When it comes time to think about the heating system in your home, a lot of technical questions arise. Of course, you want to do everything correctly, thoroughly and inexpensively. But it’s not enough just to properly plan the system itself; you also need to take care of the water flowing in the veins of your home. Excessive water hardness and abrasive impurities in it can shorten the life of your system by decades. Today there are many ways to purify water. And you definitely shouldn’t skimp on them. Savings here will entail large expenses in the future, including replacement of machinery and equipment. When using water from a well or reservoir, several filters must be used to protect the coolant. There are four main and mandatory ones:

- ion exchange resin filter

- cascade mechanical cleaning filter

- universal filter mesh

- coarse filter

The uninitiated user, of course, will have natural questions. What are heating filters for, are they useful, do you need to use them all at once and at what stage? The questions are natural and require a detailed answer. It is worth planning the installation of filters at the design stage of your home. It is necessary to allocate space for them, taking into account installation and maintenance. Provide a connection system. If the moment was missed, the filters can be installed later, but this will entail additional labor costs. Therefore, if you are still at the planning stage, it’s time to study each filter in detail.

Mechanical cleaning filter, washing cascade

A flush filter for heating systems is necessary for the mechanical purification of water supplied to a heating system with a working environment temperature of up to one hundred and ten degrees. The filter purifies water from suspended matter, mud and silt deposits, sand, etc. The cascade filter is more compact than other filters with similar functionality. The volume reduction was achieved thanks to the latest nested filter system. Two filter elements of different sizes are placed one inside the other, and the vertically directed water is twisted into a spiral and is effectively cleaned of mechanical impurities. The device is installed strictly vertically. Cleaning the filter elements is quite simple; there is no need to remove the mesh inserts. The body and bulb are most often nickel-plated. Filter elements made of stainless steel. The filter does not take up much space. Simple and reliable in operation.

Features of operating a mud filter for a heating system

The simplest product you can buy is because... it doesn't even connect to the drain. To clean the mud filter, unscrew the cap, remove and wash the mesh, and install it back. This simple operation causes difficulties when installing equipment in an inconvenient location. Frequent repetition wears out the thread and impairs the tightness of the connection. Eliminate the listed shortcomings and expand functionality with the following additions:

- The valve, connected to the sewerage system, allows servicing to be carried out “with one movement of the hand”, quickly, without disassembly.

- A rotating ring with marks reminds you of the need to wash on certain days.

- When equipped with pressure gauges and a built-in pressure maintenance device, they provide protection against pressure drops in the central supply line.

- To fully automate flushing at time intervals, a set consisting of an electric valve, a timer, and a power supply is used.

The next option, a container with a bulk filling, can be equipped with similar devices. They will make it easier to clean the filler and remove accumulated dirt.

Mud filters for heating work more efficiently. In them, washing is started as needed. It is not the indirect indicator, time, that is controlled here, but the pressure. If it rises (at the inlet), the fluid is directed along a different path. The discs unclench, rotate and are easily cleaned with a stream of water.

Mud filters for the heating system of private and country houses are quite expensive during the operational period. Some manufacturers specifically make these products with unique sizes and shapes to make it difficult to use non-original analogues.

The disadvantages of mud filters and coarse filters are noted below:

- Settling is too long a procedure. To handle large volumes of liquid, a large reservoir is needed. Accumulated bottom sediments will have to be removed.

- The previous method is not effective in relation to the smallest suspensions. Their weight is too low for sedimentation. In this case, special substances (coagulants) are used that provoke the creation of large heavy particles. The main disadvantage is the need for precise dosing of chemical compounds. Some of them are dangerous to human health.

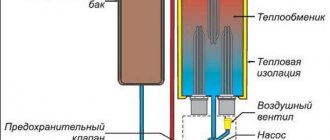

Electromagnetic filter (water softener) to protect the heating boiler from scale and lime

An electronic device that is installed on the return line of the heating system and protects the boiler from the formation of scale and lime deposits WITHOUT the use of reagent, salt, replaceable elements (cartridges, membranes, etc.). Does not require maintenance or monitoring during operation. It works on the “set it and forget it” principle. The service life is 15-20 years. Requirements – constant operation from a 220 V network. Electricity consumption – 5 W/hour.

Anti-scale protection: magnetic filter in front of the boiler

It is the increased hardness of water that poses the greatest threat to the normal functioning of boilers, pipelines, valves, radiators, and other components. In their original (dissolved) state, salts are invisible. At low concentrations they cannot be tasted. But when heated, scale forms, which worsens the consumer characteristics of the equipment, provokes minor breakdowns and major accidents. For protection, a magnetic filter is used in front of the heating boiler, which provides:

- Exchange of hardness ions for harmless sodium compounds.

