To make living conditions in a panel house comfortable, it is often necessary to insulate the walls. Laying layers of thermal protection on the outside of the building is not always possible, so you have to decide how to insulate the apartment from the inside.

To create acceptable living conditions, it is not necessary to seek help from specialists. Thanks to the variety of options for insulating walls inside an apartment and types of thermal insulation, the procedure can be done with your own hands, quickly and inexpensively.

But first you need to decide which material is best to use for internal insulation of walls in an apartment, and how to carry out installation work on laying the heat-insulating layer.

Features of indoor wall insulation

Indoor walls can be insulated only in cases where the facade of the building cannot be changed or there is no access to the outer surface of the wall. It is recommended to avoid insulating walls from inside the house because it has a number of significant disadvantages:

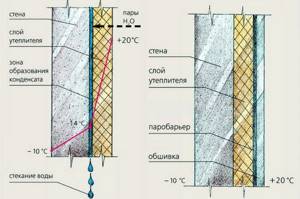

- The dew point moves indoors. The wall begins to freeze through its entire thickness, the cold meets warm air at the junction of the wall and the insulation, and condensation forms on its surface. This has many negative consequences: fungus can develop on a wet wall, the effectiveness of the thermal insulation material decreases, it lags behind the wall and collapses; In addition, the decorative finish deteriorates.

- A frozen wall loses its heat-accumulating properties. It becomes difficult to control the temperature of the air in the room - it begins to warm up faster due to the operation of heating devices or direct sunlight entering the window and cools down faster when ventilated.

- It is impossible to provide 100% thermal insulation, since it will not be possible to insulate the walls from the inside over their entire surface - cold bridges will remain at the intersection of the external wall with the internal partitions.

- The humidity in the room increases. This, again, contributes to the formation of mold and is generally harmful to health. To ensure good air exchange, you will have to constantly ventilate the apartment, which will lead to increased heating costs.

- The useful area of the apartment decreases - especially if, due to climatic conditions in the region, it is necessary to install a thick layer of insulation for the walls of the house.

- If thermal insulation work is not carried out before starting renovations in the room, all decorative finishing has to be dismantled, which complicates the work and makes it more expensive.

The most dangerous consequence of internal thermal insulation is condensation inside the room, which leads to accelerated destruction of walls and damage to finishing materials. This can be partially avoided by accurately calculating the required thickness of the insulation layer and choosing the right material. Thus, insulating a house from the inside is expensive and unsafe, but sometimes unavoidable.

13 ways to warm your apartment without a heater

- Insulate windows and doors. It is important that they are sealed and without cracks;

- If the heat is turned on, but the room is still cold, install sheets or panels of foil between the wall and the radiator. The foil will reflect the heat back into the room, preventing it from escaping through the wall;

- If the radiators are cold, try to stay in the smallest room most of the time, and close unused rooms;

- Place thick, soft rugs on the floor and hang them on the walls. They prevent heat loss. And it’s much more pleasant to stand on a warm fluffy carpet than on a cold floor. In addition, it absorbs sound and reduces the noise level in the apartment by 20-30%;

- Get ready. When the stove or oven is turned on, the air becomes dry and warm. If you are baking something, leave the oven open when finished. But it is not advisable to make dishes that create a large volume of steam. The steam will greatly humidify the air. And in winter, moist air feels colder than dry air;

- In some cases, residents leave the burners on the stove on. This will also warm the room, but it is important to constantly ensure that they do not go out. Otherwise, you can get carbon monoxide poisoning or even cause an explosion;

- Use candles. Place the products in small groups throughout the apartment. Grouped lit candles provide a lot of warmth and light and look sophisticated and elegant. They will make your home more comfortable. Classic tall white candles are suitable for grouping. They fit into every interior and look impressive;

- Close the hoods as cold air may enter through these openings. However, when the hoods are closed and not working, air exchange is disrupted. An unpleasant odor, mold or mildew may appear in the apartment. Therefore, use this method only for a short time;

- Turn on incandescent lamps. However, only classic light bulbs will help here, which release up to 95% of the energy in the form of heat. LED and fluorescent light bulbs will not be able to warm the room;

- Fill the bathtub with hot water and leave the door to the room open. Change the water as it cools. In addition, the pipes in the bathroom are always hot, even when there is no heating, except when the hot water is turned off. Therefore, always keep the bathroom door open. This method will increase the temperature in a cold apartment by one or two degrees;

- Since warm air accumulates near the ceiling, install a ceiling fan. It will disperse the air, as a result, warm currents will descend and mix with cold ones;

- Air conditioners are a modern solution to warm a room quickly and easily. Today, many models include not only cooling, but also heating functions. They are safe, practical, rational and economical.

- Use fan heaters. They consume minimal electricity, take up little space and are functional. But at the same time, the amount of oxygen is reduced, which worsens air quality. Therefore, it is important to maintain a comfortable level of humidity in the apartment.

Nuances of internal installation

Foam plastic is most often used for internal wall insulation in brick houses. Before installation work begins, any finishing is removed. The surface is thoroughly plastered and then treated with a primer.

It is very important to apply the primer evenly so that cracks do not begin to form after drying.

The insulation sheets are installed on the still damp material. The insulation material is attached using construction adhesive.

It is very important to pay attention to the components of the composition. The adhesive material should not emit toxic fumes

Insulation from the outside

For exterior work, mineral wool is most often used. The start of work follows a similar algorithm. On the outside, the panels are protected with an additional layer of primer to resist weathering, and a decorative finish is applied over the protective layer.

The corner apartment of a brick house is insulated from the outside

A brief overview of foam brands for insulating walls from the inside

In building materials stores you can see a fairly large assortment of foam brands. Let's look at the most common of them. Regardless of the brand, there can be two types of marks on the box: “PS” and “PSB”. The first indicates that the material was made using the pressing method, the second - the non-press method.

A popular brand of polystyrene foam is C-15. This type is produced using a non-press method. Due to its high density, it is excellent for both indoor and outdoor use. However, foam plastic of the S-25 PSB brand is best suited for insulating corner apartments. This is a higher density material that can also be used for floor insulation. The S-35 PSB grade is characterized by excellent resistance to extreme weather conditions. It is characterized by high fire resistance, as well as the ability to easily withstand mechanical damage. The densest variety is the S-50 PSB. This is a fairly expensive material, which is usually used in cases of frequent hail and constant strong wind.

