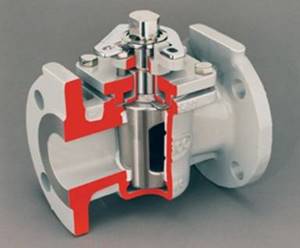

Installation of flanged valve

The installation procedure for a flanged valve is considered quite simple, although it must be performed in a certain sequence:

- Steel flanges are mounted on both ends of the connected pipes by welding. Their dimensions must correspond to the dimensions of the flanges at the ends of the valve.

- The pipes are separated to a certain distance into which the mounted valve is placed.

- The holes on the flanges of the pipe and the valve are aligned, after which bolts are inserted into them. O-rings (polymer or rubber) are placed between the flanges of the valve and the pipe, after which nuts are screwed onto the bolts.

- The final stage is tightening the threaded connections. Tightening should be carried out correctly in this order: each bolt-nut pair is tightened 3-4 turns, after which we move on to the next one until all connection points are completely fixed.

How to install it yourself?

Proper installation of a water valve is important for its safe operation and longer service life. In principle, the installation itself proceeds according to the following scheme:

- The water supply system is shut off.

- Open all the taps to allow any remaining water to drain from the pipes.

- Dismantle the worn device. The choice of dismantling method depends on the type of connection of the old product:

- pin-type - use a wrench to loosen the union nut;

- coupling - by dismantling the coupling;

- flanged - loosen the bolts used to secure the mounting flanges;

- welded - a section of pipe is cut out using a welding machine.

- Clean the pipe at the installation site from residual sealant and rust;

- Install a new valve, sealing the threaded part of the fum connection with Tangit Unilok tape or thread. For a flanged valve, no sealing material is required. Unlike fittings with a collapsible type of connection, installation of a welded device will require a special apparatus for soldering pipes.

However, there are a number of nuances that should be taken into account when working:

- choosing a convenient place to install the product so that there is no interference with the movement of the lever or handle;

- The thread may need to be lengthened. If the valve is being replaced, then after dismantling the old device, you need to clean the threads of the pipe from any remaining sealing material and try to screw a new product onto it. Quite often, during operation, corrosion destroys the metal on two or three turns of the threaded part, so it is necessary to cut off the missing turns;

- The product must be installed taking into account the direction of flow of the working medium indicated on the body of this type of shut-off valve.

Types of cranes

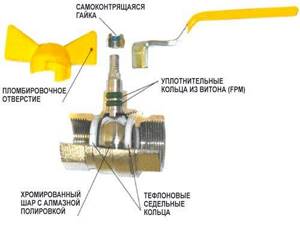

Ball

Ball valves have recently become very popular because they have an extremely simple design, which results in their long service life. In addition, they are easy to use, since to shut off the flow you only need to turn the handle 90 degrees.

The locking mechanism of this device is made in the form of a ball with a through hole. To block the passage, the ball should be turned with its hole perpendicular to the body.

The ball valve is controlled by a handle, which is connected to the ball via a rod. To seal the mechanism, two elastic rings are used that fit tightly to the ball.

The body of the ball device can be made of brass, aluminum or polypropylene. Plastic taps are installed together with plastic pipes for the heating system.

Pictured is an angle valve.

It should be noted that this fitting has the following disadvantages:

- Sensitivity to impurities in the coolant. Therefore, when using water, it is advisable to install filters.

- Not intended for smooth flow control. If it is used for these purposes, the mechanism will quickly fail.

Therefore, ball valves are often installed on the return line to completely shut off the coolant flow.

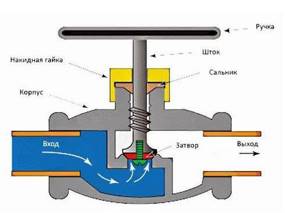

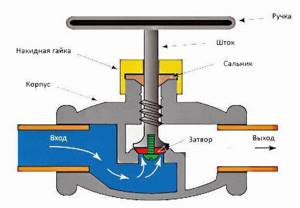

Valve device

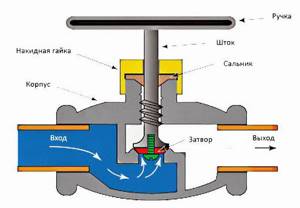

Valve

A manual valve or manual radiator shut-off valve is a structure within which the direction of coolant flow changes twice. The closing element in such valves is a rod with an elastic gasket. The position of the rod is controlled by a worm gear with a handle.

When the gasket is pressed tightly against the seat, the coolant passage is closed. If you rotate the handle smoothly, the gasket will gradually open the passage. The advantage of this design is the ability not only to completely shut off the coolant flow, but also to regulate its intensity.

However, it should be borne in mind that the rubber gasket deteriorates quite quickly, as a result of which it does not seal the flow tightly. This problem can be solved by replacing the gasket, which is easy to do yourself.

Valve with thermostat for radiator

Shut-off valve with thermostat

A shut-off valve for a heating radiator with a thermostat allows you to regulate the intensity of the coolant flow automatically. This device is also called a thermal valve or thermal valve.