- Creation of polyphosphate shells that do not allow microscopic contaminants to adhere.

- Grinding using ultrasonic vibrations.

- Transformation of the shape of the smallest particles of scale, the formation of charges of the same name on their surface using a magnetic field.

The last option is similar in effect to the use of polyphosphates. But exposure to the field does not deteriorate the chemical composition, therefore it is suitable for treating drinking water.

The noted remark should be taken into account, despite the intended purpose of this engineering system. Single-circuit boiler models are used for heating and hot water preparation. Polyphosphate compounds should be excluded not only from food. It is recommended to prevent their contact with skin and mucous membranes in order to avoid allergic reactions. It should be noted that the range of such anti-scale protection of a magnetic water filter is small, which is no more than a few tens of centimeters. In modern magnetic filters for water purification in heating systems, this figure reaches 2000 meters.

Universal filter mesh

The simplest mesh filter for heating. It consists of a body (metal) and a cylindrical mesh located inside the flask. The housing is closed with a plug or tap, depending on the type of filter. Connection system - flange. There are washable and non-washable filters. Non-flush ones must be replaced at the end of their service life. The washers last a long time thanks to cleaning. It is necessary to stop the water circulation, dismantle the cover, remove and wash the mesh, and install it. In addition to its relatively low price, the mesh is attractive due to its simple design, easy maintenance and cheap components. This filter is installed in front of the fine cleaning system. This is the penultimate level of protection. Serves to purify water from scale or solid inclusions. Pipe fittings or pumps damaged by scale will cost tens of times more than a cheap filter. The filter does not take up much space.

How to understand that the water in the heating system requires softening

Water from surface sources or not the cleanest water supply is guaranteed to be hard and needs to be softened to be used in the heating circuit of a gas boiler. You can verify this using simple examples: scale in a kettle or limescale on a tap.

Heat exchanger of a gas boiler in section. The use of contaminated hard coolant and lack of regular cleaning led to serious consequences: scale and almost complete clogging.

To be sure and test even clean water from a well, you can purchase test strips to determine water hardness. They are sold in stores with coffee machines or branded household appliance stores, pet stores. They are paper strips coated with a reagent, which must be dipped in water, and then their color must be compared with the “result palette”.

According to the current GOST 31865-2012, the unit of measurement for water hardness is °Zh (hardness degree):

- up to 2°F – soft;

- from 2 to 10°F – medium hardness;

- more than 10°F – extremely hard.

In practice, already 4-5°F contributes to the deposition of salts on the walls and the formation of scale. With these and higher results, to ensure normal operating conditions of the gas boiler, you need a water softener, which is one of the filters described below.

Coarse filter

The filter is installed when connecting the heating system to the central water supply. It is a flask with a filter element inside. The connection can be flanged or coupling, depending on the diameter of the water supply pipes. Necessary for filtering large contaminants. Effectively retains dirt, sand, large abrasive impurities. It will reliably protect the heating system from large elements, but will let small ones through. It is also not capable of chemical cleaning or water softening. He cannot purify the water to the desired state on his own. Doesn't take up much space. The coarse filter is the first line of defense for your home's water supply.

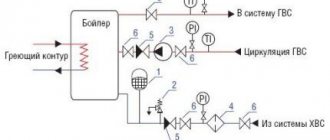

Operating principle of the boiler

Comfortable conditions after installing a gas boiler in your apartment are provided not only by heating, but by hot water. This applies to dual-circuit heating systems, which allow you to use hot water even during the non-heating season, when there is no need to run the boiler for heating. Single-circuit boilers are intended only for heating, which is not always justified. In the first case, with equal gas consumption, the consumer receives heat and hot water, in the second - only heat.

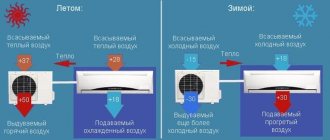

When starting a gas boiler, the hardware unit first starts working, checking the temperature in the room. This allows you to determine the required amount of heat.

Next, the gas fittings come into operation, through which fuel is supplied to the combustion chamber with simultaneous ignition of the burner (spark). The coolant is heated to a certain temperature in a heat exchanger, from where, under the action of a circulation pump, water begins to move through the system towards the pipes and radiators. As it moves through the system and cools, the coolant returns back to the heat exchanger, warms up and again flows to the radiators. This is how we can briefly describe the operating principle of a single-circuit gas boiler.

A double-circuit gas boiler allows, simultaneously with heating, to establish hot water supply in the house to an unlimited number of connection points. Its main difference from a heating boiler is the presence of a second circuit through which water is supplied to the water supply system.

