It's hard to disagree with the fact that the garage is a second home for most motorists. This is where they spend a lot of time doing what they love. Therefore, insulating your garage is an important measure, thanks to which you can take care of your health and preserve your car. As a result of sudden temperature changes and exposure to negative factors, the machine may deteriorate and lose its performance.

Recently, garages made of corrugated sheets have become especially common and in demand. And this is quite understandable. Profiled sheet is a very durable and reliable material that will last for many years. In addition, it is light in weight. In addition, this material is easy to install. But, like any other structure made of metal, such a garage needs careful insulation. The insulation process does not require special skills and abilities, so insulating a garage from corrugated sheets will not be difficult. The main thing is to stock up on the necessary materials and tools.

So, let's try to figure out how to insulate a garage from corrugated sheets from the inside. To begin with, it is worth noting that the optimal garage temperature in winter will be one to five degrees below zero. This is provided that the outside temperature is minus twenty-five. You should not heat the garage room too much, this can negatively affect the car components.

Important little things

Insulated metal gates in a garage are a whole complex of measures and it does not end only with the arrangement of the inner surface of the doors. It is

equally important to correctly install the seal around the perimeter of the doors, plus take into account the accompanying factors that reduce heat loss. Let's start with the fact that when you order or choose a door for your garage, do not skimp and take a model that has a simple door

If you constantly open a whole sash, then as soon as your neighbor comes to you several times in the winter for advice, all your warmth will disappear. After all, no matter how hard you try, you won’t be able to squeeze through quickly, the open door is too big;

Let's start with the fact that when you order or choose a door for your garage, do not skimp and take a model that has a simple door. If you constantly open a whole sash, then as soon as your neighbor comes to you several times in the winter for advice, all your warmth will disappear. After all, no matter how hard you try, you won’t be able to squeeze through quickly, the open door is too big;

Doors with and without entrance doors.

Now about the compaction. It is clear that with such large dimensions it is unlikely that the shutters will fit tightly along the entire perimeter of contact with the frame of the opening. You should immediately forget about such things as self-adhesive seals for windows and ordinary doors; they will last a maximum of a week. Rubber hoses with fastening tape are produced for garage doors and other similar structures. They can be hollow or filled with some soft porous material such as foam rubber. Such a seal is fixed to the base with self-tapping screws using mounting strips or comes with the strip;

Types of rubber seals for garage doors.

- It would also be a good idea to install a curtain on the inside next to the gate. There are several options here:

- A thermal curtain that works on the principle of a fan heater and cuts off cold air at the inlet is certainly a good thing. But, firstly, such a unit itself is quite expensive. And secondly, the power of such a garage curtain starts from 2 - 3 kW, respectively, such pleasure will cost a tidy sum;

Thermal curtain.

- The next option is more loyal. A piece of tarpaulin with water-repellent impregnation is used as a curtain. In fact, this is a classic curtain. You need to stretch a metal string or baguette on top and hang your sliding canvas curtains on it;

Canvas curtains over the gates.

- Almost every motorist has been to a car wash; remember how their driveway is equipped. The curtain there is made of vertically cut soft transparent tapes, such as polyethylene. But this is not entirely polyethylene, and if you buy such a thing in a factory version, it will be expensive. It is unlikely that your garage will have the same amount of traffic as a car wash. Therefore, you can simply cut strips of thick technical polyethylene about 10 - 20 cm wide and, with a slight overlap (10 - 15 mm), staple them to a wooden strip. Next, for reliability, screw another similar rail on top, so that the polyethylene is between them, and fasten it above the entrance to the garage. Please note that any curtain should not drag on the floor; a small gap is always left;

Polyethylene curtain.

I would also like to say a few words about the lining of the gate from the inside. Izolon and lining, as you understand, are far from the only materials that can be used for such purposes. One of the most popular in garage design is OSB-3 or OSB-4, about 10 mm thick; it has decent moisture resistance and can be bought for reasonable money. If you take plywood, then in this case you need to buy the FSF brand. For those who like a warmer design, we can advise covering the inside of the doors with PVC panels. They are glued directly onto the foam plastic with liquid nails or something similar, and a edging is put on around the perimeter;

Standard OSB board.

There is one more interesting detail. I've seen advice online about insulating gates with polyurethane foam. People say that you can buy 5 - 7 cans of foam, make a frame and fill it with this foam. They promise that such insulation can supposedly last for almost 50 years. But in the open air and with minor vibration, I have seen polyurethane foam deteriorate within 3 to 5 years. Perhaps the person used some special type of foam, but in any case, I do not recommend this method to you.

Polyurethane foam and blowing gun.

https://youtube.com/watch?v=RyWgwwnY4Nk

How to insulate an iron shed. A cheap way to insulate a shed

To insulate an outbuilding for poultry, pigs and other livestock, you do not have to be a professional builder.

