You need to approach the issue of cladding a wooden house carefully, having carefully planned and thought through the entire process at the stage of developing a private building project. This priority is due to the fact that not only the presentability of the facade, but also the resistance of the building to various external influences (temperature changes, humidity, wind and harsh solar radiation) will depend on the quality of the finishing.

How to sheathe the outside of a wooden house

Cladding requirements

In order for the future residential building to be warm and comfortable, its decoration must be treated with great care. When thinking about how to decorate the outside of a house, you should pay attention to a number of important points:

- So, when choosing a cladding, you need to take into account the cost of all the elements necessary for the work. In addition, if the facing activities will be carried out by a team of repairmen, then the cost of their services must be included in the expense item.

- It is recommended to carry out the cladding of a residential building in warm and dry weather. Thus, the finish will be fixed as firmly as possible to the base, and the structure of the material will not be damaged due to exposure to climatic precipitation.

- It is advisable to lay thermal insulation under the cladding in order to increase the energy efficiency of the building and reduce the sound permeability of the insulating layers. As a heat insulator, you can use polystyrene, penoplex or ordinary mineral wool.

- Building materials must be purchased from trusted dealers or manufacturers who have all the necessary certificates and other documents. This way, you will have the opportunity to avoid defective and counterfeit products.

- When thinking about how to sheathe the outside of a house cheaply , it is better to give preference to non-combustible products.

If you follow these rules, you can avoid additional problems in the form of downtime, damage to the coating, etc. In addition, such troubles are associated with additional time and material costs.

Wall cladding with facade bricks

Cladding a wooden house with bricks is done only after strengthening its foundation. However, it is also necessary to take into account the size of the eaves overhangs on the house. If they are more than 35 centimeters wide, then you can begin cladding the building with brick. If the overhangs are smaller, then such work does not make sense, since the wall made of facade bricks will constantly be exposed to moisture.

Brick cladding will give an old house a modern look and keep it warm

- The facade decoration of a wooden house is made in the form of a brick wall, which has a certain distance from the main surface of the building. The finishing wall must be connected to the main wall with flexible connections. They are made in the form of anchors made of polymers or galvanized wire. This allows the finishing masonry to maintain its position during seasonal soil movements.

- Anchors are installed evenly over the wall area in the amount of 4 pieces. per sq. meter. In areas of windows and doorways, additional anchors are installed along their perimeter. The anchor is fastened to a wooden wall by driving its hard end into the wood, and the other end is secured with mortar in the brick cladding.

- Before starting laying the facing wall, it is necessary to cover the foundation with a layer of roofing felt. Laying of façade bricks starts from the corner of the building. To ensure the evenness of the masonry, a cord is pulled, and the horizontal laying of the bricks is checked by a level on each row. The quality of the construction of the first row determines the further quality of the wall.

Photo gallery: brick cladding

Important! It should be borne in mind that for free air circulation between the walls in the lower part of the masonry, the vertical joints through two bricks are not filled with mortar. The resulting holes are called “vents”

A gap of about a centimeter is also left under the roof. In this way the façade becomes ventilated.

Video: how to brick a wooden house

Finishing materials decorate a wooden house and preserve it, protecting it from adverse influences. Manufacturers are constantly developing finishing materials of even higher quality. However, even the latest finishing will not protect your home if the installation technology is not followed exactly.

Facade plaster

This is the most profitable solution for the external cladding of a building. In addition to the fact that facade plaster serves as a decorative cladding, this composition also has some other advantages, which include the following:

- Providing thermal insulation makes it possible to provide the walls of the building with additional protection from the cold.

- The soundproofing properties of facade plasters have also caused a large number of positive reviews.

- In addition, plastering compositions increase the durability of the wall material, protecting bricks or blocks from fading, swelling, destruction and other influences.

There are many types of plaster mixtures on sale today. For exterior decoration you can use the following varieties:

- Silicone. This is the most expensive type of materials for finishing facades. But such plaster allows you to get very durable walls due to their unique composition. Among other things, silicone-based façade plaster does not absorb or allow moisture to pass through its structure. It also does not lose color or performance properties due to exposure to UV radiation.