2 circuits do not work at the same time. If hot water is turned on while heating the room, the heating is significantly reduced, but does not stop completely. Since this is a short-term process, such a break does not affect the temperature in the room.

When a gas boiler is operating simultaneously with heating, there is often a cessation of hot water supply for some time - from a few seconds to 2-3 minutes. This is also due to the redistribution of load between circuits. In general, according to reviews from owners of a dual-circuit unit, there are no significant inconveniences in use.

Fire safety measures

To get a properly functioning boiler, you must follow the following precautions:

- the unit must be securely fixed on a vertical surface, if this is provided for by the operational characteristics;

- exhaust gases are removed only through a ventilation circuit that is in working order and can withstand power;

- Dimensional parameters must be maintained in terms of distance to the nearest kitchen appliances, including a stove, hood, etc.;

- the coolant is selected based on criteria according to which it will not create pockets of corrosion;

- The gas pipe leading to the boiler must contain a gas shut-off valve.

It is worth considering that boilers may need spare parts even when the warranty period has not expired. This happens in such situations:

- boiler installation errors;

- inappropriate operation of a gas appliance;

- maintenance was carried out in violation of deadlines;

- fluctuations that occur in the household electrical network, they can be minimized by a stabilizer or an uninterruptible power supply;

- low quality characteristics of the coolant, which can be corrected with special filters.

Magnetic

The magnetic field changes the structure of potassium and calcium salts (and other chemical elements). In the filtration system, magnets make it possible to obtain a sediment of salts not in the form of hard scale, but only a suspension. It is easily removed.

Magnetic water treatment does not depend on the electrical network. The exception is electromagnets. They achieve the desired effect using an induction coil, therefore they consume electricity and are not so economical.

Magnetic filters with flange mounting to pipes are installed in front of the meters. These devices (for example, Magnetic Water Systems NEOMAG or FMF) are designed to soften incoming water over a wide temperature range.

Types of scale filters

Anti-scale filters differ primarily in their main application:

- to obtain drinking water;

- For shower;

- to protect household appliances.

Various salt removal methods are used. The most popular technologies:

- membrane (reverse osmosis);

- ion exchange;

- magnetic and electromagnetic;

- polyphosphate.

If it is necessary to protect home appliances from excessive contamination and harshness, then the cleaning system is supplemented with main and specialized filters for cold or hot water. They also install cartridges to eliminate high salt concentrations. In addition to options for city apartments, there are cleaning systems for cottages and industrial equipment.

Varieties

It is important to approach the choice of filter responsibly the service life and level of reliability will depend on it . There are various filtration units on the construction market. They differ on several grounds.

By design

Gas filters can be angular or linear . The first ones are also called oblique or Y-shaped because of the branch of the filter part. Inside there is a main element that purifies air or gas. Typically, devices are installed horizontally, with the branch down . The plug is located on the side at an angle. It is needed to clean the filter.

Linear modifications are called direct . Their main difference is that the filter element is not at an angle, but vertically . The plug is located at the bottom.

According to the method of manufacturing the case

- welded (steel);

- cast (aluminum or cast iron).

Housings made of aluminum or cast iron alloys are produced by casting. The higher the expected pressure, the thicker the manufactured wall of the structure.

The smallest wall thickness is determined by the casting properties of the material and the thickness of adjacent elements.

Welding is often used to make the filter housing. Its production does not require special models or molds. The walls in welded housings are thinner than in cast ones.

By filter material

When producing and selecting a filter, special attention is paid to the filter material. It must be inert with respect to gas, clean to the required extent and be minimally exposed to external factors during operation and during periodic cleaning of the filter system.

Commercially produced filters come in hair and mesh types . The first uses special cassettes filled with nylon thread or horsehair and additionally impregnated with viscine oil.

In mesh devices, a woven metal mesh , the devices are single-layer and double-layer. Mesh filters are thin, but they purify air or gas more effectively. During use and clogging, filtration sensitivity increases , and throughput , on the contrary, decreases .

Photo 1. Disassembled mesh filter: a metal mesh is visible, with the help of which the water or gas passing through it is purified.

Hair devices work on a different principle. Particles of the filter material are destroyed or carried away by gas or air flows. This leads to a decrease in basic functionality and deterioration in filter efficiency.

To minimize the loss of filter material, but maintain a high degree of gas purification, it is necessary to comply with special pressure drop standards for filter screens or cassettes.

Important! In strainer filters, the maximum permissible pressure drop is 5000 Pa . In hair, it is equal to 10,000 Pa . Before use or immediately after cleaning and washing the filter, the difference should not exceed 2000-2500 Pa for mesh devices and 4000-5000 Pa for hair filters.