All work can be easily done with your own hands.

The most budget-friendly option for thermal insulation of a shed is the installation of a double wall with cheap, readily available insulation in its cavity.

Installation of wall structure

First you need to build a second wall around the entire perimeter of the building. To do this, two boards are nailed parallel to each other, and a third board is placed on top of the seam.

Laying insulation

Insulating material must be placed in the resulting space between the wall surfaces. These could be autumn leaves, pine needles or sawdust. To prevent small rodents from infesting the shed, the heat insulator must be mixed with slaked lime in a ratio of 25:1.

The insulation layer must be at least 20 cm. Moreover, it must be placed everywhere - on the walls, ceiling and floor. It is compacted well, and then allowed to stand for another 2-3 weeks. If necessary, material is added and the space is “sealed.”

Floor insulation

How can you insulate the floor in a barn? Even ordinary clay will do. To do this, first pour soil around the entire perimeter of the building 10-15 cm above the main one, and then lay compacted clay.

At the same time, it is very important to prevent moisture from penetrating into the sawdust, otherwise they will quickly begin to rot.

Thermal protection of doors

The door in an outbuilding can be insulated with ordinary boards and roofing felt. To do this, the boards are nailed diagonally, and a sheet of roofing material is inserted between them.

By insulating the barn with your own hands in this way, you can provide warmth all year round for chickens, pigs and any other living creatures.

Insulation materials

Using traditional metal garage building materials can significantly increase the temperature in the room.

For these purposes use:

- Styrofoam. This material is considered the most common type of insulation. It is convenient to work with polystyrene foam; it is cheap;

- Penoizol. This is a liquid form of the same foam. Penoizol has fire resistance and excellent water resistance. The durability of such insulation is 40 years;

- Basalt wool. This soft and inexpensive insulation is also called mineral wool. Garages are often insulated with mineral wool. And this material is one of the leaders in terms of popularity of use.

- Polyurethane foam. The durability of this building material is 50 years;

Having decided on the type of insulation for arranging thermal insulation from the inside of the box, you can begin the preparatory stage.

Benefits of garage insulation

By completing the garage insulation work with your own hands in a high-quality manner and in compliance with technology, you can save a lot of money, because... You won’t have to resort to forced heating of the garage with powerful electrical appliances in the process of self-repair, service or car tuning.

The car parts will not be destroyed, since the room will have a constant temperature. You don't have to worry - the tools and accessories placed in the garage will not rust or fail under optimal storage conditions.

Even in severe frosts, you can safely leave the garage with your car, avoiding problems with ignition, frost-covered windows, freezing of liquid in the nozzles and washer reservoir.

When working in a comfortable room, the risks of overcooling the body in winter and suffering from heatstroke when the thermometer rises above +30°C are minimized.

How to insulate a garage efficiently and inexpensively? Let's study the pros and cons of thermal insulation materials offered on the market.

Budget insulation of the garage. Insulation for walls inside the garage

Proper insulation of a garage with your own hands

Do-it-yourself insulation of the garage from the inside will help extend the life of your car. The need for such work arises due to sudden temperature fluctuations, which lead to the appearance of condensation. Accumulated moisture settles on the car, leading to damage to the anti-corrosion coating. To prevent such situations, it is necessary to insulate the garage or install a heating system.

Why insulate walls

The enclosing structures of buildings for cars are made of large-block materials, for example, cinder block or gas block, less often of brick. Depending on the method of laying the products, the thickness of such walls will range from 12 to 30 centimeters. This width is not enough to protect the room from the penetration of cold air. Even when installing a heating system, the difference between the air temperature outside and inside the building will lead to condensation.

There is no need to artificially increase the temperature in the garage to high levels. After a car enters a warm room from a cold street, condensation will certainly appear on its surface, which will lead to corrosion of the metal. Thermal insulation of the garage should be selected and installed in such a way that the difference in temperature in the room and outside the window is minimal. The optimal performance for a car is considered to be +5 degrees.

Note! When insulating building envelopes, motorists seal all cracks, including ventilation holes. It is prohibited to clog exhaust pipes; they are used to remove accumulated moisture and help remove carbon monoxide from the room.

Types of thermal insulation materials for garage walls

In the modern construction market there is a huge selection of insulation materials. Let's consider the characteristics of the most popular thermal insulation materials:

- Mineral wool is supplied to stores in the form of rigid mats with a density of up to 240 kg/m3. Such products are characterized by high resistance to fire and allow water vapor to pass through their structure (breathe). The only disadvantage of using basalt wool is the need to install a vapor barrier film, which will protect the product from getting wet. When exposed to moisture, the insulation loses its properties.

