Why do you need non-combustible insulation and what to pay attention to

Fire-resistant thermal insulation is necessary for every home because it is not only able to insulate the building from the effects of low temperatures, but also provides safety to the user. This reduces the chance of an accidental fire to 0%. If previously such insulation materials were new, in 2021 there are hundreds of models on the market that are suitable for household stoves, fireplaces, chimneys, baths, while their efficiency remains at a high level.

Oxygen index

The first selection criterion is the oxygen index. The characteristic indicates the minimum amount of oxygen that is present per unit volume of thermal insulation. In total, there are three types of insulation, which differ in flammability threshold:

- 40%. This category includes composite polymers;

- 31%. Glass wool, basalt wool and other fibrous and cellular thermal insulation;

- 20%. It is worth knowing that such products burn well in air, so their use is unacceptable in fire hazardous areas.

Peculiarities

When choosing a fire-resistant heat-insulating substance, it must have the following parameters:

- Burning with a visible flame is permitted, but must not last longer than 10 seconds. This will prevent the fire from spreading to other areas, which will prevent a large fire from starting.

- When burning, the maximum temperature of the material used should not rise above 50 degrees.

- In addition, it is important that the thermal insulation does not lose half of its volume and mass during combustion.

If all these points are met, then the user can be confident in the selected material, because it will never let him down.

This is interesting: Fire-retardant and non-flammable mastics: types and scope of application

What types of fire-resistant insulation are there?

There are hundreds of thermal insulation models on the market, each with a unique composition and can be universal or site specific. Therefore, you need to know which ones are suitable for pipes and which ones are suitable for a house, stoves, fireplace, etc.

Bulk

This species consists of small crushed stones. They are poured into a special place in the building structure. Most professionals advise using bulk materials of different fractions to increase their efficiency, because large products will create excellent thermal insulation, while small ones will fill the void formed between them.

- Expanded clay. Eco-friendly material that is completely safe for humans and consists of natural products. The main element of the composition is clay. The product is suitable for use in hard-to-reach places. The advantage of this option is high wet strength. This product is often used for insulation of fire-hazardous objects in industrial areas.

- Expanded vermiculite. The main element of this product is hydromica. To ensure that it can be used safely, it is fired at high temperatures during production. This product is used to provide thermal insulation for small structures and low-rise buildings. The main advantage of the material is natural ingredients, high biostability. The only drawback is instability to moisture.

- Perlite. One of the popular products that is used for thermal insulation in many places with low moisture content. The material is made on the basis of volcanic glass, thanks to this solution the product is lightweight and provides low thermal conductivity.

Cellular

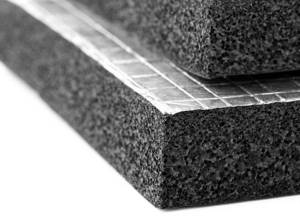

At first glance, such thermal insulation is more reminiscent of frozen soap foam, but with a high heat resistance rating. Foam glass is very popular in this category. To make it, glass chips are used, which are treated at high temperatures and sintered with coal. The advantage of such a product is durability (even a cheap product has a service life of 60 years; for more expensive models it reaches 100 years or more). In addition, foam glass has high mechanical strength and low thermal conductivity.

Its effectiveness has been proven in professional and amateur experiments. This material does not ignite either before or after 1600 degrees. All that will happen at record temperatures is the melting of foam glass, which is accompanied by no release of dangerous toxins. Due to its heavy weight, the material is used for insulating basements.

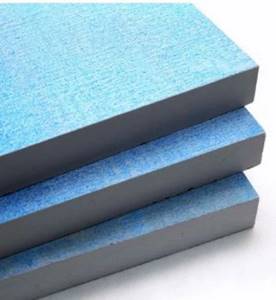

Fibrous

A popular thermal insulation that looks like cotton wool because it consists of small white fibers that are arranged randomly. This thermal insulation is available in rolls and mats, which is a convenient form factor for most buyers.

