The microclimate provided by ventilation systems in residential or industrial premises affects the well-being and performance of people. To create comfortable living conditions, standards have been developed that determine the composition of air. Agree, regular air exchange is vital.

We will tell you what the air speed in the duct should be. We will advise you on what needs to be done to ensure that the air flow always remains fresh and meets hygienic standards. Here you will find a detailed description of calculation methods and a list of rules for selecting the optimal air duct.

The information offered for review is based on data from regulatory reference books. Examples are given for the practical development of calculation methods. The text material is supplemented with visual illustrations and videos that make the difficult topic easier to understand.

The importance of air exchange for humans

According to construction and hygiene standards, every residential or industrial facility must be provided with a ventilation system.

Its main purpose is to maintain air balance and create a microclimate favorable for work and rest. This means that in the atmosphere that people breathe, there should not be an excess of heat, moisture, or pollution of various kinds.

Violations in the organization of the ventilation system lead to the development of infectious diseases and diseases of the respiratory system, decreased immunity, and premature spoilage of food.

In an excessively humid and warm environment, pathogenic microorganisms quickly develop, and pockets of mold and mildew appear on walls, ceilings and even furniture.

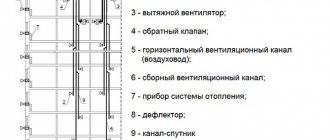

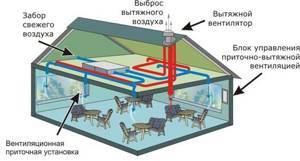

Ventilation diagram in a two-story private house. The ventilation system is equipped with a supply and exhaust energy-saving unit with a heat recuperator, which allows you to reuse the heat of the air removed from the building

One of the conditions for maintaining a healthy air balance is the correct design of the ventilation system. Each part of the air exchange network must be selected based on the volume of the room and the characteristics of the air in it.

Let’s assume that in a small apartment there is sufficiently well-established supply and exhaust ventilation, while in production workshops it is mandatory to install equipment for forced air exchange.

When constructing houses, public institutions, and workshops of enterprises, they are guided by the following principles:

- each room must be provided with a ventilation system;

- it is necessary to observe hygienic air parameters;

- enterprises should install devices that increase and regulate the air exchange rate; in residential premises - air conditioners or fans if there is insufficient ventilation;

- in rooms for different purposes (for example, in patient rooms and an operating room, or in an office and a smoking room), it is necessary to equip different systems.

In order for ventilation to meet the listed conditions, you need to make calculations and select equipment - air supply devices and air ducts.

Also, when installing a ventilation system, it is necessary to choose the correct air intake locations in order to prevent contaminated flows from flowing back into the premises.

In the process of drawing up a ventilation project for a private house, multi-storey residential building or industrial premises, the air volume is calculated and installation locations for ventilation equipment are outlined: water exchange units, air conditioners and air ducts

The efficiency of air exchange depends on the size of the air ducts (including house shafts). Let's find out what the standards for air flow speed in ventilation are, specified in the sanitary documentation.

Image gallery

Photo from

Ventilation system in the attic of a house

Supply and exhaust ventilation equipment

Rectangular plastic air ducts

Local resistance of air ducts

Rules for determining air speed

The speed of air movement is closely related to concepts such as noise level and vibration level in the ventilation system. The air passing through the channels creates a certain noise and pressure, which increases with the number of turns and bends.

The greater the resistance in the pipes, the lower the air speed and the higher the fan performance. Let's consider the norms of associated factors.

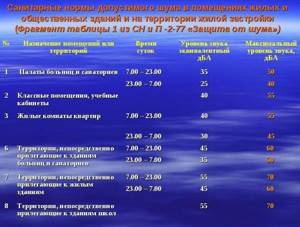

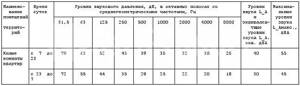

No. 1 - sanitary standards for noise levels

The standards specified in SNiP apply to residential (private and apartment buildings), public and industrial premises.

In the table below, you can compare standards for different types of premises, as well as areas adjacent to buildings.

Part of the table from No. 1 SNiP-2-77 from the paragraph “Noise Protection”. The maximum permissible norms related to night time are lower than daytime values, and the norms for adjacent areas are higher than for residential premises

One of the reasons for the increase in accepted standards may be an incorrectly designed air duct system.

