Gearbox installation

According to the rules for water supply and sewerage, the installation of a water pressure reducer must be carried out directly after the shut-off valves.

The devices are installed before the metering devices, which will protect them from water hammer and also ensure the accuracy of the readings. Therefore, this installation location is considered the most suitable and reasonable. But sometimes there are situations when it is not possible to carry out installation on this particular section of the pipeline. Installation of the water pressure regulator is carried out in accordance with certain rules. There should be no possibility of water intake before the metering device. This means that the plugs used to wash the filter will be sealed. This will eliminate the possibility of servicing the gearbox. There are several ways to solve the problem.

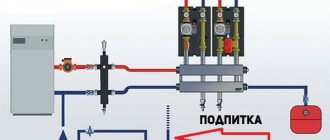

Installation diagram of the water pressure regulator in the apartment

The first method involves installing additional pressure gauges, which will make it possible to more accurately adjust the device. In the second case, the pressure reducer is installed directly in front of the manifold. This option is most often used by experienced plumbers.

Sometimes it is not possible to install a regulator at the system input. As a result, some components are left without protection against water hammer and pressure drop in the pipeline. To solve the problem, primitive models of gearboxes are used. They are not adjustable, but are quite suitable for protecting system components from water hammer.

Video:

Video:

Piston water regulator: operating principle

In a piston regulator, the balance of incoming and outgoing pressure is achieved by a spring pushing the piston (see figure below). It works like this:

Water enters the first chamber, from which it passes into the second through an opening. When the pressure in the second chamber increases, it pushes the piston, which compresses the spring. The locking disc closes the passage hole and the pressure in the second chamber decreases.

When the water pressure decreases, the pressure in the first chamber decreases. The spring pushes out the piston and locking disc. Through the passage hole, water enters the second chamber and the pressure increases.

The device of a piston water pressure regulator.

The flow force can be adjusted by moving the spring and piston through the second chamber. For this purpose, such devices have an adjusting screw. By tightening it, you reduce the outlet pressure, and by unscrewing it, you increase it.

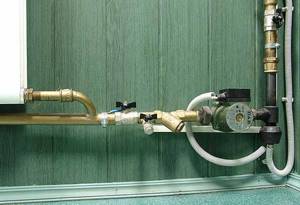

Step-by-step installation instructions

The simplicity of the design and ease of adjustment make it possible to carry out work on integrating the device into the plumbing system without having professional skills.

Installation

Installation procedure:

- Determine the installation position of the device. An arrow image is found on the body of the device and combined with the direction of water flow in the system.

- The pressure regulator is installed in the pipeline system using two half-mounts (at both ends).

The common name for this compound is “American.” Usually these spare parts are included with the product; if they are not available, they can be easily selected in any specialized store.

Depending on the material of the water supply pipes (foamed propylene, metal-plastic, metal), the appropriate half-sections are purchased. In some cases, the purchase of adapters is required.

In the polypropylene version of pipelines, connecting products are soldered to the ends of the pipes using a welding soldering iron. Then install the regulator itself by tightening the nuts of the half-mounts on both sides of the device. When the pipeline is made of metal, the connection is made using flax and plumbing sealant

To install half-slopes using this method, you will need gas or adjustable wrenches. The same tools are used to tighten the nuts on the threaded ends of the regulator when connecting it to the water supply system. If the gearbox being installed is equipped with a pressure gauge, during installation pay attention to the visual accessibility of the readings on the device dial.

Adjusting the device

The standard pressure in the water system is 2-4 atm, the real one is always higher. The factory preset of pressure regulators corresponds to an average of 3 atm. For a longer service life of the gearbox, the drop in water pressure after the device should not exceed 1.5 atm in constant operation.

To obtain the required pressure, adjust the gearbox:

- using shut-off valves (ball valve, valve) shut off the water in the home water supply system;

- using a flat or figured screwdriver, turn the adjustment screw to the desired angle;

- open the inlet tap and at the same time the faucet valve of the sink or bathtub, monitor the setting readings using the pressure gauge;

- the process is repeated until the desired results are achieved.

In modern models, a knob and a pressure scale are provided to adjust the pressure. Depending on the direction of rotation of the handle, the water flow at the outlet of the device decreases or increases.

How to choose a pressure reducing valve

Honeywell water regulator

When choosing a Honeywell water regulator, you should pay attention to the following parameters:

- water pressure regulator device;

- specifications;

- device manufacturing material.

The right combination of all these factors will allow you to select a device that will ensure the normal operation of engineering communications.

Specifications Honeywell D04FM

| Setting range (bar) | 1,5-6,0 |

| Static pressure PN | 16 |

| Production | Germany |

| Max. ambient temperature | 70 |

| Pressure reducer | Yes |

| Capacity m3 | 2.9 |

| Connection Diameter (inch) | 3/4 |

Honeywell water regulators are considered very reliable, but the cost accordingly starts from 1,500 rubles for the D04FM model.