Mineral wool can be sold in sheet form. This product has little rigidity, unlike similar products in mats. In total, 3 types of this material have become widespread:

- Glass wool. The material can withstand temperatures up to 500 degrees, while maintaining all nominal technical characteristics: service life, low weight, thermal efficiency. However, to work with such material it is necessary to have special protection because glass wool negatively affects the mucous membrane and penetrates under the skin, and the product is also prone to shrinkage.

- Basalt wool. This product is based on rock fibers, which during production are heated to over 1400 degrees. For this reason, such a product can easily withstand temperatures above 1000 degrees. Just as 10 years ago, today this material is in great demand for insulating buildings. The advantages include: low moisture absorption, vapor permeability, environmental friendliness and biostability.

- Ecowool. The material consists of recycled cellulose, which has undergone fire retardant treatment at the processing stage. The product is lightweight, not harmful to the body and has a low insulation value. The main disadvantage is low moisture resistance.

Liquid

The material is applied by spraying onto a specific surface. After several hours, the liquid substance forms a solid mass that looks and feels similar to polystyrene foam. Polyurethane is in great demand among builders.

The material is highly safe for the human body; it also instantly sticks to the surface and is evenly distributed, while filling any joints and cracks. In addition, polyurethane has a high service life and guarantees quality for decades.

Perlite

*

A unique, lightweight insulation material made from glass-like volcanic rock. The production technology involves high heating of raw materials. During heat treatment, it swells and increases in size. This gives perlite excellent insulating properties.

Loose perlite

The material is famous for a number of special positive qualities:

- Ease. The special foam structure allows it to be used in metal and wooden structures without weighing them down.

- Resistance to high temperatures makes it possible to use it as insulation for pipes or roofs.

- Thanks to its fine-grained structure, it fits tightly and fills all cracks and cavities, making it ideal for insulating old attic spaces.

- Due to its resistance to high temperatures, it is ideal for installing heated floors.

Note that perlite does not absorb moisture well and has low vapor permeability, so it should not be used in places with high humidity. The disadvantages also include the difficulty of carrying out work associated with the release of aluminum dust when laying this insulation. Therefore, a respirator and special clothing are required.

The material is produced in the form of slabs, dry mixture and sand. On sale you can find a special type of roofing called bitumen perlite. The material is highly flexible and can cover structures of various shapes.

Vermiculite

The development of new technologies has made it possible to create a modern insulation called vermiculite. For its production, hydromica is used, which is heated to a temperature of 500-1000 degrees, causing delamination of the rock. Thanks to expansion technology, the volume of the resulting raw material increases 20 times. The product is produced in the form of compressed slabs and dry heat filler.

Backfill vermiculite

Expanded vermiculite has a porous base, so its weight is light. The material also has the following technical characteristics:

- The thermal conductivity coefficient ranges from 0.05 to 0.09 W/m*K.

- The melting point starts at 1300 degrees. This quality allows it to be classified as fire-resistant insulation.

- It has high hardness and durability due to the properties of mica.

- Has good sound and thermal conductivity.

- Long service life. The manufacturer claims a service life of more than 80 years.

- The material does not rot, does not decompose, is not interesting to rodents and mold, and does not enter into chemical reactions with alkaline and acidic substances.

Due to these qualities, vermiculite is widely used as insulation for walls and floors. This natural material is relatively cheap. The most expensive are slabs or blocks. The price of one slab is about 1,700 rubles. The cost of a cubic meter of dry backfill starts from 6 thousand rubles.

Where is fire-resistant thermal insulation used?

Although most high-temperature insulation materials are used for one purpose, their applications vary. So, some can be used in the construction of large buildings and industrial facilities, while others are suitable only for insulating bathhouses or pipes.

The most widespread is basalt wool. Most often it is used for thermal insulation of external facades. The big advantage is that it can be used both for exterior and interior decoration. Because the material has all the necessary technical characteristics for this.

Mineral wool is also in wide demand for country houses, but it has slightly worse technical characteristics, which do not allow it to be used for any kind of insulation. But unlike the previous option, it has greater elasticity, which allows it to be installed in complex shapes.

