Modern technological progress has practically not affected cast iron heating radiators in all 167 years of their existence. Consumers still choose these devices due to the many positive characteristics of the products.

And even some shortcomings do not prevent the installation of cast iron batteries when installing heating systems. Next, we will talk in detail about all the advantages and disadvantages of cast iron radiators, as well as the characteristics that you need to pay attention to before purchasing.

Technical characteristics and design

Heating radiators made of cast iron are used for heating systems for residential, industrial and public premises. According to GOST 8690–94, blocks or sections are equipped with circuits in which the coolant temperature reaches a maximum of 150°C, at an operating pressure of up to 0.9 MPa.

Size restrictions according to GOST 8690–94 | ||

| Options | Minimum value, mm | Maximum value, mm |

| Nipple hole spacing | 800 | |

| Height | 400 | 900 |

| Depth | 100 | 160 |

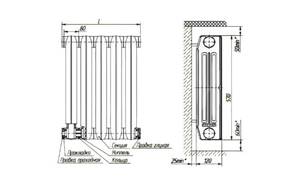

When choosing a device, you must read the technical documentation. It contains the following information:

- battery depth and height;

- excess operating pressure of the coolant;

- the interval between the center points of the nipple holes;

- number of sections.

High-quality radiators must be durable and sealed, able to withstand air or water pressure of 1.5 MPa during a test connection. Permissible deviations from the heat flow guaranteed by the passport should not exceed 4-5%. The presence of solders and casting defects is allowed, but within the parameters described in the technical documents.

Block and sectional structures must be cast from gray cast iron with flake graphite.

Review of popular models and their costs

Now there are many manufacturers of heating equipment. These are foreign and domestic companies that have been operating in the market for decades. Each company offers its own unique models, which differ in technical and visual characteristics. You can buy cast iron heating radiators in Moscow at an affordable price, so let’s look at the most famous manufacturers.

STI NOVA-500

STI Nova 500 is a modern model of cast iron radiators. The product is characterized by wall placement with side connection. Thanks to its compact size and attractive design, it is popular among many buyers. This heating equipment is relevant for high-rise buildings - it can easily withstand high pressure. The passage holes have a small diameter, and the hydraulic resistance is also low, so the radiator is good for systems with natural circulation.

The surface of such batteries has a heat-resistant polymer coating, which will preserve the original color. The model is widely popular as it is sold inexpensively.

The cost of cast iron batteries from STI is from 2,600 rubles.

Price for cast iron heating radiator STI NOVA-500

cast iron heating radiators STI NOVA-500

Alpine Air History 600

Using this model, you can heat any premises, from apartments and offices to utility and warehouse facilities. And the more sections a heating device involves, the larger the heating area.

The original design solution of this model allows it to easily fit into any interior. The sections are decorated with a colored print - an elegant, unobtrusive floral pattern. If necessary, the device can be repainted in any color.

During painting, the manufacturer uses a double coating in the form of a special primer and high-quality varnish. As a result, the surface retains its original appearance longer and does not require touch-up. Due to the large thickness of the material, you can hardly hear the water circulating in the system.

Price - 1 section of a designer radiator will cost 5,200 rubles.

MZOO MS-140M

The radiators of this company from Russia heat civil and industrial buildings of various heights. The sections themselves are made of gray cast iron with flake graphite, and the nipples are made of malleable cast iron. Manufactured devices come with 4 or 7 sections. Thanks to its high technical characteristics, the product is in no way inferior to popular European models. The radiator easily adapts to any interior.

During production, when the product is cast, a silicon film is formed on the surface of the cast iron, which makes the device undemanding to the quality of the coolant. Thanks to the increased cross-section of the channels, blockages practically do not form in the radiator.

The device is hung on the wall using simple brackets or installed on the floor on special stands. If any section fails, only the damaged element is replaced.

Price - a model with 4 sections will cost the buyer 2,050 rubles.

