Many people don’t even know that there are substitutes for it. Quality indicators are 3 indicators:

- fire resistance;

- high strength;

- low thermal conductivity.

Below are the most common vapor barrier materials:

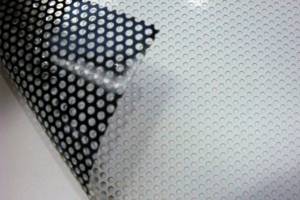

- Polyethylene with reinforced mesh. It comes either with or without perforated reinforcement. Products with perforations contain small holes that easily allow moisture to pass through. If there is no perforation, then there are no special holes. This material is quickly and easily installed with virtually no waste. Some films have a foil coating to help reflect heat. This coating is most often used in baths.

- Polypropylene. Compared to its polyethylene counterpart, this material is much stronger and UV resistant. Applies to already erected structures. One side of polypropylene is impregnated with cellulose and viscose, which improves moisture absorption. The material is resistant to damage, and the price is affordable for the average buyer.

- Bitumen-based vapor barrier. This is a liquid vapor barrier that is applied to the surface with a roller or brush. Bitumen comes in different forms. Everything will depend on temperature indicators. But if the air temperature is lower than the presented indicators, the bitumen will gradually collapse.

There are other materials used instead of vapor barriers. These are aluminum foil, cardboard, membrane vapor barrier, spunbond, HDPE. They all have their own purposes and directions.

Materials used for protection against steam ↑

As a vapor barrier, you can use materials such as glassine, roofing felt, spanboard, roofing felt, and in bathhouses and other hot rooms - thermofol or foil.

Until recently, the main material for vapor barrier was glassine, but recently more expensive and high-quality film-type materials have become more common. This is due to the fact that glassine, which is based on construction cardboard, does not meet such important parameters as strength and durability.

Vapor barrier with roofing felt is also losing its relevance, since it must be attached exclusively to a rigid flooring, which is made from OSB boards nailed to boards, or from boards connected to a tongue and groove. From an economic point of view (due to the rise in wood prices), it is considered more profitable to install a vapor barrier with film materials that do not require flooring.

Polyethylene

This is the cheapest and most accessible material. It is conditionally divided into 3 groups:

- non-perforated film;

- perforated look;

- film with an aluminum layer.

Is it possible to use all these types for floor installation? If you are making a vapor barrier on the floor, you can use any type of polyethylene. But each of them has its own specific purpose, like this:

- Non-perforated polyethylene films are used for vapor barrier of a room.

- Perforated material is intended for waterproofing.

- Polyethylene with aluminum coating is mainly used for installing floors in buildings where there is a high level of humidity.

When you come to a hardware store, you will see many names of polyethylene films, it all depends on the brand of the manufacturer. The most commonly sold brands are:

- Polinet. This vapor barrier is presented in one layer and has a non-perforated direction.

- Geotex. Its thickness is 1 layer, without perforation.

- Techno NIKOL - polyethylene film as a vapor barrier with 3 layers, reinforced with a mesh of polypropylene threads.

- TERMOFOL90. Consists of 3 layers reinforced with polypropylene threads and a layer of aluminum.

But this material consists not only of advantages, there are also disadvantages. The most important of them is the low strength of the film. But if installation is carried out carefully, the product will not last 1 year.

How to avoid mistakes with films in a wall or roof?

To understand this, you need to add a little theory.

Let me remind you that the purpose of this article is to explain “at a glance” what is happening, without delving into physical processes, partial pressure, molecular physics, etc. So I apologize in advance to those who had an A in physics