The shut-off valve design for this type of radiator is relatively simple.

Its locking mechanism consists of the following elements:

- Metal body with passage hole and seat.

- Elastic cone.

Valve device with thermostat

During operation of the device, the cone lowers and rises, as a result of which the amount of coolant passed through changes.

The position of the cone in the seat is controlled by a thermal head (thermoelement), which consists of the following elements:

- Cylinder (bellows).

- Thermal agent is a liquid or gas that fills the bellows. The thermal agent greatly changes its volume as a result of changes in ambient temperature.

- The piston is connected to a cylinder on one side and to a cone on the other.

Under the influence of temperature, the thermal agent contracts or increases in volume, which sets the piston in motion, which in turn changes the position of the cone through the rod. The thermal head allows you to regulate the temperature at which the valve completely shuts off the water.

It should be noted that there are two types of thermostats:

- Mechanical;

- Electronic.

Electronic model of thermal valve

The latter are usually equipped with a display and sensor that displays the air temperature. Such devices allow you to set the temperature conditions of the shut-off valve at different times of the day or even days of the week.

For example, from nine in the morning to five in the evening, when all household members leave, you can set the temperature to a lower value, and after five, the radiator will warm up to higher values and better warm up the room. The price of such devices, of course, is quite high.

Heating battery wiring diagram

What is a valve and where is it used?

Locking mechanisms are used not only in everyday life, although every riser is closed using this means. The valve can be included as an integral part of a gas pipeline, as well as a pipeline for transporting technical liquids. Depending on what is transmitted through the pipes, the components change, but the general principle

Design and principle of operation

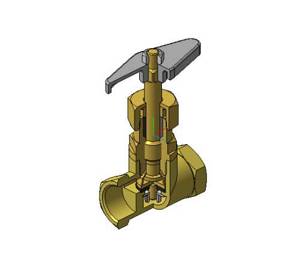

Structurally, each valve consists of the following parts:

- Housing and removable cover. The body is made of cast iron. Steel is used less frequently. Alloys are even rarer. Inside there is a cavity in which parts are located that ensure the system is sealed. Connection to the pipeline is made using a flange connection or welding. In the latter case, the possibility of dismantling and using components for further assembly is excluded.

- Locking unit. Consists of a guide and a shutter. Maximum reliability is achieved by units in which the guide is part of the housing. Water valves are made of durable metal alloys, and the valve is additionally coated with an anti-corrosion compound.

- Control element. The valve consists of a screw rod and a flywheel. The meaning of the node is the transformation of the rotational movement of the handle into the translational movement of the bolt, which is attached at the opposite end. The element is connected to the body using flanges, and the tightness ensures a vertical position.

- Yoke knot. Thanks to it, the influence of the environment moving through the pipeline does not in any way affect the performance of the control elements. The nut with the rod is protected from temperature changes. And when circulating hot liquids or gases, it always remains working.

The operating principle is as follows. The operator turns the flywheel, driving the rod with the threaded mechanism. When lowering, the damper closes the passage hole in the housing, locking it. The process is controlled, and partial blocking is allowed, which makes it possible to reduce the pressure in the pipes after the valve.

However, this does not mean that the device can be used for these purposes. With prolonged use, water “polishes” the nodes, and when the time comes to shut off the flow, it will not be possible to do it hermetically. Moreover, rust and deposits can aggravate the situation, even causing the valve to fail. But you can briefly reduce the pressure in the pipeline without fear of consequences, if this is not a periodic measure.

Features and types of device

Before purchasing flanged fittings, you need to familiarize yourself with the features of its design, as well as information regarding what material the part is made of. For industrial purposes, mechanisms that are made of cast iron or steel are often used, but for domestic needs it is recommended to give preference to bronze or brass products.

Steel structures are installed in piping systems to remove steam and liquid. In addition, the working environment can be represented by the following elements:

- liquefied or natural gas;

- ammonia;

- carbon dioxide;

- various corrosive substances.

A significant advantage of a steel mechanism is its low weight, which cast iron products cannot boast of. Thanks to these advantages, the requirements for the technical parameters of the pipeline system are simplified several times, since there is no need to use additional elements and special fittings during the installation process. In order to make a steel flanged valve, you should use stainless steel, and for the body you need to choose material grades such as A25 and A30.

However, there are technologies that allow the use of metals that do not contain alloying components. The steel flanged valve reaches 100 mm in diameter, so it can be installed even in pipelines where there is a large flow of liquid.

There are two types of housing of this design: corner and pass-through. If sections of the main line are straight, then experts recommend giving preference to straight-through valves, but their disadvantage is represented by high hydraulic resistance. An angle pipe valve is used in areas where pipes are connected perpendicular to each other.

Experts distinguish a separate group of flanged steel valves, which are straight-through and steam. Their installation is required on those pipelines where the working fluid is transported at temperatures above 400 degrees Celsius. The advantage of steam flanged structures is that they do not have stagnation zones, but the disadvantages include their large mass and size.

