What materials are non-flammable?

The group of non-combustible materials includes those that, when exposed to an open flame, retain their original state.

At the same time, they do not ignite, do not char, do not smolder and do not contribute to the spread of fire. The Technical Regulations on Fire Safety Requirements of 2008 serve as a regulatory source that classifies substances according to the degree of fire hazard. The main material on this issue is contained in Article 12 of this document. Additional information on fire and explosion hazards is contained in GOST 12.1.044-89.

In accordance with these regulations, the flammability group refers to the parameters that determine the combustion of materials under different conditions. It should be noted that:

1.

The category of non-combustible substances includes compounds that are not capable of burning in a normal environment.

2.

There is a group of substances classified as non-flammable, which upon contact with air or water become explosive and fire hazardous. This group also includes compounds that have the chemical properties of powerful oxidizing agents. To accurately determine the properties of materials and assess their fire resistance, it is necessary to find out their composition and what characteristics the substances of which they are composed have.

During certification activities and examination, the working and chemical properties of the tested substances are accurately established. The results obtained are taken as the basis for the development of GOSTs, technical conditions for the operation of enterprises, the issuance of a certificate, and the development of fire safety measures at the facility.

Flammability test method

All building materials, regardless of their multilayer nature and scope of application, are tested for flammability using a single complex and labor-intensive method, each stage of which is subject to mandatory precise recording and is carried out exclusively by organizations that have permission to conduct such studies.

Important! On the territory of the Russian Federation, only a few organizations are authorized to conduct fire tests, including: the Ministry of Emergency Situations of Russia, the Experimental Research Institute, the Pozhaudit ANO, the Kucherenko Research Institute and a number of others.

Flammability testing steps:

- Preparatory - here 12 completely identical samples of the material being tested are prepared, the thickness of which must correspond to the real values at which the material will be used. When testing multilayer materials, samples are taken from each layer.

- Exposure - prepared samples are kept in room-greenhouse conditions (appropriate temperature and humidity in the absence of drafts) for at least 72 hours, while the samples are regularly weighed. When a constant weight is reached during 2-3 consecutive weighings, further weighings are stopped.

- Checking - each of the 12 samples is placed in turn into a pre-calibrated, tested and heated combustion chamber, equipped with air supply and exhaust gas removal systems, and kept there for a certain time.

- Measurements - after completing the verification stage, the sample is removed from the chamber, measurements are taken, mass loss, temperature (and the rate of its fall), the amount of gases released and the burning time without a fire source are recorded.

- Conclusion - at the final stage, measurements taken on all 12 samples are analyzed, while - as a rule - extreme indicators (best and worst) are excluded, after which the material or product is assigned a certain flammability class.

Scope of application

The main goal of determining the degree of flammability of substances lies in the practical field.

The results of this activity are usually used in the construction and landscaping industries. The combined use of flammable and non-flammable substances will ensure high fire safety in combination with moderate production costs. The materials used in the construction industry make it possible to ensure safe operation of buildings after completion of construction. Non-flammable materials for bathhouses can reduce the risk of fire to acceptable levels. An example is the active use of hollow materials in construction.

Brick with voids inside the structure is especially often used in this capacity. In addition, it is used as a non-flammable material for stoves in low-rise structures. It should be remembered that the contact points of chimneys and stoves connected to combustible structures must be insulated using fire retardant compounds: mastic, plaster, sealant.

Non-combustible material for the chimney must be insulated at the junction with flammable elements. In the construction industry, hazardous materials are actively changing to compositions that are stable and resistant to fire. Traditional wooden floor construction has been almost completely replaced by conventional screed in combination with floor ceramics or non-flammable linoleum. Non-combustible materials for finishing walls and ceilings are widely used both in low-rise construction and in apartment buildings.

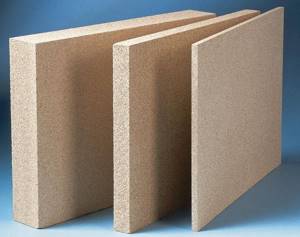

Materials based on wood and wood shavings are being consistently forced out of the construction industry. Usually these materials are replaced with block elements, for example, tufa blocks or foam concrete products. Non-combustible sheet material is used as finishing panels, both internal and external.

To insulate walls, ceilings, and floors, roll and sheet materials based on basalt and other mineral fibrous compositions are used. These products are characterized by high fire safety and are used:

- for insulation of technical openings intended for windows and doors;

- to ensure thermal insulation of the outermost floors, roofing structures, and floors of the room;

- for insulation of upper superstructures and attic floors;

- in order to ensure thermal insulation of pipelines for various purposes, including water pipelines, gas pipelines, wastewater discharge systems, cylindrical structures or rolled samples are used as heat-saving elements;

- Fibrous mineral compounds are also used for sound insulation in premises for various purposes.

Various metal structures also have a high degree of fire safety. This number includes:

1.

Cast iron and steel used to create tubular products, industrial and construction equipment, and fittings for pipelines. Cases for machines and equipment for various purposes are cast from these metals, and they are used for the production of engineering equipment.

2.

Conventional steel is actively used for the production of fittings for construction fittings. Steel is used to create elements of supporting structures for structures for various purposes.

3.

Copper, aluminum and various alloys based on them are used as conductive materials in the energy sector.

Classification of materials

The main document defining methods for classifying materials by flammability classes is GOST 30244-94. This regulatory act sets out methods for testing materials and distinguishes two groups:

- non-flammable "NG";

- flammable "G".