Video:

Modern gearboxes come in piston and diaphragm types. The piston is highly resistant to wear. But despite this, gearboxes of this type are characterized by low operational reliability. This is explained by the nature of water purification and the possibility of corrosion on the elements of the product. So, if the liquid may contain small particles of dirt and sand, which will lead to jamming of the device. The only solution is a water pressure regulator with a filter.

Pressure regulator RD-15

The RD-15 membrane water pressure regulator has two working chambers, which are separated by a diaphragm. This makes the device unpretentious in maintenance and reliable in operation. One chamber is completely sealed, which prevents water from entering it. This is where the main part of the structural elements is located. This water pressure regulator circuit allows you to protect the device from corrosion and jamming. Proper use of the reducer and the integrity of the diaphragm ensure a long service life. And the cost ranges from 300 to 500 rubles and has different versions. It is the most frequently used and has a certificate of conformity.

Pressure regulator RD-15

Parameters of water regulator RD-15

| Parameter name | Meaning |

| Nominal diameter DN | 15 |

| Conditional pressure (kgf/cm2) | 1,0 (10) |

| Regulatory zone | 40 |

| Upper setting limit (kgf/cm2) | 0,4 (4) |

| Conditional throughput /h | 1,6 |

| Regulator weight | 0,35 |

Far water regulator

When choosing a water regulator from Far or another company, you should pay attention to its technical parameters. First of all, this concerns the values of inlet and outlet pressure

Solving this problem is quite simple. You need to find out the requirements for the device in a particular pipeline, and also study the instructions for the water pressure regulator. It is here that manufacturers indicate the nominal operating pressure values.

Far water regulator

- Maximum inlet pressure: 16 bar.

- Adjustable pressure: from 1 to 6 bar.

- Maximum temperature: 75°C.

- Set pressure: 3 bar.

The operating temperature is also important. So, some models are capable of operating in temperatures from 0 to 40 degrees. Such devices are used only in cold water supply systems. For hot pipelines, models that operate in a range of up to 130 degrees are suitable.

But the cost of a far water regulator already starts at 2,500 rubles.

Video:

Valtec pressure regulator

Italian Valtec water pressure reduction valves, which are reliable and pleasing with their price (from 800 rubles), are gaining particular popularity. Perhaps this is the average price segment for water pressure regulators for multi-storey buildings.

Valtec pressure reducer VT.087

Video:

Material

Such devices must be made of durable material. If we are talking about alloys, then they must contain alloys that prevent the occurrence of a corrosion process

Experts recommend paying attention to the best water pressure reducers from well-known manufacturers. Of course, such products will cost a lot, but a long service life is guaranteed.

There are also GOST standards for valves that reduce water pressure.

Regulatory requirements for apartment pressure regulators

Kinds

There are many designs and sizes of similar devices on sale that are designed to work in various networks or systems.

When choosing, you need to pay attention to the main parameters of the gearbox:

- Connecting dimensions. This is an important characteristic, since all household networks have a standard size of threaded connections - 1/2 inches.

As a rule, gearboxes are installed as part of an assembly - a ball valve-filter and a coarse cleaning meter.All of these devices have 1/2" threads and are connected in series with each other.

If the gearbox has a different thread, you will have to complicate the assembly and look for adapters. In addition, unnecessary connections will appear, which will increase the risk of leaks.

- Maximum permissible temperature. This characteristic will help determine which line the reducer is suitable for - hot or cold.

- Device design.

Mechanical

The pressure is adjusted using a special valve that changes the size of the passage for the water flow. The valve is acted upon by a spring, the force of which balances the water pressure.

As soon as it changes, the spring will either stretch or compress, reacting to the jump that has occurred. Mechanical devices are simple, easy to install and configure. In addition, these types of devices are inexpensive, which increases their popularity among users.

Flow-through

This is a specific design designed to reduce excess water pressure while simultaneously reducing flow. There are no moving parts inside such a device, which makes it almost eternal.

The water pressure is reduced by branching the flow into a network of small channels. At the output, they are again combined into a single stream, but with changed parameters.

Note! The only problem with such devices is their dependence on water quality. Small particles gradually clog the channels, gradually disabling the gearbox.

Electric

This is a group of devices that provide precise and instantaneous adjustment of flow parameters. They have different designs, from fairly simple mechanisms with a servo drive pushing a rod with a valve, to complex devices with pressure sensors, drive devices and a lot of additional functions.

Despite their capabilities, electric gearboxes are not in great demand. They require power supply, maintenance and frequent adjustments. The price of these devices is much higher than that of mechanical models.

