What is nichrome?

Nichrome is a corrosion-resistant alloy consisting of 2 metals - nickel and chromium, and additives (manganese, sulfur, aluminum, phosphorus, iron, etc.). The alloy is resistant to temperatures up to +1300⁰C, and its plasticity allows it to be used for the production of electric heating and resistive elements, various rolled products and wire (thread). Depending on the composition, nichrome is divided into certain grades.

Characteristics and properties of nichrome wire

The production of nichrome wire is limited to two main grades: X15H60 and X20H80 . The characteristics and properties of each brand are different.

X20H80 is characterized by:

- Composition of 25% chromium, 75% nickel, 1% iron.

- Specific resistance 1.13 Ohm mm 2 /m (for wire with a diameter over 3 mm).

- Operating temperature 1250⁰C-1300⁰C.

The density of X20H80 is 8500 kg/m³, the specific heat capacity is 0.44 kJ/(kg K).

X15H60 is inferior to X20H80 in terms of technical characteristics:

- operating temperature – 1000⁰C-1100⁰C;

- composition – 18% chromium and 60% nickel;

- specific heat capacity – 0.46 kJ/(kg K);

- density 8200 - 8500 kg/m³;

The resistivity of this brand is 1.12 Ohm mm 2 /m.

The low iron content of X20H80 allows the thread to exhibit resistance to corrosion and wear. Unlike X15H60, which is more susceptible to corrosion. However, this brand serves for the production of samples, the cross-section of which is characterized by greater ductility and smaller area.

REFERENCE . As filler elements, both grades can include aluminum, manganese, titanium, silicon, iron and zirconium. At the same time, the presence of iron increases the magnetic properties of the alloy.

All about nichrome. Application of nichrome. History of nichrome. What is nichrome? Where to buy nichrome.

Nichrome easily withstands melting temperatures up to 1400°C. Density is (8200-8500) kg/m3. The flagship of the physical qualities of nichrome is considered to be a high electrical resistance of the order of 1.05-1.4 Ohm mm²/m and depends on the chosen brand of nichrome. As well as high corrosion resistance in different environments and the highest heat resistance. Nichrome is creep-resistant, which means the ability of the alloy, when heated to a certain extent, will expand over a set period of time. In addition, the alloy is ductile, perfectly holds its given shape, and can operate at operating temperatures from 1100 to 1300 °C.

An annoying feature of nichrome is its limited durability in watches. If you don’t go into tables and figures, the X20N80 brand will last you longer than X15N60 under the same operating conditions. The price difference between the brands described above is 10-15%. What to choose is up to the technologists and economists of your enterprise to decide.

As for the fechral wire . A substitute for nichrome was invented at the turn of the 20th-21st centuries. This analogue is relative to the “amateur”. The price is several times cheaper, since it does not contain expensive nickel. Instead, chrome, aluminum and iron. Vitality is extremely low. Operating temperature is not higher than 900-950 °C. The need for enterprises is low. Frequent downtime of the thermal section is always upsetting.

New generation nichromes are increasingly being offered on the market. We will not advertise them. Time will tell how they will prove themselves. Today it is extremely early to draw conclusions. Despite the perfectly written characteristics. Technologists with extensive experience and experience say that nichrome X20N80 is in no hurry in the past. And we, who have been selling nichrome for more than 20 years, will refrain from commenting. Manufacturers are trying to make a choice in favor of a more expensive, but also higher quality alloy.

Wire, tape, nichrome thread are integral parts of almost all heating devices.

At the household level, nichrome began to be used for irons, and a little later, in the food industry. Electric stoves, heaters, boilers, toasters, car cigarette lighters, heated seats, heated floors, electronic Atomizers.

Nichrome is in demand in industry for the production of heating elements in high-temperature electric furnaces and various electrical thermal units for all industries. As heating and resistor elements. Heat-resistant, heat-resistant, acid-resistant and chemically resistant alloy in certain aggressive environments. In units, rheostats operating at high temperatures, in the development of precision resistors, for which special grades of nichrome alloys have been developed. As the main heat-resistant coating for thermal spraying.

Like everything expensive and high quality, they look for a replacement. Scientists, metallurgists, and chemists are haunted by the idea of surpassing the qualities of this expensive alloy. But this has not happened to date.

to buy Nichrome from 1 kg from the company PARTAL.

We sell only Russian-made Nichrome. Strict compliance with GOST; TU, quality and brand.

Where is nichrome wire used?

Plasticity, resistance to aggressive substances and high yield strength are used by nichrome in industrial production and a number of industrial areas where electric heating furnaces are widely used. The alloy has also found application in electric furnaces, the heating temperature of which is extremely high.

Wire is also used in other areas:

- in homemade welding machines;

- in ovens for drying and firing;

- for machines cutting foam plastic;

- in the heating system of car windows and mirrors;

- in devices where an increased degree of reliability is required, etc.