Sound pressure levels are presented in another table:

When putting into operation ventilation or other equipment related to ensuring a favorable, healthy microclimate in the room, only short-term excess of the designated noise parameters is allowed

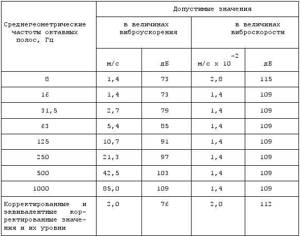

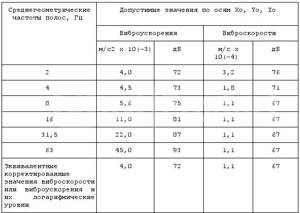

No. 2 - vibration level

The power of the fans is directly related to the level of vibration.

The maximum vibration threshold depends on several factors:

- duct sizes;

- quality of gaskets that reduce vibration levels;

- pipe manufacturing material;

- speed of air flow passing through the channels.

The standards that should be followed when choosing ventilation devices and when making calculations regarding air ducts are presented in the following table:

Maximum permissible values of local vibration. If during inspection the actual values are higher than the norms, it means that the air duct system is designed with technical flaws that need to be corrected, or the fan power is too high

The air speed in shafts and channels should not affect the increase in vibration indicators, as well as the associated parameters of sound vibrations.

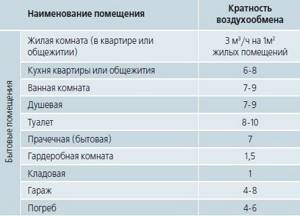

No. 3 - air exchange rate

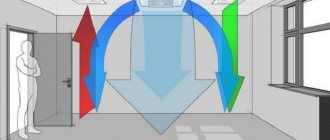

Air purification occurs through the air exchange process, which is divided into natural or forced.

In the first case, it is carried out by opening doors, transoms, vents, windows (and is called aeration) or simply by infiltration through cracks at the joints of walls, doors and windows, in the second - with the help of air conditioners and ventilation equipment.

The air in a room, utility room or workshop must be changed several times an hour in order for the degree of air pollution to be acceptable. The number of shifts is a multiplicity, a value also necessary to determine the air speed in the ventilation ducts.

The multiplicity is calculated using the following formula:

N=V/W,

Where:

- N – frequency of air exchange, once every 1 hour;

- V – volume of clean air filling the room in 1 hour, m³/h;

- W – volume of the room, m³.

In order to avoid additional calculations, the average multiplicity indicators are collected in tables.

For example, the following air exchange rate table is suitable for residential premises:

Judging by the table, frequent changes of air masses in a room are necessary if it is characterized by high humidity or air temperature - for example, in a kitchen or bathroom. Accordingly, if natural ventilation is insufficient, forced circulation devices are installed in these rooms

What happens if the air exchange rate standards are not met or are met, but to an insufficient extent?

One of two things will happen:

- The multiplicity is below normal. Fresh air stops replacing polluted air, as a result of which the concentration of harmful substances in the room increases: bacteria, pathogens, dangerous gases. The amount of oxygen, important for the human respiratory system, decreases, and carbon dioxide, on the contrary, increases. Humidity rises to a maximum, which is fraught with the appearance of mold.

- The multiplicity is higher than normal. Occurs if the speed of air movement in the channels exceeds the norm. This negatively affects the temperature: the room simply does not have time to heat up. Excessively dry air provokes diseases of the skin and respiratory system.

In order for the air exchange rate to comply with sanitary standards, ventilation devices should be installed, removed or adjusted, and, if necessary, air ducts should be replaced.

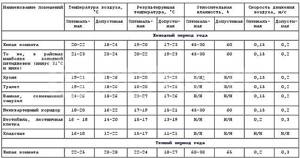

Normalization of microclimate parameters

Hygienic standards regulate the following parameters of the microclimate in the working area of industrial premises: temperature, relative humidity and air speed, as well as the temperature of the surfaces of structures and objects surrounding the human body (walls, floors and ceilings of the room, production equipment, objects of labor, etc.) . Rationing is carried out taking into account the time of year and the intensity of work performed by a person. According to GOST 12.1.005–88, a distinction is made between cold and warm periods of the year.

- The cold period of the year is characterized by an average daily outdoor temperature of +10 ºС and below,

- warm period of the year – average daily temperature above + 10 ºС.