A flanged valve made of brass is installed on pipelines through which vapor and liquid working media are transported. Paronite is used to produce O-rings, and the stuffing box is made of asbestos. The brass tool is distinguished by its manual drive, where a flywheel is used as a handle.

Another type of flanged valves are cast iron structures, for the manufacture of which manufacturers use gray or ductile iron. Locking units are represented by a complex design consisting of three main elements:

- spool;

- flywheel with threaded rod;

- oil seal.

The uniqueness of cast iron flange fittings lies in the fact that all the parts that make up the shut-off assembly are made of steel. The only exceptions are the sealing parts of the spool for cast iron mechanisms, on which a rubber or fluoroplastic gasket is installed.

Manufacturing technology and materials

Various materials are used to make the valve:

- Brass. The brass product is characterized by its small dimensions, light weight, corrosion resistance and long service life. It can be installed in both cold and hot water supply systems made of steel and plastic pipes. The disadvantage is the high cost of such products.

- Cast iron. Valves made of cast iron have a fairly large mass, but are reliable, capable of withstanding increased levels of pressure, and resistant to various types of deformation. They have a low price, so they are often used for the construction of water supply systems in private and apartment buildings, country houses and garages.

- Steel. For steel products, instead of a handle, a wheel is installed on the body, by turning which you can adjust the pressure level or stop the pressure of the moving medium. They are lighter than cast iron, have a simple design, are repairable, and can be used in heating systems with higher operating temperatures and pressures, as well as in networks where there is a risk of water hammer.

Types of locking mechanism

According to the type of constipation, all water valves and taps are divided into several types:

- Valve;

- Ball;

- Cork.

Below we will take a closer look at the features of all types of these devices.

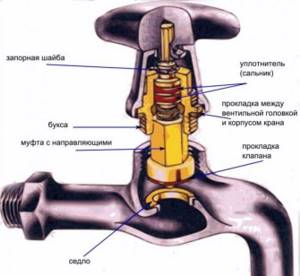

Valve valve device

Valve

Valve taps are the usual locking mechanisms. The principle of their operation is based on blocking the passage with an elastic gasket mounted on the rod. The position of the rod is adjusted by a handwheel using a worm mechanism.

Thus, when the handle is rotated, the rod rises, resulting in the passage for water opening.

Among the advantages of this mechanism are:

- Ability to withstand high pressure;

- Ability to control flow;

- Ease of Management;

- Possibility of repair.

Along with the advantages, these products also have some disadvantages:

The gasket quickly fails because it comes into contact not only with water, but also with a metal surface. True, you can replace it yourself. As a rule, the device comes with an assembly drawing of the water valve, which shows how to disassemble the mechanism and replace damaged parts.

Removing the axle box gasket

- To completely open or block the passage, you need to make several turns of the flywheel yourself, which is not very convenient.

- The mechanism is less durable than other types of fittings.

For these reasons, recently such taps are installed quite rarely, only in cases where it is necessary to regulate the flow.

In the photo - a ball valve with a diameter of ¾

Ball

Ball water valves have recently become the most common. They received this name as a result of the fact that the locking mechanism is made in the form of a ball with a through hole. To block the flow, the ball is rotated with its hole perpendicular to the pipeline.

The plumbing ball valve has a number of advantages, such as:

- Durability due to the simplicity of the mechanism;

- Tightness when the passage is closed;

- To open the passage, you only need to turn the handle 90 degrees;

- Affordable price;

- Possibility of use in conjunction with servos and other devices that allow you to control the mechanism remotely or install it in automatic flow shut-off systems. (See also the article How to choose a mixer: features.)

Ball mechanism diagram

As for the shortcomings, there are few of them:

- The operating instructions for the device imply its use only to completely block or open a passage, i.e. it cannot be used to regulate flow. Otherwise, the mechanism will quickly depressurize.

- If the mechanism fails, it cannot be repaired.

Most often, this type of fittings is used in plumbing systems.

Plug tap

Cork

The design of a plug-type water valve resembles a valve valve, the only thing is that the flow is shut off using a conical plug, which is attached to the stem. When the rod is lowered, the plug enters the hole and tightly blocks the passage.

It should be noted that in recent years such fittings have been used extremely rarely in water supply systems, since more durable ball valves are installed instead.

Plastic ball valve 1 2 inches

Which one is better to choose?

Choosing a mixer is not easy. After all, you want it to be compact, reliable, firmly “sit” in the workplace, match the style of the room and not break down for a long time.

- For the kitchen, it is advisable to choose a valve made of brass, bronze, copper with a chrome or gold coating, on which grease does not linger and dirt is easily washed off. Such faucets are durable and expensive, they are not susceptible to oxidation and rust. The faucet should also have a swivel spout with a gander height convenient for washing dishes. The price of a quality product starts from 5 thousand rubles.

- For the bathroom - the faucet body and spout should be made of brass, preferably having a replaceable cartridge. This can be a ball mixer equipped with a single lever handle or a two-valve tap. Many people prefer a ceramic water tap, i.e. with ceramic cartridge. The sealing element in it is a ceramic ring. Such products withstand the effects of hot water better, adjust more smoothly than taps with a rubber seal, last a long time, and require less repair and maintenance. Of course, with such characteristics, a ceramic faucet also has a considerable price - from 4.0 to 35.0 thousand rubles (depending on the manufacturer).

