Every owner of a private home sooner or later faces a problem related to the issue of high-quality insulation of his home.

This question may arise at the design stage or when the purchased house requires some modifications to make living in it comfortable.

Why is the air temperature inside a living space not always comfortable? This is due to the following factors:

- The heating system does not function well enough;

- there are many cracks in the walls through which cold air penetrates;

- poor thermal insulation of walls (this is the most common reason).

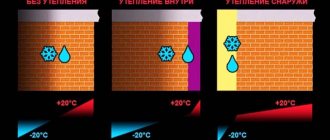

You can insulate your home in one of several ways. Experts strongly advise insulating walls from the outside ; carrying out such work from the inside is recommended in extreme cases.

This is due to the following reasons:

- If the house is insulated from the outside, the walls will be protected not only from heat leakage, but also from the destructive effects of moisture . The heat that comes from inside the house warms the walls, and when moisture gets on them and condensation forms, it favors their rapid drying.

- By insulating the walls of the house from the outside, you will not only protect the room from the cold, but also preserve the usable area of the rooms .

On the modern building materials market there is a large selection of products designed for insulating walls and ceilings. Each of the materials offered by various manufacturers has many attractive qualities. But it often happens that the choice of product depends on one important detail - the cost of the product.

Naturally, building a house is not a cheap pleasure, and sometimes at the final stage of construction work, the homeowner’s wallet becomes much thinner. Therefore, we have to resort to various tricks in order to somehow get out of this situation with dignity. As for thermal insulation, there are many options to reduce the cost of construction, one of which is the use of alternative materials.

Materials for insulation can be:

In this article we will dwell in detail on one of the possible options for wall insulation - thermal insulation using sawdust .

If you use this method correctly, you can achieve good results. This will cost significantly less money, but you need to be prepared for the fact that you will have to do a much larger amount of work.

For this technique, carpentry workshop waste is suitable. This material has both positive and negative properties. Therefore, before making the final decision to begin measures to thermally protect walls with sawdust, you need to carefully weigh everything and study this issue to the smallest detail.

Insulating walls with sawdust: pros and cons

, wood waste from hardwood , namely ash, spruce, pine, etc., is most often

For this purpose, oak sawdust is considered the most suitable option. These raw materials are expensive, but they help preserve heat in the house even in 30 degree frost.

The best option is pine shavings - it contains resin that repels rodents and bugs.

It is best to take sawdust of the medium fraction, since small ones will produce a lot of dust, and large ones will have little effect.

After the sawdust is completely dry, it is worth adding a mixture of copper sulfate and slaked lime (10% by weight).

Insulating external walls with sawdust has its advantages:

- it is easy to work with;

- getting sawdust will not be difficult for you. There are wood processing enterprises in many localities;

- long service life;

- high efficiency;

- environmental Safety;

- low specific gravity;

- excellent noise-absorbing and heat-insulating properties;

- This product can be purchased at the sawmill for free or for a nominal fee.

Disadvantages of the material:

- The insulating layer is of considerable thickness . If the sawdust layer is small, then their effectiveness as insulation will be minimized;

- high fire hazard of the material . Wood shavings readily burn. Using sawdust as insulation for walls greatly increases the likelihood of a fire occurring and spreading;

- the material is not resistant to moisture, it absorbs it well . As soon as liquid gets on the insulating layer, it is fraught with negative consequences: dampness, mold will appear, and harmful insects will appear.

Therefore, if you decide to install such a structure, you need to pay special attention to vapor and waterproofing . If these layers are made without following the technology, the insulation will quickly become unusable. To prevent sawdust from being exposed to moisture, they are treated with special reagents.

But the cost of such material becomes many times higher, and it also becomes toxic and can even cause an allergic reaction. It is not safe to use processed sawdust as a thermal insulation material in a residential frame house.

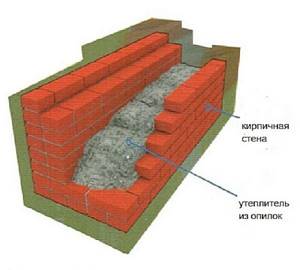

Insulation of walls with sawdust and lime

In order to make wall insulation, which includes lime and sawdust, you need to take these ingredients in a ratio of 1:10 . You need to add a little antiseptic solution (25g per 1 bucket) to the prepared mixture.

Sawdust processing

In order for a homemade heat insulator to meet standards, the first step is to prepare sawdust. They should be cleaned of any impurities (sifted, washed and dried), if any.

Next, you need to impregnate the sawdust with special agents in order to increase their fire-resistant qualities and protect them from rotting processes and the effects of pests.

