The use of non-flammable, fire-resistant insulation in particularly fire-hazardous places for fire protection, heat/sound insulation of technological equipment, including heating equipment, and load-bearing structures; pipelines, chimneys, air ducts of life support systems is one of the priorities in the design, construction, reconstruction of construction projects to ensure fire safety.

Mineral fire-resistant (fire-resistant) wool is the raw material for the production of non-combustible insulation in the form of slabs, mats, and roll materials used for structural fire protection.

According to the definitions of GOST 4640-2011, mineral wool refers to materials that have an internal structure of wool, which are made from melts of gabbro-basalt rocks and sedimentary rocks containing alumina and silica; volcanic, metallurgical slags; glass industry waste intended for the production of heat/sound insulation products.

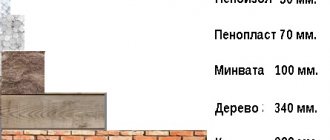

Non-flammable insulation on the rack

Kinds

The main differences between types of fire-resistant, fire-resistant wool are determined by the composition of the feedstock for industrial mass production, which in most cases gives the name of the finished commercial product:

- Basalt or stone mineral wool is a product obtained by centrifugation or blowing under pressure of a molten mass of crushed igneous basalt rock up to 1500℃ through dies made of refractory metals, rapid cooling of stone fibers. This type of wool is used to produce fire-retardant basalt material.

- Kaolin or ceramic is made from silicon dioxide - quartz sand and alumina, where the aluminum oxide content reaches 99%, by blowing a molten mass of raw materials under pressure up to 0.8 MPa to produce ultra-thin fibers used as effective thermal insulation products.

The technological production process - the melting of raw materials is carried out in electrothermal industrial furnaces at a temperature of 1750℃. The density of kaolin wool varies in the range of 80–130 kg/m3.

As binders for the formation of slabs, rolls, shells, and segments from lump wool used in construction; for cladding housings, heating tanks, and high-temperature technological equipment; sections of pipelines through which hot products are pumped, fire-resistant clay, organosilicon compounds, liquid glass (silicates), and special grades of aluminous cement are added to the resulting semi-finished product.

Most often, kaolin wool is called mullite-siliceous wool based on the geological names of the raw materials, which is reflected in the labeling of the finished product. Thus, ordinary fibers are designated MCRP, and fibers with the addition of chromium-containing compounds are designated MCRP.

On this topic ▼

Non-combustible materials and substances

Types and classification

- Cotton wool MKRR 130 , manufactured according to GOST 23619-79, is one of the most common, sought-after brands of kaolin wool, since, in addition to heat-resistant and fire-resistant properties, it is chemically inert to the effects of concentrated acids and alkalis; is an excellent electrical insulating material; has elasticity, due to which it adheres tightly to the protected surfaces of building structures, equipment casings, surfaces of pipelines, ventilation ducts; does not deform under the influence of vibration loads.

- Silica fireproof wool is produced using similar technological processes as basalt and kaolin wool. The content of pure silicon dioxide is from 96 to 98%. When heated at high temperatures, it is not capable of releasing any substances, since it is made without binding materials.

- Glass wool . The raw materials for the production of this heat-insulating material are waste from the glass industry, scrap of recycled glass containers, as well as raw materials used to make glass. Two industrial methods are used - blowing and drawing through dies.

- Slag wool , the raw material for which is slag from metallurgical production.

Types of fire-resistant wool according to the place of main use of such fire-fighting products:

- Fireproof wool for the chimney of any heating equipment - from the chimney in a bathhouse, residential building to the chimneys of geysers, diesel generator stations. The use of fire-resistant wool makes it possible to exclude direct contact of hot surfaces with building structures - floors, walls made of combustible materials, and to create fire-resistant cuts and offsets.

- Refractory wool for furnaces of metallurgical enterprises and recycling plants makes it possible to create an excellent thermal insulation casing around the casings of such high-temperature equipment.

- Fireproof mineral wool for boilers of thermal, technological power plants, boiler houses effectively serves the same purposes.

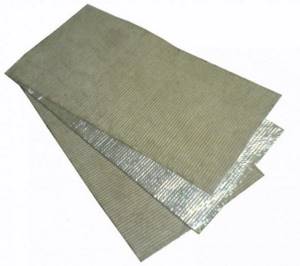

***The properties of fire-resistant heat-insulating materials partly depend on the form of release of the finished product, therefore, lump wool, which is inconvenient either for transportation or for most types of installation work, is pressed and stitched with basalt (fiberglass) threads into slabs, rolls, mats; shells for lining pipelines, including those with foil laid as a heat-reflecting layer.