- For other situations. In utility rooms and garages, an inexpensive single-valve tap will suffice. The price of such products varies from 1.5 to 3.5 thousand rubles.

Tap for water supply

Purpose

In arbitrary water supply networks - central, local or autonomous - shut-off and control equipment is used. The most common type of equipment is a water faucet.

The device is designed to regulate the throughput capacity and pressure functions of a pipeline by transforming the cross-sectional area of the lumen of the pipe channel.

The products will be able to perform two main functions:

- Locking function. The fittings have two positions - “open” and “closed”, and help to block or unlock the pipe channel. For the most part, shut-off valves have a small and ball-shaped handle rotation angle;

- Adjustment function. Here, the closed and open positions are the extreme points, and the device allows you to smoothly change the cross-section of the lumen between these extreme positions. Such faucets are used on sinks and sinks, as well as in a channel version. They can have different designs.

Shut-off and shut-off and control valves are installed at the entrances of main pipes to the facility, in each individual room, at intersections and branches, before and after the end of metering equipment and plumbing fixtures, before and after the end of pumping equipment, at water intake points.

This widespread use is explained by the fact that plumbing equipment quite often breaks down and requires repair; in addition, preventive measures are often taken that require turning off the water supply. Using shut-off valves, it is possible to cut off a section of the network or a device from the system and replace it normally without draining the water.

varieties and device

Devices can be classified according to various parameters.

To begin with, let's divide them according to their intended purpose:

- Products for household needs. These are the familiar faucets on bathtubs and washbasins, kitchen appliances, etc.;

- For business needs. These are taps installed at the end of a pipe to connect irrigation hoses, water kits and other similar needs. They can be ball or valve;

- For the needs of the water supply system. These devices are built into the system and have a coupling design (much more often). With rare exceptions, these are ball valves.

For domestic needs, not simple designs are used, but mixing ones. They allow you to regulate not only the pressure, but also the temperature of the water by mixing warm and cold flows in various proportions.

The following possible solutions are possible:

- Two-valve. The mixer has two separate valves for warm and cold water. Adjustment is made by both thumbwheels;

- Single lever or surgical. The mixer has one handle that regulates the pressure and proportion of the mixture;

- Automatic. The mixer is a three-way valve with a thermostat, and opening is carried out by a simple ceramic axle box or a servo drive at the command of a displacement sensor. Such designs are still distinguished by too high a price.

There are four types of designs: worm, ball, ceramic valve boxes and ceramic lever cartridges for the mixer.

The former are obsolete and are actually not used, since they are the least reliable and require frequent replacement of rubber gaskets.

Ball structures are easy to construct: a spherical plug with an axial slot is installed in the coupling body, which fits well to the saddle in which it is located. A spindle is attached to the ball. Using the spindle, we can turn the plug either with the slot facing the channel lumen, or with the side without the slot.

Ceramic locking mechanisms use the same principle, only it is not the ball that moves, but one plate relative to the other. Ceramic axle boxes, like cartridges, are distinguished by high reliability, smooth running, and quiet operation. But they are sensitive to water quality and require the installation of purification filters.

In most cases, household taps are simpler in design - they do not have a mixer and are a simple valve-type locking mechanism. Modern models are equipped with a ball mechanism or a ceramic valve axle box; worm-type valves are slowly being forced out of the market.

It must be stated that ball and valve mechanisms are used not only in water supply networks: they are installed on all types of pipes, so quite often the client is not able to understand how a gas tap differs from a water tap. Their designs are monotonous, only the materials and some nuances differ.

Types by connection principle

The ball valve differs in the material used in its manufacture, and also in the principle of connection to the pipe.

Coupled

A ball joint water tap is a design with threads at the ends. This type is used for industry and housing and communal services. Diameter range 8 – 100. The body is made of bronze, steel and stainless steel.

The advantages of this type of product include low weight, length, and low cost. The disadvantages include the difficulty of repair and maintenance.

Carving is divided into several types:

- VN-VN - internal thread on both ends of the product;

- NAR-NAR – external thread on both sides;

- Fitting - inside thread with fitting;

- VN-NAR - one thread is inside, and the other is outside;

- With the American one there is a thread inside on one side, and a union nut on the other.

Flanged

This type connects with a return flange. Diameter range from 15 to 800. The body is made of cast iron, steel and stainless steel.

Among the advantages of this type are:

- Ease of installation and maintenance;

- Can be used for any pressure indicator.

Disadvantages of this connection:

- Large weight and size;

- The bolt tie becomes loose, which means that over time this will lead to a decrease in tightness.

Welding

The ends are made specifically for welding. They produce products in sizes 10 – 800. The material is made of steel and stainless steel.

Advantages of the welding product:

- Absolute tightness;

- Weight and length are less than flanged ones.

Disadvantages of this type:

- There is no possibility of service;

- Difficult to install;

- Difficult to replace.