Sometimes a transition period is also considered, characterized by an average daily outdoor temperature of +10ºС. Based on the total energy consumption of the body and taking into account the intensity of labor, all types of work are divided into three categories:

- light Ia and Ib with energy consumption up to 140 W and 140...174 W, respectively (controller work, precision instrument making work, office work, etc.);

- medium-heavy IIa and IIb with energy consumption of 175...232 W and 233...290 W, respectively (work in mechanical assembly shops, textile production, wood processing, etc., associated with constant movement and carrying of weights up to 10 kg);

- heavy III with energy consumption over 290 W (work associated with systematic physical stress, with the transfer of weights over 10 kg in forges, foundries with manual processes, etc.)

For the working area of the production premises, in accordance with current regulatory documents, optimal and permissible microclimate parameters are established. Optimal (recommended) parameters represent the most favorable conditions for the best human well-being (comfort criterion) or for the correct flow of various technological processes (technological criterion). Optimal microclimate parameters according to the criterion of manufacturability are regulated by industry documents. Thus, for precision engineering workshops, the optimal temperature is 20 ± 0.5 ºС, and the optimal relative humidity is 45...50%. Optimal microclimate parameters according to the comfort criterion (Table 1.1) ensure a state of thermal balance during human interaction with the environment, do not cause stress in the body’s thermoregulation system and create the prerequisites for a high level of performance. Such parameters, for example, must be observed in production areas where operator-type work associated with nervous and emotional stress is performed (in booths, at consoles and process control stations, in computer rooms).

Table 1.1

Optimal values of microclimate parameters in industrial workplaces

| Category of work | Parameter | ||||

| Ia | Ib | IIa | IIb | III | |

Air temperature, ºС:

| 22–24 23–25 | 21–23 22–24 | 19–21 20–22 | 17–19 19–21 | 16–18 18–20 |

| Air movement speed, m/s, no more | 0,1 | 0,1 | 0,2 | 0,2 | 0,3 |

| Relative humidity, % | 40–60 | ||||

Optimal microclimate parameters are provided, as a rule, by air conditioning systems. Acceptable (mandatory) microclimate parameters are established in cases where, for technical and economically justified reasons, optimal conditions cannot be ensured. Acceptable microclimate parameters are established for an 8-hour work shift under the conditions that they should not cause disturbances in human health, but can lead to general and local sensations of thermal discomfort, tension in the thermoregulatory mechanisms, deterioration of well-being and decreased performance (Table 1.2).

Table 1.2

Acceptable values of microclimate parameters at workplaces of industrial premises according to SanPiN 2.2.4.548–96

| Period of the year | Category of work | Air temperature t in ,ºС | Relative humidity air,% | Air speed, m/s | ||

| for t in < top | for tв> top | for tв < topt, no more | for tв> topt, no more | |||

| Cold | Ia Ib IIa IIb III | 20,0–21,9 19,0–20,9 17,0–18,9 15,0–16,9 13,0–15,9 | 24,1–25,0 23,1–24,0 21,1–23,0 19,1–22,0 18,1–21,0 | 15–75 15–75 15–75 15–75 15–75 | 0,1 0,1 0,1 0,2 0,2 | 0,1 0,2 0,3 0,4 0,4 |

| Warm | Ia Ib IIa IIb III | 21,0–22,9 20,0–21,9 18,0–19,9 16,0–18,9 15,0–17,9 | 25,1–28,0 24,1–28,0 22,1–27,0 21,1–27,0 20,1–26,0 | 15–75 15–75 15–75 15–75 15–75 | 0,1 0,1 0,1 0,2 0,2 | 0,2 0,3 0,4 0,5 0,5 |

When the air temperature in the workplace tb ≥ 25 ºС, the relative air humidity φ should not exceed the following limits: 70% – at tb = 25 ºС; 65% – at t = 26 ºС; 60% – at t = 27 ºС; 55% – at t = 28 ºС. When the air temperature is outside the permissible limits, the time spent at workplaces should be limited so that the average shift air temperature corresponding to the presence of workers in workplaces and rest areas does not go beyond the permissible limits specified in Table. 1.2.

The average shift air temperature at t is calculated using the formula

where n is the number of places of work and rest per shift; t 1, t 2,…, tn and τ 1, τ 2,…, τ n – respectively, air temperature, ºС, and time of stay, h, at places of work or rest; 8 – duration of the work shift, hours. For non-industrial premises, the permissible values of microclimate parameters are given in table. 1.3.