As you know, each type of wood has its own characteristics. Oak sawdust is highly resistant to bacteria and is practically not susceptible to rotting; its size and density do not change under the influence of moisture.

We invite you to familiarize yourself with the Vapor barrier of walls from the inside of a wooden house: functions, photos, videos which side to glue, tools, vapor barrier from the outside

Softwood sawdust contains a large percentage of essential oils - a natural antiseptic that will protect walls from mold.

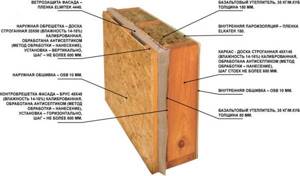

Wall pie device

One of the most important factors when building a house is the correct design of the walls. It doesn’t matter whether you carry out all the construction work yourself, or order a ready-made option, in any case, you must know the correct composition of the “pie” of a frame house.

Layers of the correct “pie” of the wall:

- Frame made of wooden beams.

- There should be insulation between the racks.

- Fiberboard (OSB).

- Horizontal sheathing.

- Insulation.

- Multifunctional membrane.

- Vertical lathing.

- Finishing.

- Vapor barrier.

- Internal lining.

If you use sawdust as wall insulation, you need to make a lathing.

First of all, you need to mount the frame. Then, at a certain distance, you need to attach wooden slats to the wall and lay the sheathing on them.

Detailed installation diagram of sawdust with clay

If you make a mixture consisting of clay and sawdust , you will get an excellent material with waterproofing and thermal insulation properties.

It is well suited for insulating the walls of a house built in any region.

This mixture will keep the house warm in severe frost and will not allow the room to warm up during the summer heat.

Insulating walls using sawdust-clay material is not as simple as it might seem at first glance.

Therefore, during the work process, you must strictly adhere to the following recommendations:

- When preparing the mixture, you must adhere to the exact quantitative ratios of the ingredients.

- The finished mixture must be applied to the walls at a certain thickness. This is the only way you can achieve maximum effect.

- For thermal insulation of walls, you need to make slabs from clay and small sawdust.

Lathing for insulation

A mixture of clay and sawdust can be made and laid in several ways; we will consider one option, that is, laying the wet substance on a sheathing pre-fixed to the wall.

What proportions must be maintained to make the mixture plastic?

Clay diluted with water should be mixed with sawdust in a shallow metal container. You can use a concrete mixer to mix the composition . The finished composition must be applied to the walls.

You can also insulate the walls with such a mixture by pouring it into the formwork attached to the frame wall . If you fix shingles on the wall, then you can spread the clay in a layer of no more than 30mm.

After the sawdust-clay layer has dried, it needs to be leveled with cement-sand mortar and only then plastered.

Manufacturing and laying of slabs

Clay insulation: step-by-step instructions

This material is devoted to the use of clay for home insulation. In this article we will look at the main features of clay, as well as some of the subtleties of the process of insulating a house using this material.

Many people know that clay is a universal material in construction. It has been used in this matter for many centuries, but every year the scope of its application is significantly narrowed. The thing is that clay is gradually being replaced by more modern materials that have better properties. Despite this, in some cases clay remains an irreplaceable resource.

The best publications in the Econet.ru Telegram channel. Subscribe!

First of all, it is worth saying that clay is a good material for thermal insulation of premises. This is precisely why it is used in modern construction. Most often, of course, clay is used when insulating small buildings, where it is enough to have small volumes of insulating material.

The most interesting thing is that the capabilities of clay often exceed the capabilities of some modern insulating materials. Even specialists in many construction stores do not hide this.

Thermal insulation properties of clay

As you know, many years ago clay was used as the main building material for the construction of walls and ceilings. The main feature of this material is hardening under certain conditions. Accordingly, clay can be soaked with water, used for construction work, and after that the material will quickly become almost monolithic.

In modern conditions, ceilings are insulated using clay. Of course, natural material is also used to insulate walls, as well as other objects, but optimal efficiency is achieved only if we insulate the ceiling. Moreover, it is far from a secret that it is advisable to use sawdust along with clay. They are added directly to the clay, thanks to which the mixture obtains good thermal insulation characteristics.

Do not think that sawdust has practically no meaning in this matter. It's quite the opposite. Therefore, if there is a need to insulate the ceiling with clay, then you will have to look for sawdust. Fortunately, they can be obtained completely free of charge from many woodworking companies. Moreover, the insulation process requires very little sawdust.

To prepare the optimal clay-based solution, we will also need a lot of water and containers. Accordingly, this process has many difficulties, so it is better to carry out insulation with partners.