Some people buy fire-resistant thermal insulation to insulate non-residential premises or attics. Here experts recommend using bulk materials; they are more suitable for this.

To carry out high-temperature insulation in places with high humidity, it is necessary to select moisture-resistant and vapor barrier insulation. It would be best if this product is stone wool.

To insulate living rooms, basalt wool is used. But besides it, you can use mineral wool in a roll form factor for insulating floors or wooden structures.

Why is thermal insulation needed?

The role of the thermal insulation material is that, due to its poor thermal conductivity, the transfer of energy through the layer of material is difficult. Thus, you can not only preserve the heat that the fireplace produces, but also protect the structural elements of the house from high temperatures.

Chimney insulation serves several purposes.

- At the external location of the pipe, intense heat exchange occurs with the cold air of the street space. A huge part of the amount of heat is released into the atmosphere, but could be used to heat the room. If you reduce this share, you will achieve higher efficiency indicators. The solution to this issue will be insulation, which is applied on top of the walls of the chimney.

- Combustion products that are emitted through the chimney contain carbon dioxide and water vapor. The temperature of all this gas exceeds a hundred degrees. Upon contact with the chimney walls, which have cooled from the external environment, condensation forms on the surface of the latter. Acids, which are a combustion product, are mixed into it. The result is a chemically active environment, leading to the destruction of the walls. The appearance of condensation can only be avoided by increasing the temperature of the pipe itself, that is, by providing it with high-quality insulation.

- In places where the chimney pipe passes through the ceiling or roof, contact of materials necessarily occurs. In the case of wooden buildings, this situation is a fire hazard. But an additional function of insulation will be to protect the ceiling surfaces.

Corner placement option

Internal insulation of fireplaces involves the localization of energy inside the firebox for the purpose of its directed transmission. The fireplace should not emit heat in all directions, especially if it is installed near a wall. It should warm those sitting directly in front of the fireplace. Special reflectors for fireplaces are installed inside the firebox and serve as a screen from infrared radiation. As a result, all the heat escapes through the combustion hole into the room.

Good to know: Fireplace complex, which includes a barbecue, grill, smokehouse, cauldron and oven

Reliable thermal insulation for stoves and fireplaces means protecting the walls of the building from the negative effects of temperature. When the fireplace is located close to the wall, a heat-protective layer is installed, since high temperatures can lead to destruction of the brickwork of the wall or fire if the building is wooden.

Peculiarities

Non-combustible material for thermal insulation must meet the following characteristics:

- combustion with a visible flame is possible, but its duration does not exceed 10 seconds (that is, the insulation can catch fire, but a fire in the presence of an open flame lasts no more than the specified time);

- at the moment of combustion, the temperature of the insulating material does not rise above 50°C;

- During combustion, insulation cannot lose more than 50% of its weight and volume.

Voting for the best high temperature thermal insulation

What high temperature insulation would you choose or recommend?

PVO-500 plates

14.81% ( 4 )

Termoizol 1000

7.41% ( 2 )

Faspan ANTIFLAME

11.11% ( 3 )

Termion Vulcan (10 l)

3.70% ( 1 )

Teploizol KS 50

7.41% ( 2 )

LTM Flamma Standard

3.70% ( 1 )

LYTX-208a2

3.70% ( 1 )

Silica fabric KT-11-TO (82)

25.93% ( 7 )

Fireproof basalt fabric

11.11% ( 3 )

Varieties

Currently, there is a wide variety of different types of non-combustible insulation.

Here are a few main ones:

- Mineral wool, the most common type of insulation, consists of individual fibers intertwined into a common structure. Mineral wool is produced in the form of mats, twisted into rolls, and in the form of individual slabs. To increase water-repellent properties, it is impregnated with special oil or phenol alcohol.

- Expanded clay is a loose fire-resistant insulation material consisting of clay in the form of individual granules as a result of exposure to high temperatures in special ovens. Expanded clay is not used in its pure form, but in the form of a special mixture.

- Perlite is a loose, lightweight fireproof and heat-insulating material obtained from rocks of volcanic origin. It can withstand high temperatures up to 900 degrees Celsius. However, it has a significant drawback - it absorbs liquid.