Auto

All gearboxes operate on an automatic principle. Therefore, absolutely any device can be included in this category, regardless of its design and technical parameters. This is precisely the value of the device - automatic pressure change that does not require human intervention.

However, there are also automatic gearboxes with a function to start circulation. When the pressure increases, they stop the pump, and when it decreases, they start it, ensuring the nominal operation of the system.

Important! Used in autonomous water supply and heating systems.

Domestic

Household gearboxes are designed to operate with flows of a certain pressure and temperature. Unlike industrial models, they are able to regulate pressure only up to 15 atmospheres. In residential buildings, apartment buildings or private houses, this is quite enough, and household appliances and plumbing require even less.

Membrane

The role of the valve is played by an elastic membrane, which is balanced by a spring. Diaphragm reducers are less dependent on water quality, so the demand for them is higher.

Find the full characteristics of membrane regulators here.

Piston

Piston devices are a classic type of mechanical gearbox. The functions of the valve are performed by a piston that closes the passage for the flow of water.

The forces are balanced by a spring, the tension of which is adjusted by a screw. The simplest, cheapest and most popular design.

Electronic

Electronic gearboxes are the most expensive and complex devices. They have high accuracy, but are quite capricious and require good working conditions.

Reference! Used in conjunction with expensive imported plumbing or household appliances.

Full information about electronic water pressure regulators in our article.

Which type and when to choose?

The choice of gearbox depends on its operating conditions, plumbing features and other factors. If the house has a lot of imported plumbing elements, dishwashers and washing machines, shower cabins, etc., you need a high-quality and accurate gearbox with a guarantee of performance.

To simply reduce drops and cut off water hammer, a simpler mechanical model is suitable.

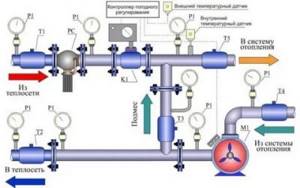

Pressure in the heating system of MKD

The operating pressure in the heating system of an apartment building is one of the most important indicators in the operation of the entire complex heating and water supply system. The quality of the transferred heat, as well as the condition of the equipment, its reliability and strength directly depend on it. Current standards must be constantly monitored by specialists and be within the established framework of SNiP. We will touch on this topic in detail in the next article.

Heating of apartment buildings

The pressure in the heating system in an apartment building performs several fundamentally important functions, including:

- The quality and level of efficiency of the existing heating system. Uniform heat is provided in the radiators of the house solely by setting the pressure and pressure of the coolant in the heating system to the established norm.

- Reducing heat loss. Thanks to the stabilization of the indicator, heat reaches the batteries at almost the same level as when entering. If the indicator is not within the norm, then the heat loss from central heating can be colossal.

An interesting feature is that even in summer the batteries must maintain a certain level of pressure in the system. This condition protects coolants from corrosion, extends their service life and helps, if necessary, to quickly turn on heat in apartment buildings.

Factors influencing the level of the indicator

What pressure the regulator will record in the central control is determined by the following factors:

- current condition of the equipment;

- location of the apartment (depending on the floor and the distance of the living space from the riser);

- heating system power;

- number of floors in residential buildings;

- pipe diameter (the larger it is, the warmer the room);

- coolant wear level.

The operating pressure in the system on the 1st and 8th floors may differ slightly. The permissible difference in this case is 10%. However, with new equipment the difference is almost unnoticeable. Please note that ideally the heat level in the room should not depend on the location of the apartment!

Optimal performance in the heating system of an apartment building

The pressure level in the heating system of a multi-storey building is set in accordance with the requirements of SNiP and GOST. According to the regulations, operating parameters must be set in such a way as to ensure a room temperature of 20 to 22 degrees Celsius while maintaining air humidity from 30% to 45%. Thus, here is what pressure in the central heating the regulator should record:

- Less than 5 floors. Performance indicators in pipes should be maintained at 2-3 atm.

- Up to 9-10 floors. In this case, the pressure in the batteries will have to be increased to a level of 5-7 atm.

- From 10 floors and more. The highest level is maintained at 12 atm.

Please note that the more floors there are in the house, the more energy we will need to power it. That is, in order for all residents of apartment buildings to receive the necessary heating at the beginning of the heating season, it will take more time if the number of floors is large.

Equipment check

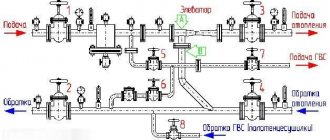

If the heating level does not suit you, then the issue may be either in the installed radiator (its quality, etc.) or in the pressure level in the system. The last indicator can be clarified and checked in critical areas of the central coolant:

- at the outlet of the coolant supply;

- at the outlet of the pipeline from the central thermal power plant or boiler house;

- before such elements as a pump, pressure regulator, sump, filter, as well as after them;

- at the entrance of the pipeline into the house.