Advantages of home insulation with clay

Obviously, insulating a house with clay has many positive aspects that you should know about. And the advantages are as follows:

- Cheapness. This material is significantly cheaper than analogues that are currently available on the market. Thus, if any problems arise with the clay insulation process, you can safely abandon this idea. Like clay, sawdust can be obtained with a minimum of effort. The main concerns lie in the arrangement of insulation, and this must be remembered.

- Light weight. Again, unlike its analogues, clay has a fairly modest weight. This, in turn, has a positive effect on the insulation process. Quite often, insulation materials are heavy, and this can negatively affect the condition of the ceiling. Accordingly, there should not be such problems with clay, but just in case, you still need to carry out some tests that will allow you to establish the strength of the ceiling.

- Fire safety. There is no doubt that clay is a material that certainly will not cause a fire or its spread. If you need to choose safe insulation, then clay is an ideal option. You should not pay attention to the presence of sawdust in this insulation, since they certainly do not pose any danger.

Well, I would like to repeat again that the process of arranging clay-based insulation is quite simple. In this case, we do not need to have any original devices, much less specialists who deal with such activities. Everything can be done by yourself. Of course, an assistant in this matter will not hurt.

Disadvantages of insulation using clay

It must be admitted that clay is far from the most effective and modern material intended for insulation. Accordingly, many modern insulation materials produced for industrial and residential buildings insulate the room a little better. However, as you know, clay is several times cheaper than most analogues on the market.

In addition, as already mentioned, experts advise using clay to insulate only ceilings or floors. In other cases (wall and floor insulation), natural material looks like a real outsider. In some cases, clay can act as an additional means of insulation.

Well, I would also like to include among the disadvantages that the insulation created can easily become unsuitable for use. Therefore, in this case, it is necessary to take into account the proportions, without which the material will either begin to crumble after arrangement on the surface, or simply will not give any effect.

Tools, devices and other components of the process This process will require quite a few tools. Often the list consists of the following components:

- concrete mixer;

- barrel;

- sawdust;

- clay;

- water;

- capacity;

- glassine;

- putty knife;

- cardboard;

- boards;

- construction stapler;

- hammer;

- nails.

It should be borne in mind that to install clay-based insulation, we will need to create a small structure that will consist of boards, cardboard and other components.

Preparation of clay-based insulating mass

This process is the most responsible. As we mentioned earlier, any imbalance in proportions can be a serious problem.

- First of all, we need an iron barrel in which our future insulation will be mixed. You need to place a certain amount of clay in this container. In this particular case, we will use about 5 buckets of natural material.

- The clay is poured on top with a small amount of water. After this, you need to leave the mass for some time to soak.

- Immediately stir the mixture. This is done until the consistency of the clay becomes like sour cream.

- Next we need a concrete mixer. We put about half of the mixture obtained earlier there. At the same time, sawdust should also be placed in the concrete mixer. As for the proportions, here for 1 bucket of clay there are 2/3 of a bucket of dense sawdust. In this case, the proportions may change slightly. Ultimately we should get a dense mixture. Accordingly, if you end up with something very liquid, you should feel free to add more clay.

Preparing the surface for clay insulation

An equally important step is surface preparation. Here we will need to do everything possible to ensure that the resulting mass is best placed on the surface and demonstrates excellent efficiency (creating formwork). Most often we have a wood base on which all events will take place.

Accordingly, we need to place a waterproofing material on this surface that will protect the ceiling from the penetration of water and moisture. You can find many materials of this kind on sale. The most important thing is to position the waterproofing correctly so that even after some time no trouble occurs.

If the surface on which you plan to install insulation is completely flat, you should think about creating small logs. These wood elements have a certain pitch between them, and filling such “sectors” with the resulting mass will be the most correct solution.

For additional thermal insulation, a layer of cardboard is often used, which is located under the film. But in this case, we slightly worsen the situation related to fire safety, since this material can ignite. As you know, the ceiling must be of the highest safety, especially when it comes to the threat of fire.

The process of insulating the ceiling with clay

It is worth noting in advance that clay insulation is a rather serious process, the implementation of which needs to be thoroughly analyzed. Most often, the issue is that the clay mass takes a long time to dry, so it makes sense to carry out such events in the summer. Accordingly, by winter the mass will become monolithic and will delight with good efficiency. With increased humidity, the clay will remain in its original state, and you can completely forget about some thermal insulation characteristics.

Separately, I would like to say about fire safety. Before the construction process, it is necessary to take into account all the details that could affect the above aspect. Most often, problems arise after the owners insulate the ceiling with clay over electrical wiring. This cannot be allowed, especially since later you will have to carry out the insulation all over again, and this is a considerable amount of work. Accordingly, if we are dealing with wiring, we can use the tubes through which it should go.