Price for cast iron radiators MZOO MS-140M

cast iron heating radiators MZOO MS-140M

Konner Modern 500

A distinctive feature of this model is that its outer part is completely flat, which allows the radiator to fit more tightly to the wall. It can easily be hidden behind curtains or furniture. Thanks to its unique design, the device emphasizes the interior, especially in styles such as “classic” and “minimalism”.

Enlarged passage openings allow the use of batteries for systems with natural and forced circulation. Cast iron products are not afraid of high pressure, so they can be installed in high-rise buildings. During production, the radiator is coated with a special super-resistant white enamel.

Price - 4 sections will cost 3,230 rubles.

Price for cast iron heating radiators Konner Modern 500

cast iron heating radiators Konner Modern 500

GuRaTec Apollo 765

The decoration of these radiators from a German company is cast iron, which is an original floral ornament. Available in 13 different colors and shades. Products are available in white, gray and black, matte or glossy.

There are also models:

- gold;

- silver color;

- with the effect of aged bronze;

- even with mother of pearl.

They are available in different heights, which allows the models to be used in rooms with a low window sill. If it is necessary to heat a large heated area, the number of sections can be increased to 15. This series of radiators is full bore - thanks to 4 side holes, the battery is connected to the system in various ways.

Price - models with 5 sections cost from 59,780 rubles. Heat-resistant sealant you will find the answer in the link.

Battery device

Heating devices can be panel or sectional. The device includes separate chambers, each of which is poured separately. They are connected into a single structure using nipples. All connections are equipped with rubber (paronite) gaskets for additional sealing. The battery also has a radiator cap and a protrusion for the radiator wrench.

The section holds about 1.2-1.4 liters of liquid (depending on the chamber parameters). The weight of each segment is 7 kg. Together with the coolant, the weight increases to 8-13 kg.

Advantages and disadvantages of cast iron batteries

One of the main advantages of cast iron radiators is their high resistance to corrosion processes. For a structure that is constantly exposed to moisture and oxidation products, this factor is identified with durability and the absence of frequent leaks.

Cast iron radiator RETROstyle BOLTON 220

When choosing batteries, the thermal inertness of the material is taken into account. Cast iron is excellent in this regard. It retains heat perfectly and releases it in sufficient volume even when the temperature of the coolant in the system drops.

Other benefits include:

- invulnerability to abrasive wear;

- inertness to chemicals, acids present in the coolant;

- no negative consequences after turning off the system at the end of the heating season, when oxygen penetrates inside;

- strength (withstands working environment with pressure up to 18 atm.);

- low hydraulic resistance;

- the ability to use any type of coolant;

- heat resistance (the maximum value can exceed +150 degrees);

- ease of maintenance;

- service life more than 50 years.

If necessary, it is possible to increase or decrease the number of sections. This is achieved through simple installation.

The disadvantages of cast iron batteries include the bulkiness of the design and heavy weight. The heating device does not always fit harmoniously into the interior of the room, especially under the window. It happens that sections protrude further than the edge of the window sill. Thermal inertness, which is an advantage, does not allow temperature control due to the slow cooling of the material.

A few simple rules

In what cases can we talk about the correct connection of batteries? When they work effectively. It's very easy to check. Place your hand on their surface, and you will immediately determine whether the radiator is heating up or not, and whether it is heating up enough. This can be done after completion of installation work, when the system is pressure tested. But there is one nuance in this moment.

Professionals touch not only the top or sides of radiator sections. They check all sections in a row, touching their lower parts. After all, according to the laws of physics, warm water rises to the top, so this part heats up the fastest. Then they check the uniformity of heating not only of sections of one radiator, but also of all radiators separately. This is very important, because one branch may fall out of the system.