- Glass wool is considered a cheaper analogue of mineral wool. Such products consist of hard and prickly fibers, so you need to wear glasses and gloves when working with insulation. After getting wet, the mats clump and become heavy, so glass wool needs to be protected from moisture penetration by laying special films or foil.

- Polystyrene foam is considered the most convenient thermal insulation material to use. The products are not afraid of dampness, can be easily cut into pieces with a regular hacksaw, and are affordable. Insulation of a garage can be done using an analogue of polystyrene foam, polystyrene foam, which will last up to 40 years. The main disadvantages of the products in question are considered to be flammability and low resistance to sunlight. Foam plastic unprotected by plaster turns yellow and crumbles.

- Another insulation for the garage, warm plaster consists of vermiculite or foam balls. Such materials have good heat-insulating qualities, but to obtain maximum effect, a thick layer of mortar must be applied to the walls.

Foam plastic and all its analogues

The insulation technology in this case is incredibly simple. It is first necessary to carry out several measures to prepare the work front - treat the walls with antiseptics and prime them. If necessary, degreasing is carried out - for metal surfaces. Next, the foam boards are simply glued to the plane without gaps or cracks. If they do form, then after finishing the work, all existing flaws are filled with polyurethane foam. There is a more complex method for assembling wood sheathing, the same as for mineral wool. The principle of its assembly will be the same in both cases, so you can simply consider it further.

Penoizol

It is similar to a modernized version of construction foam, only in larger volumes and with improved thermal insulation properties. The only difficulty is to apply it in an even layer; only a professional can do this. Fixed with staples or using lathing. Does not require waterproofing.

The description in the article of all types of insulation makes it possible to weigh the pros and cons and choose the most acceptable option. We also found out why it is necessary to insulate the garage ceiling and how to do it.

Interested in the article? Share it on social networks!

Basalt fiber slabs

The most acceptable option used for insulating a garage made of corrugated sheets is the use of semi-rigid slabs made of basalt fiber. In addition, the thermal insulation qualities of this material are quite high. In addition, slabs made of basalt fiber are an environmentally friendly material, absolutely fireproof, and this factor is important when arranging a garage.

Among the disadvantages of this material, hygroscopicity should be highlighted. In other words, the slabs are able to absorb moisture. Although it is very easy to eliminate such a defect when insulating a garage from corrugated sheet metal. To do this, you can use a special ventilation gap under the casing. Thanks to air circulation, excess moisture will be removed from the insulation, preventing condensation.

This insulation is installed in the spaces between the profiles that are fixed to the wall surface. If insulation is carried out during the construction of a garage, then it is better to use special thermal profiles to attach the thermal insulation. This will avoid “cold bridges”.

Requirements for protecting a garage from low temperature

Garages are primarily built from cinder blocks, bricks, and sometimes metal products. The thickness of walls made of cinder block or brick is most often in the range of 200-350 mm. They practically do not protect the room from low temperatures, so for comfortable operation they must be reliably insulated.

To insulate a garage internally, you don't need to seal all the holes - this won't improve the insulation, but it can cause certain problems. Without constant ventilation, moisture from the air will condense on the metal and it will begin to rust. Ventilation also prevents harmful gases from accumulating in the garage.

Many garage owners are confident that it is better to insulate the garage from the outside, because it saves interior space. But do not forget that some insulation materials release substances into the air that can harm your health. You shouldn't use them indoors, but they are ideal for external insulation.

Another advantage of internal insulation is that the materials used are less susceptible to environmental influences. With internal thermal insulation, such development is excluded.

Options for insulating structures (garages, shells)

How to insulate a metal garage with your own hands? With liquid insulation, everything is very simple: take a brush and apply the coating to the surface with a roller.

Do-it-yourself insulation of a metal garage has several options, from the inside or outside of the structure. Insulation from the outside is not a suitable method in this case. Let's consider methods of internal thermal insulation:

- Before carrying out work, the foundation should be prepared. This stage is important and cannot be ignored in order to avoid rust and insulation detachment. Corrosion is the main enemy of metal products. First of all, the metal is protected from rust;

- The unpainted base is treated with a metal cord brush. Or they put a special attachment on the grinder (drill). Thus, the work process will speed up. A sheet with old peeling paint is processed in the same way;

- If the surface has a high-quality coating, it should not be removed. Under the insulation, the paint will remain unharmed for many, many years;

- If the garage is made of galvanized corrugated sheets, with a frame of professional pipes and angles, then this material already has reliable protection that cannot be disturbed;

- After cleaning the base, degrease the surface (acetone, etc.);

- If you cover the metal with foam (penoizol), then the preparatory measures taken are sufficient. If polystyrene foam serves as insulation, it is necessary to paint the iron. You can coat it with Kuzbasslak, it is economical and reliable.