Basalt thermal insulation fibers in a non-combustible sheathing slab

Types of thermal insulators made of basalt wool

The choice of the type of heat insulator made of basalt wool depends mainly on the design of the chimney, design features, as well as the requests of the owners of the room regarding thermal characteristics.

Basalt insulation for chimneys is produced in the form of cylinders and shells, mats, rolls and cardboard. Also, basalt wool can be with or without an additional foil coating.

Might be interesting

Thermal insulation

What are thermal insulation materials: comparative…

Thermal insulation

How to insulate a roof from the inside and not make mistakes?

Thermal insulation

Roofing and drainage: heating rules

Thermal insulation

Insulated Swedish stove: pros and cons

Basalt cylinders and shells

This form of release has found its application in systems for home and industrial heating of premises. Designed for emission temperatures not higher than 300°C.

It can be used in two ways: for external and internal thermal insulation.

Depending on the brand, it varies in thickness and length: it can be sold in rolls by the meter or optionally upon order.

Basalt wool mats and rolls

This option is suitable if the contact temperature with the material will fluctuate between 450-700o.

It is not recommended for use on chimneys that will pass through walls, but it is suitable for other heating pipe configurations with non-standard diameters and layouts.

Basalt fiber cardboard

Basalt cardboard is the best option for insulating brick chimneys. It is able to withstand ultra-high temperatures up to 900°C. One cardboard sheet can be 5-19 mm thick.

It is easy to install and is highly resistant to moisture and vibration. After installation, its service life reaches 50 years.

You can choose a material with or without a foil layer. Foil is required for external insulation and to achieve certain characteristics.

Fire protection temperature depending on the type of wool

The temperature range that various types of such fire-resistant materials can withstand as much as possible during long-term operation:

- Kaolin (mullite-silica) wool grade MKRR-130 – 1150℃; MKRH-150 – 1300℃.

- Basalt mineral wool – up to 1200 degrees Celsius.

- Silica wool – up to 1100℃.

- Glass wool – 450℃.

- Slag - up to 300℃.

*** Even kaolin (mullite-siliceous) wool, although made from molten stone raw materials at a temperature of 1750℃, but containing binders with a lower melting limit, cannot withstand a critical thermal Fire-resistant wools are not intended for use in such extreme conditions.

For these purposes, other fire-resistant materials and products with protection against temperatures above 1580℃ are used.

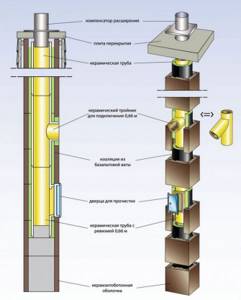

Insulation of a chimney pipe with basalt wool

The technology and mechanism for installing the casing is influenced by many factors, including the material from which the pipe is made, its diameter and others.

Basic rules for high-quality thermal insulation

Compliance with the following standards is mandatory when lining a chimney with a heat insulator:

- for a wooden covering, the layer of wool should be no less than 50mm and no more than 100mm;

- in passages through wood this layer should reach at least 5 cm;

- if mats of material are laid in several layers, then their joints must be covered with upper layers;

- for heat insulators in a cylindrical release form, when they are applied in several layers, each subsequent one must be laid with an offset of 180°;

- for boilers with liquid fuel or gas heating technology, it is advisable to use high-temperature cladding materials with a range of up to 300°;

- a protective screen is a mandatory insulation measure if materials without a foil layer were used during the work.

Insulation of a ceramic or asbestos chimney

For asbestos chimneys, the outer cladding procedure is carried out, and the layers of material are secured with special staples. To simplify and speed up the work, you can use basalt cylinders, the thickness of which should not exceed 5 cm.

Important! You will also need to additionally install an external steel casing (the best option is stainless steel or galvanized materials), and insulate the upper end of the chimney with a cement mortar.

Methods for insulating a steel chimney

The mechanism for carrying out the procedure is almost completely similar to the method for a ceramic chimney, and looks like this:

- 2 pipes of different diameters are used: a large one for the external surface, and a smaller one for interior decoration.

- One pipe is inserted into another.

- The resulting gap between the products is filled with the selected non-combustible insulation to insulate the chimney.

- If the material has a foil layer, it is not necessary to install a protective casing.

- The structure at the end must be additionally insulated.

The instructions themselves are quite simple, but they can be simplified by using ready-made sandwich pipes that replace the first 3 points of the manual. Such ready-made consumables for insulation have high heat resistance and help achieve high insulation characteristics.