- Foam glass - in structure it is a foamed glass mass formed from silicate glasses at a high temperature of about 1000 degrees Celsius using a gas former. After cooling, foam glass has significant mechanical strength.

Among all the listed types of insulation, it is necessary to focus on this type, such as mineral wool. It can be divided into several types depending on the type of original product:

- Glass wool - made from fiber obtained by mixing cullet with additives from dolomite, sand, limestone and soda. It has high chemical resistance. The temperature at which glass wool can work normally is up to 500 degrees Celsius.

- Slag wool - produced by melting blast furnace slag, has a characteristic gray color, and can withstand significant temperatures up to 600 degrees.

- Stone wool - it is also called basalt wool after the source material from which this insulation is made. Basalt rocks, when melted using special equipment, form fibers 5-10 microns thick and up to 20 mm long. Such cotton wool can withstand temperatures of 300 degrees.

The main forms of mineral wool production are mats of a certain thickness, rolled into rolls. Mineral wool is also available in the form of slabs, which have greater rigidity compared to mats.

It is worth noting: when choosing mineral wool as insulation, be sure to take into account the conditions in which it will be used and the location of its placement. Insulation in the form of mats has a longer service life and a better level of heat capacity.

This is interesting: Fire retardant compounds for metal structures

Foam glass

Sawdust as insulation: choosing insulation from sawdust.

The characteristics of the material can also be noted as its resistance to temperature changes. Foam glass has high technical characteristics that practically do not change over time.

Available in slabs and in the form of bulk material (fine crumbs). Foam glass blocks are used to insulate foundations, building facades and internal walls. The crumb is used as a bulk insulator for old roofs and for insulating pipelines.

Block foam glass

You can also add to the positive qualities of this material:

- Long service life. Manufacturers claim that it can last up to 100 years.

- He is not afraid of sudden temperature changes or bad weather conditions.

- Strength. Not subject to deformation, retains its quality under any conditions.

- Absorbs sounds and vibration well. A block of foam glass can muffle the roar of a tractor engine.

- Refractory. It practically doesn't burn. Able to withstand temperatures over 250 degrees. At higher temperatures it melts, but does not emit harmful substances.

- Does not attract rodents and will not become a breeding ground for fungus and mold.

It also has some disadvantages:

- High price. This material is considered the most expensive of all insulation materials. This is explained by the complexity of production, which requires high energy consumption.

- Low resistance to mechanical stress. When impacted or compressed, the granules crack.

There are no special requirements for the choice of this insulation, since it has recently appeared on the market and is not widely used. However, there are some recommendations that you should heed:

- Before purchasing, try to accurately calculate the amount of material. The calculation is carried out taking into account the upper dew point. It should be located inside the formation, and the adjacent wall should not be cooled below 4-5 degrees. Then condensation will not collect.

- Carefully study the structure of foam glass blocks. It should be uniform, and the slabs themselves should be the same size.

- Buy products from foreign manufacturers, since Russian production is poorly organized.

How to choose fireproof fireproof heat insulator?

Regardless of what you are buying fire-resistant insulation for - for a balcony, door insulation, for a boiler, floor or pipe, you need to strive for the following parameters:

- Maximum thermal efficiency. The lower the thermal conductivity coefficient, the more heat will remain in the premises.

- Reliability. The material must be designed for specific home structures. Fire-resistant chimney insulation should not be used for walls or floors. Insulators are designed taking into account the application, including loads.

- Life time. It is unlikely that the home owner will want to periodically carry out insulation work. It is better to complete the work once and live in comfortable conditions.

Attention! Any building material has advantages and disadvantages. When choosing, you need to not only consider the technical characteristics of a particular heat insulator, but also compare modifications with each other.