- Mineral. This construction mixture is made from sand and cement. Mineral plaster is characterized by high resistance to temperature changes, external influences and fading. But this material is often used in industrial construction.

- Acrylic. Contains acrylic, which allows you to create a protective waterproofing film on the surface of the facade. This coating is not afraid of moisture, debris, dust and dirt. In addition, acrylic plaster will not fade under the sun. The disadvantages of the material include only low vapor permeability.

- Decorative. The good thing is that it is sold ready-made and in a single color. That is, when thinking about how to cover the outside of a wooden house, you can choose the shade of plaster for yourself and decorate the building in one tone, guided by design ideas.

It should be noted that for aerated concrete walls it is recommended to purchase plaster that is designed specifically for this material. With its help, you can eliminate defects and irregularities, as well as provide surfaces with protection from temperature changes and moisture.

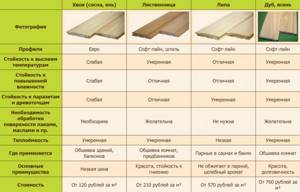

Cover a wooden house with clapboard

If you cover a wooden house with clapboard, it will turn out very well. Wooden houses are often covered with clapboard.

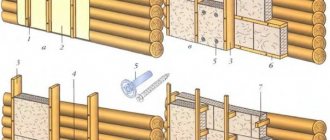

The choice in favor of lining falls due to its environmental friendliness, ease of installation, strength and durability. Also, the lining does not require maintenance. The lining is attached to a timber sheathing; insulation and vapor barrier are laid in between.

The humidity of the lining, which should be chosen for cladding a wooden house, should be no more than 15%, preferably 12%. In clapboard sheathing with a humidity higher than specified, cracks will appear.

Houses are covered with clapboard both outside and inside. For exterior cladding, you should choose wood species that are most resistant to moisture or hot air. Depending on the region where the house is built.

Facade paint

This is also a budget solution for cladding a house. For example, paint is perfect for finishing an old brick building that has lost its former luster, but the walls are quite durable.

Facade paint is a composition with the addition of a structuring filler. A ten-millimeter paint layer allows the walls to not only have a pleasant appearance, but also reliable protection from external factors.

A characteristic feature of this coating is that it can be used to process an unprepared base. The unique composition and structure of facade paint will mask all existing defects. In addition, this type of building composition can “breathe,” which has a beneficial effect on both wooden and block/stone walls.

Basic rules for exterior decoration

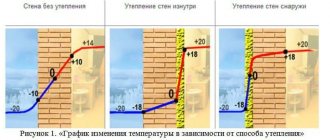

To maintain normal humidity levels in the room, the cladding must have high vapor removal rates.

The building material from which the wall is made must be less vapor-permeable than the thermal insulation layer, which, in turn, is less vapor-sensitive than the material for the external cladding of the wall.

The rule for increasing vapor permeability should be taken into account in regions with high air humidity and in regions where low temperatures are observed in winter

If the characteristics of the materials do not have the necessary vapor permeability, condensation will accumulate at the boundaries of the layers, creating favorable conditions for the growth of mold, fungi, and rotting of surfaces.

When the temperature drops, the sedimentary moisture will freeze, which will lead to the destruction of the wall and finishing. After several years, the facade will have to be changed.

Before deciding how to decorate the outside walls of a house, you need to familiarize yourself with the technical characteristics of the materials. Although it is clear that all facing panels and sheets, except wooden ones, have a low vapor emission index.

Cladding the facade of a house does not require work with cement mortar; the material is installed using fasteners, so it can be done at any time of the year

If you choose cladding made of artificial materials with low vapor permeability, it is necessary to provide a façade design in which vapor emission will occur in a different way.