For internal insulation, only the first two options are used.

A brief overview of mineral wool brands for insulating walls from the inside

There are four most popular varieties of mineral wool: P-75, P-125, PPZh-200 and PZh-175. For interior work, only the first two varieties are used. Cotton wool P-75 is the lightest and has a relatively low density. P-125 is more rigid and is used for interior decoration in cold climates. The last two types, due to their increased density, are used only for outdoor work.

The best manufacturers of insulation materials are: Isover, Isorok, Ursa, and Rockwool.

Advantages

Sometimes insulating concrete walls from the inside is the only way to eliminate the problem of cold walls.

This happens for a number of specific reasons:

- The first reason is that not all rooms can be thermally insulated from the outside.

- The second reason is the possibility of thermal insulation of internal walls at any time of the year and at any external air temperature, as well as the absence of the need for finishing work, in contrast to the technology of thermal insulation work on the outside of the house.

- And the last advantage of internal insulation over external insulation is the preservation of the appearance of the structure in its original state, which is important when carrying out work with complex historically valuable building facades.

Why is it better to insulate walls from the outside?

In addition to the above, insulating walls inside an apartment is not recommended for the following reasons:

- The area of the room is reduced. To make good heat and sound insulation, you need a fairly thick layer of thermal insulation, at least 4-5 cm.

- During the renovation, you will need to completely vacate the room, as some materials not only stain things and create dust, but are also toxic until they dry.

- Due to changes in wall thickness, the dew point moves inside the apartment. In other words, condensation will form not outside, but inside the room, which will lead to dampness and mold. In addition, moisture that has settled inside the wall itself and collected in droplets can freeze in the wall cavities, literally destroying the house from the inside.

- Thermal insulation materials for walls inside an apartment should be more environmentally friendly and safe, and their price is usually quite high.

More details about the third point. The main enemy of internal insulation is condensation. Its appearance if the standards are not followed can be expected with an almost 100% guarantee. Why is this happening? The fact is that, for example, in summer the difference outside the window and inside the room is insignificant and does not have indicators with a minus sign.

In winter, the situation changes radically: when there is a minus outside the window, and a significant plus inside the apartment, the uninsulated walls begin to freeze more and more deeply. The result is condensation formed on the inner surface of the wall.

If the walls are insulated from the outside, the entire force of frost and cold wind falls on the insulation and is absorbed by it. The wall remains “warm”, as far as this term can be applied to the wall. In this case, the dew point is in the wall and condensation simply has no chance of appearing.

But if the walls are insulated from the inside, then the wall freezes, which means moisture will form as the dew point moves to the insulating material.

Moisture can lead to more than just the formation of mold and mildew. It also tends to freeze. And in this state it is an even greater enemy: it spoils the walls, enlarges existing cracks, and is capable of creating a new gap that will increase the rate of destruction of the wall. The goal is to prevent the appearance of moisture in any of its manifestations.

But if there is no choice and the walls can only be insulated from the inside, then it is necessary to select the optimal material.

Brief overview of materials

When considering the materials that are used for internal insulation of housing, it is worth paying attention to several of the most popular options used for both residential (private and multi-apartment) and public buildings:

- Foamed polyethylene (penophenol), installed so that there are two gaps in the structure - between the interior decoration, insulation sheets and the wall. However, violation of the technology leads to a shift in the dew point and moisture entering the material. To improve performance parameters, penophenol is used together with other insulation materials.

- Expanded polystyrene (foam plastic) is practically the best thermal insulation of walls from the inside, with minimal weight and low thermal conductivity. The moisture resistance of the material allows you to do without vapor barrier. Among the disadvantages is the release of harmful substances during combustion.

- Polyurethane foam, which also has good thermal insulation properties and easy installation. Provides maximum sealing, but the disadvantages include, as for foam plastic, the release of harmful substances during combustion.

- Spraying is an option that leaves no seams. Suitable not only for internal, but also for external insulation. Considered suitable only as a finishing touch.

- Paint based on ceramic components. It dries quickly (after 12 hours wallpaper is glued over the material), but does not protect against dampness - and therefore against mold and mildew. Used as an additional layer.

Cork is considered an expensive (and this is practically its only drawback), but effective material for insulation. Provides good protection of rooms from heat loss, does not require wallpapering or painting, and does not reduce the area of rooms. Due to its low heat resistance, mineral wool is considered not the most suitable option for internal insulation. Therefore, it is rarely used and only in extreme cases. Due to the low resistance of the material to moisture, rooms insulated from the inside are at risk of dampness and, as a result, the appearance of mold and mildew.

Insulation materials

The modern construction market offers an alarmingly large selection of thermal insulation materials. The “ordinary” man in the street, not familiar with the specifics of the work, is dizzy from such diversity. Unscrupulous sellers take advantage of this, instilling the idea “the more expensive, the better.” Today we will not consider all the options for insulating the external walls of a house, but we will talk about the most inexpensive, high-quality materials that have been proven over the years.

Styrofoam

Among the most popular insulation materials, foam occupies a special place. This is an inexpensive material that properly performs its intended function. It is perfect for external insulation, as it provides 100% thermal insulation regardless of air humidity and temperature changes.

This material is non-toxic and fireproof, but a reservation should be made here. The foam itself does not burn, but melts and at the same time emits black acrid smoke, which is hazardous to health. But if you follow safety measures, it will last a long time and faithfully. The words about non-toxicity and harmlessness to health are confirmed by the fact that even children's products and food products are packaged in polystyrene foam.

Polyfoam is not susceptible to mold, fungi and insects. It does not deteriorate, does not swell or shrink, maintaining its original shape. The service life of the material ranges from 20 to 50 years, depending on the quality.

External insulation of the walls of a house with foam plastic allows not only to protect the interior from the vagaries of the weather, but also transforms the outside of the house. The material creates a very convenient surface for finishing, ranging from relief plaster to siding or slabs.

Working with polystyrene foam is quick and easy; all you need is basic skills and equipment.

Stages of insulating the external walls of a house with polystyrene foam:

- Prepare the walls by cleaning them from dust and dirt with a construction brush. If there are cracks or chips, seal them with plaster so that the foam sticks well.