How to choose the optimal type of material

When choosing high-temperature thermal insulation, it makes sense to pay attention to a number of points:

- humidity level in the room. Only non-hygroscopic or low-hygroscopic materials are suitable for saunas and baths. At a minimum, the thermal protection should completely restore its properties after drying;

- maximum operating temperature. Thermal insulation must have some margin of thermal stability. If the temperature in the protected area is expected to be no more than 200 C, it is better to choose an option with a limit of 400 C;

- flexibility. It will be problematic to secure a hard slab on uneven surfaces. This is especially true for round chimneys. It is better to pay attention to flexible thermal insulation.

- durability. It is desirable that the service life of the heat-insulating material is no less than that of the high temperature source;

- weight. The lighter the material, the more securely it will be fixed in the designated place.

Ideally, thermal insulation should simultaneously reliably protect surrounding structures from overheating, not absorb moisture and not deteriorate over time. Soundproofing properties will also not be superfluous.

The range of high-temperature thermal insulation on the market is large enough to choose the best option. However, before purchasing, you need to understand all the features of the conditions under which the insulating material will be used. Knowing these parameters will greatly simplify the choice.

Video - Which insulation is better

Cotton wool as insulation

Any construction wool is characterized by high fire safety characteristics. Including ecowool and glass wool. These characteristics have nothing to do with vapor barrier and thermal insulation properties. They consistently withstand temperatures up to +500 degrees C. All wools have fire-resistant characteristics to a large extent. They do not support combustion; the flame, coming into contact with them, immediately dies out. Such properties make mineral wool one of the most popular insulators, including for baths and saunas.

Advantages:

- exceptional fire resistance;

- low price;

- variety of release formats;

- environmental certificates.

Flaws:

- the building material absorbs moisture well, when damp, it loses its thermal insulation properties;

- Some modifications contain hazardous components.

Note! If the insulation satisfies the fire safety and thermal insulation design, but is extremely hygroscopic, this deficiency is compensated for by technological solutions. In this case, it is necessary to provide effective waterproofing and vapor barrier.

Mineral wool production formats

Bulk

Bulk insulation materials are expanded clay, perlite, vermiculite, which are very resistant to fire and have a flammability class of at least G1 - an oxygen index of at least 30%.

Expanded clay is obtained by firing clay. The granules are heavy and have high thermal conductivity. This non-flammable thermal insulation is of a loose type and is therefore inconvenient to install. However, it is cheap and environmentally friendly. Expanded clay is characterized by the size of the fractions. So, up to 5 mm is sand, up to 40 mm is gravel. If large fractions are crushed, the result is crushed stone.

Thermal and fire-resistant qualities when using expanded clay are significantly increased. This is especially true for hard-to-reach places where such insulation can simply be poured. Expanded vermiculite is used for walls in low-rise construction. It is resistant to microorganisms, environmentally friendly, but has low moisture resistance.

Perlite

Perlite comes in the form of volcanic glass granules. The fraction ranges from 1 to 10 mm. Thanks to its light weight and the ability to adjust the thickness of the protective layer, it serves as an excellent heat insulator.

In practice, 30 mm of perlite is equivalent in effect to 150 mm of brick. Perlite is suitable for thermal insulation of roofs and walls and can be an alternative to brickwork. The disadvantage is that it absorbs moisture well and is fragile.

Liquid fire retardant insulation

These synthetic building materials are characterized by high thermal insulation parameters. Among them there are many modifications that are non-flammable and environmentally friendly. For example, polyurethane. Liquid fillers fill the smallest cracks, completely preventing cold from entering the premises.

Advantages:

- efficiency;

- environmental Safety;

- fire resistance;

- filling density.

Flaws:

- application requires special equipment and skills;

- high price.

Application of liquid polyurethane

Bulk insulation for walls, ceilings and floors

Each bulk non-flammable insulation for walls and ceilings has its own thermal conductivity parameters. When using, you need to accurately calculate the thickness of the backfill. This method of insulation is complex, both in design development and execution. Building materials vary in environmental safety; some release toxic substances when heated. But all of them are ideally non-flammable and fire-resistant.

Advantages:

- good thermal insulation parameters;

- does not attract animals;

- fire resistance;

- low cost.

Flaws:

- require precise calculations and site preparation;

- Some modifications emit hazardous substances at high temperatures.