To ensure uniform heat distribution across all batteries, specialists use thermostats or taps. They are installed directly on the heating device. Cranes are most often used due to their simple and reliable design. And they last longer. Experienced plumbers try to install them in such a way that they perform double duty:

The diameter of the pipes was changed, thereby regulating the flow of coolant, and therefore the temperature inside the radiators. Allowed the removal of air pockets. Of course, Mayevsky cranes are usually used for this, since they are more efficient. However, conventional flow-through taps last 3-4 times longer.

Air locks are most often the reason why batteries or entire branches of the system do not work. To quickly get rid of them, it is necessary to shut off the working branches, thereby directing the entire coolant flow to the faulty lines. Then you should open the taps on each radiator in turn, through which the air is squeezed out.

Attention! In heating systems with forced circulation of hot water, it is easier to remove air pockets.

Criterias of choice

When choosing cast iron batteries, you should focus not only on aesthetic qualities. Technical and operational characteristics must be taken into account.

Manufacturer

Of the heating devices on the market, products from well-known brands deserve attention:

- Demir Dokum;

- Exemet Prince;

- Guratec;

- Conner;

- Roca;

- Iron Lion.

Large companies ensure high quality of their products by equipping their production with modern high-tech equipment. They provide warranties and service for their radiators.

Cast iron radiator Viadrus Hellas 270/218

What are there

Heating radiators are available in different types. When choosing the appropriate option, it is recommended that you familiarize yourself with the comparative analysis table.

| Peculiarities | pros | Minuses |

| Cast iron | ||

| Heavy dimensional structures with high heat transfer. | – corrosion resistance – do not require frequent cleaning – affordable price – durability | – specific design – dimensions |

| Steel | ||

| Panel construction with proper coolant circulation and laconic design. | – economical energy consumption – adjustable – light weight | – susceptibility to corrosion – low resistance to water hammer |

| Bimetallic | ||

| The structure consists of two parts: the inner one is made of steel, the outer one is made of aluminum. | – minimal coolant volume – high heat transfer – strength | – over time, the bond between metals is broken – high cost |

| Aluminum | ||

| Lightweight structures with vertical internal channels. Assembled from sections. | – compactness – high operating pressure – lack of thermal inertia – low price | – the need to remove air from the collector – low resistance to corrosion – hydrogen evolution |

The quality of room heating depends on how correctly the radiator is chosen.

Cast iron radiators are:

Each radiator section has one or more channels.

| Single channel | These are outdated models. Their height is greater than that of multi-channel devices. Due to their size and simple design, batteries are widely used in educational and medical institutions. |

| Dual channel | The design of each section has two channels. Due to this, it is possible to increase heat transfer. The efficiency of heating the room is also increased thanks to additional fins, which are absent in single-channel models. The design is characterized by compact dimensions and optimal heat dissipation. |

| Three-channel | Three-channel sections are considered the most effective in comparison with other devices. Batteries are distinguished by their large weight and size, and the greatest depth. When choosing this option, you should take into account the load on the wall and dimensions. |

Design

Cast iron radiators have different installation methods. Wall-mounted models provide for fastening the structure to the wall. Here it is important to take into account the bearing capacity of the supporting surface. If its strength is insufficient, it is recommended to purchase floor-standing batteries. Their lower part is equipped with legs or supports that are installed on the floor along the wall. Most often, installation is carried out with additional fixation of the upper part of the sections to a vertical surface.

It is appropriate to choose floor-standing models to equip a room with panoramic windows.

In the store you can choose a universal model that can be mounted on the wall and/or mounted on the floor.

Cast iron radiator Demir Dokum Tower 4036 with side connection

What connection

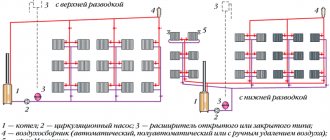

When purchasing a radiator, it is important to consider how it is connected, taking into account the circuit diagram. Cast iron models are available in one-sided (side) and universal versions. The first type of connection is considered the most common. The supply line is connected to the upper outlet of the battery. The return line enters the lower hole of the outer section.