Installation of shut-off valves in the system

In a heated towel rail system, a shut-off fitting closes the radiator and at the same time the flow of warm air. The valve position is adjusted using a control handwheel or a small switch knob (in modern products).

When installing a valve, the material from which it is made and the design type (ball, valve) are taken into account. Installation can be threaded or flanged. The first type is performed when small diameter pipes need to be connected to the system - up to 6 cm, the second - for large-sized pipes (up to 160 cm).

To install a “Grohe” or “Hansgrohe” thermostatic locking mechanism on a heated towel rail, you must:

- Screw the valve into the coupling

- On the other side, attach a pipe to the coupling. This is achieved by screwing the threaded pipe fitting into the fitting seat.

- Seal the joints of individual elements with fluoroplastic film. If a brass corner valve is installed, the joints can be soldered by welding.

Device design

The valve design is quite simple, and the product consists of the following main parts:

- Frame.

- Locking device.

- Handwheel or locking handle.

The body of the product is made by casting. A locking device is installed inside the housing, and the flywheel is brought out. The body also has threads on both sides, through which the valve is connected to a water or gas pipeline. The cross-sectional diagram of shut-off valves is as follows:

Types of valves

To determine the position of the device and find out how the valve opens or closes, you first need to know the type of device installed.

In household systems the following are most often installed:

ball valves. There is a metal ball in the body of the device, which serves as a locking mechanism. The body and locking element are usually made of durable metals (brass, steel, bronze), which ensures a long period of use of the device;

Valve with ball-shaped locking mechanism

plug valves. The locking elements in this type of device are cylindrical or conical plugs. The plug valve body is also made of high-strength metal. The locking mechanism allows the valve to be used in pipelines with aggressive media.

Valve with cylindrical plug

In most cases, ball valves are installed on heating and water supply systems, and plug valves on gas pipelines.

Types of shut-off valves

The following types of shut-off pipeline valves are distinguished:

- taps;

- gates (valves);

- valves;

- flaps.

Crane classification

Shut-off valves are primarily designed for low-pressure domestic pipelines.

The shut-off valve design is as follows:

- frame;

- locking element;

- handle;

- set of sealing gaskets.

Elements included in the stopcock

Devices can be classified according to several criteria:

- type of locking element;

- installation method.

An element that blocks the flow of a passing medium can be:

- ball. In accordance with this, the valve is called a ball valve (figure above);

- cone in the form of a plug (plug valve).

Plug type stopcock

The taps can be attached to the pipeline:

coupling method. The fixing nuts are screwed onto the thread prepared on the pipe;

Threaded tap

- flange method. The fixing elements are flanges connected to each other with bolts;

- welding method.

Devices mounted on flanges and by welding

Each tap has its own symbol. The markings on the device body must include:

- nominal diameter (DN);

- conditional pressure for which the device is designed (PN);

- material used to make the tap;

- manufacturer;

- additional reference materials (date of manufacture, batch number, etc.).

Symbols of the main parameters of the crane

If you know the markings, you can always choose a locking device yourself.

Using Gates

A shut-off valve (valve) consists of a body with two ends for attaching the device and a seat that is closed by a shutter.

Pipe shut-off valve

The main distinguishing feature of a valve from a faucet is its high tightness class, which allows the device to be used on gas pipelines.

A valve, like a faucet, can be connected to a pipeline using couplings, flanges or welding.

Valves are produced that are actuated by:

- flywheel (manual control);

- electric drive (electronic control), including using a remote control.

The marking of shut-off valves also contains:

- symbol of the device model;

- passage;

- designation of the type of connection to the pipeline;

- pressure;

- execution material;

- Climatic performance;

- document on the basis of which the valve is manufactured.

Designation of valve parameters

Purpose and types of valves

The most commonly used element of any pipeline is the valve. The device consists of a body and a cover, between which the shutter is located.

The simplest type of shut-off valves

The purpose of shut-off valves - valves - is any pipelines whose diameter varies from 15 mm to 2000 mm.

The advantages of the device, compared to other types of shut-off valves, are:

- ease of maintenance and design;

- small sizes;

- low resistance.

Gate valves can be made from the following materials:

- become;

- cast iron;

- non-ferrous metals and alloys made from them.

The valves are controlled:

- manually (rotating the handle);

- electric drive;

- hydraulic drive.

Valves with electric or hydraulic drive are mainly installed on industrial pipelines.

The designation of shut-off valves (valve) determines:

- type and name of the device;

- nominal working diameter;

- maximum pressure in the system;

- type of drive;

- position of the device in working condition;

- accommodation category;

- Climatic performance;

- type of connection of the device to the pipeline.

Designation of valve parameters

Purpose of dampers

The closing element in the damper is a disk that rotates around an axis.

Type of shut-off valves for pipelines

Valves are mainly used on pipelines that have a large diameter and are under low pressure, since the tightness class of the device is quite low.

The damper can be controlled:

- a flywheel that drives the axis of rotation (manual control);

- hydraulic drive;

- electric drive.

In most cases, the body of the locking device is made of cast iron, and the rotary disk is made of steel.