Selection of location and material

When choosing a place to quickly build a metal garage on your own site, try to choose an area located closer to the exit. This way it will simply be more convenient for you, at least in terms of the fact that in winter you will have to spend less time and effort clearing the exit from snow.

At the same time, the garage should be located not very far from the house. At this point, it all again comes down to ease of use.

The construction site is pre-leveled, and the access to it is cleared of various kinds of obstacles.

To build a garage, buy corrugated wall sheeting. It is marked with the letter “C”. The marking also contains a digital designation indicating the wave height of the sheet. For example, if the sheets are marked C-20, this means that in front of you is wall corrugated sheeting, each wave of which is 20 mm high.

To create the most rigid and reliable structure, use a profiled sheet with a high wave. The most budget brands are S-8 and S-10. However, it is strictly not recommended to use such sheets for building a garage. They will require frequent installation of fasteners, as a result of which the overall tightness of the structure will noticeably decrease.

In addition, thin sheets “walk” even in light winds, making an unpleasant sound.

As for the thickness of the sheet, a corrugated sheet with a thickness of 0.5 mm is sufficient for building a garage.

In addition to corrugated sheeting, you will need to buy a number of additional materials and assemble certain tools.

Kit for self-construction of a garage from profiled sheets

- Concrete solution.

- Reinforcement bars.

- Pipes for constructing the frame.

- Pipes and angles for installing gates.

- Self-tapping screws.

- Bulgarian.

- Welding machine.

- Electric screwdriver.

- Scissors for cutting metal.

- Electric jigsaw.

The procedure for carrying out work on self-insulation of a garage

Regardless of whether the garage is a permanent or metal building, it is advisable to insulate it from the inside and outside. For these purposes, polystyrene foam is best suited, since mineral wool will retain moisture, which will lead to the formation of condensation and the appearance of rust on metal elements.

Tools and materials

To insulate surfaces with foam plastic from the inside of the garage, as well as from the outside, you will need:

- insulation (foam);

- reinforced mesh;

- vapor barrier film;

- glue/liquid nails, polyurethane foam;

- wooden beams;

- self-tapping screws, plastic dowels “umbrellas”;

- primer;

- electric drill, screwdriver, level.

A set of materials and tools for carrying out insulation work Before thermal insulation of the garage, it is necessary to install a ventilation system in it. If it is installed correctly, it will not cause heat loss, but will remove excess moisture and carbon monoxide from the room.

Without ventilation, the garage will lose its ability to “breathe”

Sequence of wall insulation

To insulate a garage with polystyrene foam, you first need to clean the walls of old paint and the metal elements of rust. To do this, use a stiff brush and chemicals (solvents, removers). Irregularities in the concrete surface and cracks are sealed with cement mortar or putty.

Next, thermal protection of the walls is performed in the following sequence:

- waterproofing surfaces. For these purposes, dense polyethylene film in rolls is used. It is placed on glue, and the joints are sealed with tape;

- installation of wooden sheathing. The beams are attached to the waterproofing layer with self-tapping screws at such a pitch that the insulation fits between them. Wooden elements are pre-impregnated with drying oil;

- heat insulator laying. Sheets of foam plastic are coated with glue on the reverse side and placed in the sheathing;

- application of finishing coating (upholstery with clapboard, plasterboard, OSB boards).

Fastening foam plastic using a frame method allows you to securely fix the insulation on various surfaces. Due to the lightness of foam sheets, they can be mounted directly on glue. And for additional fixation of the material, use special disc dowels.

Fastening foam plastic using the adhesive method allows you to quickly insulate the surface with minimal labor costs

When insulating the outer walls of a garage with polystyrene foam, the adhesive method is also used. A reinforcing mesh is pulled over the insulation, which will allow the material to be secured and securely joined to the façade finish.

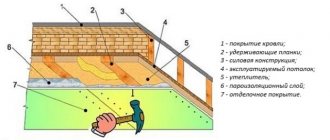

Diagram of a thermal insulation pie from the outside of the garage

Ceiling insulation

The technology for insulating a given surface largely depends on what material it is made of. If the ceiling is metal, you can insulate it in the same way as the walls. In the case of a concrete floor, the foam is attached to the surface using dowels with wide heads. A reinforcing mesh is stretched over the heat insulating layer and the ceiling is finished.

Insulating a garage door

This element, especially if it is made of metal, is the main source of heat loss in a car storage room. Therefore, the garage door also needs to be insulated using polystyrene foam. The insulation process is carried out in the following sequence:

- the door is cleaned from rust with a metal brush and coated with an anti-corrosion primer;

- foam sheets are attached to the dried surface using liquid nails or using a frame method;

- The gates are covered with OSB boards or clapboards.