The problem can be solved in two ways:

- Install a ventilated façade . To do this, vapor-permeable thermal insulation and ventilated gaps are placed between the wall and the finishing material, on the basis of: on each section of the wall with an area of 20 sq.m., including windows and doors, there is a gap with a useful volume of 75 sq.m. cm.

- Cover the inside of the wall with a layer of vapor barrier . In this case, the cladding can be attached to the wall of the house, without an adjacent insulating layer. Due to the vapor barrier coating, moisture does not appear on the surface of the wall and finishing material, the structure remains dry, so the cladding material can be selected without taking into account vapor permeability.

In the first option, the upper part of the holes remains open to evaporate vapors. The facade in this case performs a protective and decorative function.

With the advent of expanded polystyrene, the second method of wall cladding began to be used more often. Extruded polystyrene foam has low vapor permeability and is an effective heat insulator, which allows you to save on space heating.

When insulating walls on the inside of a building, the exterior finishing of the facade is reduced to attaching beams and cladding material

When finishing the walls from the inside, any facing material can be mounted on the façade, from wooden panels to porcelain tiles.

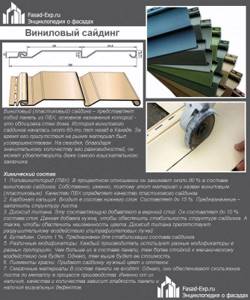

Features and benefits of siding

This type of facing material is considered very popular today. This is due to its affordable cost and excellent performance properties . Siding is long, thin panels with perforated edges for easy installation. Thanks to its design features, such cladding takes on beauty and integrity during installation.

In addition, siding panels have a very wide selection of colors. There are also various imitations on sale - marble, brick, natural stone, wood, etc. Thus, with the help of siding, you can easily give your house a unique look. There are several types of material:

- PVC panels. These are panels with a cellular structure, characterized by low weight. Due to its high density, polyvinyl chloride siding has not only good decorative, but also thermal insulation characteristics. The material is not subject to rotting and is completely resistant to moisture.

- Metal siding panels. Thin panels made of aluminum, zinc or steel. Their thickness is 4-6 millimeters. Installing them is quick and easy. Metal siding is highly resistant to corrosion and climatic influences. You can install the canvas yourself, which allows you to save on the services of a professional team.

- Wood siding. Absolutely environmentally friendly material, characterized by minimal thermal conductivity and attractive appearance. But wooden panels are afraid of exposure to moisture. And even after antiseptic and paint treatment, wood has much less durability than PVC or metal.

- Fiber cement boards. This type of siding is made on the basis of polymer fibers and a cement mixture. The result is a very durable and durable coating.

One of the main advantages of siding is that it can be installed on top of a ventilated facade, since this material will not interfere with air microcirculation .

Features of building insulation

Insulation of houses is mandatory in the northern regions, but in the southern parts the usual building cladding will be sufficient, which will perform the function of insulation

Insulation of houses is mandatory in the northern regions, but in the southern parts the usual building cladding will be sufficient, which will perform the function of insulation. Insulation of the house can be done using ordinary polystyrene foam. Polystyrene foam is an inexpensive material and easy to use. It has low vapor permeability, so when laying it, you must consider the ventilation system. Lack of ventilation can lead to wood rotting and destruction.

Mineral wool is one of the most common environmentally friendly insulation materials. Insulation is carried out using frame technology:

- fill the void between the beams;

- lay a vapor barrier layer (foil, roofing felt);

- fix the frame at a distance of 0.4 m along the wall;

- fill all voids with mineral wool;

- lay an additional layer of insulation, which serves as protection against moisture and wind;

- The final stage is the cladding of the house.

Traditional option - wood

For facade finishing of a residential building, you can use unedged or edged boards. The last solution is lumber with smooth edges. An ugly building material is lamellas made from uncleaned and unprepared logs. As a result, sapwood, bast and bark remain at the ends of the board products. This cladding material can be used to finish wall structures with an overlap or herringbone pattern.

Such cladding, subject to proper and timely care , can last up to twenty years. After this, the boards will have to be replaced. This cladding option is perfect for a small country house, because wood has the ability to “breathe” and retain heat inside the building.