The main insulation process includes the following steps:

- First of all, glassine is placed on the prepared surface. This material is often small in thickness, so it is attached to the wood surface using a stapler. If we have a concrete base, then wide tape will do. The most important thing is to ensure good density of the flooring material. As already mentioned, cardboard can be placed under this layer, which will improve the thermal insulation properties.

- Next comes the time to use our clay mass. It is worth keeping in mind that the clay dries for quite a long time, after the prepared mixture you can use it the next day, and even after a longer period of time. We take the barrel containing the clay and fill the voids on the surface. As mentioned earlier, there must be a kind of formwork, which will become an excellent form for clay. The ideal layer thickness should be about 30 cm.

- Of course, many people may think that it is the thickness of the layer that decides everything here. However, it must be borne in mind that too large a mass of clay can have a negative impact on the overall situation related to the operation of the home. Clay is a heavy resource that can damage the ceiling with its large weight. In any case, making a layer of material more than 30 cm simply does not make sense. If there is too little clay, then such insulation will not provide any effectiveness.

- If cracks appear on the surface, it is necessary to immediately begin to act so that the problem does not acquire colossal proportions. To solve this, you need to arm yourself with raw clay and try to grout the cracks.

- You need to wait approximately 2 weeks for the clay to dry. After this, you can safely carry out all other construction activities. At this stage, the created formwork is dismantled (if necessary), after which it is possible to create a wooden floor based on a layer of clay. Obviously, there is no need for this, especially since free access to insulation allows you to quickly get rid of all possible problems. But if this surface is necessary for the movement of people, then it is still worth thinking about creating a floor.

Today, many builders significantly simplify this process. The thing is that the above formwork has many problem areas. For example, after a long period of use, it will be very difficult to remove clay. Accordingly, such work takes a lot of effort.

To avoid this, you can simply create small tree shapes. They can be placed on the surface and filled with clay and sawdust. Further, when you need to carry out some actions with the surface, it is enough to simply remove the form, each of which has very little weight. published If you have any questions on this topic, ask them to the experts and readers of our project here.

PS And remember, just by changing your consumption, we are changing the world together! © econet

Advantages and disadvantages

Recently, the popularity of environmentally friendly construction without the use of artificial materials and without harm to the environment has been increasing. Clay is an affordable material, and sawdust is a waste-free way to use wood. Sawdust has very low thermal conductivity and can retain heat for a long time. Clay is a binder and gives sawdust the opportunity to retain its properties for a long time.

- Insulating walls with sawdust will be very cheap or even free.

- You can repair finished insulation yourself and very quickly. It is enough to mix a small amount of the mixture and troubleshoot.

- The resulting material is an excellent sound insulator on par with the most modern inventions in the construction industry.

- Walls with clay “breathe”, condensation does not form on them, and they do not require the installation of a vapor barrier layer.

Preparing sawdust for floor insulation

First, the sawdust must be treated with a special antiseptic. This must be done to prevent rodents from infesting them. Wood pulp should also be treated with fire retardants to increase the wood's resistance to fire. This will reduce the degree of combustion of sawdust. After this, they need to be mixed with lime and cement.

For the convenience of preparing the mixture, it is better to use a floor or layer of plywood. Pour the ingredients onto the surface and mix with a shovel until smooth. The proportion for such a solution is as follows: five parts sawdust, one part lime and cement (or gypsum), half part water. The most important thing is not to over-moisten the mixture! It should gather into a lump and not fall apart. Then everything is prepared correctly and you can start insulating the floor.

Technology

The process of insulating walls with sawdust concrete is a difficult and labor-intensive process that requires great physical strength, endurance and patience. One person can complete all the work, but with assistants the process will take much less time.

Clay is a heaving material, which means that when it freezes in a water-saturated state, it will swell and collapse greatly. It is recommended to carry out insulation of walls in the summer, then before the first cold weather the mixture will have time to dry and gain strength.

How to prepare the solution?

Clay with sawdust works well as wall insulation only if the materials are selected, prepared and applied correctly. The process of insulating a house begins with preparing a solution and selecting materials. Both components of the mixture can be obtained for free. But it is worth paying attention to their quality.

Clay

The material is available, inexpensive, and in some cases can be obtained for free. You should pay attention to the quality of the material: the presence of foreign objects in the material is not allowed.

You can use clay that you just brought, but to obtain the ideal consistency of the mixture and the durability of the insulation, you need to prepare the clay. To do this, fill it with water, mix it and leave it for the winter. During this time, the material goes through several cycles of thawing and freezing. Natural heaving forces the material to expand and contract again several times, the clay becomes homogeneous and plastic.