The pressure in the pipes must be checked using special tubular strain gauges. Today, many systems are equipped with automatic level control. In this case, additional installation of special sensors of various types is necessary.

Varieties

The heating system of apartment buildings relies on 3 types of pressure in the system, including:

- Static. It is also called manometric. It is calculated according to the principle of 0.1 MPa (or 1 atm) per 10 m. It is noted in shut-off valves, pipes, and radiators. The more floors in the house, the higher this figure. It is also necessary to specifically use powerful pumps to increase this pressure in order to overcome the rising columns of water.

- Dynamic. It is fixed directly when the central pump is turned on.

- Working. It is calculated as the sum of static and dynamic pressure.

Please note that residents often purchase radiators or pipes for their home that exceed the specified diameter in diameter. Because of this, the heat level in their apartment increases. However, this disrupts the stability of the central pipeline and requires large energy costs.

Checking the tightness of the system

The operation of the heat pipe system is ensured not only by normal pressure, but also by high-quality tightness. Typically, the level of tightness is checked before the start of the heating season to ensure that residents have adequate heating. The check is carried out in 2 stages:

- "Cold" check. The pipeline is deliberately filled with cold water, after which the pressure level in the system is measured. During the first 30 minutes after filling, it should not fall below the established standard - 0.06 MPa. When 2 hours have passed after filling, this level may drop to 0.02 MPa. If during this check depressurization (breaks) was detected, this means that the system is not ready for the start of the heating season and needs repair work.

- Hot water test. It is produced immediately before the heating season. Hot water is supplied to the pipes at a higher pressure than is permissible, after which the set pressure is also measured. The test results also determine the integrity and suitability of the equipment.

If residents want to check their equipment individually, they can personally contact special private companies that engage in this type of testing. This procedure is affordable, can be done quickly, and results in a maximum reduction in heat loss.

How does the hot water system work during surges?

Minor deviations from the established pressure standard are normal. However, if the difference is observed consistently and affects the quality of heating, then an urgent check of the equipment is necessary. Please note the following features:

- The jumps are mostly upward. This indicates that the heating system is becoming airy.

- The difference is downward. They show that there is a failure in the circulation of coolant through the pipes.

If you put off checking all systems, they can fail very quickly. Therefore, security officers are forced to turn off the heating in this case in order to quickly find the cause of the breakdown and solve it.

Pressure in the heating system of an apartment building Link to the main publication

Source: https://okommunalke.ru/voprosy/davlenie-v-sisteme-otopleniya-mkd

Step-by-step installation instructions

The simplicity of the design and ease of adjustment make it possible to carry out work on integrating the device into the plumbing system without having professional skills.

Installation

- Determine the installation position of the device. An arrow image is found on the body of the device and combined with the direction of water flow in the system.

- The pressure regulator is installed in the pipeline system using two half-mounts (at both ends).

The common name for this compound is “American.” Usually these spare parts are included with the product; if they are not available, they can be easily selected in any specialized store.

Depending on the material of the water supply pipes (foamed propylene, metal-plastic, metal), the appropriate half-sections are purchased. In some cases, the purchase of adapters is required.

In the polypropylene version of pipelines, connecting products are soldered to the ends of the pipes using a welding soldering iron. Then install the regulator itself by tightening the nuts of the half-mounts on both sides of the device. When the pipeline is made of metal, the connection is made using flax and plumbing sealant

To install half-slopes using this method, you will need gas or adjustable wrenches. The same tools are used to tighten the nuts on the threaded ends of the regulator when connecting it to the water supply system. If the gearbox being installed is equipped with a pressure gauge, during installation pay attention to the visual accessibility of the readings on the device dial.

Adjusting the device

The standard pressure in the water system is 2-4 atm, the real one is always higher. The factory preset of pressure regulators corresponds to an average of 3 atm. For a longer service life of the gearbox, the drop in water pressure after the device should not exceed 1.5 atm in constant operation.

To obtain the required pressure, adjust the gearbox:

- using shut-off valves (ball valve, valve) shut off the water in the home water supply system;

- using a flat or figured screwdriver, turn the adjustment screw to the desired angle;

- open the inlet tap and at the same time the faucet valve of the sink or bathtub, monitor the setting readings using the pressure gauge;

- the process is repeated until the desired results are achieved.

In modern models, a knob and a pressure scale are provided to adjust the pressure. Depending on the direction of rotation of the handle, the water flow at the outlet of the device decreases or increases.