- Glue the foam plastic with a special compound onto the pre-primed wall. You need to glue the sheets in a checkerboard pattern, pressing them closely together. To ensure that the material holds well, additionally secure it with plastic dowels.

- Install fiberglass mesh over the slabs. To do this, apply a thick 5 mm layer of glue to the sheets and “drown” the mesh in it.

- All that remains is to plaster the surface, cover it with facade paint or perform any other finishing.

Penoplex

Today you can often hear advertisements for high-quality and reliable penoplex insulation, which is why many people believe that this is the name of the material. In fact, the material is called extruded polystyrene foam, and it is produced under the Penoplex brand.

Extruded polystyrene foam is used for internal and external insulation of houses of any type. Today it is one of the most popular materials, and this is explained by its excellent performance characteristics.

Advantages of penoplex:

- environmental friendliness;

- low thermal conductivity;

- high density;

- retains heat better than foam;

- high strength;

- high density;

- low vapor permeability;

- absolute fire safety (ignition temperature 500C, which is unrealistic at home);

- durability;

- ease of working with the material;

- relatively low cost, which quickly pays for itself.

Unfortunately, ideal building materials do not yet exist, so even with such a large list of advantages, penoplex also has disadvantages. The most obvious is poor adhesion. Since the material is very dense, it does not absorb adhesives well, so it is difficult to glue it to a vertical surface. To do this, additional fixation is performed with dowels, but most builders recommend using penoplex for internal insulation.

External insulation of the walls of a house with penoplex is best done in the basement area, since even additional fixation of the material will not protect it from damage. In other words, it very quickly begins to fall off and spoils the appearance of the building. In the area of the plinths, you can make a ventilation space or use an outer layer of waterproofing to prevent the adhesive layer from getting wet and breaking down.

https://youtube.com/watch?v=KA5pPEDRxwY

DIY insulation instructions

Due to the variety of thermal insulation materials, you can choose any of those on the market to insulate your room.

When purchasing, consider not only your financial capabilities, but also the requirements for the quality of the purchased material. It would be a good idea to ask the seller about the accompanying documents and the insulation quality certificate

Let us consider in detail the most popular options for internal thermal insulation of a room.

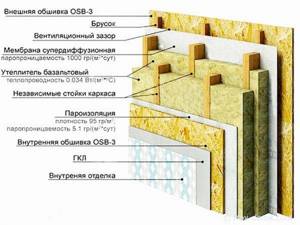

Method #1 - mineral or glass wool

To lay the material, you will need to make a frame from profiles and prepare sheets of drywall in advance for the purpose of subsequently closing the structure.

It is better to buy moisture- and fire-resistant plasterboard sheets - they will additionally protect the insulated wall from the penetration of dampness from the outside.

Step-by-step instructions for laying thermal insulation material:

- Install the profile along the entire perimeter of the wall, along the ceiling, walls, floor, and also make partitions between them in increments of 30-40 cm.

- Place mineral wool or glass wool in the prepared cells, leaving no empty spaces.

- Cover the structure with thermal insulation tightly with a vapor barrier film, make an overlap of 20-30 cm on the floor, ceiling, and adjacent wall.

- Seal the vapor barrier material to the floor and wall using double-sided tape.

- Cut the sheets of drywall with a construction knife into pieces of the required sizes.

- Install them using a screwdriver.

- Remove excess vapor barrier with a knife.

- Treat joints, cracks and holes with self-tapping screws with finishing or acrylic putty.

- After drying, level the surface with putty.

- Wait until it dries completely, then sand the wall with a fine mesh.

After completing the entire procedure, prime the surface and after a few hours it will be ready for finishing with decorating materials.

To perform the work, use a material with a high energy saving rate and a thermal conductivity of about 0.030 W/(m*°C). The properties of mineral wool are indicated on the outer packaging

This mineral wool has improved insulating properties compared to other similar materials. It can also be used to soundproof the ceiling.

Method #2 - PSB-S foam

A universal and most popular type of insulation, which is widely used in construction due to its low cost and decent heat saving performance. Choose high-density material with a width of 35-50 mm or more.

Polystyrene foam can be laid in several ways: in a pre-prepared wooden frame, from a metal profile followed by plaster covering, or by gluing it to the wall surface

If you wish, you can decorate the walls with tiles, wood panels, paint or use another option

The frame method is carried out according to a similar scheme as when insulating with mineral wool. Let's look at the method of gluing to a plane in more detail.

Follow this order of work:

- Apply an antifungal primer to the walls that you plan to insulate to prevent the subsequent formation of mold.

- Wait until the surface is completely dry.

- Install a waterproofing layer - this will provide additional moisture protection.

- Mix the adhesive solution in a bucket or other container by hand or using a drill and a whisk attachment.

- Start attaching the sheets from the bottom left corner and lay them in a checkerboard pattern.

- Measure the width and length of the plate required to fit on the wall and carefully cut a piece.

- Glue the prepared part of the material using the prepared mixture.

- After completing the entire procedure, leave the wall to dry for 1-2 days.

- If desired, you can additionally secure the foam with umbrella dowels: drill 5-6 holes in the insulation along the edges and in the middle, then drive in the dowels and plastic nails.

- Seal wide joints with polyurethane foam that does not contain substances that can damage the material - read the instructions. It is enough to cover narrow cracks with an adhesive mixture.

- The final stage is the installation of the reinforcing mesh by applying an adhesive or putty base to the surface, which will make the structure more reliable.

- After drying, level the surface with finishing putty.

Before wallpapering walls, be sure to apply a primer to the surface.

In addition to the presented methods of laying insulation, you can perform thermal insulation using other materials.

If you have a loggia, it is also advisable to insulate it. We provided guidance on how to independently insulate a loggia in the following article.

Decorating walls with cork - the problem of dry air

The included batteries reduce the level of air humidity to a critical level. Does this seem insignificant? You should also think about health. In low humidity conditions, bacteria multiply faster and the skin and mucous membranes dry out. It is during the winter period that we get sick more often, complications from colds to bronchitis and pneumonia occur, the skin peels, irritation appears, dryness leads to wrinkles.