Clay can be “skinny” or “fat”; plasticity depends on the fat content. When using “oily” (plastic) clay, it is necessary to add a little sand to the insulation composition.

Clay for preparing the solution

Before starting work, the clay must be prepared: left for the winter in a water-saturated state.

Sawdust

Sawdust is a waste product from the wood processing industry. They can be specially purchased at a low price at any enterprise. To insulate walls, you can use different sawdust, which have their own beneficial properties:

- Oak almost does not change its size and density under the influence of moisture, almost does not rot, and is resistant to bacteria.

- Coniferous sawdust is less susceptible to mold formation than other types of wood due to its high content of essential oils.

When insulating walls, you can use a mixture of several types of sawdust.

Before starting work, sawdust must be prepared:

- First, the sawdust is removed from impurities, sifted and washed.

- After this, the sawdust is thoroughly dried.

- Dry sawdust must be impregnated with compounds that protect the wood from rot, mold and fire.

Sawdust for preparing the mixture

You can use mixed sawdust to obtain better properties of the thermal insulation material.

Preparation of the solution

To properly prepare the mixture, you need a set of tools:

First, the clay is soaked in one of the barrels. Leave it for several hours and stir occasionally until it becomes homogeneous. After this, 1–2 buckets of clay are poured into a concrete mixer and sawdust is gradually added there in a ratio of 3:2, respectively.

To achieve better thermal insulation properties, technical salt is added to the mixture, but in this case the proportion of clay and sawdust changes to 1:1.

After a short stay in the concrete mixer, the mixture is ready for use; it is poured into a second barrel or installation begins immediately.

Application

To apply insulation to the walls, you can use formwork, but this method is very labor-intensive; it is much easier to prepare slabs from insulation:

- To make slabs, you need to make several molds for them in advance. Their size will depend on the parameters of the wall. You can prepare the forms yourself by assembling them from plywood and blocks using nails and a hammer. The thickness of the insulation boards will depend on the average winter temperature and the presence of technical salt in the mixture.

- The mold is filled with the prepared solution in small portions and periodically leveled. It is advisable to minimize the number of air bubbles and thicken the mixture.

- The installation of the slabs is carried out after the material has hardened; you can use slabs that are not completely dried, it is enough that they simply hold their shape.

- The plates are installed close to each other and secured.

- The joints, chipped corners and gaps are covered with the remains of the clay mixture.

Installation of clay slabs with sawdust

For installation, wooden guides are used, slabs are placed between them and then the joints are rubbed with the remainder of the clay mixture.

This technology for home insulation ensures cleanliness in the room during installation. Raw clay is a very dirty material that is difficult to clean. It is not recommended to use it in rooms where installation work has already been completed. The slabs can be prepared in another place, keeping the room clean.

It is very important to dry insulation boards correctly. When the slabs dry quickly, a dense dry crust forms on the surface, preventing the water inside from escaping, which leads to uneven drying, damage and loss of thermal insulation properties. To dry the slabs evenly, they must be left in a room with sufficient humidity and protected from direct sunlight.

The nuances of ceiling insulation using clay

Clay is a building material that is considered environmentally friendly due to its natural origin. It is easy to mix with water until smooth, and as it dries, the clay becomes hard and retains heat excellently. It is often used to insulate floors in small rooms.

It is quite difficult to use it for insulation in its pure form, since it creates a significant load on the ceiling, and the drying process takes quite a long time. And if you reduce the thickness of the layer, then the necessary effect of the thermos is lost. To build an insulating “pie,” various additives, such as straw, sawdust and other natural ingredients, are mixed into the clay solution. If all proportions are correctly observed, the effect of such insulation can surpass the performance of many more modern materials. It is strongly recommended to use a concrete mixer when mixing, since the mixing process is very labor-intensive.

Expert opinion

Konstantin Alexandrovich

The recommended application layer is from 30 centimeters. This layer takes a long time to dry. Because of this, it is better to carry out insulation work with clay in the summer, since the wet composition does not have the ability to retain heat.

Pros and cons of clay insulation

The popularity of clay insulation is due to its following properties:

- The most affordable price. There is simply no other insulation material that can compare with clay in terms of cheapness. You can dig up and deliver the material yourself.

- Clay is not able to burn and maintain combustion, and therefore prevents the spread of fire. It is allowed to be used even in the area where chimneys are laid.

- The material is not attacked by harmful insects, rats and mice, and also does not mold.

- Adding low-weight fillers to the solution significantly reduces the mass of the original raw material. This allows you to avoid creating excess load on the building’s floors and its walls.