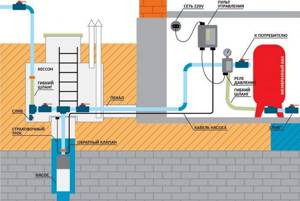

Hydraulic accumulator: operation and reasons for its failure

One of the most important “team players” is the hydraulic accumulator, which allows you to create and store a supply of water, protect the system and equipment from force majeure situations. This device is called differently, sometimes not quite correctly: expansion or storage tank, hydraulic tank, expansion tank, membrane tank, or simply - HA. This is a closed container that has a hydraulic chamber that changes its volume. In order to imagine how a hydraulic accumulator works, it is necessary to consider its design.

Membrane tank design

Any hydraulic tank has a certain number of elements. It includes:

- housing made of stainless steel;

- membrane (pear), which is made from special, elastic and durable rubber (EPDM, BUTYL);

- air supply nipple;

- a flange equipped with a valve, it is intended for pumping water;

- special instruments - pressure gauge, pressure switch;

- platform (supports).

As you can see, the device is quite simple, but continuous, intense work can “ruin” even the most reliable structures. Modern high-quality models of storage tanks have a long service life, work for a long time, and without “whims”. However, you need to know about possible malfunctions of the hydraulic accumulator, since some breakdowns cannot be ruled out.

Vessel tasks and their implementation

The storage tank consists of two chambers: one contains air, the other contains water. The last compartment deserves special attention. This is a rubber bag, or membrane. The principle of operation of the storage facility is based on compressing liquid with compressed air. When water is consumed in the system, the pressure drops.

The hydraulic tank immediately reacts to changes that have occurred: it quickly restores parameters by supplying a new portion of liquid, but without the slightest involvement of the pump. Naturally, the rare activation of this main device of the pumping station guarantees its longer operation.

Using a relay for the hydraulic tank, two important parameters of water pressure are set: its upper and lower limits. When the value becomes minimal, the pump “helps” the accumulator: it turns on and works until the pressure again reaches the maximum (preset) level.

The membrane tank eliminates the most common problems that arise during the operation of autonomous water supply, heating systems or economical solar systems. Water accumulators help:

- stabilize blood pressure;

- quickly equalize water pressure during intensive use;

- prevent the occurrence of water hammer, which is extremely dangerous for the system;

- guarantee the supply of water when the pump fails due to power outages, but in this case the hydraulic tank must have a large volume;

- significantly extend the life of the main element of the pumping station, since rare periods of operation of the hydraulic machine eliminate rapid wear of the equipment.

The peculiarity of a membrane tank is that the efficiency of this vessel device is not determined. The device either works or it doesn't.

Symptoms of a faulty accumulator

The membrane tank is a relatively simple design. Therefore, possible malfunctions of the accumulator can often be detected visually.

One of the signs of its “inaction” is the frequent operation of the safety valve. When the pressure in the system rises to the limit, it releases water, protecting appliances and pipes. Other symptoms of malfunction:

- unjustified activation of the pump at each water intake;

- uneven flow of liquid from the tap - in jerks, in small portions;

- a pressure gauge showing that the change in pressure occurs abruptly: in this case, the arrow of the device first rises sharply, then drops to zero.

If these signs are detected, you can be almost sure that the accumulator is either not working correctly or is faulty. Finding the source of the problem and eliminating it is the next operation that the owners of the hydraulic tank and pump (pumping station) will have to do.

You cannot delay repairing a faulty hydraulic tank. Ignoring the incorrect operation of storage equipment will lead to the fact that the problem will soon affect not only the tank, but also other elements of the water supply or heating system. This scenario is unlikely to inspire anyone, since in this case the costs of correction will significantly increase.

Why is it needed and how does the RDV work?

Water is supplied to both the centralized and autonomous systems by pumping equipment. Fundamentally, these schemes differ only in the number of branches, the diameter of the pipes and the number of shut-off valves. And pressure surges due to various technical reasons are possible in any of them. The water pressure regulator in the water supply system stabilizes the pressure and dampens the hydraulic shocks that occur in it.

In autonomous systems it is installed at the entrance to the house, in front of the meter, in centralized systems - in front of the apartment wiring. Such a mechanism will not hurt in private houses connected to a centralized water supply, despite the fact that there is a common water supply.

Regulator functions

The mechanism, which is also called a pressure reducer, acts as a stabilizer in the household water supply network. Without it, equipment designed for a certain pressure and responding to its changes fails faster. This applies not only to household appliances that consume water, for which water hammer becomes a serious test. But also electric boilers, gas water heaters, boilers, water meters.

When the gearbox cannot be built into the beginning of the intra-house network, it is installed directly in front of the washing machine or other expensive equipment Source www.rmnt.ru

The pipelines themselves, especially the junctions and joints, also suffer from water hammer. With frequent pressure surges, they lose their tightness and begin to leak.