Finishing work

When all surfaces of the garage are insulated, you can begin to decorate them. If the insulation was laid using frame technology, you can use various methods of covering the attached joists using sheet materials (gypsum plasterboard, OSB boards, plastic), lining. If the foam plastic has been glued, it will be convenient to apply textured plaster over the reinforcing mesh.

Finishing the garage will not only provide an additional layer of thermal protection, but will also provide the room with a presentable appearance

For the storage and long-term operation of a car, the correct temperature and humidity conditions in the garage are important. It can be organized by insulating the premises. The simplest and most convenient option would be to use polystyrene foam. This material will allow you to quickly insulate all surfaces of the structure, preventing heat loss. It is simple and easy to work with, so even a person without experience can carry out insulation.

High-quality insulation and features of insulation of a garage made of corrugated sheets

The advantages of prefabricated structures are that they can be installed on almost any site, even without installing a foundation strip. On the one hand, this is good, as it allows you to build a beautiful and reliable garage in one day. But there are important nuances that must be taken into account even at the stage of building a garage from this material:

- Up to 50 percent of the heat is lost through the floor and ceiling of the garage, so special attention should be paid to installing an insulated floor;

- high humidity in a metal garage, especially with internal insulation, causes not only rot and mold, but also rapid corrosion of the metal. Therefore, it is necessary to install a good ventilation system (natural or forced);

- all cracks and gaps in the garage door must be sealed, since when cold bridges appear and the dew point shifts inside the room, humidity and heat loss increase;

- When choosing insulation, you need to choose a material that is resistant to moisture and temperature changes - this is polystyrene foam or sprayed polyurethane foam.

Modern prefabricated garages made of corrugated sheets with insulation, which is placed inside, are much more convenient, but also more expensive. To insulate such a structure, it is enough to install seals on the gates and carefully seal all moving parts (hinges, the perimeter of the gate and the contact areas of the leaves).

Features of choosing insulation

For thermal insulation of this garage structure, you can choose the following materials:

- polystyrene foam is an inexpensive and lightweight material that can be installed quickly and easily. The thickness of the expanded polystyrene sheet is chosen depending on the climate of the region; for the south, 20 mm thickness is sufficient, and for the northern regions, at least 40 mm. The material has an average fire safety class, so additional protective finishing is required - plaster, OSB boards.

Important. Foam plastic is sensitive to high temperatures, so it is better to insulate the roof of a metal garage with mineral wool, as well as the wall of the building, which is located on the south side.

- mineral wool is a non-flammable warm material; for insulating corrugated sheets, it is better to choose mineral basalt wool in slabs with a foil-coated heat-reflecting layer. The downside of mineral wool is that when it gets wet, it loses its insulating properties, so it is imperative to perform high-quality waterproofing and eliminate all cold bridges.

- sprayed polyurethane foam - creates a completely sealed durable insulating coating that is resistant to moisture, temperature changes and mold. The only disadvantage of the material is that it is expensive, but for insulating garage doors it is an ideal solution;

- backing for linoleum made of polyethylene with foil coating - a lightweight, durable and reliable material for insulation, you can install it yourself using any universal waterproof adhesive directly to the wall. It is important not to forget about sealing the joints, since moisture that gets under the insulation layer causes corrosion of the corrugated sheets;

- Astratek - paint insulation, the best external coating for walls and garage doors, guarantees reliable insulation. But for the roof you need to choose a different insulation option, since astratek quickly collapses under the influence of rain and snow on the roof. The material is not cheap, but it guarantees convenient and quick thermal insulation of the garage.

A budget-friendly and reliable popular material for garages made of corrugated sheets is polystyrene foam and mineral wool. If you perform the installation correctly, following thermal insulation technology, you can reduce heat loss in the garage to zero.

What materials are suitable for insulating a garage?

Mineral wool

An important advantage of using mineral wool to insulate a garage with your own hands is the ability to create a breathable insulation layer. The fibrous structure of the cotton wool does not interfere with the natural circulation of air inside the garage; exhaust gases, evaporation of fuel and other technical liquids, which are always stored in abundance on the shelves, will quickly erode outside without stagnating or poisoning the air. An additional argument in favor of cotton wool can be its non-flammability. In a garage where there is a lot of flammable stuff, this can be a deciding factor.

Among all the variety, it is recommended to choose basalt or stone wool. It has the best thermal conductivity of 0.03-0.1 W/m °C and at the same time serves as excellent sound insulation.