- One of the most important advantages of the material is its high environmental friendliness and safety.

- Simple insulation technology allows you to complete all the work independently.

- Clay has a positive effect on the condition of the wooden parts of house floors and allows them to maintain high performance characteristics for a long time.

- It is possible to reuse the dried clay mixture. To do this, you just need to fill it with water. Thus, the generation of waste during work is practically eliminated.

- Soaking with water gives the clay special plasticity, which allows the material to reliably isolate all the recesses and cracks present on the insulated surface, regardless of its configuration.

- There is no need to install wooden flooring on the attic floor, since the dried clay solution itself is highly durable and hard.

Despite the impressive list of advantages, modern materials for thermal insulation have significantly displaced natural materials.

This is due to the fact that along with the advantages there are also noticeable disadvantages:

- This method cannot be called the most effective. Professionals advise using clay insulation in combination with a modern type of basic insulation.

- It is necessary to strictly adhere to clearly defined proportions when mixing the clay solution. Otherwise, its structure will be too crumbly and the insulator will not cope with its functions.

- The mass of the clay mixture turns out to be quite significant even in combination with lightweight components, such as sawdust. This fact must be taken into account so as not to overload the floors of the building.

Finishing

The slabs of clay with sawdust themselves have an uneven surface; it can be leveled using a special plaster mixture made from sawdust - wood concrete.

The mixture is applied after the insulation boards have completely dried. Plastering of walls occurs in 2 layers: first, rough rough plaster, then grouting without adding sawdust.

To prepare the solution you need to take small sawdust, water and clay with lime. The materials are mixed using the previously described technology and immediately applied to the walls, further increasing thermal insulation. Apply the solution with a spatula and level it as much as possible. The layer thickness is 2–3 mm.

The final layer will be the same solution, but without adding sawdust; it is carefully applied to the walls, leveled and soon hardens. After this, the room can be wallpapered or painted. The material is durable, reliable and easy to repair; the insulation will serve the owners for many years.

Hello, our dear readers.

We live in difficult times. The cost of living is growing exponentially every day, forcing you to save on literally everything, or at least try to do so. Of course, it was time for building materials. So, some are trying to find out what kind of insulation clay is.

The product is essentially a “ball” product, you don’t have to buy it in a construction store, just take it and dig, there are places for this in any village. Let’s also look for the truth, because if the “Kulibins” are right, then there is no point in buying environmentally questionable foam plastics.

Do-it-yourself floor insulation technologies with sawdust

This material is practically never used in its pure form, without any binders. Even dry installation requires mixing with lime or pouring with a solution of boric acid.

For all methods, it is necessary to cover the subfloor with a waterproofing film - roofing felt or polyethylene - before backfilling. It is also necessary to consider a ventilation system, which is absolutely necessary for any sawdust insulation.

Dry filling method

Involves backfilling without adding binders:

- Sawdust for dry floor insulation must be well dried.

- Before filling, it is recommended to mix with slaked lime. One volume of lime per 10 – 15 volumes of sawdust. This mixture repels rodents and destroys insect larvae.

- You can also spill the mixture before filling with a solution of boric acid as an antiseptic. Then it will need to be dried again.

- Backfilling is carried out in two layers. The bottom one is filled with shavings 10–15 cm high, then carefully compacted.

- The second layer is filled with sawdust dust. It fills the voids in the chips. Final compaction is being carried out. The total thickness of the two-layer backfill must be at least 30 cm.

- The poured insulation should stand for 2 - 3 days. Since it will settle during this time, it will be necessary to bring it to the required level.

- You can immediately pour the initial layer 10 - 15 cm more than required. It will settle exactly to this thickness.

- Before laying the finished floor, check whether there will be a gap for ventilation of the insulation.

Dry insulated floor

The dry method is used relatively rarely. More often, the addition of binding elements - cement or clay - is used. This worsens the thermal insulation qualities, but provides protection against fire and sharply reduces the possibility of sawdust rotting.

Method of insulation with cement-sawdust mortar

Procedure:

- A sand substrate 5 cm thick is laid on the prepared subfloor.

- Materials are prepared - a mixture of shavings and dust, cement and water. The ratio is for 10 volumes of sawdust, 1.5 volumes of cement and 1 volume of water.

- The sawdust mixture is thoroughly mixed with cement.

- Then water is added and the resulting solution is also mixed. It is better to add water in small portions to avoid poorly mixed pieces of solution.

- Copper sulfate can be added along with water as an antiseptic.

- The solution is unloaded onto the prepared substrate between the lags. A layer thickness of 10–15 cm is sufficient.