Dampers are installed:

- welding method;

- flange fasteners.

The valves can be used in chemical pipelines and sewer systems. They are practically not used for water supply or heating.

The brand of shut-off valves - valves, as well as the batch number, diameter, pressure and area of definition are indicated on the device body similarly to the previously given diagrams.

How to choose a water valve

When choosing a valve for a water supply system, it is recommended to pay attention to:

- device type;

- the material from which the valve is made;

- method of fastening.

Types of water valves

The following types of water valves are available:

- valve;

- ball

The principle of operation of a valve valve is to shut off the water using a gasket mounted on the stem.

Operating principle of a valve

The main advantages of the valve valve are:

- the ability to control water flow;

- the ability to carry out repairs yourself.

The disadvantages of valve valves include:

- fragility of the device. The gasket, which acts as a lock, comes into contact not only with water, but also with the metal body of the valve, which leads to increased natural wear;

- difficulty using the device. To completely block the flow, it is necessary to make several revolutions with the control flywheel.

Ball valves shut off the water thanks to a shut-off mechanism made in the shape of a ball. When the control lever is turned, the hole in the ball turns over perpendicular to the fluid flow.

Operating principle of a ball valve

The advantages of ball valves include:

- simplicity of the device, which guarantees a long period of use;

- complete tightness in the closed position;

- ease of use. To completely shut off the water, you must turn the control knob 90º.

The disadvantages of ball valves are:

- impossibility of limiting the flow (exclusively complete overlap);

- impossibility of carrying out routine repairs. If the device no longer performs its functions, a complete replacement will be required.

To completely shut off the flow of water, it is more advisable to install ball valves. If you need to regulate the water flow, it is better to install a valve valve.

By design, the water valve can be:

passable. A straight-through valve allows water to flow in a certain direction and serves to shut off the flow. Installed exclusively on a flat section of water supply;

Direct water flow valve

direct-flow. A type of straight-through valve with less hydraulic resistance;

Straight-through valve with lower resistance

corner. The valve is installed on the corner pipe connection. The incoming flow is perpendicular to the outgoing flow.

Valve for installation on pipe bends

Selecting valve material

The water shut-off valve can be manufactured:

- made of brass. The material is characterized by its low weight, small overall dimensions and durability. The main disadvantage is the high cost. The brass valve can be installed for both cold and hot water;

- made of bronze. The cost of a bronze valve is higher than that of a brass valve, and the characteristics of the devices are almost identical;

- made of stainless steel. Relatively cheap devices are more susceptible to scale deposits. Therefore, they are practically not used for hot water;

- made of plastic. Plastic valves are also durable and low cost. Plastic is practically not subject to corrosion and scale deposits.

Brass or bronze valves, as well as stainless steel devices, are installed on metal pipelines. Plastic valves are installed exclusively on plastic water pipes.

Selecting a valve mounting method

According to the method of fastening, water valves are divided into:

threaded Installation is carried out using a thread and a locking locknut, which is located on the water pipe and the device itself. The threaded valve must be selected according to the type of thread (internal, external), its diameter and pitch. Installation is possible on both metal and plastic water pipes;

Valve for water supply with internal thread

flanged. They are fastened using special devices (flanges) located on the edges of the valve and water pipes, and connected to each other with fastening bolts. The devices are installed primarily on metal water supply systems;

Valves fixed using special elements

welded Mounted by welding. Weld-on valves can be installed on metal and plastic pipelines.

Water valve installed by welding

Threaded and flanged valves can be removed for repair and reinstalled. It will not be possible to install a welded valve a second time.

Installing a valve on plastic pipes

In most cases, plastic valves are installed on plastic pipes. To install the device you will need:

- scissors for cutting pipes;

- device for welding plastic pipes;

- valve.

Plastic pipe welding machine

The process of installing a valve on a plastic pipe is as follows:

- cutting out the section of pipe required for installation of the device;

- alignment of pipe ends;

- heating the prepared areas on the welding machine;

- pipe connection.

To obtain a reliable connection, it is recommended to keep the parts until they cool completely.

Scheme for installing fittings on plastic pipes

Having certain skills and knowing the simplest instructions, you can install the valve on various types of pipes yourself. If a person doubts his abilities, then he can call a professional master to carry out the work.

Valve valve design and operation

The most important working part of the valve is the seat with a shutter moved manually by a spindle. The water valve, the design of which is shown below, contains threads in the body and on the stem, which have the property of braking. As a result, the valve disc is pressed tightly against the seat, shutting off flow when the valve is closed. In the open state, the flow area remains unchanged when the water flow moves.

Typically, the body is not threaded because it wears out quickly. To do this, a running nut is attached to it, into which the spindle is screwed. Then, instead of the worn-out unit, you can install another one, and the housing will be preserved. All parts are interchangeable with a water valve (GOST 12.2.063-81, GOST 5761-74).

The valve is opened by turning the handle. At the same time, the spindle moves progressively, freeing up the passage for liquid. If the rotation is performed in the opposite direction, the valve will close.