This property of the alloy, such as strength, has provided nichrome wire with a place in all environments where chemicals, heat and high temperatures are indispensable.

Peculiarities

Nichrome wire has a rare set of properties that make it almost irreplaceable in some areas. Among the distinctive characteristics:

Corrosion resistance. As you know, rust is the weak point of most metal products. In this regard, nichrome is unique - it does not oxidize under the influence of the environment and has a long service life.

High electrical resistance. The resistivity of nichrome wire reaches 1.1-1.4 Ohm*sq.mm/m. If we compare these figures with ordinary steel, then much less nichrome (in meters) will be needed to release the same amount of heat. This makes it possible to make structures made of nichrome alloys compact and light in weight.

Heat resistance. The two-component composition remains operational at a temperature of 1400 degrees. In this case, there are no temperature deformations.

Nichrome is an expensive material, but its outstanding strength, physical properties, and durability justify such a cost.

How to determine nichrome?

Nichrome, as a slightly silver or white material, is not easy to recognize. In addition, it often has a dark gray tint associated with an oxide (oxidizing) film.

However, it is possible to determine the appearance of the material by the following characteristics:

- dark green film on the surface;

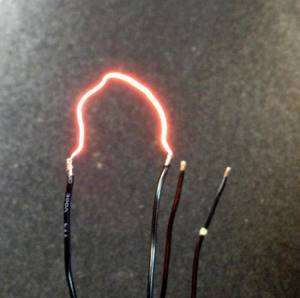

- turning the wire into a spiral after heating.

The last sign indicates the high resistance of nichrome to deformation.

ATTENTION . The mode of alternating long-term and short-term use of the thread will help maintain the quality characteristics of nichrome wire.

Differences from other wire

Often, unscrupulous sellers sell similar-looking materials under the guise of nichrome. In order not to fall for this “bait” and not overpay for a product you don’t need, we suggest that you familiarize yourself with the distinctive features of nichrome wire:

It is difficult to judge the type and origin of the material from a photo of nichrome wire, but it is possible. Thus, the new material has a shiny, white-gray hue. A used product, on the contrary, has a dark gray color. This is due to the presence of an oxide film. When removing oxides, the color of nichrome should change to light.

A simple practical way is to check the magnetic properties. Two-component wire is not magnetic, and alloys with added iron have weakened magnetic properties.

Rigidity. Take the material in your hands and try to bend it. Nichrome is noticeably stiffer than copper-plated or soft steel wire.

Where can I find nichrome wire?

The easiest way to find nichrome wire is to go to a special store (vape shop). True, nichrome thread is not cheap there, and for 1 meter you will have to pay a decent amount.

There are other options where you can find nichrome wire:

- radio markets;

- soldering irons;

- hair dryers;

- fan-type heater;

- electric stove with open spiral;

- Internet.

The ability to detect metal on the radio market is not very great, compared to a soldering iron (working or faulty). A soldering device can be found in a garage, or in a Fix Price store, where the product costs a penny. To find what you are looking for, the device must be disassembled and the wire pulled out. As a rule, the nichrome thread in the soldering iron is thin. Winding 10 turns on a pencil will help determine its cross-section. The length of the wound wire reaches up to 2.5 m.

Soldering Features

The features of nichrome soldering are as follows:

- Use of tin-lead materials POS 50 and POS 1 for solder.

- Careful preparation of flux.

- Proper processing of the working surface.

Before soldering, the working surface is cleaned with sandpaper and treated with cotton wool soaked in an alcohol solution of copper chloride. Next, apply flux and begin the process.

IMPORTANT . Flux is prepared by mixing several elements: 100 g of technical petroleum jelly, 5 g of glycerin and 7 g of zinc chloride powder.

When tinning nichrome with copper leads, it is better to use 2-3 g of citric acid. This is enough to service one wire. To remove acid, the wire must be placed on rosin, dipped, and a soldering iron is used for further work.

Currently, nichrome and products made from it are used almost everywhere. Neither exposure to an aggressive industrial environment, nor high temperatures, nor heavy loads during work can defeat such a resistant material.

What is nichrome?

Nichrome is an alloy formed by two metals - nickel and chromium, and additives (iron, manganese, aluminum, sulfur, phosphorus, etc.).

Depending on the components, it comes in different brands. This alloy has the ability to withstand high temperatures (up to 1300 ˚C), therefore it is used in the manufacture of resistive and electric heating elements. Nichrome has a fairly high ductility, thanks to which it can be used to produce various rolled products and even threads. The presented alloy is also resistant to corrosion.

Making nichrome wire

Nichrome is an alloy of two metals: nickel and chromium. Supplemented with additives: iron, aluminum, phosphorus and sulfur to achieve the required quality. There are different brands depending on the ingredients.