- The readiness of the hardened sawdust-cement layer is determined by pressing on it. It should be elastic, but not pressed through.

- Laying the top layer of waterproofing and laying the finished floor.

Floor insulated with cement-sawdust mixture

Insulation with sawdust and clay

The advantage of clay as a binder is that it is also a natural material. But preparing the clay-sawdust mixture is more complicated.

Preparing a mixture of clay and sawdust

- You will need two containers - one for kneading clay, the other for mixing it with sawdust and shavings.

- It will be useful to use a construction mixer, since it is difficult to stir the clay by hand.

- The clay is soaked and mixed until a thick, homogeneous mass is obtained.

- Mixing clay and sawdust is carried out in a volume ratio of 1:1.

- To improve the thermal insulation properties, technical salt is added to the solution.

- The finished solution is laid out on the subfloor in several layers. Each new layer is added after the previous one has partially dried.

- The total thickness of the layer is brought to 10 - 12 cm. After this, it is left until completely dry.

- After the solution dries, cracks may form on it. They need to be additionally coated with a small amount of the same composition.

Laying clay-sawdust insulation

In conclusion, it should be repeated that when using wood chip waste for floor insulation, it is necessary to comply with the rules for preparing the material and treating it with antiseptic agents. The work itself of laying sawdust insulation, although it requires effort, is accessible to anyone.

A little physics

Before delving into the technological aspects of using the product, let’s look at its physical and technical characteristics. And they are not too happy. Thus, the density of hardened clay is 1600-2400 kg/m3 (slightly less than that of concrete), and the thermal conductivity is 0.7-0.9 W/m°C.

It turns out that clay as a wall insulation is, to put it mildly, useless, so why is it still used?

The fact is that this material is an excellent binder, the strength of which is not affected in any way by the sucrose found in organic fillers (it is destructive for concrete), and this, in turn, opens up the widest scope for maneuver.

Clay with sawdust as insulation

One of the most popular options is clay with sawdust for insulation on the ceiling. Wooden shavings, especially in their loose state, retain heat well, and you can collect them in any carpentry shop for a nominal fee.

There is only one drawback: over time, the loose mass sags, losing part of its thermal insulation properties.

But if it is mixed with gypsum or liquid clay, the “fluffy” structure will remain for a long time, which means that the use of such technology is not without meaning.

Types of sawdust

Sawdust comes in a variety of varieties, and each type is significantly different from each other. Taking into account the peculiarities, it is also necessary to use various preparatory measures and laying methods. For greater understanding, we should take a closer look at the main differences.

Dimensions

By fraction, the material is of the following type:

- Trash. Small particles of wood that appear when it is cut. The size of the debris is affected by the saws used for cutting. It also mainly contains wood dust.

- Shavings. Often this is waste generated during carpentry work when planing and drilling wood.

A small amount of dust is the most optimal solution for thermal conductivity, creating a dense coating that does not allow heat to pass through and only shrinks slightly over time. If the insulating layer consists exclusively of shavings, then its quality indicators are lower and in the future its volume decreases significantly.

Taking these features into account, both types of material are mainly used, but in different proportions.

Wood type

It determines whether sawdust is suitable for use as thermal insulation or not. For insulation, it is recommended to give preference to materials made from coniferous wood - pine, larch, spruce. The resin present in them acts as a barrier, preventing the occurrence of rot and repelling rodents and insects.

Sawdust from beech and oak trees is also a suitable option. Waste from birch trees has low thermal conductivity, but unlike coniferous trees, it is much easier to rot.

Moisture level

This is one of the main indicators that should be taken into account especially when carrying out insulation using the dry method without the use of additional binding materials. In such a situation, the moisture level should not be more than 12-14%.

Sawdust obtained during carpentry work has the lowest degree of humidity, since in these cases dried wood is used. Most of the material that appears when cutting logs does not have an optimal level of dryness, which is why additional drying is required before using it.

Material quality

It is affected by the following:

- Duration of storage of sawdust after receiving it. The more time has passed since then, the more likely it is that they have begun to rot. With this in mind, it is better to purchase the material immediately after it occurs.

- Presence of bark in sawdust. If they are present, there is a significant reduction in quality. The bark not only reduces thermal insulation properties, but is also a suitable environment for insect larvae and the beginning of the rotting process.

- At some enterprises, wood waste may contain traces of automobile oil, but in addition to its unpleasant appearance, this in no way has a bad effect on the quality of the sawdust itself or its performance.

Recipe

If you are interested in clay with sawdust as insulation, the proportions here are simple. For three buckets of clay, take two buckets of wood shavings, mix it all and fill the space between the joists with the resulting mass.