The non-flammable group includes compounds that can withstand the following tests:

- reduction in the mass of the substance being tested - no more than 50%;

- the temperature should rise by no more than 50%;

- Stable burning time with open fire is up to 10 seconds.

All types of materials that participated in the tests and did not pass even one of the criteria are classified as flammable. Construction objects also differ in fire resistance. Among this category, two types of development can be distinguished:

1.

All structural parts are made of non-flammable compounds.

The main load-bearing elements have a maximum degree of fire resistance, allowing them to withstand up to 2 hours of exposure to an open flame. 2.

The difference in the second category is the use of metal structures that are not treated with fire protection. Metal elements should be used to create openwork elements of trusses, beams and other samples in the roof area of a building. In this case, the fire resistance limit will be 1.5 hours.

Objects that meet the above fire resistance requirements to the greatest extent meet fire safety standards. As an additional classification of non-flammable compounds used in the construction, reconstruction and repair of structures, several types of division are used.

Depending on the type of product produced, substances are divided into:

- produced in the form of a roll, tile, technological sheet;

- in the form of a bulk substance;

- in the form of rigid elements, such as metal trusses or reinforced concrete slabs.

Depending on the purpose of the product:

- finishing decorative materials, for example, tiles for various purposes or wall panels;

- building structures produced in finished form, for example, slabs, bricks, floors;

- bulk materials for various purposes, heat-insulating and sound-proof molded products.

Varieties

Non-combustible building materials are classified according to several criteria. By purpose they are distinguished:

- insulators;

- for insulation;

- non-combustible finishing materials for walls, floors, and ceilings.

In addition, the products differ from each other in the way they transfer heat:

- temperature-resistant due to physical and chemical properties;

- materials that reflect heat.

By release form:

- leafy;

- panels;

- roll

By place of use:

- for interior decoration;

- for installation outside buildings and structures.

Important! In addition to the basic fire-fighting properties, fire-resistant products may have additional parameters. For example, moisture resistance allows it to be used in the kitchen, bathhouse or swimming pool. High sound absorption rates allow the material to be used for insulating music studios, cinemas and other facilities.

Fireproof fireproof panels "Gypsoacryl"

Types of substances

It is customary to distinguish three main types of non-flammable substances of different origins.

The first type includes solid materials presented in various structural and aggregate states. These can be bulk substances, structures, and individual piece products. This number includes:

- various rock samples, both hard and softer, including limestone, dolomite, marble;

- concrete and reinforced concrete products;

- loose rocks, including gravel, sand, crushed stone;

- binders - chalk, clay, cement, gypsum, lime, plasters, mortars;

- cast iron and steel products of various types and designs - angles, channels, beams;

- non-ferrous metals, including bronze, copper, brass, aluminum alloys;

- mineral fibers, such as basalt;

- various types of textile materials, including asbestos fabric, basalt fiber;

- regular and fire-resistant glass.

Liquid substances:

- foaming agents and detergents;

- all types and conditions of water, from a drinking source to use as a coolant;

- synthetic liquids that cannot burn;

- acids, alkalis, salts in the form of an aqueous solution.

Gaseous substances:

- carbon dioxide;

- nitrogen;

- freon;

- argon.

Requirements for fire safety of materials

The modern regulatory framework is not limited to one document regulating the fire safety of substances and materials. The list of main documents includes: 1.

GOST 30244-94 contains information on the procedure for testing building materials susceptible to fire.

The norms of the document do not apply to paint and varnish products, granules, bulk substances, and solutions used in construction. 2.

GOST 4640-2011 regulates the conditions for the production of mineral wool from rocks of various origins, slag waste from metallurgy, and silicate materials.

The main area of application of fibers is construction. 3.

NPB 244-97 contains standards relating to finishing and facing materials, waterproofing, roofing samples, floor coverings.

4.

GOST 32313-2011 regulates the quality of products of various shapes made of mineral wool, made in the form of slabs, mats, cylinders with and without the use of metal.

Used in industry and construction to impart thermal insulation properties. 5.

GOST 21880-2011 defines the technical conditions for the production of mats used for thermal insulation of housing and communal services and industrial buildings.

Products are produced using stitching technology. 6.

GOST 32603-2012 regulates the production of metal panels using insulation based on mineral wool.

7.

GOST 32314-2012 contains information about products made from mineral wool. The scope of application of the products is the construction industry.

The standards contained in these regulations do not limit the requirements for materials to fire resistance alone. The documents also contain other characteristics of the compositions used in the production field:

- resistance to various deformations after heating or exposure to water;

- moisture resistance and hygroscopicity;

- thermal conductivity qualities;

- ability to withstand mechanical loads, including tearing and bending;

- specific viscosity of a substance.

Non-combustible substances and materials in a cold state demonstrate completely different qualities than when exposed to an open flame.

It is important to establish the suitability of a particular structure for use as a reliable link capable of withstanding design loads, including exposure to open flame. Added: 05/19/2020

Liquids

The demand for non-flammable liquids is primarily due to the need to ensure the safe operation of hydraulically driven mechanisms. For these purposes, one or two-component systems are used.

The latter can consist of mineral oils and water in two versions: with a predominance of oil (about 60%) or water (about 90%).

A mixture of glycols and water also consists of two components, which contains about 70% organic polyhydric alcohol. An anhydrous synthetic non-flammable liquid consisting of a single halocarbon component with high fire extinguishing ability.