Table 1.3

Permissible values of microclimate parameters in the serviced area of residential, public and administrative premises according to SNiP 41-01-2003

| Period of the year | Air temperature, oС | Relative air humidity, %, no more | Air movement speed, m/s, no more |

| Warm | No more than 3 ºС higher than the calculated outside air temperature (parameter A)* | 65*** | 0,5 |

| Cold | 18**–22 | 65 | 0,2 |

For rooms with constant occupancy of people, the temperature should be no more than 28 oC, and in areas with an estimated outside air temperature of 25 oC and higher - no more than 33 oC.

**For rooms with people wearing outerwear, the temperature should be 14 oC. ***In areas with a calculated outdoor air humidity of more than 75%, humidity up to 75% is allowed.

Presented in table. 1.3 standards are established for people staying indoors for more than 2 hours continuously. Hygienic regulation of the content of harmful substances in the air of the working area. Harmful substances are substances that, upon contact with the human body, can cause occupational injuries, occupational diseases or health problems that can be detected both during work and in the long-term life of the present or subsequent generations. Harmful gases and vapors released during production form gas and steam-air mixtures with air, and liquid and solid particles form aerosols. Aerosols are called mists if they are formed by liquid droplets, and dusts if they are formed by solid particles.

The main standard indicator of the content of harmful substances in the air of a working area is their maximum permissible concentrations (MPC). MPC is the maximum content of a harmful substance, expressed in milligrams, in one cubic meter of air, which during daily (except weekends) work for 8 hours or another duration, but not more than 41 hours per week during the entire working period, cannot cause diseases or abnormalities in health that are detected by modern research methods in the process of work or in the long term of the life of the present or subsequent generations.

Harmful substances are divided into four classes according to the degree of danger:

- 1st – extremely dangerous substances with MPC <0.1 mg/m3;

- 2nd – highly hazardous substances with MPC = 0.1...1.0 mg/m3;

- 3rd – moderately hazardous with MPC = 1.0...10.0 mg/m3;

- 4th – low-hazard with MPC > 10.0 mg/m3.

Based on the nature of their impact on the human body, harmful substances are divided into general toxic substances that cause poisoning of the entire body or affect individual organs (lead, mercury, arsenic, benzene, toluene, etc.); irritating, causing irritation of the mucous membranes of the respiratory tract, eyes, skin (acids, alkalis, chlorine, fluorine, sulfur and nitrogen containing compounds); sensitizing agents that act as allergens (platinum, aldehydes, various solvents, varnishes based on nitro compounds, etc.); carcinogenic, causing malignant tumors (fuel oil, tar, bitumen, chromium, nickel, asbestos, etc.); mutagenic, leading to genetic changes (lead, manganese, formaldehyde, radioactive isotopes); affecting reproductive (childbearing) function (mercury and its compounds, lead, styrene, benzene, carbon disulfide, radioactive isotopes).

Harmful substances that affect the same body systems are called unidirectional. Otherwise, harmful substances are multidirectional. This feature is important for assessing the combined effects of harmful substances on the human body. When unidirectional substances act, their concentrations must satisfy the condition

- where qi is the concentration of the i-th substance in the air of the working area, mg/m3;

- MPCi – maximum permissible concentration of this substance, mg/m3;

- n – number of substances.

For substances with different directions, this condition is simplified and reduced to the case when they act separately: qi ≤ MPCi

Algorithm for calculating air speed

Taking into account the above conditions and the technical parameters of a particular room, it is possible to determine the characteristics of the ventilation system, as well as calculate the air speed in the pipes.

You should rely on the air exchange rate, which is the determining value for these calculations.

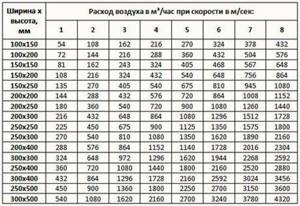

To clarify the flow parameters, the table is useful:

The table shows the dimensions of air ducts with a rectangular cross-section, that is, their length and width are indicated. For example, when using channels 200 mm x 200 mm at a speed of 5 m/s, the air flow will be 720 m³/h

To make your own calculations, you need to know the volume of the room and the rate of air exchange for a room or hall of a given type.

For example, you need to know the parameters for a studio with a kitchen with a total volume of 20 m³. Let's take the minimum multiplicity value for the kitchen - 6. It turns out that within 1 hour the air channels should move about L = 20 m³*6 = 120 m³.