What does this have to do with wall plugs? A humidifier will solve this problem! That's right, but decorating the walls with cork panels will allow you to not turn on radiators at all or turn them on less often and reduce the power of electric heaters, and this will increase air humidity. In addition, the remarkable property of cork finishing has been revealed to maintain optimal conditions not only for temperature, but also for humidity in the room. Not only does it prevent the temperature from dropping or rising too much, but the change in humidity is much slower.

Let’s say, you say, we manage to solve these problems, insulate a cold wall from the inside, but cork also has its drawbacks, it is more expensive than wallpaper, for example. Let's look at the main opinions against cork panels.

Why insulate a corner apartment?

The layout of corner apartments in terms of energy consumption for heating is not the most optimal due to the presence of two external walls. And as a rule, in such conditions, even the presence of additional heating devices does not save residents from the cold. Before the heating season, when the temperature outside drops sharply, heat begins to quickly leave the room, which is why the apartment becomes cold, dampness and fungus appear. If the walls are not insulated, it will be uncomfortable to be in such a room.

Freezing corner in the apartment

When the central heating comes on, the situation improves slightly as it becomes warmer, but corner walls can freeze. This leads to damage to the plaster layer and peeling of the wallpaper. As a result, mold and various types of fungus begin to develop in such places. Such a microclimate causes discomfort and does not have the best effect on the health of residents. Due to the dampness and low temperatures, colds are becoming a common occurrence for many residents of corner apartments.

Features of apartment insulation

There are two fundamentally different ways to insulate an apartment:

- from the inside;

- outside.

Each of them has its own advantages and disadvantages.

How to insulate an apartment from the outside

From the point of view of overall efficiency, the external method is significantly superior to the internal one. Its main advantages are as follows:

- Higher quality of thermal insulation.

- The best microclimate after insulation (not only temperature, but also humidity).

- The area and volume of the apartment is not reduced.

- The condensation zone (dew point) is carried out from the living quarters to the facade or into the thickness of the external walls.

- The service life of wall structures increases.

Insulation of the outside with sheets of foam plastic under plaster

Related article: Independent insulation of balcony walls from the inside.

The disadvantages of the external method are the following circumstances:

- Coordination with the operating organization and architectural supervision authorities is necessary.

- Carrying out such work on your own is very dangerous and is also prohibited by regulations.

For external insulation, it is necessary to involve an organization that has a license to work at height. Formally, the owner can carry out thermal insulation on the ground floor on his own; in practice, regulatory organizations try in every possible way to prevent this.

How to make an apartment warmer from the inside

There are not many advantages to this method. The main ones are the following:

- The cost of materials and labor is significantly less.

- The complexity of the work and the qualifications of the workers are also lower.

- You can do the work yourself without waiting for approvals. Sometimes, especially if there is a small child in the apartment, this is a decisive factor. Literally: we decided in the morning, we already insulated it in the evening.

Insulation from the inside with basalt wool along metal guides

Material on the topic - how to properly insulate walls.

The internal method has many more disadvantages and risks; it is much more difficult to properly perform internal insulation and not harm your apartment and residents.

Installing insulation inside creates the following problems:

- The dew point moves indoors. It will be necessary to take special measures for waterproofing and condensate removal.

- If this is not done, high humidity in the rooms will lead to the formation of mold and mildew. This can make finding people impossible.

- The wall stops receiving heat from the living space and freezes through.

- The moisture contained in it freezes and thaws, which reduces the service life of the wall.

- At the joints of an insulated wall, floor and ceiling, so-called “cold bridges” are formed.

- Internal thermal insulation reduces the area and volume of rooms, thereby reducing the quality of housing.

- Many insulating materials are not recommended for use in residential premises. They can emit unpleasant or even harmful fumes. During combustion, toxic substances may be formed.

The thicker the layer of internal insulation, the more the wall freezes and the further the condensation zone moves inward

How to insulate a corner apartment

An unpleasant feature of corner apartments is that two wall surfaces are external. Installing additional radiator sections does not always help. The coldest spot will be the corner between the two outer walls. If the seams between the panels are poorly made, it will definitely freeze, no matter how hot the radiators are.

Conscientious developers pay special attention to the thermal insulation of corner apartments

How to insulate a cold corner in an apartment from the inside? First you need to check the condition of the fillet weld. In inexpensive or older homes, the seams may be in poor condition. Heat leakage through the seams is detected by a thermal imager.

It is impossible to repair interpanel seams on your own - you must force the operating organization to carry out this repair. It consists of dismantling the seams (in other words, they are opened from the outside with a hammer drill), laying (or spraying) new insulation and applying a new layer of plaster.

If repairing the seams does not give the desired effect and the corner rooms are still cool, you will have to insist on external insulation of the walls.

Insulation on wooden guides

How to stay warm in a cold apartment

- Warm drinks and food, especially soups and broths, increase body temperature;

- To stay warm and not freeze in a cold apartment without heating, it is important to dress properly. Experts advise using several layers of clothing. It is optimal to wear cotton items downwards, and fleece or wool or artificial materials on top. Loose pants and a sweatshirt or a thick, long robe work well;

- Be sure to wear warm socks and slippers. If your feet are constantly cold, use warm black tights, tights, leggings or gaiters. Wear items under your main clothing. They are able to retain heat;

- Play sports. Twenty minutes of vigorous exercise will improve your circulation, help you stay warm, and keep you warm after exercise. In addition, sports activities will strengthen the immune system and make the body more adapted to the cold;

- You can warm up cold shoes, bed and even your body using a hairdryer. But do not cover the device, otherwise it may overheat and catch fire!

- While sitting in a chair, use warm blankets or a shawl. You can use a special electric blanket for sleeping. It is more effective and cheaper than old classic heaters. This blanket maintains the desired temperature for the required time;

- A heating pad has been helping to keep warm in cold weather for many years. If you don't have one, use a plastic bottle filled with hot water. However, it will cool quickly and the contents will have to be changed;

- Alternatively, take a sleeping bag. It warms perfectly, especially products designed for zero temperatures. You can wrap yourself in a bag like a blanket, or sleep like under a blanket;

- Take a second blanket, a warm blanket or blanket for sleep and sleep in socks. Wear thin cotton socks to help your skin breathe and prevent your feet from getting sweaty and getting colder;

- Take a hot bath or shower, or periodically use hot foot and hand soaks. After water procedures, apply lotion or oil to the skin. Such compositions act like another layer of thin clothing.