Lateral connection can be left or right.

With a universal (bottom) connection, the supply pipe is connected to the lower left inlet of the radiator. On the right side, the return line is also fixed at the bottom.

Number of sections

You can buy heating appliances section by section, starting with one unit. There are also assembled models consisting of 4; 7; 10 sections. The number of segments can be very different, depending on the product range of a particular brand.

Heated area, m

How many sections are needed to heat the room is calculated taking into account the area of the room and the height of the ceilings. For 1 m2 a power of 100 W is needed.

Radiator heat output

This indicator is measured in watts (W). The technical documentation for each model indicates what heat transfer it is capable of producing. The range of radiators is wide - from 70 to 4264 W.

Center distance

Measured in mm. The standard values are: 300/350/500 mm. Along with them, devices with non-standard intervals are produced: 200/400/600 mm and more. The value can reach 2000 mm.

Height/width/thickness

When deciding on your choice, you need to pay attention to the dimensions of the battery. Parameters such as height, width and thickness are taken into account. The values are indicated in the passport. Unit of measurement – mm.

Flaws

- Heavy weight, which requires the use of powerful fasteners. It is this drawback that turns off many buyers. Depending on the model, the weight of one section can be 6-7 kg, so the weight of a 7-section unit can reach up to 50 kg. Installing it may require physically strong guys.

- Filling wide sections of the radiator requires a large volume of coolant. This drawback does not allow them to be used in conjunction with a heat pump.

- Unsightly appearance of old classic models. Many people do not like the appearance of old radiators from the second half of the 20th century; they are considered unattractive, unsightly and even ugly. However, as they say, there are no comrades according to taste; in many houses they still work and do not bother anyone. Due to their reliability and low price, they continue to be installed in modern buildings. However, for those who still do not like them, cast-iron designer heating radiators have been developed, which, in addition to their beautiful appearance, are distinguished by a high price.

This heating device will decorate any room.

So, the most expensive devices are retro-style cast iron radiators with all kinds of ornaments and patterns on the outer surface. Their cost can reach up to 40 thousand rubles/piece. For example, the cost of a 9-section Demrad Retro Z9 is 40,100 rubles, and the cost of a 3-section Demrad Retro Z3 is about 16,000 rubles. But for that kind of money, the owner of the house gets a real work of art that can decorate any room.

In a public area.

MS-140 radiators are one of the oldest and most common heating devices in the entire post-Soviet space. They are used both in residential and industrial premises. At the moment, their production is carried out by OJSC Santekhlit (Bryansk region, Lyubokhna village) - the largest plant in Russia for the production of sectional cast-iron heating batteries. The first cast iron product at this plant was produced back in 1755. Also, the production of MS-140 is carried out at the Minsk Heating Equipment Plant.

The popularity of the MS-140 is fully justified:

- Large cross-section of channels, due to which blockages rarely form. Even if blockages form, they can be easily removed. Due to its large cross-section, the battery has high hydraulic characteristics;

- Resistance to water hammer and corrosion;

- The quality of the coolant does not matter, which is important in heating systems from thermal power plants.

Some popular models

Konner Modern are modern cast iron heating radiators that combine beautiful appearance and high heat output. The depth of their sections is only 80 mm, which is almost 2 times less than that of the MS-140-500, with almost the same power - 0.150 kW, which is only 10 W less than its more massive brother. This makes Konner Modern batteries more economical because... it is necessary to heat almost 2 times less coolant.

Cast iron batteries of the ChM-1 (single-channel), ChM-2 (dual-channel), and ChM-3 (three-channel) models, which are produced at the Cheboksary Aggregate Plant, are also popular. They are characterized by increased operating pressure (1.2 MPa) and temperature (up to 150°C). Thanks to this, they can be used in steam heating systems.

With a supply pipeline built into the brick wall.