Ceiling insulation with expanded clay

Cellular materials

Cellular non-combustible insulation is similar in structure to foam. A large number of closed cavities with air causes low thermal conductivity.

Foam glass has good thermal insulating properties, which does not change for 100 years and does not absorb moisture. Foam glass, obtained by sintering broken glass with solid gas-forming agents, is used to make panels and housings for laying pipes. Foamed glass is an ideal non-flammable insulation for deep basements in wet soils.

All presented heat-insulating products have clearly expressed non-flammable properties. Thermal stability is due to mineral raw materials.

Porous insulators with fire resistance parameters

This is a fireproof building insulation of the latest generation. Mostly, the materials are made from natural raw materials: glass, coal and other components. Up to 80% of them consist of voids. Insulation materials do not support combustion, do not emit toxic substances, are easy to cut, and are suitable for insulating any external and internal structures, including chimneys.

Advantages:

- high thermal insulation characteristics;

- fire resistance;

- low price;

- environmental Safety.

This building material has no deficiencies identified.

Foam glass production formats

Choosing fire-resistant insulation is a pressing task for many potential owners of country houses. Watch the tests of thermal insulation materials for non-flammability in this video:

Glass wool - material features

Based on ordinary mineral wool, fiberglass is also used for thermal insulation of walls. The material is obtained from broken glass using the spunbonding method by drawing when it comes to fine fiber and by the blowing method when it is necessary to obtain a coarser fiber.

Thermal insulation is sold in the form of rolls and slabs. The latter are more often used for the walls of ventilated facades, as well as roofs, attics and basements. Rolled thermal insulation material is suitable for insulating all horizontal surfaces, including floors.

The main disadvantage of fiberglass wool is the high risk of skin irritation during work.

Criterias of choice

- achieve high thermal efficiency by choosing insulation with a low thermal conductivity coefficient. In addition, we must not forget that when insulating a room, only 20-25% of heat loss occurs on the walls. In this regard, the issue of insulation should be approached comprehensively; the maximum effect can be achieved only by creating an absolutely airtight structure.

- An important criterion is the cost of the product. It should be remembered that high-quality insulation cannot be cheap. An unjustified price reduction means a violation of the insulation manufacturing technology, which directly affects its technical features.

- When purchasing modern mineral wool insulation, you should pay attention to the location of the fibers . Preference should be given to products with a chaotic arrangement. Unlike analogues with horizontally or vertically oriented fibers, they are characterized by higher thermal and sound insulation rates.

- Fire-resistant facade material, in addition to low thermal conductivity , must demonstrate good moisture strength and biostability. For finishing the inside of a house, environmental safety characteristics and the absence of toxic substances in its composition are important.

- If mineral wool insulation is not subject to loads (for example, it is laid on a frame or between load-bearing structures), you can choose a less dense (up to 90 kg/cubic m) option. It's cheaper. If pressure is applied to the material, then the indicators of strength and tensile strength and compression become important.

These qualities are demonstrated by denser (semi-rigid and hard-hard) analogues, which are more expensive.

A few recommendations

When choosing fireproof insulation, first of all pay attention to the place of its application. For insulating foundations, non-mineral materials such as foam glass, polystyrene foam or polyurethane foam are more suitable.

When insulating roofs and facades of buildings, preference is given to basalt wool with a density of about 140 kg/m3.

The environmental friendliness of the material is also taken into account. If the house is still under construction, it is better to insulate the external walls with expanded clay, perlite or vermiculite. In old buildings this is not always possible, so glass wool or spray foam is used.

Properly selected insulation will protect the structure from destruction and significantly reduce the cost of heating the house in the winter months. Don't go after cheap prices. It is better to purchase high-quality materials from large companies with a good reputation. In this case, they will last for several decades and will fully cope with their functions.

In what cases is it necessary to use non-combustible insulation?

When building a private house, the owner independently chooses thermal insulation materials based on his capabilities and needs.