If you have periodic heating outages or have small children who cannot be cold, it is better to buy at least one heater. Choose oil radiators, wall-mounted or floor-mounted heating convectors. If you are purchasing only one product, it is better to choose a portable or mobile model so that you can easily move it from room to room.

With the help of heaters you will quickly warm up. But be prepared that they consume a large amount of electricity and dry out the air. If the radiators do not heat well in an apartment with the heating on, be sure to contact the management company! And when the heating season begins and ends, as well as what to do if there is no heating in the apartment, read the link https://vsepodomu.ru/zhkh/otopitelnyj-sezon/#i-3.

Is it worth insulating the house from the inside?

Regulatory documents say the same thing, for example, SP 23-101-2004, dedicated to the design of thermal protection.

Typically, this method is considered justified only for residents of apartment buildings who cannot convince their neighbors to chip in to insulate the entire facade.

If external insulation is still possible, installing a heat insulator inside is a big mistake.

Why are experts so categorical? The inconvenience of interior work for residents and the reduction in living space have already been discussed. But there are also more serious negative effects. Here they are:

The service life of the wall is significantly reduced

If the wall is insulated from the outside, it is heated by the heating system and never freezes. If the insulation is placed inside, the wall will be in a zone of low temperatures and will either freeze or thaw as the weather changes.

Any building material contains a small amount of water, so this mode of operation is detrimental to it.

In the characteristics of a material indicating its frost resistance, for example, M100, the number indicates precisely the maximum permissible number of freeze-thaw cycles.

Condensation may form inside the wall

If air, usually containing a large amount of water vapor, penetrates into the wall from a room, the position of the so-called dew point is important. Before we talk about it in more detail, we remind the reader that the solubility of steam in air depends on the temperature of the latter

Before we talk about it in more detail, we remind the reader that the solubility of vapor in air depends on the temperature of the latter.

The warmer the air, the more steam it can hold. If the air cools, the excess steam turns into condensate.

It is obvious that in the thickness of the wall the temperature gradually decreases from the inside to the outside. The dew point corresponds to the temperature at which the relative humidity of the air entering from the room reaches 100% and excess steam in it begins to condense. Much depends on in what part of the wall the steam turns into water and in what quantities.

Under certain conditions, the result of internal insulation can be abundant release of condensation at the insulator-wall interface or inside the wall itself. In a damp zone, thermal conductivity increases sharply, and if it is on the surface of the wall, then mold also appears here. If moisture has condensed inside the supporting structure, it will cause cracks to appear when it freezes.

In order to insulate from the inside and not encounter the problem of dampness, you need to choose the right thermal insulation material.

Tips and thoughts on how to heat a private house

With the onset of the winter months, coolant consumption increases sharply. The lower the temperature outside, the more difficult it is to heat the room. But in recent years, prices for basic coolants have begun to rise. And the forecast for the future is disappointing. Winters will not become shorter, gas will not become cheaper. After the long winter of this year, many had to think about how to heat a private home so that the family budget would not suffer.

In the past, everyone tried to connect the house to gas and use it for heating. This possibility does not always exist. Some home owners have calculated that it is now more profitable to change the heating system. There are other ways to reduce heating costs. Let's talk about everything in order.

Typical mistakes when working

Common mistakes to avoid:

- Bad insulation. You need to buy material from trusted people or stores. Don’t be fooled by cheap prices and “summer sales.” Often, large discounts on construction products are placed in order to quickly sell out expired or low-quality goods. Buying bad material is the key to quickly deteriorating the insulation and the entire wall.

- Poor sealing of seams. This leads to moisture seeping through such joints. They become “cold bridges” through which cold and dampness pass from the street to the room.

- Low vapor permeability of the material. Since the heating of the room is turned on at home, and people themselves breathe, bathe and cook, the humidity in the room will be increased. The steam needs to go outside and not settle on the interior walls, causing mildew and mold. Therefore, before purchasing insulation, you need to take into account its vapor permeability. The higher it is, the better.

In other cases, it is important to try to lay the material as tightly as possible on the wall. For example, glue on polystyrene foam and polystyrene foam should be leveled with a comb and not with a spatula

Then it won’t turn out that due to the large amount of mortar, the tiles have moved away from the wall. The glue will be evenly distributed over the entire area, due to the fact that there are additional voids.

If you are interested in how and with what you can insulate brick walls from the inside and outside, take a look at this section.

Cold batteries in the apartment: what to do?

High-quality radiators are the key to warmth and comfort in the house. If the radiators are many years old and the apartment is cold in winter, it may be worth replacing them. But before you run out for an expensive purchase, do a survey: sometimes the batteries do not heat up due to air locks or due to the negligence of utility services. Where to complain if it’s cold in the apartment, we told you here.

Many modern radiator models are made with a temperature regulator, so you can set the appropriate temperature. High-quality heating appliances can last faithfully for decades, so after spending just once, you will forget about cold radiators in the house for a long time.

There are several types of radiators:

- Cast iron is the most classic option, which has been used for heat supply for more than a hundred years. Cast iron batteries are durable, resistant to corrosion and have high heat transfer. They are not afraid of hard, poor-quality water and pressure changes. The disadvantages of cast iron radiators include bulkiness and unaesthetic appearance. However, the modern design of these batteries with monograms and original coloring will fit well into a classic-style interior.

- Aluminum - durable, lightweight and elegant heating devices. Ease of installation, optimal price and high heat dissipation make aluminum batteries an ideal choice for many. However, this type of radiator is susceptible to corrosion with a high alkali content in the water.

- Steel radiators are often used to supply heat to private homes and offices. They have excellent heat dissipation and corrosion resistance. Their disadvantage is their sensitivity to water hammer - sudden changes in pressure in the pipe.

- A bimetallic radiator, in simple terms, consists of a steel core and an outer aluminum layer. This design is optimal for city apartments: the steel pipeline is not subject to corrosion, and aluminum, which has good thermal conductivity, perfectly supplies heat to the room. However, all these advantages are overshadowed by the high cost of the product.

- Copper batteries provide effective heating of the room due to their thermal conductivity - it is much higher than that of aluminum and even more so than that of steel and cast iron. But the price of copper radiators, as well as bimetallic ones, will not please everyone.