Recommendations for selection

Before buying a filter for a gas boiler, you should consult with a specialist who will recommend a suitable device and give recommendations.

General recommendations for selection:

- If you plan to use a gas boiler frequently, it is better to give preference to an electromagnetic device: it will not allow scale to accumulate on parts, and will also work for a long time without additional maintenance.

If funds are limited, you can use a polyphosphate filter or a cartridge ion exchange filter.

But it should be remembered that you will have to constantly change the filler and the service life of these filters is shorter compared to electromagnetic ones.

- When choosing a device, you need to immediately decide where to install it. Sometimes installation requires a large space, which is not always possible.

- Be sure to make sure you have a warranty card. Good manufacturers of such devices never sell their product without providing a guarantee for it.

- It is preferable to purchase devices from well-known brands, since such products are more difficult to counterfeit. Often, unscrupulous sellers sell counterfeits under the guise of a well-known brand at a very low cost, so you should also pay attention to differences in prices for filters from the same manufacturer.

- If the tap water is hard, then in order to better protect the gas boiler, it is recommended to buy two filters at once , focused on different degrees of water purification.

- To simultaneously soften the liquid and protect the internal parts of the boiler from possible damage, it is better to use devices that soften water and have the ability to create a protective film on the heating elements.

If you follow all the recommendations described above, you can choose a device that is suitable for the price and technical characteristics.

Design features of the equipment

The following methods for separating impurities are used in filters for heating systems:

- settling devices are based on gravitational forces - when the flow speed decreases, sedimentation of solid particles is observed,

- in mesh variations, water passes through cells of a given size. Anything larger than these holes remains in the filter,

- in magnetic models, the active element attracts metal scale and particles of similar composition.

The simplest mud settling tanks are a cylindrical body with two pipes, with a flange plug at the bottom. There are jumpers in the cavity that change the direction of water flow. Magnetic models reduce the intensity of scale formation on internal surfaces.

Modern filters for water purification in a heating system combine 2 or all principles of medium processing.

Maintenance of dirt filters

Any type of filter requires periodic maintenance, as debris constantly accumulates inside the device.

Maintenance of mud trucks

How to clean the device:

- The taps located on the sides of the device are closed; in this case, it is not necessary to drain the coolant from the system.

- Before disassembling, it is necessary to install a container to drain remaining water.

- The filter has a plug that needs to be removed.

- The mesh is washed and installed in its original place.

- The muffler is installed.

- The couplings are tightened.

- The taps open.

Periodic cleaning of filters increases the service life of the entire system.

Features of installing a water filter on a gas boiler

A gas boiler, like the entire heating system, will not tolerate amateurism, so the installation of the filter element should be done by a person who understands this. The general procedure depends on the type of device selected.

Before starting installation, you need to prepare the necessary tools and materials. To work you will need:

- brush for cleaning pipes leading to the boiler;

- a device for cutting and sealing pipes if the pipeline is plastic;

- a device for cutting threads if the pipeline is metal;

- pliers;

- tow;

- sealing tape.

Preparatory work is required. Pipes are cleaned of plaque and scale. To do this, the heating system is washed, the pipes themselves are cleaned with a special brush or brush.

You need to make sure that the purchased filter matches the diameter of the gas boiler pipes, taps, and whether there is enough space for its installation. It is recommended to mount the device in an easily accessible place so that it can be serviced later. As a rule, this is the place before the pipe enters the heating boiler. When using an electromagnetic cleaning device, you need to think about the connection and install the device based on the availability of an electrical outlet.

Manufacturers usually include installation and operating instructions for their products, so read the instructions carefully. Installing a filter involves several steps.

- The pipe is cut at the place where the filter is installed.

- The first shut-off valve is installed and soldered. It is fixed with tow or sealing tape.

- The filter itself is installed and fixed.

- The second swelling valve is installed according to the same principle as the first.

For reliability, it is recommended to install filters for gas boilers for water on special brackets on which they will be supported.

After completing the installation work, you need to start and check the functionality of the system. First you need to run the water and see if there are any leaks. If everything is dry, turn on the gas.

Whether the electromagnetic device works or not will be immediately clear, because it is connected to the network. If filters of a different type were used, it may take some time to check them.

The duration and efficiency of the filter for gas boilers for water directly depends on the periodic and scheduled maintenance of the device. During the heating season, it is recommended to clean the device at least once a month. To do this, turn off the water in the area where the filter is installed. The coolant is poured into a previously prepared container, the internal mesh is removed from the device and it is thoroughly cleaned under running water. After this, the structure is assembled in place, the taps are opened and the liquid is released into the circuit. To avoid mistakes at any stage, it is better to invite an experienced specialist.