It is also necessary to find out the cross-sectional area of the air ducts installed in the ventilation system. It is calculated using the following formula:

S = πr2 = π/4*D2,

Where:

- S is the cross-sectional area of the air duct;

- π is the number “pi”, a mathematical constant equal to 3.14;

- r is the radius of the air duct section;

- D is the cross-sectional diameter of the air duct.

Let's assume that the diameter of the round duct is 400 mm, substitute it into the formula and get:

S = (3.14*0.4²)/4 = 0.1256 m²

Knowing the cross-sectional area and flow rate, we can calculate the speed. Formula for calculating air flow speed:

V = L/3600*S,

Where:

- V —air flow velocity, (m/s);

- L — air flow, (m³/h);

- S – cross-sectional area of air channels (air ducts), (m²).

We substitute the known values, we get: V = 120/(3600*0.1256) = 0.265 m/s

Therefore, in order to ensure the required air exchange rate (120 m3/h) when using a round duct with a diameter of 400 mm, it will be necessary to install equipment that allows you to increase the air flow speed to 0.265 m/s.

It should be remembered that the previously described factors - parameters of the vibration level and noise level - directly depend on the speed of air movement.

If the noise exceeds the norm, you will have to reduce the speed, and therefore increase the cross-section of the air ducts. In some cases, it is enough to install pipes made of a different material or replace a curved channel fragment with a straight one.

What is taken into account when determining air speed

To correctly perform calculations, designers must fulfill several regulated conditions, each of them is equally important. What parameters depend on the speed of the air flow?

Indoor noise level

Depending on the specific use of the premises, sanitary standards establish the following maximum sound pressure indicators.

Table 1. Maximum noise levels.

Exceeding the parameters is allowed only in short-term mode during start/stop of the ventilation system or additional equipment. Vibration level in the room Vibrations are generated during fan operation. Vibration indicators depend on the material used to make air ducts, the methods and quality of vibration-damping gaskets, and the speed of air flow through the air ducts. General vibration indicators cannot exceed the limit values established by government organizations.

Table 2. Maximum permissible vibration values.

During calculations, the optimal air speed is selected that does not enhance vibration processes and associated sound vibrations. The ventilation system must maintain a certain microclimate in the premises.

Values for flow speed, humidity and temperature are contained in the table.

Table 3. Microclimate parameters.

Another indicator taken into account when calculating the flow rate is the air exchange rate in ventilation systems. Taking into account their use, sanitary standards establish the following requirements for air exchange.

Table 4. Air exchange rate in various rooms.

| Household | |

| Household premises | Air exchange rate |

| Living room (in an apartment or dormitory) | 3m 3 / h per 1 m 2 of residential premises |

| Apartment or dorm kitchen | 6-8 |

| Bathroom | 7-9 |

| Shower room | 7-9 |

| Toilet | 8-10 |

| Laundry (household) | 7 |

| Walk-in closet | 1,5 |

| Pantry | 1 |

| Garage | 4-8 |

| Cellar | 4-6 |

| Industrial | |

| Industrial and large premises | Air exchange rate |

| Theatre, cinema hall, conference hall | 20-40 m3 per person |

| Office space | 5-7 |

| Bank | 2-4 |

| Restaurant | 8-10 |

| Bar, Cafe, beer hall, billiard room | 9-11 |

| Kitchen space in a cafe, restaurant | 10-15 |

| Supermarket | 1,5-3 |

| Pharmacy (shopping area) | 3 |

| Garage and auto repair shop | 6-8 |

| Toilet (public) | 10-12 (or 100 m 3 per toilet) |

| Dance hall, disco | 8-10 |

| Smoking room | 10 |

| Server room | 5-10 |

| Gym | not less than 80 m 3 per 1 student and not less than 20 m 3 per 1 spectator |

| Hairdresser (up to 5 workplaces) | 2 |

| Hairdressing salon (more than 5 workplaces) | 3 |

| Stock | 1-2 |

| Laundry | 10-13 |

| Pool | 10-20 |

| Industrial dyeing cel | 25-40 |

| Mechanical workshop | 3-5 |

| Classroom | 3-8 |

Calculation algorithm The air speed in the air duct is determined taking into account all the above conditions; the technical data is indicated by the customer in the assignment for the design and installation of ventilation systems. The main criterion when calculating the flow rate is the exchange rate. All further coordination is made by changing the shape and cross-section of the air ducts. The flow rate depending on the speed and diameter of the air duct can be taken from the table.

Recommended air exchange rate standards

When drawing up a building project, calculations are made for each individual section. In production these are workshops, in residential buildings - apartments, in a private house - floor blocks or separate rooms.