The device is connected to the pipeline through the inlet and outlet pipes. They can be distinguished from each other by the presence of an arrow indicating the direction of flow.

Mounting methods

Water valves can be connected to the process in different ways: fixed using special elements or mounted by welding.

Flange connection

This type of connection uses a special metal flange with a rubber gasket.

Loose flanges are placed on the end of the pipe and the valve nozzle, a gasket is installed between them, then the entire assembly is bolted together.

Coupling fittings

The connecting pipe has an internal thread with a fine pitch, and the outside is shaped like a hexagon for ease of use with a wrench. The coupling is screwed onto the thread and sealed with flax strands or FUM tape.

Tsapkova

This method of fastening is characterized by the presence of an external thread at the end of the connecting pipe and a collar at the end of the pipeline.

The valve branch pipe is pressed against the pipe with its end and secured in this position using a union nut. The tightness of the connection is ensured by a metal gasket and special lubricants.

Choke

The fitting is a short piece of pipe (bushing) with internal threads at both ends. With this type of connection, the connecting ends of the fittings are screwed onto the pipe and secured with a union nut.

Welding

This is a one-piece type of connection, the tightness of which is ensured by welding.

Types of taps

Water valves can be divided into several main types:

- Cone taps. Such mechanisms are used quite rarely, since they wear out very quickly, which leads to their frequent replacement.

- Valve valves. Among the advantages of such designs, one should highlight the ability to work even in very chlorinated water without losing technical features. Repairing such valves is relatively simple and often only requires replacing the seal.

- Ball valves consist of a special housing that houses a ball with holes. When turning it, this allows you to both block and open the flow of water. Such systems are very often used in household systems and have different designs, which allows them to be selected for any type of interior.

It should be noted that water valves can have different types of connection to the main pipe:

Safety and Maintenance Precautions for Safety Valves

There are various safety valves for all equipment. Therefore, installation of safety valves should only be performed by those who understand this issue. Deploying the wrong valve, which does not match your piping and may result in poor installation quality, will not work properly

It is therefore worth mentioning that professional assistance in purchasing and installing the right equipment is essential

- thread is used quite often. Such valves can be found everywhere in household use;

- flange connection is also used everywhere. Often this type of valve is used to shut off large pipes.

When choosing a water valve, you should pay attention to the quality of its performance, which will significantly extend their service life. Stainless steel valves have a long service life if properly maintained and maintained. Despite the low maintenance requirements, programmed checks on these accessories are recommended to ensure the safety valves last longer and last longer.

Safety valves must undergo functional and resistance tests and meet the minimum requirements required for their manufacture

Despite the low maintenance requirements, programmed checks on these accessories are recommended to ensure the safety valves last longer and last longer. Safety valves must undergo functional and resistance tests and meet the minimum requirements required for their manufacture

Stainless steel valves have a long service life if properly maintained and maintained. Despite the low maintenance requirements, programmed checks on these accessories are recommended to ensure the safety valves last longer and last longer. Safety valves must undergo functional and resistance tests and meet the minimum requirements required for their manufacture.

Not all valves on the market are manufactured using the appropriate components

Therefore, it is important to find out where to buy safe and reliable valves. Reliable and reliable suppliers have good recommendations and affordable conditions for your purchase

What is the difference between a valve and a faucet?

The difference is not in the type of valves, as many people, even plumbers, are accustomed to thinking. Taps and valves are different, although they are often called by the same name. This difference lies in the design of the housing. If the valve is intended to be installed at the junction of two pipes in order to, if necessary, shut off the liquid supply, then the tap is located at the end of the pipeline. A tap is a kind of limit switch that serves to supply water when the need arises.

Now you need to find out what is the difference between a valve and a gate valve. Many people believe that there is no difference between a valve and a valve, however, this is not true. What a valve is and why it is needed is already known. Now let's analyze the valve to find out its main differences from the valve.

The valve performs similar tasks as the devices discussed in the material. However, the valve is not able to regulate the flow rate, so it only closes and opens the flow. The valve cannot regulate the liquid pressure due to its design features. The damper in such a device moves only up and down. The difference between a gate valve and a valve can be seen clearly in the photo below.

Options for wiring diagrams of a two-pipe system

Upper wiring

A system with overhead wiring is suitable when implementing natural circulation (without the use of pumps) (gravity heating system). It has lower hydrodynamic resistance. In this case, the upper supply main pipe is partially cooled. Due to this, additional coolant circulation pressure is generated.

Bottom wiring

In a system with bottom wiring, both the supply and discharge pipes are located nearby.

There are such modifications of the lower wiring:

- “star” (radial) - from the collector to the radiator there is its own supply and its own return pipe;

- “loop” - collectors bypass all radiators in series

The principle of difference between one-pipe and two-pipe wiring

So, is the heating system one-pipe or two-pipe? In each case, it is necessary to have preliminary calculations and a design (see Leningradka single-pipe heating system), on the basis of which both heating devices and the main pipes themselves will be selected (see reinforced polypropylene pipes for heating). The final decision is yours.

Controls and technical characteristics

Manual control has now been replaced by modern methods of controlling control valves, based on the use of various types of drives and combinations of sensors that detect the slightest changes in the state of the pipeline contents.