The easiest way to lay mineral wool is in the form of semi-rigid mats. The mats fit tightly into the spacer of the frame mounted from timber or galvanized profile on the internal surfaces of the garage: walls, ceiling, gates

And don’t forget that in order for mineral wool to preserve its thermal insulation properties, it is important to use a vapor barrier membrane that will remove excess condensation and prevent moisture from accumulating inside the insulation

Polystyrene foam is perhaps the most popular material for do-it-yourself garage insulation. It can be cut and processed without problems using simple tools, such as a knife. It has extremely low thermal conductivity - only 0.03-0.04 W/m °C. And it's cheap.

Although there were some downsides. Polystyrene foam noticeably eats up the internal space and is also flammable; it is better to keep a fire extinguisher in a visible place.

You can mount foam sheets on internal surfaces using polystyrene glue, polyurethane foam or plastic dowels (they will require sheathing). The optimal thickness of the insulating layer is 50-100 mm. The joints must be sealed with polyurethane foam.

Thermal insulation plaster

In addition to the binder element, gypsum or cement, such plaster contains porous materials - quartz sand, vermiculite or expanded polystyrene, which provide heat-insulating properties. Thermal conductivity coefficient of warm plaster: 0.065 to 0.13 W/m°C.

Heat-insulating plaster is applied to the walls and ceiling using standard technology: installing beacons, preparing the mixture, applying the mixture to the surface, leveling. It is recommended to apply one or two layers up to 50 mm thick on the walls, and one layer of 5-30 mm on the ceiling.

It is best to use insulating plaster for garages made of brick or cinder blocks. It will insulate the room and allow you to level the walls and ceiling.

Thermal insulation paint

Thermal insulation paint is a new word in room insulation. It is a polymer composite filled with hollow ceramic microspheres.

Read more about the structure and features of thermal insulation paint in the article All about ultra-thin ceramic thermal insulation

The thermal conductivity of paint is about 0.065 W/m °C, which is approximately comparable to warm plaster. Only the insulation layer will be only 2-4 mm. What a saving of internal space.

In its finished form, the insulation is a liquid consistency, which is applied like regular paint, using a brush, roller or spray gun. This method of application will be especially appreciated by owners of metal garages. After all, the internal surfaces of such garages have a complex profile due to various corners, beams and protruding fasteners, and it is quite difficult to attach a tight-fitting layer of insulation to them. But painting the surface of any profile, no matter how complex, is not difficult.

However, it would be a mistake to assume that a thin layer of heat-insulating paint will create the desired microclimate in the garage. Yes, it can replace a fairly thick layer of traditional insulation. But for the desired result - +5°C inside the garage - you will still need to supplement it with a layer of another insulation, mineral wool or polystyrene foam.

DIY garage insulation

: Timber pediment: do-it-yourself construction technology

In order for thermal insulation to give the expected effect, each stage of the work must be performed correctly.

Therefore, we will divide the whole process into several steps:

- ceiling insulation;

- insulation of internal walls;

- external insulation.

Now about each stage separately.

Ceiling

Interior finishing of a metal garage with insulation should begin from the ceiling. And here the optimal choice would be mineral wool.

The ceiling of cold buildings is the main area through which heat escapes.

How to cover the ceiling? The process looks like this:

- installation of guides (lathing) on the ceiling made of wood or metal profiles;

- the pitch of the lathing is the size of the width of the mineral wool slab;

- laying a waterproofing layer (polyethylene or roofing felt);

- installing mineral wool mats in the gaps of the sheathing using glue or mastic;

- sealing seams between slabs;

- laying a vapor barrier layer;

- exterior finishing.

If you want to save money, then take polystyrene foam. Installation is carried out in a similar sequence.

Internal walls

Next comes the finishing of the metal garage inside, but we are already working on the walls.

In the case of a wall, it is better to insulate an iron garage with foam insulation, as well as polyurethane foam. Choose any option.

But here a big role is played by whether you took liquid foam insulation or solid in the form of slabs.

If it is a liquid material, then you need:

- install a wooden or metal frame;

- pull the reinforcing mesh onto the frame;

- fill the surfaces with foam insulation;

- lay a vapor barrier;

- perform finishing work.

Decide for yourself how to cover the walls at the finishing stage. This can be done with plaster, drywall, and boards or plastic panels.

When using penoizol, it is important to use a vapor barrier membrane to protect the room from moisture from the inside.

If you chose slabs, then the finishing principle is the same as when using mineral wool. For installation you will need mastic or glue.

Practice shows that it is better to entrust the insulation of an iron garage with liquid insulation to specialized specialists, and not to take risks by finishing it yourself. It is required not only to have the equipment, but also to be able to handle it.

External walls and roof

All that remains is to insulate the iron garage from the outside. And for this, the method of external painting is used.

The sequence is:

- clean metal walls and roofs of debris and dirt;

- remove unnecessary items, if any;

- clean with anti-rust agents;

- degrease surfaces;

- Apply the first layer with a roller or brush;

- wait for it to dry;

- apply another layer.