If you want to make a residential building look presentable using wood, then you can use a block house. These are the same wood panels, however, they have a convex surface, imitating a natural log. This type of finish looks very expensive and presentable. It is noteworthy that purchasing siding for a block house allows you to save several times on external cladding.

Facing with stone and facade bricks

Unlike natural stone, artificial stone has less weight, which means it is easier to deliver, work with, and the load on the foundation will be less.

To fasten heavy natural elements, additional wire, screws, hooks, anchors and other fasteners are used.

A gap of 5 cm or a little more is left between the wall and the finishing layer.

Stone as a facing material

Stone cladding will be expensive and will require a lot of effort and professionalism - not surprising, because it is one of the best materials, environmentally friendly, non-flammable and solid.

It is better to start façade finishing after the house has completely settled. Not earlier than a year after construction. The decision to finish with natural stone should be made at the stage of laying the foundation.

If you really want to, but the foundation is not suitable, it is better to use light rocks, for example, limestone or sandstone.

Panels for facade finishing

It is possible to finish the façade with light polyvinyl chloride panels. This material is very attractive and cheap. The cladding can imitate brick, marble, wood, natural stone and other materials. Such façade panels are distinguished by their very low weight, so their installation should not pose any problems.

Using these finishing cloths you can cladding the entire cottage. Moreover, the material can be combined by finishing the corners and base of the building with natural stone, and the wall surfaces with wood or marble.

Cladding a wooden house with facade tiles

Facade tiles, which are most often used for cladding wooden houses, are called clinker tiles. Clinker tiles are durable and strong. It will perfectly protect a wooden structure. Gives a very good thermal insulation effect.

Regarding the installation of clinker tiles, you can easily do it yourself. Installation, as a rule, does not cause any difficulties. The cost of facade tiles is affordable for almost everyone. This material is quite accessible.

Under the influence of heat, moisture, temperature changes, clinker tiles do not change their properties and appearance.

Subscribe to our Yandex.Zen channel

Finishing with thermal panels

This is a unique material that can perform two important functions at once - insulation and facade cladding. During the production of the material, a special decorative coating is applied to the heat-insulating surface. In appearance it resembles stone or marble, is not subject to combustion and has a low degree of water absorption.

Thermal panels are made on the basis of foamed polystyrene (foam), extruded polystyrene and mineral wool. The installation method depends on the type of heat insulator: foam and polystyrene are fixed with a special glue. Joints and cracks can be sealed with mastic or covered with an aluminum strip.

This is an excellent solution for simultaneous cladding and insulation of a residential building. But unfortunately, there are not so many reviews about the material yet, since it has recently appeared on the domestic market.

Clinker thermal insulation panels are also available for sale. In this case, clinker tiles are glued to the thermal insulator. However, the cost of such material is quite high. Such facing materials also include decorative stone. It is often used for finishing ventilated facade systems.

When choosing what to cover the outside of your house with, you need to be vigilant. Remember that a properly tiled façade not only makes a house more attractive, but also increases its service life.

Selection of finishing material

Modern construction technologies provide us with a fairly large range of finishing materials that meet all the necessary requirements. However, each of these materials has its own characteristics in terms of both the decorative design of the house and its immediate functional characteristics. It should be noted that, due to their specific nature, not all existing materials are suitable for finishing wooden buildings. Let's consider the most optimal cladding options.

Wooden lining

Wood lining allows you to preserve the natural and natural appearance of the house, while significantly improving its external design and functional characteristics. It is a flat board that is easily mounted and joined to adjacent ones in the longitudinal direction using special spikes.

Cladding a wooden house with clapboard

On a note! This material is absolutely environmentally friendly, high strength, and also provides an excellent level of temperature and acoustic insulation.

The main disadvantage of wooden lining is its relative vulnerability to insects and rodents. This problem is partially solved by treating the surface with special protective agents. The second disadvantage of the material is fading, so a house with this finish should be painted approximately every three years.