There is another reason why it is advisable to use a water reducer: it is convenient to use water dispensing devices. It’s not pleasant when a stream from a tap or shower head with adjusted temperature and pressure suddenly begins to randomly change these parameters.

Operating principle

Despite its modest size and simple design, the RDV copes with pressure regulation independently, without connecting additional equipment. And it does this automatically.

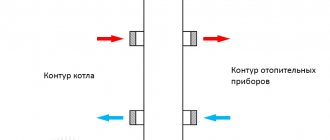

The principle of its operation is similar to how the flow of water is regulated by a valve tap, when unscrewing it the rod and piston rise and open a lumen of a certain cross-section. But in this case, as the pressure in the system increases, the piston remains motionless, and the force of the water flow increases. Whereas the water pressure valve in the reducer in such a situation changes its position and reduces the clearance.

At the outlet of the device, the pressure drops to the values set by the settingSource i.ytimg.com

We will trace the entire path of water through a system equipped with an RDV.

Water is supplied to the house from a well, a well or a centralized system using pumps that set a certain pressure.

Due to a pump malfunction, the tap on a branch being closed, or for some other reason, the pressure changes sharply, which threatens the equipment connected to the network with failure.

Passing through the reducer, the flow of water puts pressure on its operating element, which contracts and automatically reduces the clearance of the valve.

Changing the flow area does not allow water to move with the same pressure; it decreases and the water leaving the reducer flows to the points of consumption with standard pressure indicators.

In houses with water supply from a well or well, a hydraulic accumulator is often installed, equipped with a similar mechanism - a pressure switch. This device operates from an electrical network and is designed to turn on the pump when the pressure in the hydraulic tank drops, and turn it off when the specified parameters are reached. In this case, a water pressure reducer in the water supply system is not necessary, since the pressure will not exceed the maximum values set for the accumulator.

Autonomous water supply system with hydraulic accumulatorSource cdn.sovet-ingenera.com

But the pressure in the pipes will change within the limits specified by the relay. If the maximum pressure set for the hydraulic tank is more than 3 atmospheres, and for normal operation of household appliances it must be lower, then a regulator should be installed.

Devices of Russian and foreign production

Gearboxes on the market are represented by brands from Russia, Europe and China. Recently, Chinese industrialists have not only been repeating analogues from Europeans, but also introducing new solutions.

European manufacturers:

- HONEYWELL is an American brand;

- WATTS – German production;

- HEIZ – Austrian manufacturer;

- CALEFFI - Italy;

- OFICINE RIGAMONTI is the oldest Italian manufacturer.

Russian representatives:

- VALTEK is a Russian leader with production in Italy;

- STOUT - ;

- UNI-FITT;

- PASKAL - Republic of Tatarstan (produces only diaphragm gearboxes).

What problems does the device solve?

Apartment water pressure regulator solves a number of complex problems. So, it allows:

- Protect the pipeline and plumbing equipment connected to it from a sharp increase in water pressure in the main. During the operation of a utility line, the water pressure in it can exceed the normal value and even reach the maximum permissible level. Most often, residents of multi-storey buildings suffer from this problem. In such buildings, in order to raise water to the upper floors, the liquid pressure has to be significantly increased. As a result of this, the integrity of the main line and some expensive plumbing fixtures may be compromised.

- Protect plumbing and pipelines from water hammer, which can also cause significant damage to utilities.

- Reduce the input pressure to the set value. If the inlet pressure is slightly higher than the required value, then the plumbing fixtures may not function properly or even fail. For example, an instantaneous water heater has built-in protection that blocks the operation of the device if the input pressure is incorrect. Problems can also arise with storage boilers. If the safety valve does not operate properly, hot water will be released unnecessarily. This will lead to excessive consumption of both water and electricity.

- Reduce water consumption. Pressure affects how much liquid flows out of the faucet in a certain time. If you reduce this figure, you can save a lot on water. For country houses this problem is more pressing. After all, reducing liquid consumption will reduce the amount of wastewater. Therefore, the services of vacuum cleaners will be needed less often.

- Reduce the risk of flooding as a result of problems in the main line. So, if a leak occurs, water will flow at a low speed, which will reduce the consequences of such a problem.

- Reduce noise in water intake devices. If the water flow has high pressure, this leads to noise in mixers and taps. Stabilizing the pressure allows you to reduce noise or eliminate it completely.

Installing a pressure regulator in a pipeline can solve many problems. This is especially true for eliminating an increase in fluid pressure, which can lead to destruction and malfunction of plumbing fixtures, since the faucets in the apartment are designed for pressures of up to 5 ATM.