You can easily not only walk on such insulation, but also dance, but you can’t call it too effective. Of course, the proportion of wood material can always be increased, but then the insulation will lose strength, which means that some kind of floor will have to be invented on top of it.

Ceiling insulation

Cardboard or glassine is spread over the entire area .

The clay-sawdust mass is applied to it in thin layers, the next layer is added after the previous one has partially dried. When the thickness reaches 10-12 cm, the work can be considered complete. In summer and ancillary non-residential premises, a five-centimeter thickness of insulation is sufficient. Make sure there are no microcracks.

The design of some houses is such that the construction of formwork is not required : its functions are performed by closely spaced ceiling beams. In this case, the voids between them are filled with clay and sawdust.

To form and install insulation you should have on hand:

- boards in the required quantity;

- nails and hammer;

- putty knife;

- tape or stapler;

- waterproofing film;

- cardboard (used in ceiling insulation).

Adobe as insulation

Another interesting option for using clay is adobe. Previously, it served as the main structural material for the construction of walls, but today it is used only as insulation.

Here the filler is no longer sawdust, but straw. Again, an environmentally friendly product with excellent thermal insulation properties and, again, the purchase of which will not ruin your budget.

To acquire adobe, you only need to have a wooden mold and the desire to work. Kneading (clay and straw are kneaded with feet) is usually done right next to the clay quarry, where the resulting mass is filled into molds, and the blocks dry there.

The whole process is quite labor-intensive, but if this point doesn’t bother you, you can get a material with a thermal conductivity of 0.1 W/m°C, and this is already a pretty good indicator.

Composition of clay insulation

Red clay is considered optimal for the preparation of insulating composition. Red clay is quite hygroscopic and plastic. You can also use white clay, which is slightly inferior in these characteristics.

The maximum insulation effect can be achieved if insulation is carried out with clay with the addition of sawdust or chopped straw.

It is better to choose sawdust from coniferous or oak wood. When preparing this component for the manufacture of insulation, the sawdust should be dried and soaked in an antiseptic. To protect against rodents, lime should be added to the solution.

Clay-straw insulation is also actively used, when instead of sawdust, chopped straw is introduced into the clay solution. Most often, the roof or ceiling is insulated with straw, but it is also possible to insulate the walls.

Preparing a mixture of these components is one of the main points in the process of insulating the walls of a frame house. The result of insulation will depend on the quality of the composition. If the proportions were violated during the preparation of the clay mass, the insulation will not perform its functions fully; most likely, after drying, it will crack and crumble.

The process of applying the clay mixture is not that long. It will take more time for the clay layer to dry out, which at above-zero temperatures will take at least a month.

Expanded clay as insulation

But still, the best filler should be considered not sawdust or straw, but ordinary air. The developers of expanded clay were probably guided by these principles when they created their product.

Yes, if anyone didn’t know, expanded clay is foamed and fired clay. This insulation is proven and, especially in Soviet times, was used everywhere in construction. Among its disadvantages are its rather significant weight (and in private construction, every kilogram counts) and fear of water.

By the way, hydrophobia is a common disadvantage for all clay insulation, so if you plan to use them in a humid environment, you can abandon this idea right now - nothing good will come of it anyway.

Unfortunately, you won’t be able to make expanded clay at home, but its market value is not too high anyway, so if the strength of the floors allows it, take note of the material.

Well, that's practically all. We have dealt with clay as an insulation material. Tips on how to use this wonderful natural product were given. It's time to say goodbye. Goodbye and see you soon on the pages of our blog.

How to choose sawdust for thermal and sound insulation of the ceiling

Sawdust is divided by fraction:

- small;

- average;

- big.

Experts recommend giving preference to the second type, because fine-grained materials are difficult to work with, and coarse-grained ones cannot provide high-quality heat insulation.

When purchasing wood shavings formed from round logs at a natural moisture level, make sure they are thoroughly dried. If they are not sufficiently dried, you need to lay them out on a horizontal surface and leave them for a week under a canopy. In humid weather, the drying period is increased. It is also recommended to place thick burlap under the sawdust.

It is better to choose coniferous wood as sawdust for insulating the ceiling in a private house, because... They have a high level of resin, which helps prevent insects. The bath should be insulated with larch shavings. Such material, when mixed with ash, reduces the risk of rotting processes.

Important: after purchasing sawdust, you must wait at least six months. This will reduce sugar, which causes rot.

Indicators of high-quality sawdust are the absence of moisture and mold. It is necessary to ensure that foreign impurities and debris do not get into the chips. If this happens, the material is sieved, and large particles are selected by hand.