What is the difference between eurolining

Comparative characteristics of wooden eurolining

GOST 8242-88. Profile parts made of wood and wood materials for construction. Technical conditions. File for download.

GOST 8242-88

Prices for wooden lining

Wooden lining

Block house

In fact, a block house is a type of wooden lining. It is made only from coniferous trees. The main difference between this finish is the shape of its elements - this material imitates cylindrical logs. The internal surface of the block house is flat, which simplifies the installation process using the tongue-and-groove technology. Unlike ordinary wooden lining, a block house has better protection against weather conditions and insects. However, it should be noted that the price of this material is significantly higher, which, of course, is its main disadvantage.

finishing the facade of a wooden house with a block house

Block house installation diagram

Block house prices

Block house

Vinyl siding

This material has excellent resistance to high positive temperatures. It practically does not deform and has a low coefficient of thermal expansion. In addition, vinyl siding is easy to maintain, easy to clean, and does not require periodic repainting. The available color range is so wide that anyone can choose a shade to their liking. Vinyl panels can be installed not only using self-tapping screws, but also using regular nails.

Vinyl siding - technical specifications

The best siding manufacturers according to ratings

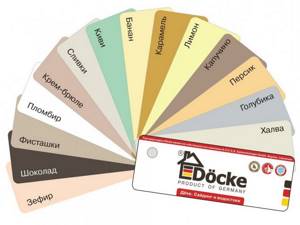

TM DOCKE. Vinyl siding, facade panels

But even such a functional material has its drawbacks. It is intended for use in countries with temperate and warm climates, so it does not tolerate extreme cold well. The strength of the material is also low; vinyl panels require quite careful handling. In addition, when choosing this type of siding, keep in mind that when exposed to direct sunlight, dark-colored panels can noticeably fade within a couple of years.

Facade finishing with vinyl siding

Metal siding

This finishing material, in comparison with vinyl, does not have a number of key disadvantages. First of all, it is much more protected from sunburn. This allows you to safely use siding in darker colors without the risk of getting a faded facade on the sunny side of the house in two or three years. In addition, even at very low temperatures the metal does not lose its strength and wear resistance.

There are three main disadvantages of metal siding:

- susceptibility to corrosion in case of violation of the outer protective layer;

- vulnerability to impact loads and the possibility of profile deformation;

- high coefficient of thermal conductivity (metal quickly heats up and cools down).

Metal siding colors

Siding prices

Siding

PVC panels

Panels made of polyvinyl chloride are identical in characteristics to vinyl siding, since they represent one of its varieties. However, in terms of creating original design solutions, PVC elements give builders greater opportunities. Such panels allow you to create high-quality imitation of stone, brick and marble surfaces, and are also easily combined with standard vinyl siding, which allows you to give building facades a unique and exclusive look.

Variety of PVC panels for facade cladding

Prices for PVC cladding panels

Facing PVC panels

Siding analogues

In addition to siding panels, you can also clad your house with other materials that are no less common on the construction market.

These include:

- decorative plaster;

- porcelain stoneware;

- sandwich panels;

- natural and artificial stone;

- tree;

- brick.

Each house cladding option has its own advantages and disadvantages. Before choosing a cladding option, you should be guided not only by the aesthetic appeal of the material, but also by its technical characteristics .

Brick

The brickwork that is used to clad the building is designed to give the building strength and protect the internal load-bearing wall.

The structure of facing brick can be:

- ceramic;

- clinker;

- silicate;

- hyper-hyped.

Based on the front surface, bricks are classified into:

- smooth;

- raised;

- glazed;

- engobed.

Brickwork can be of different colors, and the material itself differs not only in texture and composition, but also in color.

The main advantages of brick cladding are strength, resistance to external influences, and protection of the house.

In addition, the brick has:

- fire resistance;

- environmental friendliness;

- frost resistance and low thermal conductivity.

The disadvantage of brick cladding is its significant weight. In addition, the price of bricks is quite high.

Brick