Building codes require the use of non-combustible insulation only when constructing the following objects:

- saunas, baths;

- car maintenance and fuel stations;

- underground parking lots, garages;

- premises equipped with stove heating;

- high-rise residential buildings;

- children's and medical institutions;

- buildings that are regularly visited by large numbers of people.

The use of fire-resistant materials is also necessary in rooms where flammable products are stored.

Rating of the best fire-resistant insulation materials

TechnoNIKOL Technoacoustic

A good model that is suitable for insulating ceilings and floors. The main element in the composition is basalt. Sold in slabs of 12 pieces per pack. You can find smaller or larger quantities. The product belongs to the NG category, which means that it is not subject to fire and will begin to melt at high temperatures. The service life of this material is 50 years. In addition to excellent temperature resistance, the material does not transmit sound. Also, metallurgical slags are often included in the composition of wool, which increases its effectiveness.

Sold at a price of 1,200 rubles for 12 pieces.

TechnoNIKOL Technoacoustic

Advantages:

- Resistance to high temperatures;

- Wide range of applications;

- Price;

- Workmanship;

- Convenient form factor.

Flaws:

P-600-450-150-1

Foam glass is an excellent option for equipping industrial buildings with thermal insulation. In appearance, the material resembles frozen bubbles with a porous surface. Production is carried out using the method of sintering glass elements with coal. The product is highly resistant to various temperatures, which makes it possible to use it in many fire-hazardous places.

The average cost is 20,000 rubles per cubic meter.

foam glass thermal insulation P-600-450-150-1

Advantages:

- Shows high resistance to temperatures;

- When melting, it does not emit toxic substances;

- Safety;

- Durability (100 years);

- Easy installation;

- Simple processing.

Flaws:

- Large mass, so it is recommended to place the insulation in basements;

- High price.

Expanded vermiculite

The material is perfect for carrying out various construction and repair work on insulating a house with a fire-resistant substance. It is obtained by firing natural hydromicas. It is a granular substance that shows high resistance to harmful microorganisms and temperatures. Most often it is used in the construction of small low-rise buildings, because there it shows the greatest efficiency.

Acceptable operating temperatures at which expanded vermiculite does not lose its properties vary from -256 to +1100 degrees Celsius. In addition to excellent fire-resistant properties, the product has a positive effect on the soundproofing characteristics of walls.

The average cost is 1,000 rubles per bag.

Expanded vermiculite

Advantages:

- High efficiency;

- Wide scope of application;

- Natural composition, which affects the safety of the human body;

- Price;

- Withstands mechanical stress.

Flaws:

- Poor resistance to moisture.

Perlite M-75

This is an excellent choice for those who are going to insulate their home for a long time. The main element of the composition is obsidian hydroxide granules. The main advantage of this option is low weight, as well as high thermal insulation. Suitable for insulating outbuildings and roofs with any slope, which is a big advantage. This product is also used to fill voids in wall masonry. It is highly resistant to record temperatures, and when melted it does not emit any pungent odors that can harm humans or nature.

Sold at a price of 3,600 rubles per cubic meter. m.

Perlite M-75

Advantages:

- Safety;

- Fluidity, this allows the material to completely fill the voids;

- Inorganic;

- Withstands temperatures over 1000 degrees;

- Soundproofing;

- Cost-effective;

- High performance indicator.

Flaws:

- Weak resistance to mechanical stress;

- Absorbs moisture.

SILCA 250KM

These are lightweight calcium silicate boards that are highly resistant to high temperatures and have excellent performance properties. They can be used in domestic ovens where a reducing atmosphere is present. Such slabs are more often used for the back layer of lining.

Sold at price: 1,700 rubles per piece.

SILCA 250KM

Advantages:

- Withstands temperatures up to 1100 degrees;

- Provides excellent protection for ovens;

- Safe materials are used in production;

- Hard surface;

- Reliability.

Flaws:

Expanded vermiculite - subtleties of application

To insulate walls on the construction and finishing materials market, you can also choose the bulk material obtained by firing natural hydromica - vermiculite. This is granular thermal insulation with a special scaly structure, which exhibits increased resistance to microorganisms.

The material is actively used in the field of low-rise construction, for thermal insulation of attics and external walls.