The choice of radiator depends not only on your tastes and financial condition, but also on compatibility with your heating system. Therefore, before purchasing, you should determine whether the characteristics of the heating device (pressure, permissible temperature, heat transfer, etc.) correspond to the characteristics of the heating system.

If it is cold in your apartment, you should not cover the radiators with decorative panels. It is also not recommended to place batteries in deep niches under windows - this will make the radiators warm much worse.

Types of insulation

Before insulating a wall in an apartment, you need to choose the optimal material. It provides the following parameters:

- low degree of thermal conductivity;

- breathability;

- waterproofing qualities;

- environmental cleanliness.

The material must also be resistant to fire and have a long service life.

Minvata

The product is made from natural raw materials – basalt fibers. This material can be used to insulate a wall in an apartment from the inside and outside. It provides good thermal insulation, allows air to pass through, but is susceptible to moisture. This insulation does not burn, and when melted it quickly fades, does not release toxic components, and prevents the spread of fire. When laying the insulator from the inside with your own hands, you need to use guide strips.

Laying a mineral insulator does not require professional skills or special efforts. The main disadvantage of the product is the gradual loss of shape over time. To ensure the quality of insulation, a vapor barrier layer is needed. If the walls are concrete, then you need to choose a high-density insulator.

Expanded polystyrene sheets

Expanded polystyrene is a sheet material for insulating any walls except wood. It does not contain or release toxins under normal operating conditions, therefore it is safe. Installing polystyrene foam is quick and easy, and you can do it yourself. The service life of this material is long and it is easy to cut.

Expanded polystyrene is resistant to strong compression, but it is flammable. When ignited, it releases harmful components into the surrounding space. It is not advisable to use insulation on wooden walls. It also does not muffle external noise well enough.

Extruded polystyrene foam

Such thermal insulation is easy to process, although it has high elasticity. This option makes joining sheets somewhat difficult. The material is resistant to moisture and is lightweight. When installing the product on brick or concrete walls, you can do without a vapor barrier. To eliminate cold bridges when attaching sheets, polyurethane foam is used.

Styrofoam

95% of the total volume of the material consists of air bubbles, so it has a low mass and provides a good level of insulation. Its cost is low and installation is simple. Polystyrene foam can be used at any air temperature.

Keramoizol

A special feature of this insulation is its liquid consistency. It is packaged in cylinders of different sizes. The material provides good insulating properties, is vapor-tight, and resistant to moisture. It does not require preliminary creation of lathing for installation. The advantage of the product is its durability, efficiency and reduction of repair time.

Spraying is carried out in several layers: 4-6. They are applied to the base at right angles to each other. The only disadvantage of keramoizol is its high price.

Penoizol

This is a type of polyurethane foam that has a foam-like shape. It is characterized by high installation speed. There are no joints or seams between the layers of foam, and the insulation itself quickly hardens. It is environmentally friendly and non-flammable. The cost of spraying work is low.

Astratek

A fairly new insulating material manufactured in the form of a suspension. It contains solid particles of various polymers. The product is applied with a spray gun, but for small areas a paint brush is suitable. The advantage of the material is that just 1 cm of its layer gives the same efficiency as 50 cm of mineral wool. It also doesn’t steal space in the room.

The surface of the base after applying Asstratek remains smooth and uniform. After the insulator has hardened, preparation for cladding is minimal. The high price is the only disadvantage of the insulation.

Non-standard method of insulation - electric

A new, but quite effective way to insulate walls in a corner apartment is to use the principle of heated floors. Panels with electric heaters are mounted indoors on the surface of the walls and connected to the electrical network. The control unit is installed in a separate accessible place

For proper installation, it is very important to wait for frost, and then turn on the equipment until the walls are completely dry. Only after this an additional thermal insulation layer is laid and decorative finishing is performed.

This method of insulation is very effective, but has one big drawback. In cold weather, you will need to regularly maintain a stable temperature to prevent the formation of dampness and condensation. This will lead to additional energy costs. The purchase of an insulation system itself will require considerable expenses, and after that you will have to pay for regular operation. However, this approach allows you to create an ideal microclimate inside the corner room in cold weather.

Materials used to insulate the walls of a panel house

There are special requirements for such materials. The construction market is full of insulation materials, but not all of them are suitable. After all, we are talking about being inside the apartment. Here is a list of thermal insulators used for panel houses:

- PPU (polyurethane foam);

- EPS and other polystyrenes;

- Mineral wool;

- Reflective thermal insulation materials.

Let's look at each of them in more detail.

Polyurethane foam

Representative of spray-type insulation. Two-component raw materials, which before application are mixed in special equipment and applied from a gun. Somewhat reminiscent of polyurethane foam. After spraying, it increases tenfold, creating a monolithic layer.

Advantages:

- Can be applied to any surface without prior preparation.

- Penetrates into the most inaccessible places, covering cracks and recesses.

- A monolithic layer is created without cold bridges, which allows for high-quality insulation of a panel house.

- It has good sound and heat insulation characteristics.

- Not afraid of moisture.

- Withstands loads.

- Easy.

- Long lasting.

But there are also disadvantages. For example, you won’t be able to insulate the corner room of a panel house yourself. After all, this requires a special compressor, a hose system and the correct mixing ratio of the components. Only professionals do this. Therefore, you will have to look for specialized companies. PUF also does not allow air to pass through and can release harmful substances.

Mineral wool

One of the most popular materials for insulating a panel house from the inside. It's a matter of composition. Mineral wool is a product of rock processing. This means that cotton wool is absolutely safe and does not harm health. It is available in the form of rigid mats or in rolls. The cost is high, but the user knows what he is paying for.

Benefits of cotton wool:

- 100% environmentally friendly product, does not emit harmful substances.

- It is vapor permeable, which means the walls will breathe, condensation and high humidity will not accumulate in the building.

- Protected from fire.

- Some of the best sound and heat insulation characteristics.

- Long operational period.

- The material will not be damaged by rodents and insects.

The main disadvantage is vulnerability to moisture. When wet, mineral wool loses its characteristics

Therefore, in order to insulate the wall correctly, it is important to take care of the presence of a waterproofing layer. Basalt wool is one of the best representatives of cotton insulation

It is protected from moisture and can withstand enormous temperature changes. If you buy basalt wool, you don’t have to use protective membranes.