Pressure standards in the heating system of an apartment building

The pressure that should be in the heating system of an apartment building is regulated by SNiPs and established standards. When calculating, take into account the diameter of the pipes, types of pipelines and heating devices, distance to the boiler room, number of floors.

Types of pressure

When talking about pressure in the heating system, we mean 3 types:

- Static (manometric). When performing calculations, it is taken equal to 1 atm or 0.1 MPa per 10 m.

- Dynamic, occurring when the circulation pump is turned on.

- Allowable working, which is the sum of the previous two.

In the first case, this is the pressure force of the coolant in radiators, shut-off valves, and pipes. The higher the number of storeys in a building, the more important this indicator becomes. To overcome the rise of the water column, powerful pumps are used.

The second case is the pressure that arises during the movement of fluid in the system. And the operation of the system in a safe mode depends on their sum—the maximum operating pressure. In a multi-storey building its value reaches 1 MPa.

GOST and SNiP requirements

In modern multi-storey buildings, the heating system is installed based on the requirements of GOST and SNiP. The regulatory documentation specifies the temperature range that central heating must provide. This is from 20 to 22 degrees C with humidity parameters from 45 to 30%.

To achieve these indicators, it is necessary to calculate all the nuances in the operation of the system during the development of the project. The task of a heating engineer is to ensure a minimum difference in the pressure of the liquid circulating in the pipes between the lower and upper floors of the house, thereby reducing heat loss.

| Number of storeys | Working pressure, atm |

| Up to 5 floors | 2-4 |

| 9-10 floors | 5-7 |

| From 10 and above | 12 |

The actual pressure value is influenced by the following factors:

- Condition and power of equipment supplying coolant.

- The diameter of the pipes through which the coolant circulates in the apartment. It happens that, wanting to increase temperature indicators, the owners themselves change their diameter upward, reducing the overall pressure value.

- Location of a specific apartment. Ideally, this should not matter, but in reality there is a dependence on the floor, and on the distance from the riser.

- Degree of wear of pipelines and heating devices. If you have old batteries and pipes, you should not expect pressure readings to remain normal. It is better to prevent the occurrence of emergency situations by replacing worn-out heating equipment.

How pressure changes with temperature

The working pressure in a high-rise building is checked using tubular deformation pressure gauges. If, when designing the system, the designers included automatic pressure regulation and control, then they additionally install sensors of various types. In accordance with the requirements specified in regulatory documents, control is carried out in the most critical areas:

- at the coolant supply from the source and at the outlet;

- before the pump, filters, pressure regulators, mud traps and after these elements;

- at the outlet of the pipeline from the boiler room or thermal power plant, as well as at its entry into the house.

Pressure in summer

During the period when the heating is inactive, both the heating network and the heating systems maintain a pressure whose value exceeds the static one. Otherwise, air will enter the system and the pipes will begin to corrode.

The minimum value of this parameter is determined by the height of the building plus a margin of 3 to 5 m.

How to raise blood pressure

Checking the pressure in the heating lines of multi-storey buildings is necessary. They allow you to analyze the functionality of the system. A drop in pressure level, even by a small amount, can cause serious failures.

In the presence of centralized heating, the system is most often tested with cold water. A pressure drop over 0.5 hours by an amount greater than 0.06 MPa indicates the presence of a gust. If this is not observed, then the system is ready for operation.

Immediately before the start of the heating season, a test is performed with hot water supplied under maximum pressure.

Changes that occur in the heating system of a multi-storey building most often do not depend on the owner of the apartment. Trying to influence blood pressure is a pointless undertaking. The only thing that can be done is to eliminate air pockets that have appeared due to loose connections or incorrect adjustment of the air bleed valve.

The presence of a problem is indicated by characteristic noise in the system. This phenomenon is very dangerous for heating appliances and pipes:

- Relaxation of threads and destruction of welded joints during pipeline vibration.

- Stopping the supply of coolant to individual risers or batteries due to difficulties with de-aerating the system, the impossibility of adjustment, which can lead to its defrosting.

- A decrease in the efficiency of the system if the coolant does not stop moving completely.

To prevent air from entering the system, before testing it in preparation for the heating season, it is necessary to inspect all connections and taps for water passage. If you hear a characteristic hissing sound when you test run the system, immediately look for the leak and fix it.

You can apply a soap solution to the joints and bubbles will appear where the seal is broken.

Sometimes the pressure drops even after replacing old batteries with new aluminum ones. A thin film appears on the surface of this metal from contact with water. The by-product of the reaction is hydrogen, and due to its compression, the pressure decreases.

In this case, you should not interfere with the operation of the system - the problem is temporary and goes away on its own over time. This happens exclusively during the first time after installing radiators.

You can increase the pressure on the upper floors of a high-rise building by installing a circulation pump.