Before installing a ventilation system, it is known what the routes and sizes of the main lines are, what geometry the ventilation ducts are needed, and what size pipes are optimal.

Do not be surprised by the overall dimensions of air ducts in catering establishments or other institutions - they are designed to remove large amounts of used air

Calculations related to the movement of air flows inside residential and industrial buildings are considered to be the most complex, so experienced, qualified specialists must deal with them.

The recommended air speed in air ducts is indicated in SNiP - regulatory state documentation, and when designing or commissioning objects they are guided precisely by it.

The table shows the parameters that should be followed when installing a ventilation system. The numbers indicate the speed of movement of air masses at the installation sites of channels and gratings in generally accepted units - m/s

It is believed that indoor air speed should not exceed 0.3 m/s.

Exceptions are temporary technical circumstances (for example, repair work, installation of construction equipment, etc.), during which the parameters can exceed the standards by a maximum of 30%.

In large premises (garages, production workshops, warehouses, hangars), instead of one ventilation system there are often two.

The load is divided in half, therefore, the air speed is selected so that it provides 50% of the total calculated volume of air movement (removal of contaminated air or supply of clean air).

If force majeure occurs, there is a need for a sharp change in air speed or a complete suspension of the ventilation system.

For example, according to fire safety requirements, the speed of air movement is reduced to a minimum in order to prevent the spread of fire and smoke into adjacent rooms during a fire.

For this purpose, cut-off valves and valves are installed in air ducts and transition areas.

Setting up an existing ventilation system

The main way to diagnose the operation of ventilation networks is to measure the air speed in the air duct, since knowing the diameter of the channels it is easy to calculate the actual flow of air masses. The devices that are used for this are called anemometers. Depending on the characteristics of the movement of air masses, the following are used:

- Mechanical devices with an impeller. Measurement limit 0.2 – 5 m/s;

- Cup anemometers measure air flow in the range of 1 – 20 m/s;

- Electronic thermal anemometers can be used to take measurements in any ventilation networks.

It’s worth looking at these devices in more detail. Electronic thermal anemometers do not require, as in the use of analogue devices, the organization of hatches in channels. All measurements are made by installing a sensor and receiving data on the screen built into the device. The measurement errors of such devices do not exceed 0.2%. Most modern models can operate both from batteries and from 220 v power supply. That is why professionals recommend using electronic anemometers for commissioning work.

As a conclusion: air flow speed, air flow and channel cross-sectional area are the most important parameters for the design of air distribution and ventilation networks.

Advice: In this article, as a clear example, the aerodynamic calculation method for a section of an air duct of a ventilation system was given. Carrying out computational operations is a rather complex process that requires knowledge and experience, and also takes into account a lot of nuances. Do not do the calculations yourself, but entrust it to professionals.

Subtleties of choosing an air duct

Knowing the results of aerodynamic calculations, you can correctly select the parameters of the air ducts, or more precisely, the diameter of the round sections and the dimensions of the rectangular sections. In addition, in parallel, you can select a forced air supply device (fan) and determine the pressure loss during the movement of air through the channel.

Knowing the amount of air flow and the speed of its movement, you can determine what cross-section of air ducts will be required.

To do this, take the formula inverse to the formula for calculating air flow:

S = L/3600*V.

Using the result, you can calculate the diameter:

D = 1000*√(4*S/π),

Where:

- D is the diameter of the air duct section;

- S – cross-sectional area of air channels (air ducts), (m²);

- π is the number “pi”, a mathematical constant equal to 3.14;.

The resulting number is compared with factory standards approved by GOST, and the products closest in diameter are selected.

If you need to choose rectangular rather than round air ducts, you should determine the length/width of the products instead of the diameter.

When choosing, they are guided by the approximate cross-section, using the principle a*b ≈ S and size tables provided by manufacturers. We remind you that according to the standards, the ratio of width (b) and length (a) should not exceed 1 to 3 .

Air ducts with a rectangular or square cross-section have an ergonomic shape, which allows them to be installed flush against walls. This is used when installing home hoods and masking pipes above suspended ceiling structures or above kitchen cabinets (mezzanines)

Generally accepted standards for rectangular channels: minimum dimensions - 100 mm x 150 mm, maximum - 2000 mm x 2000 mm. Round air ducts are good because they have less resistance and, accordingly, have minimal noise levels.

Recently, convenient, safe and lightweight plastic boxes have been produced specifically for indoor use.