How to calculate the number of sections for a bedroom

There are several methods for determining the number of segments. The simplest option involves using the formula: N = (100 x S)/Q

How to calculate the number of radiator sections - online calculator

Explanation of values:

- N – number of sections;

- S – room area;

- Q – section heat transfer indicator.

The calculations use an average value of 100 W. This is exactly the power of the device required to heat 1 m2.

You can get a more accurate result by taking into account factors such as:

- ceiling height;

- wall thickness;

- number of windows;

- climatic features of the region;

- on which side is the room located, etc.

All these are called correction factors. They are assigned the designations K1...K10. The formula with their participation is as follows: N = K1 x K2 x...K10 x (100 x S)/Q. This option is considered the most accurate.

Types of cast iron batteries

The more sections there are in the battery, the better it is able to warm up the room.

In terms of their structure, such batteries can be compared to a construction set, since they are assembled using sections of the same type. Cast iron central heating batteries are made of gray cast iron; the water channels in them usually have the shape of a circle or an ellipse; rubber or paronite gaskets are additionally placed inside them.

Based on the number of channels, radiators can be single-channel or double-channel, and have different widths and heights, depending on the number of sections. The width parameter is also affected by the area of the room, the number of windows and the thickness of the walls.

The more sections there are in the battery, the better it is able to warm the room, so it is important to accurately calculate the room parameters before installing such radiators. The height of the equipment usually ranges from 35-150 cm, depth - 50-140 cm

The depth directly determines how accurately the battery fits into the overall interior of the room.

Floor-mounted and wall-mounted models can be found on sale. The former are secured using special brackets, the latter are supplemented with mounting supports or “legs”.

Battery installation

Installation of heating devices is carried out by specialists. You can also handle the installation yourself. But it is recommended to hire an assistant for the job. It is difficult for one person to hold and secure the weighty structure.

Do It Yourself Battery Preparation for Polypropylene Connection

Preparatory stage

First you need to prepare the surface on which to attach the radiator. It should be clean and even. It is impregnated with liquid glass and covered with a heat-reflecting screen to increase system performance.

Before starting installation, it is important to make sure that all components are available, and that the battery itself is suitable for the type of connection to the circuit diagram.

Installation work

The radiator installation process consists of the following steps.

- Fastening brackets to the wall using dowels. You need at least 4 of them. The places where the hanging elements are fixed are sealed with concrete mortar. Further work is carried out after its complete polymerization.

- Air vent installation. The connection is made through an adapter to the upper manifold. Free openings of the collector are closed with plugs.

- Hanging the radiator on brackets.

- Installation of ball valves at the inlet and outlet of the battery. This will help to maintain and change the heating device without shutting down the entire system. At this stage, control valves are also installed.

- Connecting the inlet pipe and return pipe to the radiator.

- Checking the tightness of connections.

At the final stage of installation, the batteries are filled with hot water under low pressure. This will help avoid water hammer and damage to individual elements of the system.

Features of connecting a heating radiator to polypropylene pipes

After hanging and finishing the piping of the heating radiator, it is connected to the supply and return pipes made of polypropylene. To do this, you need to have a welding machine for plastic pipes and a set of wrenches. The diagram for connecting a metal radiator to polymer pipes is shown in the bottom figure.

- 1 – coupling;

- 2 – ball valve;

- 3- transition coupling from metal to polypropylene;

- 4 – connecting polypropylene ring;

- 5 – polypropylene pipe of the heating system.

Using the apparatus, first weld the ring with the adapter coupling, and then connect the ring to the supply pipe. All other connections are tightened with a wrench. For connections to metal pipes, clamps, washers and through nuts are used.

How to properly wash cast iron batteries

Clogged radiator channels lead to reduced heat transfer. To prevent this, it is recommended to carry out maintenance in a timely manner. If a low temperature of the battery is detected in relation to other heating devices or the riser, flushing is performed.