Vermiculite is not resistant to moisture and this is its main disadvantage. When using material for thermal insulation of walls, it is necessary to consider additional waterproofing.

Types and properties

Insulation can have a different base and production technology, which determines its appearance and technical characteristics. Let's consider the main types of non-flammable thermal insulation material.

Bulk

They are stones and formations of various fractions that are poured into the space of the building structure. As a rule, for greater thermal efficiency, it is recommended to use bulk insulation of different sizes: larger ones provide thermal insulation, smaller ones fill the space between them.

Bulk types of non-combustible insulation include the following materials.

- Expanded clay. Environmentally friendly material based on clay. Suitable for thermal insulation of hard-to-reach places. In addition to high thermal insulation characteristics, it has moisture resistance. Expanded clay is ideally suited for insulating fire-hazardous objects; it has long been used in the organization of industrial furnaces.

- Expanded vermiculite. The product is based on hydromicas that are subjected to high-temperature firing. Typically, this material is used for thermal insulation of low-rise buildings, as well as attic spaces and external thermal insulation. It is environmentally friendly and has improved biostability, but its disadvantages include its inability to withstand moisture. Only high-quality and correctly installed waterproofing can level it out.

- Perlite. The material is based on volcanic glass, which ensures low thermal conductivity and low weight. Just 30 mm of perlite can replace a 150 mm layer of brickwork in terms of its thermal efficiency. Disadvantages include low moisture resistance.

Cellular

Externally, such insulation materials look like frozen soap foam. The most common fire-resistant cellular thermal insulation material is foam glass. It is produced by sintering glass chips with coal or other gas-forming agent. It is characterized by durability (service life reaches 100 years), mechanical strength, and low thermal conductivity.

Foam glass does not burn even at record high temperatures; only the material can melt without releasing dangerous toxins. The material is moisture-resistant, but quite heavy and bulky, so the optimal place for its use is basements.

Fibrous

Externally, the material resembles cotton wool, since it consists of chaotically located fine fibers of a white or milky shade. Such insulation is called “cotton wool”. Release form: rolls or mats.

Mineral wool also comes in sheet form. Sheet products have less rigidity compared to their mat counterparts. If we talk about fire-resistant fiber insulation, then they include several types.

- Glass wool. Withstands heating up to 500°C, maintaining its technical characteristics. These include thermal efficiency, durability, and light weight. However, the material is prone to shrinkage, and during operation it requires special protection, since thin fibers prick, dig into the skin, and the smallest particles irritate the mucous membranes of the upper respiratory tract.

- Basalt wool. Basalt wool is based on fibers from rocks that are pre-heated above 1300°C. This determines the ability of cotton wool to withstand high temperatures, up to 1000°C. Today, stone wool is one of the best thermal insulation materials: it has a low moisture absorption coefficient, is vapor permeable, does not shrink, is environmentally friendly and bioresistant.

- Ecowool. 80% consists of recycled cellulose, which has undergone special fire retardant treatment. The material is environmentally friendly, has low weight and low insulation coefficient, but low moisture resistance.

Liquid

The raw material is sprayed using special equipment and, after hardening, forms a mass that resembles polystyrene foam in appearance and feel. The most famous type of liquid fire-resistant insulation is liquid polyurethane.

It is characterized by environmental safety, and thanks to the method of application and improved adhesive properties, it is evenly distributed over the surface, filling cracks and joints. This, firstly, ensures the durability of the thermal insulation, and, secondly, guarantees its quality and the absence of “cold bridges”.

Application area

Thermal insulation materials of class NG or G1 are used for finishing premises outside or inside. They are usually located between the main wall and the cladding. The installation method depends on the type of insulation, its thickness, and the characteristics of the room.

Stone wool

Indoors

When using non-flammable thermal insulation materials for interior work, they are combined with plasterboard or gypsum fiber panels and built between partitions. A non-combustible coating is placed on the frame between the main wall and the false wall or parts of the interior partition. In this case, you can use any type of insulation; in addition to insulation, this provides sound insulation.