Expanded polystyrene

The simplest and most effective heat insulator used to insulate a panel house. Not to say that it is the best for these purposes. After all, polystyrene foam is made from synthetic materials, which means that when heated it can release harmful substances. The second disadvantage is that foam does not allow moisture to pass through. This means that dew will begin to accumulate on its surface. The microclimate is disrupted, the wall will become wet and covered with mold.

However, the material also has its positive sides:

- Light weight.

- Affordable price.

- Protection from moisture.

- Ease of use.

- Long service life.

One type of expanded polystyrene is extruded polystyrene foam (EPS). It resembles polystyrene foam, but has improved characteristics, is more durable and dense. It is not so spoiled by rodents. The cost of the product is higher, but with it the insulation of walls in a panel house will be of better quality. In addition, EPS is slightly better protected from fire.

Foil insulation

This is a type of reflective insulation. The material consists of several layers: insulation and foil on one or both sides. Thanks to the foil layer, the insulation is reliably protected. And 90% of the heat is reflected from this aluminum surface. However, of the above thermal insulation options, this one is less effective as an independent layer.

Advantages of foil thermal insulators:

- Reflects infrared rays.

- Does not allow moisture to pass through.

- Reduces noise and vibration.

Otherwise, using thin penofol for a corner room, which is heavily exposed to wind loads and freezes, is irrational.

All that remains is to weigh the pros and cons, compare these materials and choose the best option for yourself. Since a panel house does not have good thermal insulation, it is not worth saving on insulation. It’s better to pay a little more, but enjoy the warmth and comfort inside for a long time.

Installing insulation on brick walls

Before starting work, it is important to decide what material will act as insulation. It is important to begin with to weigh all the pros and cons and understand that condensation will form during internal insulation in any case. If you nevertheless decide to install foam plastic or any other material from the side of the room, you must attach a vapor barrier material to the wall that will extend to the ceiling and floor. The seams are taped and should be laid overlapping each other.

Now you can install the sheathing, the step between the elements of which should be less than the width of the thermal insulation used, if it is elastic. The depth of the frame must correspond to the thickness of the insulation. Thermal insulation slabs are laid out in cells, covered with a vapor barrier, and the seams are sealed. The next layer will be a counter-lattice, which is sheathed with chipboard or any other sheet material. This work is necessary to ensure that the materials inside are as well ventilated as possible.

Why do you need to do it?

A certain amount of thermal energy and moisture is always released in the premises, and this is explained by the continuity of human life processes.

Heat is released during cooking, the operation of household appliances, etc. The level of moisture in the air changes after daily washing, boiling water, mopping floors and other activities associated with the use of liquid. Note that the air temperature determines its ability to retain moisture.

If the walls are poorly insulated, the cooled air leaves condensation on their surface. Water settled on the walls becomes a source of fungal mold, which threatens the health of the human body. Mold spores enter the respiratory system and cause asthma or allergies. In addition, the fungus destroys the materials used for the construction of walls and spoils the appearance and quality of clothing.

To get rid of such problems, insulation is installed inside a brick house. In this case, the walls made of brick stone cease to maintain contact with the warm air currents in the room, and therefore there is a possibility of them freezing to the point of contact with the layer of thermal insulation. This means that the insulation efficiency will be low.

A completely different result is achieved if the thermal insulation is placed outside, but sometimes situations arise when such solutions are not possible to implement.

So, the internal surfaces of the walls are insulated in the following cases:

- if there is no permission to change the architecture of the facade walls of the facility;

- expansion joints are made along the external walls;

- walls separate technical premises, elevator shafts and other objects that do not have access for installing a heat-insulating layer;

- The design assignment involves the arrangement of internal insulation for brick walls.

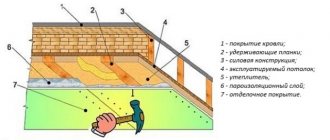

Pie wall elements

Before insulating the walls of the house and attic, it is necessary to correctly lay the layers of the cake. Pie walls are sequentially laid layers of materials that serve to provide a comfortable microclimate in the house.

The elements of the wall pie of a wooden house are:

- wooden frame made of timber. Most often made of beams 15x15 cm;

- horizontal wooden sheathing, sometimes a metal profile is used;

- insulation made of mineral wool or expanded polystyrene;

- The membrane is multifunctional, performing the function of protection from winds and at the same time acting as a vapor barrier. It is a dense polyethylene film;

- vertical lathing;

- finishing material;

- vapor barrier film;

- internal cladding (plasterboard, lining).

wall pie

For all wooden wall elements, it is necessary to use high-quality wood, which must be dried naturally. In addition, materials should be chosen of high quality and durable so that the walls perform their functions for many years.

Selection of material and tools

There are many brands of insulation of several main types on the modern market:

- Mineral wool. Basalt, glass and slag.

- Foam plastics.

- Polyurethane foam.

- Ecowool.

- Bulk materials. (They are practically not used when insulating apartments)

When choosing a material, you need to compare the available alternatives according to the following parameters:

- Thermal conductivity. The lower the better.

- Moisture absorption coefficient. Materials with lower values work more efficiently.

- Breathability. Lower values also mean better thermal insulation.

- Fire resistance class. Indicates the fire safety of the material.

- Life time.

- Compound. It is better to choose materials without harmful components.

- What is the price. The last but one of the most important characteristics.

The most popular materials have the following characteristics.

Basalt wool

Made from volcanic rocks, the structure consists of short fibers of high rigidity. Supplied as mats

It has a high density, special attention must be paid to the strength of fastening the mats to the wall

The material is completely non-flammable and slows down the spread of fire. Does not contain harmful substances. It does not form them either during operation or during a fire.

On the topic - how to insulate a door in a private house.

Glass wool

Made from industrial waste and broken glass. Its structure is formed by long elastic fibers. Available in rectangular mats and rolls. It has lower density and greater elasticity than basalt wool.

It is also fireproof and does not form harmful substances.

A major disadvantage is the reduction in thermal insulation characteristics when wet.

Cut glass wool

Expanded polystyrene

Foamed polystyrene is often called polystyrene foam. The material has good thermal insulation properties and is easy to install on rigid structures.