Regulatory requirements

The following regulatory documents are directly related to fire-resistant and fire-resistant wool, providing definitions regulating the technical conditions of production and fire testing:

- GOST 28874-2004, which classifies all types/types of refractory materials, defining fire resistance as a technical characteristic of a commercial product to withstand prolonged exposure to high temperatures without melting.

- GOST 4640-2011 – on technical conditions for mineral wool.

- GOST 23619-79, which establishes technical conditions for the production of fire-resistant heat-insulating mullite-silica fiberglass materials.

- GOST 30244-94 – on methods of fire testing for the flammability of building materials.

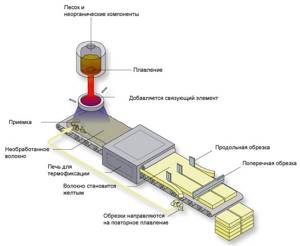

Mineral wool production

The procedure for making fire-resistant mineral wool varies depending on the characteristics and type of material. For the production of basalt slabs, inorganic (rock and dolomite) and organic (dust removal agent, water repellent, phenol-formaldehyde resin) components are used.

At the initial stage of insulation production, these components are mixed together and then entered into the oven. In it they melt at a temperature of 1600°.

Next, the mixture enters a centrifuge, in which thin threads appear under the influence of centrifugal force. They are fed to the next section of the production plant, where they are processed with organic components.

At the end of the process, the resulting material is sent under a press, through which the shape of the plates is set and their elasticity increases. Finally, the mineral wool is re-processed at a temperature of 250°.

Application

Due to its excellent fire-resistant characteristics and heat-saving properties, mineral wools are used in construction for the construction of objects for almost any purpose, for laying/installing utility networks/systems, and assembling technological equipment; as well as in the manufacture of various products where the technical parameters of these products are in demand.

On this topic ▼

Fire safety during construction

Buildings, private houses, baths

Application area:

- For the production of fire-resistant insulation materials.

- For insulation, and often at the same time fire protection of ceilings, floors, roofs, technical, attic floors; facades, basements, attics of buildings.

- As a heat-insulating filling of cavities in brickwork; joints, gaps, cracks between reinforced concrete structures.

- For thermal insulation, preventing freezing of pipeline networks, technological communications of populated areas, industrial and warehouse facilities.

- As carriers of catalysts, filters for the purification of high-temperature gases, including acting as fire arresters for flammable gas mixtures.

- In the production of various products - from pipe products to vehicle brake pads as a reinforcing, heat-insulating base.

- For reinforcing refractory (fire-resistant) concrete.

- For constructive fire protection of load-bearing and enclosing building structures made of wood, metal, reinforced concrete; ducts of transit air ducts of ventilation units; exhaust chimneys, shafts of smoke removal systems.

- For thermal insulation, fire protection of pipes, fireplace chimneys, stoves.

- As a fire-resistant, heat-impervious protective coating, lining for combustible waste disposal furnaces; steam boilers, gas turbines of thermal power engineering facilities.

- For thermal protection of metallurgical furnaces, technological installations for oil refining, gas condensate.

- As a binder in the production of fire-resistant coatings, pastes, fire-retardant plasters.

- For thermal insulation of containers and tanks with compressed and liquefied gases.

- For filling the internal space of fire gates, partitions, hatches, doors.

- In heat/sound insulation of engine compartments, engine rooms, generator rooms of automobile, railway transport, sea and river vessels.

Fireproof insulation

Thermal insulation materials have many important characteristics. One of them is fire resistance. To protect the building from fire, only fire-resistant insulation should be used. Next, we will analyze in detail the features of fire-resistant basalt wool.

Analysis of key aspects

Unfortunately, many modern insulation materials belong to the class of combustible materials (for example, penoplex, which is so popular today). Despite this, they are used in many areas of construction, which is not entirely justified. Non-combustible mineral wool is an excellent solution in terms of safety and thermal insulation efficiency.