You can clean the inner surface of the channels from rust and other deposits by dismantling the radiator. It is taken out to the bathroom, which is recommended to be pre-covered with rags. This will prevent damage to the enamel during manipulation of the heavy structure.

A shower hose is inserted into the inlet. The watering can is first removed. Under pressure, all the dirt comes out of the sections. There is no need to rush into washing. Solid particles fill any recesses and gaps, so when performing the procedure you need to turn the structure over and shake it slightly.

When the water from the radiator begins to come out clean, close the outlet hole with a twisted rag. A hot solution of soda ash is poured into the inlet hole. Next, the outer side is tapped with a wooden hammer (moderately!). This promotes the detachment of plaque from the internal walls of the canals. After draining the detergent, repeat rinsing with running water until no more solid particles come out.

Design as a factor of choice

Cast iron radiators are rarely made to look beautiful. Their task is to transfer heat, and not to please the eye. But some radiators are stylized and then used to create a beautiful interior. This is facilitated by an unusual shape or color on top of a standard primer.

Photo 2. Decorative heating radiator made of cast iron. Covered with black paint, decorated with decorative forging.

Some batteries are made in retro style. They are painted with an ornament and given a dark color. The radiators themselves have wheels, so they just need to be placed on the floor without attaching them to the wall.

And they also create abstract models of radiators. The main component is cast iron, but it is combined with another metal. They are available in various forms, so these batteries are suitable for any room.

Is it possible to paint cast iron radiators?

Cast iron batteries can and should be painted to prevent the formation of rust and maintain the presentability of the structure. If the radiator is in poor condition, it is better to dismantle it and flush it. After this, it is important to thoroughly clean the surface and let it dry. In this case, simple wiping with a rag is not suitable.

In order for the paint to adhere better, before painting you need to degrease the surface with an alcohol composition or solvent.

Painting is done in two layers. Each ball should dry well. Proper polymerization will prevent cracking of the coating during the heating of cast iron.

When choosing paint materials, you need to make sure that the product has heat resistance (up to +80° and above). Of the huge number of varieties, preference should be given to alkyd and acrylic paints. They produce a special coating for the heating system. The can says “radiator paint”.

When purchasing a new battery, you can order painting in any color from the manufacturer. The coating is applied using modern technologies. Thanks to this, the paintwork lasts a long time.

What is better to use today?

Cast iron radiators are reliable; if they are placed correctly, you can “forget” about them; they will work properly for a very long time. Much depends on the nature of the premises. If you have to install heating in an apartment in a five-star hotel, then sectional cast-iron accordion radiators will look clumsy. On the other hand, if you install modern cast iron heaters and cover them with a decorative screen, then this arrangement can be successful.

Aluminum radiators have many advantages:

- They have high heat transfer.

- Heating appliances are economical.

- Easy to install and light weight.

- They are relatively inexpensive.

- They look aesthetically attractive.

Disadvantages include:

- Possible leakage at the joints.

- Heat is not always distributed along one front.

- Service life is limited.

- It is necessary to do preventive maintenance quite often.

- Sometimes air “cushions” appear.

- Aluminum is susceptible to corrosion and requires special treatment.

The last point seems to be the most problematic; if the process water inside the battery is saturated with alkaline elements, then accelerated wear of the thermal unit occurs. Another drawback: aluminum radiators do not have a large margin of safety; if there is a pressure surge in the thermal circuits, emergency situations may occur. That is why such radiators are installed mainly in private houses, and cast iron ones are used in central heating.

If you do not want to use cast iron batteries for central heating, then you can consider the bimetallic option. Essentially these are the same aluminum radiators, only with a special steel tube inside.

In private homes, the use of cast iron radiators is impractical. Feel free to consider aluminum models. They are more modern, have better heat transfer and distribute heat more evenly in the room.

In terms of heating costs, there is essentially no difference between cast iron and aluminum radiators.