I think there is no point in teaching you how to paint walls. Everything here follows the standard algorithm.

A mistake many people make is applying one coat and painting over rust and debris. This coating quickly deteriorates. Plus, the insulation is low efficiency.

Insulation of walls from the inside

The choice of insulation, as well as the technology for insulating enclosing structures, will depend on the material from which the enclosing structures are made. Many car enthusiasts are interested in the question of how to insulate a brick garage. First you need to clean the surface from dust and dirt, mount a frame into which the thermal insulation will be installed.

The sheathing is made from a plasterboard profile. The guides are fixed to the wall with dowels, which are driven in every 30 centimeters. The distance between the guides must correspond to the width of the insulation boards. To finish the walls, you can use sheets of plasterboard or asbestos fiber. It is better to use the latest products, because they have a high degree of fire resistance compared to similar materials.

Advice! Asbestos fiber is quite fragile; to prevent its destruction as a result of various mechanical influences, reduce the pitch between the frame guides.

Insulation of garage walls from the inside is carried out using mineral wool or other products made in the form of slabs. In this case, the mats are inserted between the guides, their position is fixed using special hooks. After this, they begin to install the vapor barrier membrane, which should be connected to the cotton wool insulation.

We also insulate the garage from the outside, using warm plaster or special paint. Carrying out such work shifts the dew point, which will protect the walls from moisture penetration and further freezing. The owner of the building must install forced ventilation. This system is designed for intensive air exchange.

Insulating a garage with foam plastic is suitable for insulating metal walls. Expanded polystyrene boards are fixed to the base surface using an adhesive mixture. To securely fix the thermal insulation, it is necessary to first clean and degrease the metal. The sheets are fixed to the walls with the seams aligned, and polyurethane foam is poured into the gaps. Polystyrene foam is subject to combustion, so a thin layer of plaster must be applied to its surface.

Metal garage walls are often insulated with polyurethane foam or special paint. If there are voids between the frame, insulation is carried out using penoizol. The liquid mass penetrates into the wall through special holes. The foam clings well to surrounding surfaces, hardens, turning into high-quality and reliable thermal insulation.

Insulation materials

When it comes to houses, foam insulation is usually performed, and basalt wool insulation is also used. You can even use liquid insulation.

But what about metal structures like a garage?

Before you insulate an iron garage from the inside with your own hands, you should decide on the best insulator option. You can choose from polystyrene foam, mineral wool, as well as penoizol and polyurethane foam.

They usually choose individually, based on personal preferences or money.

- Styrofoam

. It is cheap, has low thermal conductivity, is lightweight and has a long service life. Not afraid of fungus and mold. Easy to use. But when heated, it can release harmful substances. Foam plastic has a solid vapor barrier, which leads to moisture accumulation. Under the sun and exposure to chemicals it is destroyed. Does not have decent mechanical strength. Plus, foam is chewed off by mice; - Mineral wool

. Thermal conductivity is low, mechanical strength is high. Not afraid of temperature changes, as well as microorganisms and chemicals. Installation is simple. But it is important to avoid contact of mineral wool particles with mucous membranes, eyes and respiratory tract. Service life is shorter than that of competitors; - Penoizol

. Also low thermal conductivity, good vapor permeability and mechanical resistance. Can be attached directly to metal walls. Does not burn. It can be liquid or granular. Does not create cold bridges. But during installation, shrinkage occurs. Tensile strength is low. Absorbs moisture. If you take liquid penoizol, you won’t be able to apply it without special equipment; - Polyurethane foam

. Clings well to surfaces. Can be applied by spraying. It is lightweight and also has a wide operating temperature range. It lasts a long time. But there is low vapor permeability, as well as a decent fire hazard and price. Under the rays of the sun, the properties of the heat insulator are somewhat reduced.

So insulating a metal garage from the inside with your own hands is not always possible. Liquid insulation that is sprayed onto the wall requires special equipment. There is no point in buying. It's better to rent. Or turn to the masters who will do everything themselves.

External and internal insulation of the garage

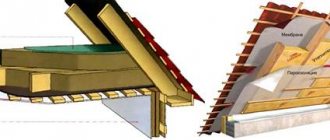

There are two types of garage roof insulation:

- External, which is performed above the roof;

- Internal, which involves laying thermal insulation on the inside.

The choice of materials for external insulation largely depends on the characteristics of the roof itself. For example, a slate roof will require completely different materials than a conventional roofing felt roofing.

Conventional garages without an attic are much more common, and it would be most advisable to insulate the ceiling in the garage from the inside. External work is quite complex - you will have to remove the roofing, install a water barrier, lay insulation, and then reassemble the entire structure. This option does not have any particular advantages, so later in the article we will talk exclusively about the internal insulation of the garage roof.