Why doesn't it burn

The first mineral wool (fiberglass) was a completely combustible material. At the slightest source of fire, it ignited quite quickly, which sometimes led to serious fires. Today, manufacturers take into account all aspects of safety, so they create fire-resistant materials. The most fire-resistant is basalt wool. It is made on the basis of basalt rocks. As a result, such material can easily withstand temperatures of up to 1000 degrees, which is more than enough for standard conditions. Volcanic rocks are also used in its production. All this raw material does not burn at all, but at temperatures above 1000 degrees, it begins to melt. And this happens very slowly. Another type is slag. It is made from various wastes (slags) of the metallurgical industry. The melting point is slightly lower - 850 degrees. However, it has significantly lower efficiency (in terms of thermal conductivity), so it is more rational to use the basalt variety. Rocks and metal waste a priori cannot burn. Therefore, materials made on their basis are classified as NG class. However, the synthetic fibers inside can melt (or even burn). They serve as a fixing element that provides shape (mat or slab). As a rule, in the event of a fire, synthetics immediately burn out (when the temperature reaches 250 degrees). However, then the combustion stops.

Release forms

The most common form of basalt wool production is slabs. They are easy to use and highly efficient. The following varieties are distinguished:

- Soft. The density of such models does not exceed 60 kg/m3, and thermal conductivity ranges from 0.032-0.35 W/m*C. It is permissible to use them for insulating structures that are not subject to serious physical stress.

- Semi-rigid. Density up to 120 kg/m3, thermal conductivity 0.035-0.39 W/m*S. This type of mineral wool is most often used for thermal insulation of vertical structures.

Important! When using such models, it is necessary to create an additional strength frame.

- Tough. This is mineral wool with increased density (up to 180 kg/m3). Thermal conductivity is in the range of 0.039-0.042 W/m*C. It can be used in any design. It is often used for roof insulation.

Another common form is mats. They have a width of 610 or 1220 mm. The length can vary from 2.5 to 10 meters. The mats are stitched with a special fiber, which provides flexibility to the material. The thickness also varies, but most often it is 50 mm. For cold regions of our country, two layers are required.

Thermal insulation mats with aluminum foil are especially popular. It provides maximum protection of the insulation from all external irritants. Its presence completely prevents condensation from entering the structure of the wool, which ensures its maximum service life. In addition, this provides additional sound-absorbing properties.

Application area

Non-flammable mineral (basalt) wool can be used for thermal insulation of any floors. This measure will provide additional fire safety to buildings. However, its use is not always rational, because the cost of such material is much higher. It is used to insulate the following objects.

- Private houses made of timber. As you know, wood burns well, so the use of fire-resistant insulation is simply necessary.

Advice: to reduce the flammability of timber, it should be coated with special impregnations. However, this measure does not completely eliminate the problem.

- Baths. Such buildings are subject to serious temperature loads, so especially resistant grades should be used for their thermal insulation.

- Industrial buildings. This measure is mandatory for safety reasons.

- Heating and water supply systems. This is also a mandatory measure. In tandem with mineral wool, it is necessary to use kaolin. It is laid as the first layer and absorbs the lion's share of the temperature load.

- Gas and other explosive lines.

- Buildings located near fire hazardous objects. This also applies to public buildings (schools, kindergartens, shops, etc.), that is, those buildings where there is a constant concentration of a large number of people. Insulation should prevent the spread of fire.

Main manufacturers of non-combustible mineral wool

Many manufacturers, both foreign and domestic, are engaged in the production of fire-resistant insulation. However, there are several of the most recognized ones.

- The leader in the fireproof insulation segment is Rockwool. This is a Danish company that has proven itself to be the best. Thermal insulation from this manufacturer is more expensive than that of domestic competitors, but it is distinguished by its highest quality and improved performance characteristics.

- URSA is a subsidiary of the Catalan concern URALITA. The company has 14 factories in 9 European countries. Positioned as Rockwool's main competitor. The emphasis is on the production of mats and insulation for roofing.

Important! Beware of fakes - real packaging from URSA should have 2 blue bears and a red inscription.

- Knauf (Germany). The range of insulation from this manufacturer is lower than that presented above. However, the focus is on excellent quality. In Russia, the products of this concern are in particular demand in the industrial sector.

- Isorok. This is a Russian manufacturer that provides strong competition to foreign analogues. The main advantage is relatively low prices. In the context of constant fluctuations in the ruble exchange rate, products from Russian manufacturers are beginning to enjoy increasing popularity.

[content-egg module=GdeSlon template=compare]

Advantages and disadvantages

The advantages of all types of fire-resistant, fire-resistant mineral wool include:

- High thermal resistance even with prolonged, constant fire and thermal contact without decomposition or destruction of the internal structure.

- Low density, which is a priority when choosing thermal insulation and fire retardant coatings for load-bearing structures and interfloor ceilings of construction projects.

- Low thermal conductivity and low heat capacity, which form excellent thermal insulation and energy-saving characteristics of this product.

- Dielectric properties, important when used at thermal power facilities, even when operating temperatures increase to 700–800℃.