The main disadvantage of the material is that it burns well, and releases substances harmful to health. Polystyrene foam is also very fragile and not resistant to tensile and compressive loads; it chips easily. Extruded polystyrene foam does not have this disadvantage.

Installation of foam plastic with adhesive composition

Polyurethane foam

This foamed plastic, also called penoizol, has excellent thermal insulation properties. It is sprayed liquid, foams and hardens on the insulated surface in an even continuous layer without seams and without joints that cause heat loss.

It has excellent moisture resistance, zero hygroscopicity and vapor permeability. A significant disadvantage is the high cost of spraying equipment.

Spraying polyurethane foam

Ecowool

A new heat insulator on the Russian construction market is made of cellulose fiber impregnated with boric acid and sodium triborate.

The material is the most environmentally friendly, does not burn and does not form any harmful substances. It is also sprayed onto vertical surfaces, wetted with a water-adhesive composition.

The equipment costs less than for spraying polyurethane foam, but also seems expensive.

Auxiliary materials and tools

In addition to the insulation itself, additional materials will be required:

- vapor barrier membrane and double-sided tape for gluing its panels.

- External cladding: plaster or ventilated facade made of plastic or porcelain stoneware.

- Internal lining – moisture-resistant gypsum board, wallpaper.

- Products that prevent the development of mold and mildew

- Lathing made of wooden slats or metal profiles

- Fasteners

The usual tools are needed for general construction work. You will need:

- hammer drill or impact drill;

- construction knife;

- hacksaw;

- Bulgarian;

- screwdriver;

- tape measure, level, square.

To apply protective compounds you will need a spray gun or roller.

How to insulate the walls of a house from the inside so that they are not cold: progress of work

To avoid mistakes when performing internal thermal insulation, work is performed in the following sequence:

- wall preparation - clean the walls before plastering;

- waterproofing - polymers or polyethylene film are applied to the walls, the edges are secured with construction tape;

- a metal or wooden sheathing is installed, the wood is treated with an antiseptic and fire retardant agent;

- insulation is applied to the space between the sheathing;

- A vapor barrier film is installed, and the joints are treated with sealant.

The final point is to install the cladding: plasterboard sheets, wooden lining, plasterboard or other finishing materials.

In order for the house to always be warm, comfortable and cozy, it is necessary to reduce heat loss as much as possible through additional wall decoration. Insulation will be of high quality if you choose the right material and follow the instructions for installing the thermal insulator.

Polymer materials

Their use in construction is gaining popularity due to the quality, availability and variety of materials.

Penoizol (liquid polymer with a foamed structure) does not require additional waterproofing, which reduces the cost of home insulation. The quality will not be affected.

Polystyrene foam is popular due to its low cost. The material is easy to cut, install, strong and durable.

expanded polystyrene effective concrete floors

Polyurethane foam is applied to the floor surface by spraying. As a result, an even layer of insulation is formed, without joints or gaps. A sufficient thickness of the coating is 5-10 cm. When insulating with polyurethane foam, no additional vapor barrier is required. The work is done very quickly, compared to laying other types of thermal insulation.

Popular thermal insulators for interior work

Nowadays, internal insulation of brick walls can be carried out using different methods, which is why it is so important to correctly choose the most suitable material for these purposes, taking into account the characteristics of the given structure. The material is selected taking into account its fire resistance, thermal conductivity and density

These indicators affect the weight of the material and the thickness of the insulation. And the service life largely depends on the strength of the material.

The material is selected taking into account its fire resistance, thermal conductivity and density. These indicators affect the weight of the material and the thickness of the insulation. And the duration of operation largely depends on the strength of the material.

The most popular insulation materials include:

- Expanded clay. This insulation is added to the base, after which a monolithic frame is formed from it;

- Mineral wool. This insulation has good moisture absorption, so it allows you to insulate the house from the inside. Glass wool, which is also used as insulation, is one of the varieties of mineral wool;

- Warm plaster. This material is a universal insulation material because it can be used both inside the house and for facade work. The insulation retains heat well, but it is a heavy material, so it is used only in houses with a reinforced foundation;

- Cellulose wool. This material retains heat well, has excellent absorbency, but is subject to mechanical stress; experts recommend this insulation for interior work;

- Cork insulation. The positive characteristics of the material include its ability to retain heat well, however, it is flammable;

- Styrofoam. The reasonable price and the ability to use this material for both interior and facade work have made it popular. However, this insulation has disadvantages: it does not “breathe” and releases harmful compounds during the ignition process.

Less popular insulation materials are: extruded polystyrene foam, penofol, penoplex, polyurethane foam and penoizol.

Criteria for choosing material, requirements for insulation, which is better

When choosing insulation of walls inside a brick house, first of all, it is necessary to take into account the thermal insulation properties of the material. In addition, the most significant characteristic of the material is vapor permeability.

The following actions will help prevent contact of freezing brick wall surfaces with steam:

- Wall cladding with a polymer heat insulator such as extruded polystyrene foam, sprayed polyurethane foam, high-density foam or penofol.

- Use of mineral wool insulation material.

- Applying a thick layer of heat-insulating plaster.

When planning to insulate your home, you should also consider the method of installing the heat insulator.

When choosing insulation of walls inside a brick house, first of all, it is necessary to take into account the thermal insulation properties of the material.

Preparatory work

If you plan to insulate the walls from the outside, you should dismantle elements such as the air conditioning system, satellite dish, etc. This is due to the fact that thermal insulation made in large solid sheets is more effective than laying the material in small pieces.

Surface treatment

Preparing the surface for installation of insulation includes cleaning and priming. Cleaning must be carried out in cases where the outside wall of the house was painted or covered with a decorative “coat”, but at the moment this coating has cracked, is peeling and peeling off.

After cleaning, prime the wall and wait until the surface dries completely. Optimal conditions for outdoor work are dry, windless weather and air temperatures from 5 to 30°C.

Fastening material

Installation of insulation should begin from the top and lay out row by row horizontally. A necessary condition for the most effective insulation is to extend 5 cm or more beyond the panel seam line, and when working with brickwork, extend beyond the outer perimeter of your apartment.

Foam or polystyrene slabs are attached to the wall using “fungi” at the rate of 5 or more pieces per slab. If polystyrene boards protrude beyond the edges of windows or doors, pieces of the required shape are cut out with a saw.