According to the purpose and conditions of use, the following types of control are used:

- hydraulic;

- electrical;

- electromagnetic.

- pneumatic.

Like other types of valves, the main technical parameters of the control valve are:

- capacity in Kv;

- diameter DN;

- nominal pressure rating;

- working temperature.

The specified characteristics can be found in the technical documentation supplied by the manufacturers to the product.

Features of repair work

When operating a water valve, the mechanism is often subject to various breakdowns. The faucet may leak because the sealing gasket has become unusable or the shut-off element has fallen off the stem. The low quality of the metal leads to the fact that the rod gradually bends, and due to the scale located between the walls of the cylinder and the shut-off unit, the valve is not able to shut off the water supply.

Carrying out repair work on the water supply system.

If the shut-off assembly has lost its shape, bent or fallen off the stem, the valve must be replaced completely, since you can only correct the tightness of the structure with your own hands. To replace the valve, you need to twist the valve head with an adjustable wrench, then remove the union nut, flywheel, rod and oil seal bushing. After the valve is completely disassembled, you should install a new gasket of the same diameter, then use a thick layer of flax to wrap the stem and compact it with a screwdriver.

You need to install a sleeve on the rod that will press the packing, and then screw everything in with a union nut. The repaired valve head must be assembled and screwed into the cylinder of the structure. After the union nut has been tightened, you need to check the tightness of the mechanism. If the repair work does not bring the desired results, it is recommended to replace the water valve with a new one.

Often, for the faucet to function normally, you only need to clear the mechanism of blockages that impede the normal pressure of water flow. To remove serious blockages, the valve must be removed completely, but small accumulations of dirt can be removed without special tools. It is strictly forbidden to use pliers to repair the device, as they can strip the threads, as a result of which the entire valve will need to be replaced. In the absence of a wrench or wrench, it is better not to start repair work at all.

There are many different models of water valves on the market today. Due to the variety of choices, you can easily choose a design that meets all the requirements and desires of the buyer.

Repair of a water tap due to valve malfunctions

During prolonged use of a water tap, the walls of the tap socket may become chipped. If most of the circumference is damaged, the valve cannot be repaired, since in such a seat the gasket is not centered, fidgeting in the seat, as a result of which it begins.

In such cases, the valve is purchased in a store or turned on a lathe from brass. When recessing the valve yourself, it is necessary to provide for the presence of a so-called undercut - the diameter of the base of the socket should be 1-1.5 mm greater than the diameter of the edge of the socket, which allows the gasket to be securely held without using a screw.

You can also change the valve by removing it from an old faucet head, which may be in stock from a previous repair.

When unscrewing the head, the valve may remain in the valve seat. To remove it, use a wire hook or tweezers.

To avoid the valve falling out of the spindle, it is necessary to wind the shank with linen winding and insert it into the spindle with force. Linen threads will wear out over time and come out with water.

Design features of the case

Valves, depending on the shape of the body and the method of installation on the pipeline, can be:

- direct-flow - in them the flow of transported liquid moves through the body from inlet to outlet without changing direction, the spindle axis is located at an angle to the axis of the passage hole. This design helps straighten the flow and reduce hydraulic resistance, but increases the working stroke of the valve, the parameters of the construction length and the weight of the product;

- pass-through - a product with the same direction of flow of moving water at the inlet and outlet and the axes of the inlet and outlet pipes shifted parallel to each other. Passing through the valve body, the water flow is forced to make at least two turns at right angles, which leads to the formation of high hydraulic resistance and the formation of stagnation zones;

- angular - in them the flow turns by 90º only once, therefore the level of hydraulic resistance is lower. Such products have restrictions on the area of use - they are placed on the pipeline plan only on its rotating sections;

- mixing - in them the adjustment of the proportions of water occurs due to the mechanical rotation of the internal elements of the body. Designed to shut off and mix cold and hot water flows.

Removing blockages and painting

Often, a water valve needs painting, which is a great time to check and clean it. It is necessary to completely remove the old paint, inspect the surface of the mechanism, and prime the metal with drying oil.

We must not forget that complete removal of the valve will inevitably entail shutting off the water intake on the riser, so if it is possible to make repairs without turning it off, this should not be neglected.

It is often necessary to remove blockages that are preventing water from flowing with sufficient pressure. Serious blockages require complete removal of the valve, but small ones can be removed very simply, even without the use of special tools.

This can be done like this: you need to turn on all the taps in the house, including the tap on the cistern. Then open and close the water valve a couple of times. The pressure will rise significantly, and a small blockage will simply be washed away by the pressure of water on its own.

The gasket itself is very similar to the material for the tap, but it is stronger and denser, because it is under high loads.

We recommend installing fiber, paronite or heat-resistant rubber under the gasket, because elevated temperatures (for a pipeline with hot water) significantly deteriorate the properties of the rubber gasket.

Replacement may be necessary for both the stem and the spindle, also remember to lubricate the handle to turn off the water pressure, make sure that the valve fasteners are tight.