- Excellent chemical resistance to strong acids and alkalis.

- Resistance to seismic vibrations and vibration influences.

- Soundproofing qualities.

- Oil/moisture resistant.

- Not wetting with melts of non-ferrous metals.

- Long period of operation without loss of thermal insulation and fire retardant parameters of the product.

- Safety of use due to the absence of release of toxic volatile compounds both during normal operation of heating and technological equipment, and during severe overheating of housing surfaces; as well as in the event of a fire, contact with an open flame inside a construction site, where mineral fire-resistant (fire-retardant) wool, or rolled, slab products based on it, are used as fire-resistant, heat-insulating coatings.

- Low cost of products, which is important both for customers of construction and reconstruction of large production facilities, and for the construction of multi-storey and private houses.

- A significant reduction in the volume of more expensive ceramic refractory products as part of the structures of casings, linings of heating and technological equipment, a reduction in material consumption, in situations where replacement with fire-resistant mineral wool is possible.

Due to its structure, softness, and elasticity, lump wool is easily stuffed into thermal insulating casings of equipment, but more often such products are used in the form of rolled, slab insulating materials, including in the form of finished products; for example, half-cylinders for thermal insulation of pipelines of engineering and technological communications.

The disadvantages include the need for extreme caution, the mandatory use of thick protective clothing, respiratory tract and eye protection devices when carrying out any work with fire-resistant mineral wool, due to the fact that the smallest ultra-fine fibers of such products can harm human health.

Materials for insulation of chimney pipes

It is advisable to start a project for insulating chimney pipes at the time of construction of a house or cottage, but thermal insulation work can be carried out at any stage, even if the dwelling has already been built. Next, we will consider the main methods, methods and materials that are suitable for carrying out this procedure.

How can you insulate a chimney duct?

The integrity of the chimney pipe is affected by two main factors that must be taken into account during insulation work:

- Dew point. This point concerns the release of condensate, the negative impact of which was discussed above. The fact is that in the absence of proper thermal insulation, the dew point moves inside the pipe. That is, the warm air that rises during the heating of the room rises up from the direct heating source, reaches a certain point inside the chimney, and settles there in the form of condensate drops. This is especially dangerous for metal and brick products, since excess moisture is absorbed by the material and destroys it from the inside, freezing and turning into ice;

- aggressive negative impact of gases released from combustion. During the heating process, harmful chemical compounds inevitably appear, which destroy the entire home heating system. This especially applies to weak acidic solutions of nitrogen or sulfur. With prolonged exposure, they can destroy a chimney made of almost all materials.

To protect yourself from such harmful factors, you can choose one of the following insulation materials:

- non-flammable insulation for chimneys made of slag wool;

- glass wool;

- basalt wool.

The most popular and widely used are thermal insulators made of basalt wool.

Non-flammable thermal insulation materials made from slag wool

This version of fire-resistant insulation for chimney lining is available in two forms: in rolls and mats. It also varies in density and size, depending on the individual characteristics of the pipe, the purpose of the lining and other design factors, which are taken into account separately in each specific case.

Their main feature: preservation of structure and properties even with strong heating up to +400°C. They are fire-resistant and non-flammable, therefore reducing the risk of fire to a minimum.

Metallurgical slags are used as raw materials for production.

The disadvantages of this material include:

- presence of residual acidity;

- the possibility of a hostile environment occurring when moisture gets on the material.

Despite these negative aspects, this fire-resistant chimney insulation is widely used in repair and insulation work, as it maintains an ideal price-quality ratio.

Glass wool insulation materials

Glass wool is an insulating material with a fibrous structure. It is produced from broken glass or raw materials used during glass melting.

Depending on the manufacturing method, glass wool is divided into:

- thin, which is obtained by spunbonding (pulling) from glass melt;

- rough through the blowing method.

Glass wool is sold in the form of rolls or slabs.

Insulation for pipes made of basalt wool

Basalt rocks are used as raw materials for the production of insulation.

- The method of using inorganic elements provides complete resistance to rotting and fungi.

- Basalt wool for chimneys has high strength and heat resistance, so it is preferred to be used as non-combustible thermal insulation to prevent fire inside the chimney.

- The insulator fits well and adapts to the insulation surface. Has a long service life. After installation, it serves without loss of its characteristics for 30-40 years.

- Based on strength, basalt wool is divided into: soft, semi-rigid and hard.

Basalt wool has an additional useful property in the form of protection against moisture, therefore it is a more universal method of thermal insulation in comparison with glass wool or slag fiber.