Minimum pressure

Based on the condition that the superheated water in the heating system does not boil, the minimum pressure is assumed.

degrees C

atm

It can be defined as follows:

A margin of approximately 5 m is added to the height of the house (geodesic) to avoid airing, plus another 3 m for the resistance of the heating system inside the house. If the supply pressure is insufficient, then the batteries on the upper floors will remain unheated.

If we take a 5-story building, then the minimum supply pressure should be:

Pressure drop

In order for the heating system to perform its functions normally, the pressure drop, which is the difference between its values at the supply and return, must be of a certain and constant value. In numerical terms, it should be in the range from 0.1 to 0.2 MPa.

A downward deviation of the parameter indicates a failure in the circulation of the coolant through the pipes. A fluctuation in the direction of increasing the indicator indicates airing of the heating system.

What are they?

Manufacturers now produce the following types of water pressure reducers in water supply systems.

- Mechanical. The most common ones are cheap and take up minimal space. Consists of a body and a spring valve. It is adjusted using an adjusting bolt, which changes the compression force of the spring or membrane.

- Automatic. They are a modified variation of mechanical ones. They have a built-in switch. They are installed in water supply systems, where the pressure is provided by an additional supercharger (pump). When the pressure drops to a certain point, such a reducer automatically starts the pump to increase the water pressure to the required level.

- Electronic. They appeared relatively recently and are a combination of an automatic gearbox with a built-in pump. They require power to operate and are controlled by a program.

Automatic gearbox. Depending on the pressure, the toggle switch turns on or off

Based on the design of the valve itself, it is divided into the following.

- Piston. The cheapest ones are based on a spring-loaded piston, which blocks the cross-section of the water supply. The disadvantage of these is that they do not perform their functionality well at high flow rates of water through the pipe.

- Membrane. It is based on a spring-loaded membrane installed in a separate sealed chamber. They are more reliable, since the adjusting mechanism does not come into contact with water, they retain their function at high speeds of water movement (on average, up to 3 m3*h), but are more expensive than piston ones.

- Electrical. The valve position depends on the pressure reading from an electronic sensor and is driven by an electric drive.

Electronic regulator. Multifunctional, but not cheap

Pressure drop

If the pressure in the system drops, then most likely there is a coolant leak. The most vulnerable places are joints, seams and joints. To check, turn off the pump and observe changes in static pressure. If the pressure continues to decrease, you need to find the damaged area. For this purpose, experts recommend disconnecting different sections of the circuit, and after determining the location of the damage, replacing or repairing these elements.

A short-term drop in pressure sometimes occurs due to the operating characteristics of the regulator, which periodically releases part of the water from the supply to the return. If the radiators heat up to the required temperature, and evenly, then the pressure drop is due to the regulator. Also, reasons for low blood pressure may be:

- decrease in water temperature;

- removal of air through vents, due to which the volume in the coolant system decreases.

Which ones can you eliminate on your own and which ones can’t?

The vast majority of malfunctions occur due to hard water and the presence of limestone impurities in it. The more mineralized the water, the faster the pressure reducers begin to fail.

However, this difficulty can be easily resolved. The device can be quickly disassembled, cleaned, gaskets or O-rings replaced, and it will work as good as new.

There are not so many irreparable breakdowns. Mainly these are mechanical defects of the body and internal filling. These include the breakage of a spring or rod, as well as cavitation destruction of the seat and the walls of the gearbox.

Cavitation needs a little explanation. This phenomenon occurs when the control device is chosen incorrectly, namely, its flow characteristics do not correspond to a particular pipeline.

If the regulator is noisy during operation, then this is the first sign of cavitation and that it must be changed.

Cavitation processes occur when the spool is almost always in a half-closed state - the cross-section of the manifold is minimal. In this position, an area of increased pressure appears in the connecting manifold.

Under such conditions, all the prerequisites for the chemical decomposition of the metal begin to arise. It actively destroys the seat for the spool - the contact of the piston becomes loose.

As plumbers put it, the fittings begin to mercilessly cut, i.e. she starts missing. It is very difficult, if not impossible, to correct this defect on your own - most often a complete replacement is required.

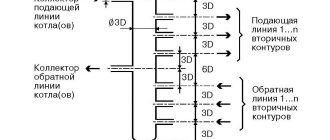

To prevent this from happening, you need to adhere to one rule - do not reduce the pressure in the pipeline with one reducer by more than 2.5 times. If this cannot be done, then the “cascade” method must be used, i.e. use two step-down devices.

Thus, a reduction from 10 to 3 atmospheres with one unit cannot be done without violating this rule. Then you need to use 2 devices - the first will reduce from 10 to 6 atm., and the second from 6 to 3. In this case, the risk of cavitation and noise generation will be guaranteed to be eliminated.