Wire is produced from alloys based on nichrome, ferronichrome and fechral by drawing under pressure. The drawing technology takes place without additional heating of the workpieces. In order for the wire to be soft, it is fired in thermal ovens and cooled naturally. Quality regulations are established by GOSTs. Chrome gives strength and hardness, nickel gives ductility. The temperature depends on the amount of nickel in the alloy . Maximum temperature 1300 degrees .

In the industrial sector, two brands are more commonly used:

Х20Н80 and Х15Н60;

X20H80 - X - chromium, 20 - the presence of chromium as a percentage; N - nickel, 80 percent nickel content.

This material is used in the manufacture of electric heating and resistive elements and industrial electric heating devices, in laboratories, furnaces, household products, and thermal apparatus.

High resistance to electric current makes it possible to reduce the weight and size of electric heaters. The thicker the wire, the greater the heat transfer. When heated to maximum temperature, the metal remains unchanged and does not lose its qualities. The alloy is resistant to corrosion and rust; resistant to aggressive environments.

Advantages of nichrome

The main advantages include:

- high electrical resistance;

- high heat resistance and heat resistance;

- excellent mechanical properties;

- plasticity and weldability, allows easy processing of the product;

- resistance to deformation under high pressure at temperatures above 400 °C;

- refers to non-magnetic materials.

Disadvantages of the material

In addition to its advantages , metal also has its disadvantages:

- high price;

- The heating temperature is insufficient; in other alloys it is much higher.

Nichrome thread

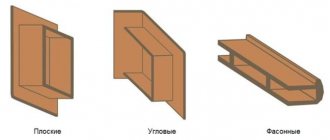

This product comes in three varieties. To facilitate the work of the manufacturer with the consumer, each type is reflected in the labeling. So:

- the letter “H” indicates that the nichrome thread is intended for the manufacture of heating elements;

- products with the symbol “C” are used in the production of resistance elements;

- The “TEN” marking indicates that such material can be used in the manufacture of electric heating tubular elements.

The alloy density is from 8200 to 8500 kg/m 3. The diameter of the semi-finished product is presented in a fairly wide range and is 0.01-0.08 mm. There are also products that go beyond this size, but this is rather an exception, designed for the use of this material in highly specialized areas.

Upon completion of the production process, the manufactured nichrome thread is wound onto spools, in which it is supplied to customers.

Advantages

Among the advantages of this material are:

- high heat resistance and heat resistance (in the working area the temperature can reach up to 1250 degrees);

- the ability to maintain shape stability under the influence of high temperatures;

- the plasticity of the material, which makes it easy to process even in a cold state;

- high electrical resistance.

Thanks to the listed advantages, this semi-finished product has a fairly wide range of applications.

Application

Nichrome thread is used in the manufacture of heating elements because it is highly wear-resistant. For the manufacture of heating elements, the thinnest rolled products with a diameter of 0.04-12 mm are used. The higher the nickel content in the alloy, the higher the ductility of the material.

Nichrome thread is also used in medicine. Since it does not cause allergic reactions, it is used as a suture material. Studies have shown that a cut sewn up with thin rolled nichrome material heals very quickly. In addition, such a thread is used in plastic surgery for intracavitary operations.

Pharmacological institutes and research laboratories cannot do without this material, where it is used in heating mantles as a heating element.

Purpose

The use of nichrome wire in various fields of activity is due to its advantages. In instrument making it is used as a unit of resistors, rheostats, and heaters. Cables and ropes are produced from large-diameter blanks.

Many household appliances (toaster, soldering iron, iron) contain nichrome. In medicine, nichrome threads are used in plastic surgery and intracavitary interventions.

Welding of metal structures

Features of cold rolled sheets - production technology, features, dimensions, properties and markings

Technical features of hot-rolled sheet - classification, manufacturing method, application options and processing features

The clever “Kulibins” manage to design wood cutters and burning devices from nichrome rods.

Where can I get nichrome thread?

There are several options for how and where you can purchase nichrome products.

Today, in almost all settlements there is a reference information about the availability of goods and services. When contacting her, the operator will provide information about which organization sells nichrome products and its contact information.

If such a product is sold in another city, then in this case you can use a special one. But here you will have to pay extra for shipping.

Where else can I get nichrome thread? You can also purchase it in specialized stores, for example, such as “Skillful Hands”, “Radio Components” and other similar pavilions. As a rule, the sellers of these private stores know each other very well, and if such a “private seller” does not have nichrome thread in stock, he will be able to tell you where it can be purchased.

Every locality has a market where you can buy almost anything. The main thing is to have a good look around the entire bazaar and, if necessary, even ask around the sellers.

Nichrome thread is a high-quality plastic product with excellent technical characteristics. Buying it or getting it by any other means, although quite difficult, is still possible. To do this, you just need to take the initiative and use all the above methods.