Instructions for insulating the floor yourself in an unheated garage

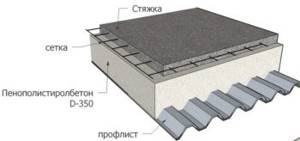

The cheapest way to insulate a garage floor is to make an expanded clay pad and fill it with concrete. True, in this case the finished base will have to be completely disassembled, and the whole process will be labor-intensive.

Work order:

- Dig a pit up to half a meter deep in the ground and line it with roofing felt, extending onto the walls. Seal the waterproofing seams with bitumen mastic or simply seal them.

- Fill the hole with expanded clay to a height of 30 cm and cover it with reinforcing mesh.

- Prepare concrete mortar and pour screed of the required thickness. Try to make the base sloping towards the gate to drain water.

Insulation under cement pouring can also be done using polystyrene foam. There is no need to fasten it - just lay the sheets tightly on a leveled surface covered with film and foam the seams. Waterproof the top again, lay reinforcement and pour concrete mortar.

For cement screed you need sheets with a density of at least 25 kg/m3

Thermal insulation of the floor in a garage with a cellar

When it comes to a garage with a cellar underneath, floor insulation has to be done especially carefully. Here a lot depends on the design of the ceiling. Ideally, if it is wooden - the fight against excess humidity in the basement does not give 100% results, and solid wood, unlike concrete, not only accumulates moisture, but also readily releases it.

The scheme of a thermally insulated floor will look like this:

- Waterproof insulation laid between the joists - the lightest foam plastic will do, since there will be no load on it.

- A diffusion membrane with one-way permeability so that the wooden beam can “breathe” through it. In this case, 10–15 cm of the lag at the ends remain free.

- Extension sheathing 5 cm high - provides a ventilated gap above the insulation layer.

- Subfloor made from edged boards.

For a garage with a basement - the best option

This solution will cut off the cold coming from the basement, and allow excess moist air into the garage. Here the ventilation ducts come into operation, preventing moisture from accumulating and destroying the wooden structures and the car itself. However, all lumber should also be protected from rotting - for this they are treated with antiseptic impregnations and given time to dry.

Proper insulation of the garage. Why do you need to insulate your garage?

The temperature regime that has a positive effect on the condition of the car differs significantly from the one in which a person is comfortable. If in residential premises the standard is to maintain the air temperature at +20-22 degrees Celsius, then for storing a car +5 degrees is considered the most optimal. At this temperature, almost no condensation forms on metal parts, causing destructive corrosion.

Therefore, to create a microclimate suitable for technology in the garage, other approaches to insulation are used. After all, the desire to recreate room conditions in the garage using insulation and heating devices will harm the vehicle. For example, in winter, when entering a heated room from the cold, the car will instantly fog up, the air humidity will increase, and the car will sit in such a warm-humid fog all night.

How to properly insulate a garage? Let's figure it out.

Design features of the garage that affect the insulation process

The main feature of the garage, which directly affects the insulation technology, is the thin walls and roof. Even garages built from brick or cinder blocks rarely have a wall thickness of more than 25 cm. And the thickness of metal garages is measured in millimeters. Such walls are not able to provide the necessary thermal insulation and require proper insulation.

For comparison, in residential premises the thickness of external brick walls ranges from 51 cm (two-brick masonry) to 64 cm (two-and-a-half brick masonry).

Garage made of profiled sheet metal

When choosing future insulation and calculating the thickness of its layer, you need to strive to ensure that the temperature inside the garage is maintained just above zero.

Moreover, if installed correctly, the insulating layer will work for the desired result at any time of the year: in winter it will retain heat inside the garage, and in summer it will prevent heating outside. This is achieved due to the so-called thermal inertia, which occurs due to a decrease in the thermal conductivity of surfaces in the direction from outside to inside.

You can create the desired direction of thermal inertia by insulating the garage from the inside. Then, outside in relation to the external atmosphere, there will be a material with higher thermal conductivity - cinder blocks, brickwork or metal, and inside - thermal insulation with low thermal conductivity.

How is the insulation attached?

Polyurethane adhesive foam is used as fastening material. If you have never used such foam before, then working with it will bring you delight, since installation with it is reliable, quick and easy. The main advantage of this glue is the quality of the polyurethane foam.

Adhesive foam is applied to the insulation. After five minutes, the sheet with the material applied to it must be glued to the cleaned surface of the gate.

Sealant or polyurethane foam is used to fill the seams that appear between the sheets of insulation. After an hour, when the adhesive foam has completely dried, the joints and seams between the insulation sheets can be sealed with foam. Excess foam can be removed with a knife. To ensure that the insulation of metal garage doors has an attractive appearance, the installed insulation is finished with clapboard.